Leaderboard

Popular Content

Showing content with the highest reputation on 11/16/22 in all areas

-

Did I get your attention? I delivered that art deco clock to the customer yesterday (the one posted in the clock thread) and he asked me if I would service his '60s era Oyster Perpetual. He said the crystal "clouded up" from time to time. I knew there was moisture incursion. Looking at the watch, I could see some signs of rust at the lower edge of the dial. While this looked like a fun challenge, I do not have the tools to open the watch, I know parts are difficult to find and expensive, and a donor movement would be out of the question. So, with a heavy heart, I sand "No." Those who have followed my journey know that I do not shrink from challenges (not all have ended well!!), but I had to wave this one off. I told him to seek a qualified watchmaker.3 points

-

2 points

-

They will be fine in the cleaning solution. To make the hammer heads soft brush the leather with a little oil. They won't become soft over night it will take a long time but it will sink in and make the leather soft.2 points

-

Got the caseback tools and wouldn’t touch it with visible rust on the dial unless they were giving it to me to be mine! Tom1 point

-

1 point

-

You're on the ball today matey, beat me to it, i think Col just got opening for closing mixed up though.1 point

-

wait wait wait @Birbdad. You trying to open or close the barrel? That item is for closing the barrel, there's no tool for opening it. That being said, why not just buy the closing tool? They're less than $10? You can't open a Seiko barrel like the guys show on YT, you'll bend the top cover. You'll have to gently separate the two halves using a sharp knife or small sharp screwdriver. It takes practice to do that without marring the barrel.1 point

-

Hi With unmarked movements of some age the best course of action is to expose the front plate and use the Bestfit book identification section to compare the setting levers with the drawings, The size of the movement will help in locating the watch.1 point

-

I was being confused I would normally agree but is that really how the tool is supposed to be used? I normally don't use the tool can as I'm trying the close pocket watch barrels and they just won't fit in the one that we have at work. I was looking to see if I had dimensions anywhere because this is a school project they make it at school or can make it at school like the PDF that's attached. But it brings up a problem I snipped out an image tool doesn't exactly work the way I thought it was supposed to work. Then found a video shows using the tool. https://youtu.be/FIM2LZ1JEBY Wostep Barrol closer CCF12182012_0001.pdf1 point

-

Nasty teeth no wonder you had problems. A clock depthing tool wouldn't help because the runners cannot take a fusee wheel unless you make a runner that could hold it, then you have the means to work out what the correct depth should be.1 point

-

1 point

-

there are very troubling signs in your image. The gasket does not look nice and clean it looks like a lot of debris on the gasket and it looks like a lot of debris on the movement ring and none that would be good in the watch itself. This is where people forget when they never get their watch service the gaskets will disintegrate. Disintegrating gaskets are bad because then moisture would get in and that's then very very bad and that's not always going to be visible. then pictures are usually helpful but the video would be better. As we need to see what happens when buttons are being pushed. hard to tell but the case clamp on the left-hand side doesn't quite look right in other words it doesn't match the one on the other side? has anyone been the watch before you? this watch isn't quite like a stopwatch a stopwatch has way more metal on metal contact I have a stopwatch at work that the stopwatch wasn't working and it was basically just sticky grease holding things in place. But you wouldn't want to service this watch and see understand why the chronograph isn't working. oh? It's back to the video but if the watches never ever been cleaned if you push and the buttons to the push it all? If the watch was super super dirty maybe the buttons art even moving? This is back to when the back is off a new push the buttons what do you see happening anything happen at all? Because something you should move the return the zero won't work unless you're in the right position so it has to be stopped the start stop should work. And yes usually Omega chronographs are worth buying expensive to prices could1 point

-

I remove the hammer heads and clean by hand, if they get wet the leather goes rock solid. I know some people replace the the leather when servicing/restoring. I'm sure other people have hteir ways of doing this task1 point

-

In order to replace a shock spring, it’s generally easier if you have a jeweling tool (with the appropriate anvil and pushers). You would record the existing shock block depth with the jeweling tool, push out the shock block, replace the shock spring, then push the shock block (with shock spring in place) back to the correct depth. Some people have reported that they CAN reinsert the shock spring into the shock block without having to remove the shock block from the main plate, but it’s quite a difficult process, as you have to insert the shock spring at a very specific angle, and risk damaging the shock spring…1 point

-

There's no fix for this that won't involve a lathe at least, and some skilled work on that machine. Any type of glue will definitely not hold up, and even very careful soldering would never come close to the strength of the original material. If I needed to do this, I would bore the bridge out in a faceplate in the lathe, to the diameter of the broken off tube, then (from underside) make a small additional recess a little bit larger, perhaps just 0.10mm deep. This would accept a tube of the original diameter, which has a corresponding lip on it to fit the recess, that gets pressed in. Would need a left hand tap to thread the tube*. The press fit should hold up to the stress of tightening the screw, and the lip would prevent pullout under load from winding (the winding pinion pushes up on the crown wheel while turning it). *For those without a full selection of left hand taps, which is pretty much everyone, on a piece like this in brass you can take a similar left hand screw from an assortment and file 3 flats at 120 degrees and make a tap that will work fine for a use like this.1 point

-

According to the seller; "With some easy to polish off surface rust" Anyhow, they are all out and with no real damage to the box or the punch-holder. Will put the punches tonight in the vinegar and tomorrow it's another day @tomh207 After the refund I paid €100 for the set. Once done, I'll make a special "you are my friend"-price Thanks all for your help / support and I'll be back with the end result1 point

-

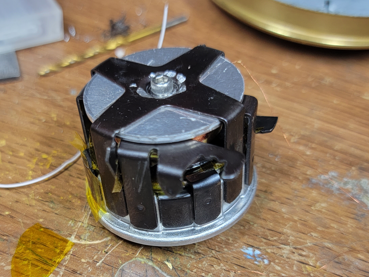

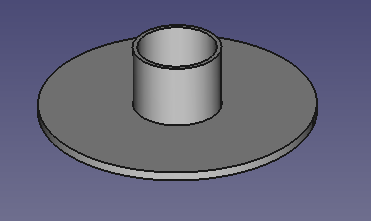

Got this clock for free and found that the coil was open as the connecting wire had broken from the enameled wire. It is riveted together so I had to cut one of them to get it apart. Had to soak the coil assembly in water and IPA so that the paper would come off. Then I found the end of the coil that had broken. Unwound a few turns so that I had plenty to work with. Then I made a bobbin for the coil so that it set firmly in the case. 3D printed. Now to assemble, I had to drill out the rivet and tap some 440 threads. It is all assembled and working. However, I need to make a connector piece to mount some metal tabs so that there is no stress on the enameled wire. I have some ideas working in my head.1 point

-

Thanks for the quick reply and it's as I feared, way beyond my pay grade. One for the parts bin then, or keep my eyes out for a donor or replacement movement. The movement comes from a very nice WWII watch so it's a bit of a shame.0 points