Leaderboard

Popular Content

Showing content with the highest reputation on 02/21/24 in all areas

-

Here's the 20 February, 2024 update from Cousins in case they haven't sent you one... Cousins in High Court Next Week Fighting for Parts and Now Fighting for UK Law ALSO! Since deciding last year to serve our High Court claim on Swatch, Cousins has been very active in explaining to the outside world what the consequences of the Swiss verdict will be if it is recognised here in the UK. Of necessity, we have had to stay silent about this work, but as it has now been included as part of our evidence to the High Court, we can reveal more about it. At the end of my last news story (https://www.cousinsuk.com/page/news), I outlined that the Swiss decision affects wholesaling in any industry, but the true extent of its consequences go way beyond that. At the simplest level, the ruling opens the door to manufacturers being the sole source of supply for anything, which in turn gives them the power to control or eliminate wholesalers and other intermediate markets such as retailers or repairers, with potentially devastating consequences for long standing government policies on consumer rights, sustainability, and the right to repair. However, at a higher level are two issues relating to the function and creation of UK law. The basis of UK and EU Competition Law is the protection of consumers, which in all but the most exceptional of circumstances is achieved by maximising competition in every market, to give consumers the capability to choose the price and service levels that suit their individual requirements. Consideration of the effect on consumers and competition is the core principle of the law itself and has been at the core of every judgement in Competition Law, but the Swiss verdict creates a precedent which eliminates that principle. If that is acceptable in one part of the law, inevitably it will be argued that other parts of the law need not consider the effect on consumers. Setting of precedents is a normal part of the legal process, but those precedents have to be in line with principles of the law, not acting in reverse of them. The Swiss verdict has raised serious issues about firstly, whether or not the actions of the Swiss courts comply with the treaties that exist between our countries, and secondly whether it is acceptable for a foreign jurisdiction to interfere with the base principles of UK law. Cousins very quickly brought these issues to the attention of the Department for Business and Trade (DBT), and our Trade Attaché in the British Embassy in Switzerland, both of whom reacted positively and promptly. The issue was extremely pertinent at DBT, because the Minister for Trade was just commencing talks on a new Free Trade Agreement with Switzerland. Our local MP, Sir John Whittingdale OBE, came to our offices for a full briefing within 48 hours of being notified of the issue, and with his assistance the matter has now been brought to the attention of no less than six government ministers and four departments, including the section within the Ministry of Justice that deals with international treaties. In addition, Cousins has been very active in engaging with the UK Competition and Markets Authority, who have examined in detail the papers relating to next weeks’ High Court hearing and have taken the highly unusual step of writing to us to indicate their potential interest in the case if the Swiss decision is not recognised. In itself, this might seem to a layman to be a rather ineffectual action, but it has much greater significance in the legal world. “Global Competition Review” is probably the leading subscription news service for Competition Law professionals in the UK. They are frequently the first source for their readership on the most significant stories in that sector, and with their kind permission reproduced below is an article they published ten days ago. You will be pleased to learn that the article very quickly made its way into their “Top 5 Most Read” list. I hope to get one more update out to you before next week’s hearing. Regards, Anthony3 points

-

Hi, I'm from the pacific north west. I'm pretty new to watch repair and modding. I've primarily just be doing basic cleaning and a few batteries. But I have some interest in modding, and possibly even getting into restoring some older mechanical pieces down the line. Things I've been contemplating and looking at modding/fixing are: Gen 1 Fossil Hybrid HR -I really want to put a sapphire crystal on it -it's got the common fogging issue, even after a trip to the repair center where they gave me all new internals and gaskets Bertucci A-T2 super classic -interested in a mechanical movement for it -I've been having issues with it loosing time ever since a battery change2 points

-

2 points

-

Not sure about copyright but found the picture and a very good article here, fig 17. https://bhi.co.uk/wp-content/uploads/2023/02/08-HJAugust22-AOTM.pdf Dell2 points

-

You can't do this without replacing the entire movement together with the gongs. And the holes for the winding arbours in the dial then will be 3 and in different places... So actually You will need entire new clock.2 points

-

2 points

-

When the day disc is in place, it kicks it up anyway. So, the actual issue was that the Unlocking yoke maintaining plate was not installed right and was not holding down the date indicator driving wheel. Its back together and working, but now my winding stem no work right, so ill be "practicing" some more2 points

-

Hello! My late father left me this clock (by the pictures, it appears to be a Junghans Wurttemberg from 1932). If I remove the back plate, I can tease the movement to tick for a few seconds, but then it stops. I would very much like to have this beauty back in working order (I believe the disk at the top of the second photo actually strikes the top of enclosure as part of the alarm). I live in coastal North Carolina and am searching for a reputable repair shop to send it to (the only one in my area said that it'd be 3-5 months before they even could take a look at it). Please reply here with your comments - or to me personally at *****@*****.tld with suggestions about next steps. Thank you.1 point

