Leaderboard

Popular Content

Showing content with the highest reputation on 06/28/22 in Posts

-

2 points

-

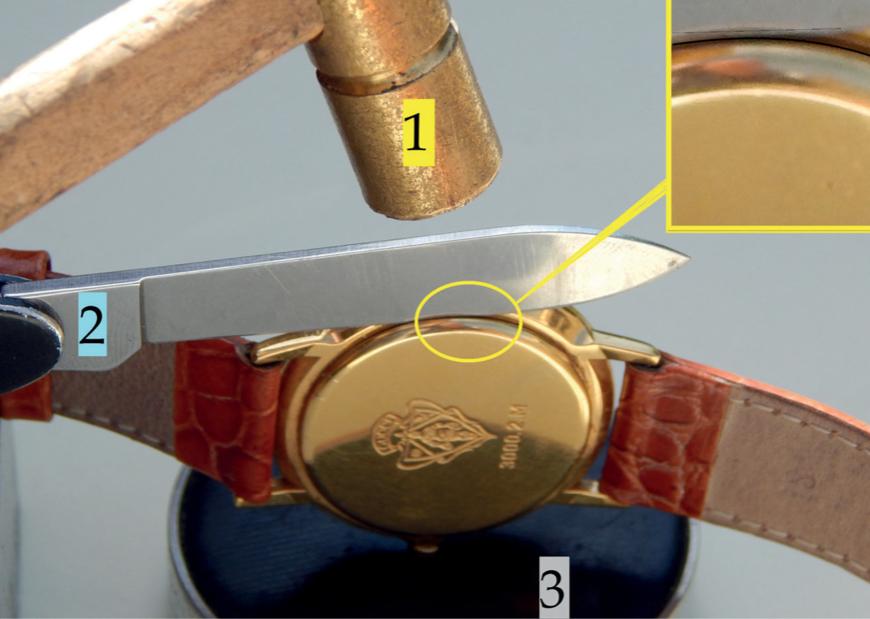

It looks like snap-on. Look for a seam, maybe even a pronounced notch, around the outer diameter of the case.2 points

-

Way back when the super for my building was a punch press operator during the day. He was missing several fingers. No doubt operators under time pressure would disable the safety manacles on the press, they were uncomfortable and interfered with loading the press. Modern optical fences are much better.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

If anybody's interested I did a long speil on this forum about lubricants. Below is the link to the start of the topic. Follow the comments through as my inputs are in the comments. FYI I spent many years as lubrication applications engineer covering many industries. http://www.watchrepairtalk.com/topic/638-lubricants-basics/1 point

-

1 point

-

Congratulations! When pressing the bezel back on you should put the pressure to the bezel only (or just the outer rim of the crystal)! Again you need the right tool. Your press with the right die should work.1 point

