Leaderboard

Popular Content

Showing content with the highest reputation on 02/04/24 in all areas

-

This will depend on the cal movement and style of case. Water damage can mean a lot of things from fully corroded to just a few spots. Unless you can see the watch movement and dial forget it.2 points

-

Hi @Endeavor you don’t tell her but next time she pulls them out of the drawer you will have to explain the bulge and the bits of dust but by that time you will have an excuse ready.2 points

-

AND the replacement cost for the (silk?) stockings I'm using recovered Hard-disk drive Neodymium magnets. These are incredible strong and will pick up anything of steel. When working on movements with "no-room-for-error", I sweep the floor before I start, else the magnet will pick up all kinds of stuff you didn't know you had in your house ... If you're still up to it, suc6 with another attempt2 points

-

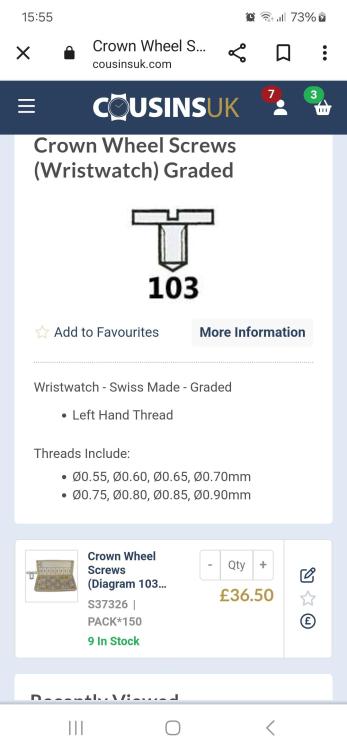

Hi befor shelling out £36. Have you tried sweeping the floor with a magnet. A long one off a knife rack or the like. Secondly borrow @ pair of the wife’s stockings and put over the end of the vacuum tube and push it up the tube then sweep the floor then if all else fails £36 it is.2 points

-

I have successfully completed my first attempt at electro-plating. I have a few cases that were prepped by stripping the old plating and fully polishing (which took ages doing by hand). About 2 weeks ago I bought a book on the subject of electro-plating. I read the book cover to cover a few times (it was a very small book), and I thought I had a pretty good understanding of the process of electro-cleaning, surface activation, and the application of bright nickel plating. I also received some incredible help from a member of this forum who provided me with some info and tips that they've learned throughout their time in plating. I'm happy to say that my first try at this wasn't a total failure! Here are the results just after the final rinse. I wanted to plate about 20 microns on the case. My thought was that it would give me a little cushion to smooth out some of the defects. Thankfully the defects were actually quite minor. There was a small section where the plating looked to have a slightly rough surface. I believe this occurred when I was adjusting the position of the case in the tank. I bumped the anode and it came into contact with the case for several seconds. Everything else turned out quite nicely, with the exception of that rough patch. About 1 minute on a soft cotton buff with some white Dialux smoothed it out beautifully. I'm really pleased with the results!1 point

-

I only know because I am used to the model. I have 2 (two) 2789 and 3 (three) 2789 movements. This was the first watch that I ever disassembled. Knackered beyond belief actually. Broke pivots on wheels, Escape wheels. Pinged balances, yes, more than one. Pinged nearly every part in the first few month. Goodness, I was poor then1 point

-

Have to admit it Never. Got the photograph idea from you. Good innit.1 point

-

Hi all, greetings from Canada. I joined this forum to hopefully tap into your expertise and learn from watchmakers all over the world.1 point

-

Like you. I've had trouble with screws. My fault I may add. All parts into different areas. only used 4 sections. Screws became mixed when after cleaning replaced them into an area. Learned my lesson. I now use box which has top and bottom compartments. 6 Bottom for case and strap. 24 Top for all others. It does mean that I put each section into a differnet cleaning basket. It's worth it. Now I know what screw goes with what part.1 point

-

Hi. If thats a Hattori the construction has changed with all the plastic. Yes if you are changing movement a like that put all the original parts back on a try it out, then if it works move on to the next change verifying each step. Too many variables leads to trouble. But having said that you realised your mistake so that’s a plus point. Well done.1 point

-

When disassembling I keep the screws and the corresponding components together. Or if it's a complicated movement, put some of the screws back in the mainplate before cleaning. A lot of times the screws have different part numbers, but they are the same screw. Sometimes on the service sheets it shows this.1 point

-

With chiming clock movements the spring for the chiming side is much stronger and bigger and the barrel is bigger and arbor So I don't think you have made a mistake. What you need to be careful with is the going and strike springs they can be the same. Always keep the barrels, springs and arbors separate. Get your self three plastic tubs so you have all the strike side in one and so on.1 point

-

Hi. Yes it’s just hype just about every watch is electronically tested. The balance spring terminal curve is distorted and it’s out of the regulator which is probably why it’s distorted. Just remove the balance from the watch and most of the distortion will disappear. Lay the balance on its cock and post some pictures it’s not that bad.1 point

-

1 point

-

1 point

-

@rossjackson01 pointed me to a youtube video where the same watch was serviced by Kalle Slaap.1 point

-

That's an interesting idea. I'll give it a try and see if something happens. If the bezel is screwed on I guess that the worst that can happen is... nothing Kalle Slapp used this auto punch style back remover in one of his vids. It could damage the bezel edge or the threads if the bezel is screwed on. Thing is any damage is more evident to the bezel than the back.1 point

-

The ETA 2325 is circa 1950s. I tried copper plating today and it worked really well - I got a nice thick layer. There were some deep scratches on the lugs - I should have filed more before plating, as I've sanded through the plating getting them out, so I'll have to add a bit more copper plate. But on the rest of the case, the copper has filled the holes and marks really well. I'm impressed how much copper plating fills defects. For anyone who's just done nickel plating, I recommend copper plating first. It's like a filler primer spray on a car.1 point

-

To test if the case is zinc, soak it in vinegar. It should start bubbling like crazy. Nickel is magnetic and should stick to a magnet. Cases could also be made of brass and then nickel or chrome plated.1 point

-

I've seen quite a lot of watches of this era which are made from solid nickel with a chrome plating. In some instances where the chrome has been damaged the underlying Nickel has shown through with a very yellow colour.1 point

-

1 point

-

First, let me say that putting the battery in upside down is almost certainly not going to get the watch to run backwards. The reason I say that is that the watch relies on a CMOS IC that requires the correct voltage to operate. The IC contains an oscillator circuit, and a binary counter to divide the 32768Hz down to 1 Hz, and a driver transistor to drive the coil with the pulses from the output of the counter. If you put the battery in upside down, the most likely scenario is that the watch will simply not operate (and the battery will probably drain quite rapidly due to a reverse polarity protection circuit in the IC). The worst case scenario is that if you put the battery in back to front, the IC will fry. So the fact that it is going backwards is more likely to be a mechanical issue, or the rotor has somehow been subject to some very strong magnetic field (a neodymium magnet perhaps) and is now magnetised backwards. This *might* work, but typically the rotors have more than one set of poles, so I would be surprised if a strong magnetic field didn't simply kill it. I guess if it reversed one set of poles, it might take two steps backward for every one step forwards or something like that. Given the cost of a replacement module, that would probably be the easiest fix, but I am genuinely curious to see if my theory is correct. I do have a job lot of Ronda movements, so I may pull one of those apart and see if I can re-create the effect.1 point

-

What's up with you, I did a perfect job on my first watch, no pings, breakages etc. Hehe. No need for the sad face, I was joking. I've pinged and broken more than my fair share, to start with. Like most of us.0 points