Leaderboard

Popular Content

Showing content with the highest reputation on 12/20/22 in all areas

-

Hi everyone! As promised I managed to finish the overworked prototype of the 3D printed watch baskets before christmas! Here are some pictures so you can see the current build: And here is a link to the short video explaining everything! https://www.youtube.com/watch?v=MecNpr7wiGc Hope you guys enjoy the design ! There is still room for potential improvement so please leave any questions, comments or suggestions. Always curious to hear from you all!3 points

-

3 points

-

You are probably going about the removal in an appropriate way but the spring has suffered from age deterioration and just gone brittle, trouble is so might all the replacements of that age as might NOS parts. Also next time it might be worth trying a couple of old oilers to tease them out, the trouble with tweezers is that they can move rather abruptly and crush the spring, oilers may exert less of a sudden shock. Also probably just talking out the back of my hat as I have been known to do on occasion You might go through a few before you find one that survives not only removal but replacement as well. Good luck, and us know how you get on.2 points

-

Imagining you are in the U.S., you could have bought it for 28 bucks from a real watch supplier http://www.julesborel.com/products/tools-lubricating-oils/Synt-A-Lube, and I don't think they would charge 40 bucks for shipping. Even if you ordered from Cousins in the U.K., shipped to the U.S. would probably be less than 67 dollars! Is it at least in original Moebius packaging? I've said this before, but do please try to buy parts and supplies from the actual real watch parts and supplies dealers. They are crucial to the repair industry, and there are fewer and fewer all the time. And, you might find that they are actually cheaper than Ebay or Amazon. Edit- just checked, Borel would be $4.50 for shipping.2 points

-

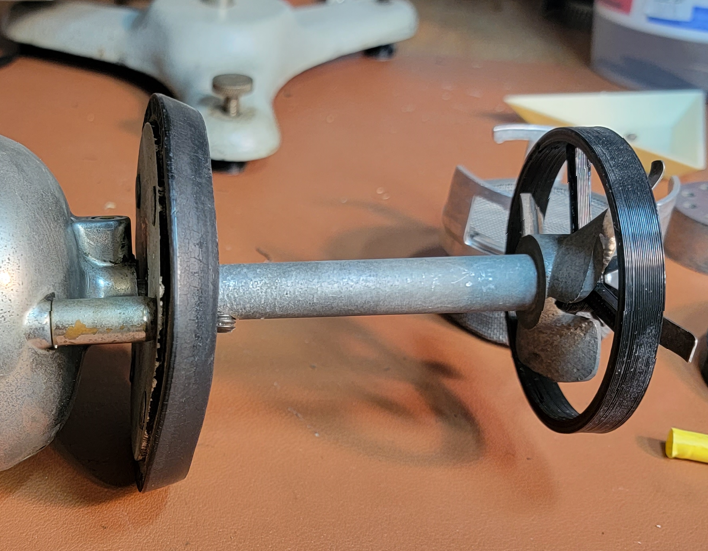

Nice work. What filament did you use? PLA? Recently I had to deal with an accident where the aluminum spinner of a L&R Watchmaster cleaner was shattered. After scratching my head, I came up with a 3D printed piece that retrofit to the undamaged spinner shaft. Here I show the piece I printed and the finished product. I was, at first, concerned about the interaction of the L&R solutions and the PLA material. I did several tests and concluded that there was no chemical reaction with the PLA--happy about that.1 point

-

Try releasing one prong of the spring at a time from the setting lip, when you tweeze both prong simultaneously you are stressing the spring twice as strong. There is no need for any special tweezers, I use one prong of No 4 tweezers. Good luck1 point

-

1 point

-

Haha. Gert I know you are right but i cant help it lol. I have this thing about having plenty of stock. Not only the old crystals along with them came around 800 calibers of different stems. I cant resist a bargain. At some point i will start repairing watches again . At any rate i should have enough gear, if anyone here is stuck for a stem or a staff i should have it1 point