-

Hello all, I'm a hobby horologist and have just gotten hold of a Seamaster with a 1342 in it....not working.....(sound familiar?)....a new battery didnt change things...just made thecsecond hand to mobe a little then stop. so I'm here joined to see if I can get any info as to how to move forward....any hints or tips would be gratefully received...1 point

-

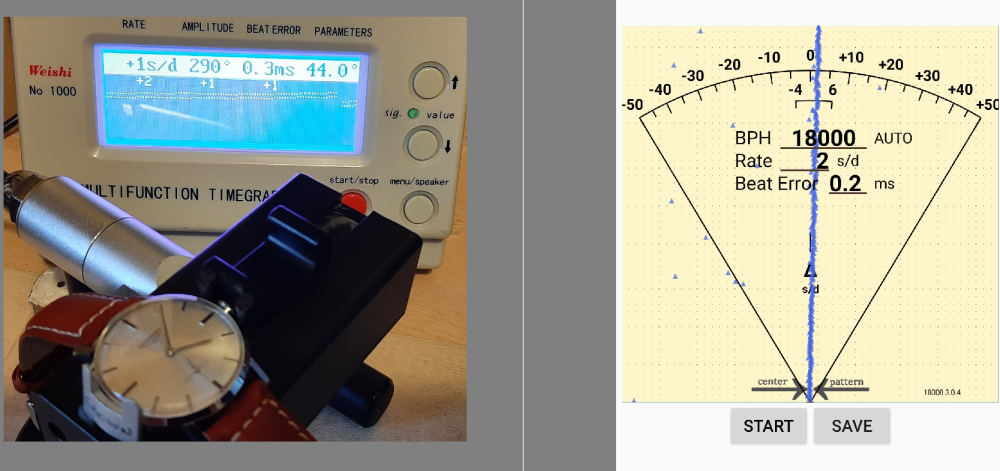

Ya I remember, you didn't say anything about poising the balance, I guess you didn't , so I gathered you must have mastered fitting in staffs. Thats really something. There use to be staff fitters in my neck of the woods, thats all the guy did all day so got real good at it, hardly ever a restaffed balance needed poising. Congrats, good results, enjoy your watch in good health.1 point

-

Richard, Thanks for the kind guidance. Now that I know how the spring is oriented, it makes all the sense in the world. Thanks again, Don1 point

-

1 point

-

Looks authentic, but we will need a picture of the movement to tell for sure. No reason to not be able to open the back, try harder. Also, ask Google what is 'spring bar' and how it acts, the bracelet is fixed to the case by 2 of them. But looking the condition, probably the bars must be cut as they are 'glued' forever with dirt. The other option is to remove the movement and soak the rest in some solvent or degreaser for several days... he crystal can be replaced with generic acryle domed crystal with proper size. Serial number will help to date the watch, but will be useless if parts searched - this is not a car. By the way, why did You bought it?1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

The printing on both back and dial look very sus.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Rightly or wrongly the British public voted for Brexit. I found the EU response astonishing, rather than "sorry to see you go, let's sit down like adults and work out how to proceed ", they spat the dummy like a petulant toddler.1 point

-

1 point

-

1 point

-

All has been said I totally agree with both. You can get a good Westminster chime for under £50. If you want a high grade one like an Elliott then you are talking over £200, if you can get a Smiths chime parts are available and normally many on ebay. Nvoss no question on here is silly.1 point

-

Acrylic crystals are friction fit, maybe someone tried to glue in an undersized one which lead to your issues? You can search on sites like CousinsUK or Eslinger (depending where you are int he world) for a new one. Fortunately acrylic crystals are not expensive, so measure up the case and order your crystal, however, I would advise that you also order one size above and one size below to save you the time and frustration of having to re-order a new one if the one you get turns out to be over/under sized.1 point

-

I agree with Nevenbekriev. What you currently have is a striking clock, not a chiming clock. Not only would the whole movement need to be changed, the dial would need to fit exactly in the front hole and you would need to take out the gong (am guessing it is a coil on a stand) and fit a set of chime rods. There is also the risk that the pendulum on the replacement movement would not have enough room. If your clock is in good order, enjoy it for what it is. If you still want a Westminster chimes clock, you can get them on Ebay - you might get a bargain.1 point

-

I would of liked to know the answer but glad it worked out. Post photos , once finished.1 point

-

Just a quick update to let you know I was able to satin polish the case without removing the bezel which I protected using double layers of Kapton tape. Even so, the diameter of the bezel was considerably smaller than the case so the tape was just a precaution. So, the case is looking like new again! Now just waiting for new mineral crystals for the case and case back which seems to take forever. I think I'm done with Postnord1 point