-

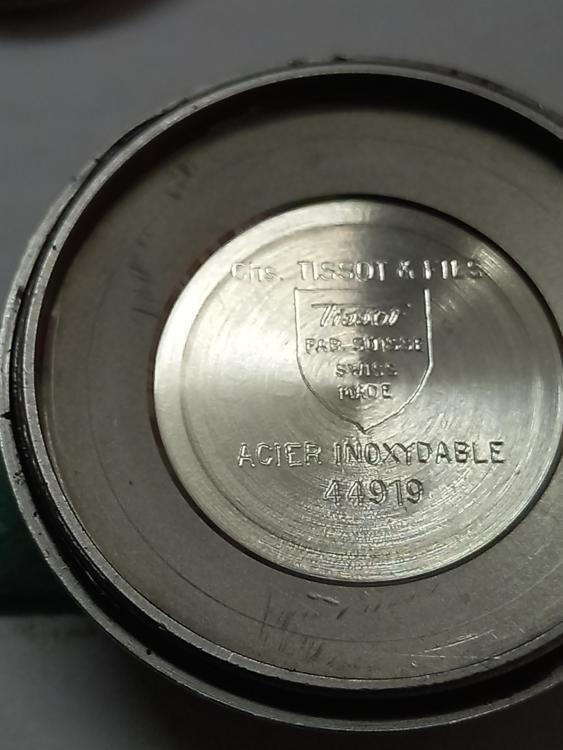

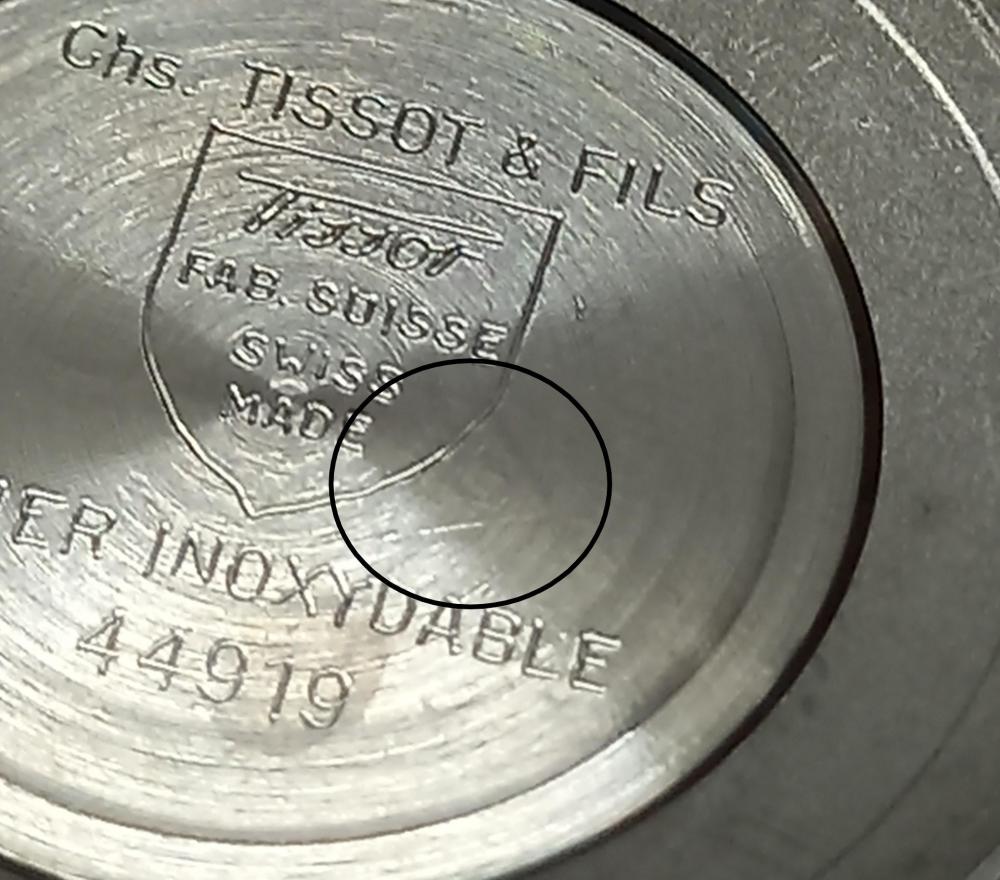

A lot of us in the watch hobby are aware of the fact that Tissot and Omega are quite closely related, one good example is the Tissot 2481 which is the same movement as the Omega 1481. Even the 10xx Omega's can sometimes be found branded as Tissot. I have this Tissot and while handling it recently I noticed that its bracelet clasp is signed Omega. Cool but I did not think anything about it... watch straps are easily swapped. Over the weekend I decided to look into the quickset which wasn't ...quicksetting. On this calibre, the quickset is by pushing in the crown. I decased the movement and cycled the quickset, my initial guess was that the stem was cut a hair too short and the crown did not have enough travel to activate the quickset. With the movement out of the case and the crown having unrestricted movement the issue with the quickset remained so it needed some further investigation under the dial. As I am a bit swamped with watch work I decided to reinstall the movement and come back to it some other time. On blowing the inside of the case out with my puffer, I happened to notice this, the little Omega cartouche in the middle of the crystal inner. You will find this on most original acrylic crystals. I've never seen this before on Tissots. Next I re-examined the caseback... Normal Tissot at first glance but it looked a bit unusual. It seemed like it had been machined and then restamped. On closer examination, I can make out a mark in the area circled below, can you see it? Its a bit hard to see in the pic and even with the caseback in hand you really need to have the light at the correct angle but the Omega logo can be faintly seen! My guess is that there were a surplus of cases/bands which was diverted to Tissot which then machined off the existing markings and engraved their own logo and numbers. Anyway hope you guys enjoy this insight into the Tissot/Omega relationship! Anilv1 point

-

An interesting and lovely example of the history of Omega's and Tissot's collaboration to become the holding company SSIH in 1930.1 point