-

Hah, my middle one (13 now, ouch) is the one that is always doing stupid sheet. Always catching his finger in a door, falling out of a tree after his zipline snapped or otherwise getting himself hurt in other creative ways. He's the reason we have private medical Anyway Rich, I suspect you need to lay off eBay for a while. The amount of "random stuff" you've collected since you've been posting here is abnormal. Seriously. You might even feature in one of those hoarding TV shows my man.1 point

-

1 point

-

1 point

-

How about a used leather strap for now. A ten hours charge under luminescant light, saves the capacitor.1 point

-

1 point

-

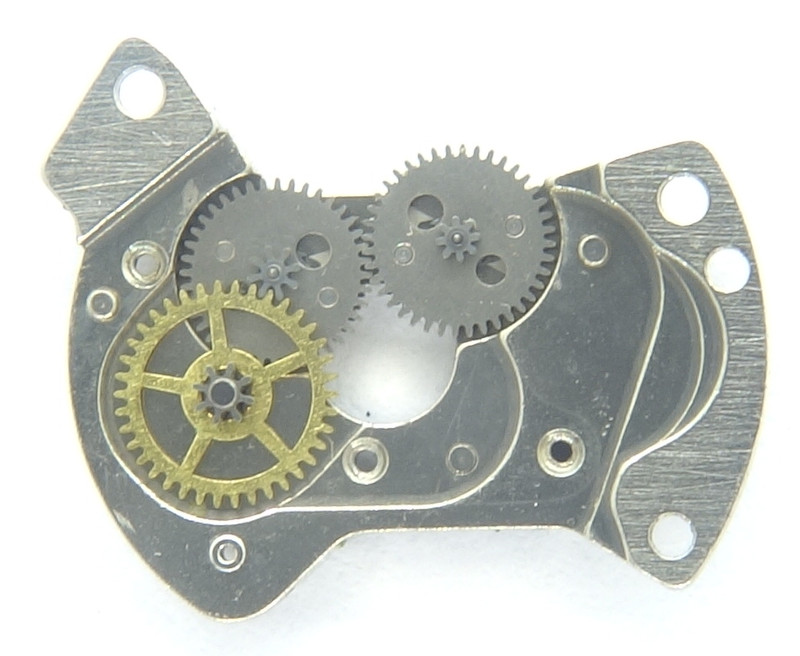

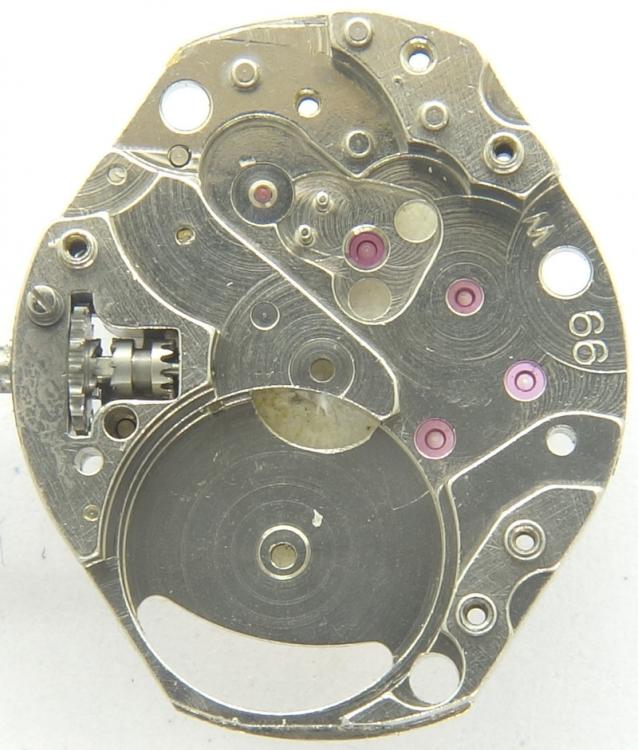

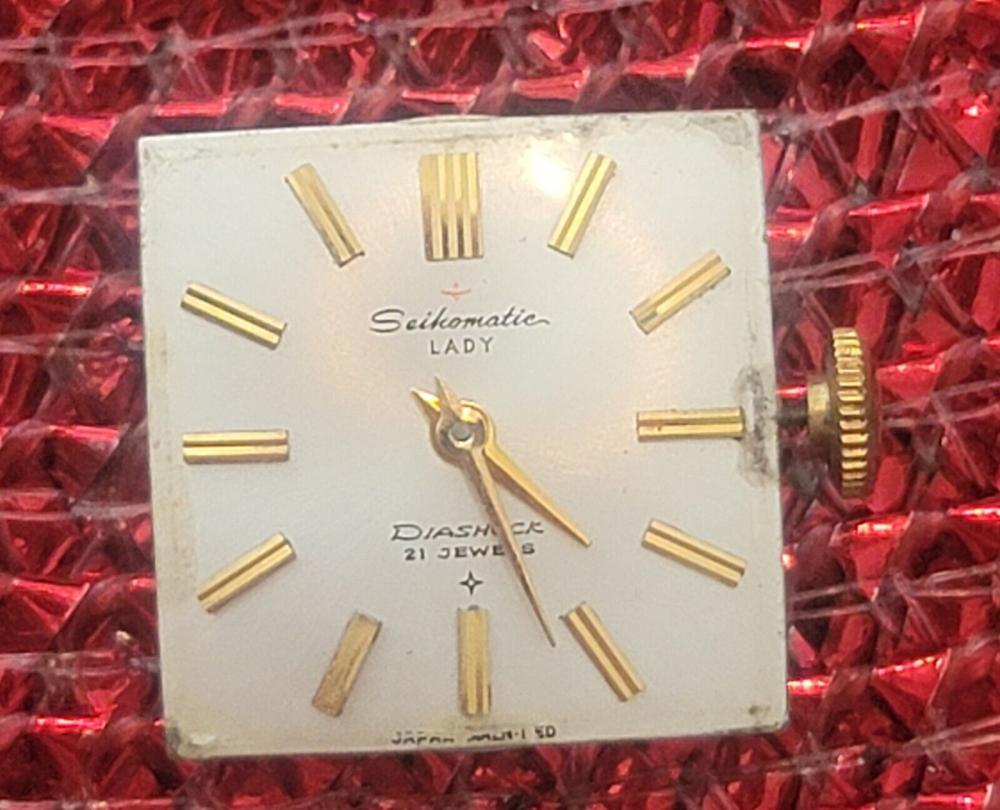

Incoming is an eBay find (project watch): a Seikomatic Lady model 27004 from the early 1960s. Not working but I hope to correct that. This has the 2101 movement which is probably the first automatic movement for Ladies watches ever made by Seiko (photos by the seller). https://17jewels.info/movements/s/seiko/seiko-2101/ As the following photos from 17jewels.info show, the 2101, based on the 21a, itself an evolution of the 11a, has the typical construction of a manual wind ladies watch of that era (6 3/4 x 8 lignes Tiny Form): with the addition of the automatic winding module: I'm currently practicing on some 1104a and 11a non working Ladies movements from speedtimerkollektion (servicing /balance restaffing /hairspring manipulation/ bridge jewel adjustment) and should hopefully have enough experience in a few months to tackle this project. Looking forward to working on this example of one of the first Seiko automatic watches.1 point

-

God with how clumsy i am and how i walk at light speed becaus1e i'm 6 foot 4 i bash my arms on corners and door frames so often i will probably have to buy like 5 acrylics for this old seiko when i get it fixed up. I will be just absolutely wrecking them Haha. I'll definitely have to get very familiar with polywatch and how to polish the things.1 point

-

Understandable Col they do work well with high domes, but as david has said they cant be used on much else. I would say a good portion of the vintage swiss watches and a lot of the british I've come across have a high dome acrylic crystal either original or been replaced. Probably because they are easy to fit and give plenty of dial clearance, some just dont look right though.1 point