-

I think the main thing slowing me down is not having a proper work bench which forces me to work under a 10x scope for much of my work as hunching over with a loupe absolutely kills my back and neck. I sit on the floor to do my disassembly under the loupe and it's amazing how fast it goes compared to my assembly and oiling which i do under the scope. Getting a proper working area would probably do wonders for speed and then i would only do a few oiling operations and my hairspring adjustments under the loupe. So I learned something about seikos service center when i was talking to some other pros from a group i'm in, some of them know some seiko watchmakers or seiko employees. that "service" for 118 dollars isn't actually a service. What they'll do is take out your movement, throw it in the trash and put in a new movement pre lubricated from the factory which is pretty hit or miss then see that it's in in spec (reminder spec for this movement is like -45 to + 35 or something, real broad.). This is actually what most service centers do. The parent company makes movements for so cheap there's really just no point in actually taking the time to do a full service repair on it. I think this is different from really high end makers however. One of the things i offer as service that they don't which is why i get deltas often 2/3rds to 2/5ths lower than factory is i do a full adjustment of hte hairspring, make sure it tracks the regulator arm (It NEVER does on the factory with their low cost movements.), i recenter the hairspring and get the regulator pins real close and that brings the deltas down from a factory of like 15 to 30 to as low as 6 which is the lowest delta i've gotten on one of these. They keep PHENOMENAL time for the cost once you do this. But this guy said he would prefer to keep the movement intact as like me he considers that to be as much the watch as the case and hands and he has a sentimental attachment to the watch. If he had opted for a simple movement swap i'd probably have been able to do it for like 90 bucks and upgraded him to an nh36 he could hand wind.1 point

-

I've used 0.1 mm copper wire. It's commonly sold for circuit board repair, in small quantities for just a few dollars. Grab a bit with some tweezers. It's a bit small to hold on a pin vice. It's soft, so less chance of chipping the jewel. And you can bend it when something straight can't get access or would block your view.1 point

-

It is that one but I'm in the uk, only non working ones here. The one in the watch needs a lot of repair, both battery terminals were snapped off. There is some movement from the rotor which is just a switch to move the minute hand once with each activation of it. Its very inconsistent when I supply power, i think I've traced it to the coil, very high resistance reading. Its looking like i need a donor movement.1 point

-

Just using some at the moment 9415, uv light wont pick it out on an escape wheel I'm lubricating. I tried charging it up to see if thats a thing. Glows in the pot but not in the watch. The 9010 lights up but theres more of that .1 point

-

traditionally anything that has a End stone people like to use 9010. It's just what they like to do. let's see if we take this out of order when I was in watchmaking school we use 9020 for the entire gear train. With 9010 on the balance. I've since abandon the 9010 all together and I used use 9020 is my light oil. The only place I use the HP 1300 is on the center wheel anything like the barrel arbor I use 9504. Then there other tech sheets out there I even found one that agrees with my used for 9020 on the balance jewels and basically everything else. you should try lubricating a watch with a high viscosity oil and see what happens to your amplitude you might be in for a surprise. things aren't always as they seem to be. I'm not sure I'm looking at the same spec sheets you are exactly which caliber of Seiko are looking out for the third wheel? Then Seiko does specify a grease on some of their high frequency watches and it's covered in one of their lubrication sheets. and the reason they put on the bottom were on the pivot is because of course grease does not migrate like oil what it1 point

-

Still the basics apply, the size of the part, torque and pressues within its bearings is a big factor, Alex says that lubrication has 2 purposes, to reduce friction and to reduce wear. Those are closely related, if you reduce friction things are going to move more freely requiring less effort to move them ( energy sparing ) and then the reduction of wear is an added bonus as part of that reduced friction ( two birds with one stone ) .The oil itself creates a bearing surface at a molecular level to keep moving parts seperated. Higher pressure heavy duty parts like the barrel and center wheel arbors need thicker viscosity oils that will cope with the higher shearing forces involved maintaining their viscosity for longer periods of time compared to thinner oils. Smaller lower torque faster moving wheels put less pressure demand on lower viscosity lubrication that have to balance with now being thin enough NOT to add molecular friction ( damping effect from slower moving less free flowing oil ) that can rob energy. The wheels coming down the train towards the balance decrease in size, torque and pressure in their bearings. If we could all afford to buy 4 or 5 oils of different viscosity, one for each wheel then that might be ideal. Maybe more if we include pocket watches and ladies watches. But instead we non professionals compromise and use 2 or maybe 3 oils at most in the train . Where one oil might be a little too thick and another might be a little too thin. Figuring out where we change from thick to thin is how we differ. I have an idea where i think it is and what i want to do, someone else might have a completely different idea. On top of that fingers are crossed that the oil stays where it is put. No wonder lubrication is such a controversial subject.1 point

-

1 point

-

Hi having annealed the spring end and reshaped a made thr hole leave it alone, the last inch of springs is relative soft incase you need to form it slightly to pick up on the arbour. I have had new springs that required a gentle coaxing.1 point

-

1 point

-

Hi if this is to be used for playing with to learn then trying the spring repair is ok .. first remove rather rest of the spring from the barrel then anneal about 1 to 1 /2 cm from the end then drill a hole in the spring and reshape with a needle file.. with round nosed pliers re curve the spring end to receive the arbour . The end without the arbour should fit round the arbour hole in the barrel. Not a difficult procedure but time consuming.1 point