-

1 point

-

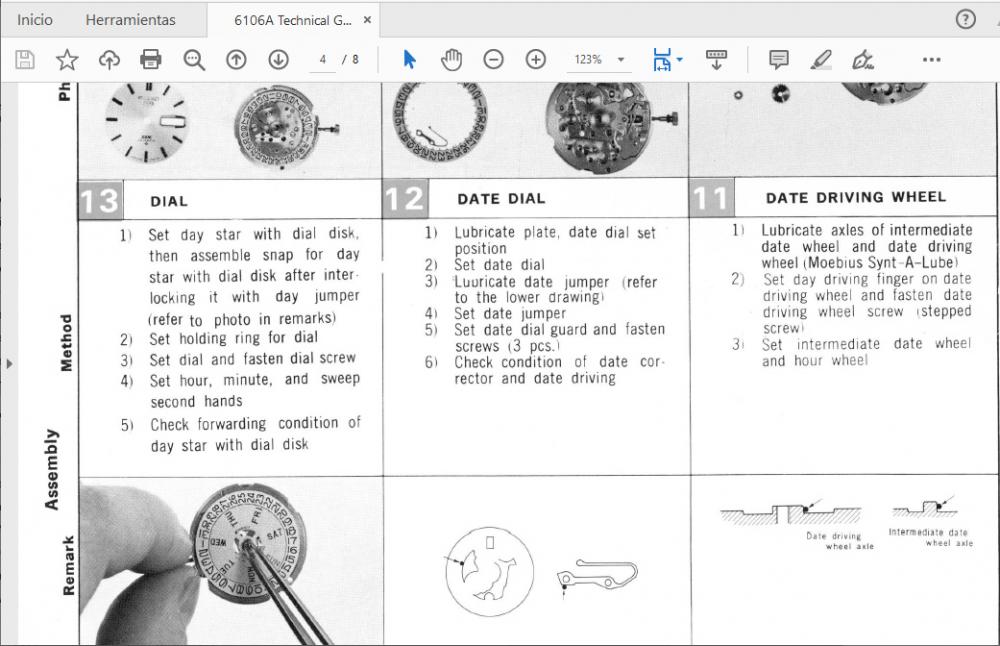

You can also try lubricating the tip of the date jumper and the zone of the main plate where the date wheel rests (between 1 and 5 in your photo) (I use HP1300 there). Seiko not always recommend lubbing these areas, but sometimes they do, like in the step 12 of the 6106 assembly. However, it should not be necessary.1 point

-

Would have been 36 USD from Otto Frei in the USA including USPS shipping). From Cousins in the UK it would be 27 USD using untracked mail or 37 USD using tracked registered Royal Mail. Both are reputable and well established suppliers.1 point

-

Hi so when you advance the date manually its ok and indexes correctly, yes. but not when working on its own power, i should check the driving wheel and finger for wear. The detent spring and detent also for wear and lack of tension. I have attached the sheets for the 7005 and the 7009 as they employ similar systens. 277_Seiko7009A.pdf 3113_Seiko 7005A (1).pdf1 point

-

Perhaps. If so, we will require photographic evidence.1 point

-

I was telling my wife how the spring mysteriously appeared and she said, "I forgot to tell you that I found the spring on the floor this morning and put it on your mat. I didn't know if it was just a scrap piece of wire but picked it up just in case". My belief in watchmaking elves has now been destroyed.1 point

-

The cheaper baskets do have a larger mesh size than say bergeon baskets. Is it the screw apart brass baskets ? . Ive moved away from those, personally a think too heavy and the large amount of the chunky brass threaded section could cause some damage to delicate parts. The ones with lids on seem safer as long as the lids are a good fit. I have a tendency to clean the springs by hand, they dont take a lot of cleaning and then i always know where they are. Clean them and then i pop them in a contact lens case to keep safe, and the balance jewels and springs on the other side.1 point

-

Found some information on your movement but also found the mystery. Step dissection now the mainspring Log and that's where we get a mystery. Apparently your mainspring came in different wits and of course different Lengths. https://17jewels.info/movements/c/cupillard/cupillard-233/ http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Cupillard_233&1 point

-

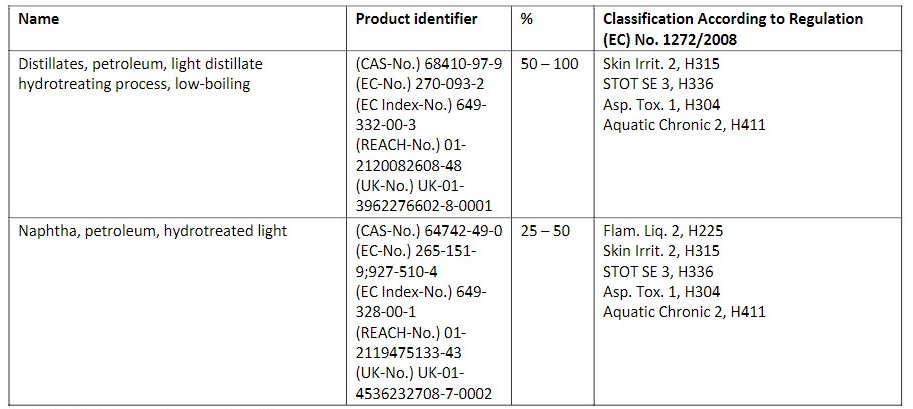

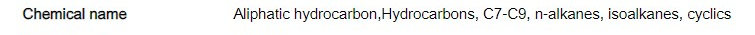

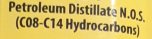

Hello @nickelsilver, I think you're right. A lot of people (including me) use the "trade names" that were created as a convenience and shorthand within a sector or industry ("Kleenex") or even the marketing department of a single leading company ("ESSO Premium Gas") to refer to things as if they were either canonical or categorical. When it comes to petrochemicals, both of the above appear to be happening. As you mention in your posting, gasoline may not be the best option for cleaning watch parts. What we call "Gas" is actually a recipe sold out of pumps at fueling stations that represents the removal (and addition) of tons of things from the feedstock crude oil that in and of itself is a highly complicated organic chemistry stew that resulted from millions of years of the "fermentation" of ancient variegated vegetable matter. There are no fixed points to start from, and then we humans made it even more complicated by adding stuff. My (guess) is one of the biggest problems with using gasoline these days is all the additives, some of which may not evaporate, leaving a deposit or film behind. This may be by design. If I remember right, it was an engineer working under Charles Kettering (of General Motors fame) who first proposed the addition of lead to fuel to eliminate an undesired characteristic of that fuel, that is to say engine knock, or premature detonation. This was in 1921 and a little history of that can be found here: https://bit.ly/3Rdctyw A very interesting general timeline of gasoline additives and their phasing-out (usually due to health or environmental concerns) can be found at: https://bit.ly/3dMfxTA The CAS System The Chemical Abstracts Service (CAS) system, which you rightly point out as a candidate fixed starting point, tracks molecules by their chemical composition. It may be our best option as a lookup because (A) It attempts to segregate things down at the molecular level; and (B) The CAS number is something that seems to be printed on the side of things due to regulatory requirements. At least that number is being divulged. The CAS number(s) listed for ZIPPO liquid lighter fuel as of 2021 are: Source: https://bit.ly/3wxLVzQ The CAS number(s) listed for RONSONOL liquid lighter fluid as of 2015 are: So ZIPPO and RONSONOL do share an ingredient (64742-49-0) and that ingredient is identified in the ZIPPO documentation as the one that is desired ("Naphtha"). But in other places on the Internet it is baldly stated that "ZIPPO removed Naphtha from RONSONOL after the takeover": This, along with a potential recipe change for RONSONOL, is leading to a LOT of confusion. Hydrocarbon Families The next thing we might want to address is the fact that the RONSONOL recipe may vary according to the target jurisdiction. In other words, your RONSONOL may not be my RONSONOL. In the 2015 RONSONOL datasheet, the following hydrocarbon group (C7-C9) is listed in the ingredients: Source: https://bit.ly/3Km4cWx But my RONSONOL the following hydrocarbon group (C8-C14) is listed in the ingredients: So the same branded product does not appear to have the same formulation worldwide! This may be due to regulatory restrictions, economics or some other factor(s) that I am unaware of. It may also be the case that C7-C9 and C8-C14 share enough characteristics to be substitutes for each other and both classes fall under the same generic trade name(s). This is beyond my (current) understanding and knowledge. Questions: - Do you have a can of RONSONOL on hand? - Does your can list C7-C9 or C8-C14? - Can you post a photo of your RONSONOL hydrocarbon labeling? NAPHTHA For those still seeking "Naphtha" as a cleaning agent...good luck. It's actually a family of compounds with a bunch of different trade names and a bunch of different CAS numbers, and therefore a really hard target to hit in terms of procurement. It is also a highly toxic and flammable substance that is subject to very tight regulation everywhere. Perhaps even worse, "Naptha" has many, many aliases: Trade Names Naphtha Hi-flash naphtha Benzin Petroleum benzin Petroleum naphtha Benzin B 70 Amsco H-SB Super VMP Amsco H-J Solvents, naphthas Kwick Dry Naphtesol M Exxon Naphtha 5 Naphtha 5 HI-SOPL Exxsol D 3135 Naphtha 200 Paragon 100E+ Paragon 100E Plus Naphtha HT Shellsol D 25 Terlitol D 60 Texsolve V Shellsol D 40 Sanstar-sol 600D Aromina 150 CAS Numbers Even at the molecular level, the substance we call "Naphtha" is a bit of a moving target. While everything does seem to have a unique CAS number according to the Common Registry of the American Chemical Society, that may not prove to be ultimately true in the sense of a 1:1 mapping between a CAS Number and a Trade Name or even a CAS name. If you search the ACS CAS registry with the phrase "Naphta", you are presented with a single result that has been assigned the CAS number: 8030-30-6. But in that result, the following CAS numbers are either associated or deprecated with respect to the name "Naphtha": 8030-31-7 50813-73-5 54847-97-1 116010-52-7 121448-83-7 345960-90-9 1217187-52-4 Source: https://bit.ly/3TaLkOi But the ZIPPO lighter fluid MDS lists the CAS number for its "Naphtha, petroleum, hydrotreated light" as: 64742-49-0. Unfortunately, this number does not seem to appear in the ACS CAS datasheet for "Naphtha" at 8030-30-6. But when you use the ACS CAS lookup service to look up the number ("4742-49-0") and not the name ("Naphtha"), you do indeed get navigated to a datasheet titled "Naphtha (petroleum), hydrotreated light", which is located at: https://bit.ly/3wvTF5z The ACS owns the CAS system and assigns the numbers. If anyone knows what "Naphtha" is, the ACS should. CONCLUSION Depending on where you look (and when) RONSONOL is either 0% or 100% "Naphtha". "Naphtha" (to me) seems like a bit of a rabbit hole. Lots of fun to explore - if you have the time - but maybe not a path to clear results or a clear way forward in the immediate term to address the original question posed. While the confusion is being worked out we need to get out of this "analysis paralysis". It might turn out that the RONSONOL you use where you are contains "Naphtha" whereas the RONSONOL I use where I am does not contain "Naphtha"...but both fluids may work equally well to clean watch parts. What I plan to do now is an evaporation test with my RONSONOL liquid lighter fluid to see if anything is left behind. I have already identified, characterized and documented the substance to be tested. What remains is to test it. My test protocol will be to A) Fill three clean glass containers with approximately 1ml of RONSONOL Lighter Fluid (directly tipped from the canister). B) Allow the fluid to evaporate under covered but well-ventilated circumstances C) Shine a light through the bottom of the containers D) Attempt to detect if any residue remains Until I get my digital microscope, the best I can do in terms of magnification is 2X or 4X. I'll post my results soon. g. ----1 point