-

it brings up an interesting problem with all the oils that expire. then there's a problem of why do the oils expire? All the organic oils are oils with organic materials you have the potential going bad but what about the synthetics? If you look at the early advertisements when they first introduce their synthetic oils they basically said they lasted forever. So forever should mean you shouldn't have to have a date. then there's the other concerned that people have which is contamination. Specifically getting the oil out of the bottle without contaminating the bottle. That's why companies like Rolex supply lubrication put things in syringe is so there's no dipping things in the bottle. Then the other reason why they put dates on things is up until dates you had no idea how old that ball was. The bottle could've been 10 years older 20 years old maybe it could've been sitting someplace in the sun which would be bad it got hot or you'd end up with bad lubrication even though it's a brand-new bottle. So people feel better about buying stuff with a date on it. then with all of that we now throw in nice clean watch which you lubricate with your oil that supposed to expire in the bottle and what does this mean for the watch? With all sorts of varying how often a watch should be serviced for years to six is typical that means that when the oil expires in the bottle you're supposed to get another six years at least of it sympathetic. I'm not sure what the organic oils that expire in two years you might be pushing another two years for servicing if you're working in a shop your collecting money to service stuff people bring you then you should be concerned about having the best quality and condition lubrication's. If the manufacturer recommends? I have a link to a variety of interesting Omega documents you want to get at least number 40 it's on lubrication https://www.cousinsuk.com/document/search?SearchString=working then in case you're curious yes if you had Swatch group access which you don't worry Omega's lurking with the technical documentation there are way more these than just what cousins house but at least we do get the lubrication one so we see Omega's current recommendation of variety lubricants all synthetic of course we don't even have the 8200 mainspring grease because they don't use it. notice it must be kept in a dark place because lights not good for oil and it has a maximum temperature so no putting the models on the sunny shelf just because a look pretty there. So even without the oil manufacturers recommendation because are all synthetics the recommending six years **BLEEP** bottle. Really important thing they recommend keep the lid closed on the oil is you don't want to get dust in it and then they recommend weekly changing. On the other hand they have really deep pockets and they can replace the oil faster than every seven years but it does give you a hint that even the watch companies not necessarily using huge quantities if they're telling you you keep your oil for 60 smears another a severe bigger bottle at last forever. Which strangely enough is what I found out home I just wasn't going through it that fast although I didn't always change the oil of the cups every week either but you can do things at home you wouldn't do if you are taking money in the shop then the rest the guy has techniques unfortunately are missing the working instruction which has cleaning and then there's another one that talks about epilam all missing. Also notice the corners of this document every single page has been watermarked something appears to paranoid over where documentation comes from which is why anyone who is Swatch group access is never going to give us their documentation because it will tell the world where it came from which might be bad for people that have accounts with Swatch group. yes about this? You did read the working instruction up above every seven years toss all your oils what could that possibly cost you? Suppose you're like me your lecture he discovered that oh dear you should change your oils from time to time. So in my case I have local material houses I can just go downtown walk in and say I have money I need lubrication. Once Debbie decided that I probably wasn't totally insane she started selling me various lubricants. Now it's not just a hobbyist who complains about the cost of oil everybody does. Even the people that own the shop were bringing in money to pay for this still complain about the cost of oil. From memory I blew $200 that day and I was still missing a couple of bottles of stuff unfortunately the HP oil did not come in little tiny bottles so I ended up with bigger bottles and they ran about $100 each so now I'm up to $400 oil so at that point in time I formulated a theory for John and the theory goes like this at home there my personal watches. Typically if the lubrication breaks down you're going to see a performance issue it will show up on the timing machine. This is not 100% true so if you follow this recommendation follows so at your own risk. In other words if the oils spread like 90 $10 as we can see an disappear and your pivots are no longer lubricated or very common on automatic watches metal on metal bearings if you don't lubricate your watch the lubrication does anything undesirable other than getting gummy and sticky like just disappearing you may grinder watch into a ball of dust and I don't want to hear about it so my current theory for John is that synthetic oils originally advertised would last for ever and that the oils that I have should last forever especially at the rate I'm going through my home is a consequence I'm never going to replace the oils at home. I would like to add one to it at work I've become quite fond of 9504 versus the grease of choice at home that I liked for all these years which was PML stem grease that runs about $20 to really nice stuff versus fortunately at work I didn't have to buy it I just asked for it and it showed up so I think unless you're doing watches for money you doing your own personal stuff be keeping an eye on things because you have a timing machine if you see a performance decrease you should definitely be concerned. Your visually looking at your watches like is at 9010 that everybody but John is using yes I use 9020. But you see the oil gone out of the balance pivots you can make a choice you want to service your watch are not another minor problem that happens to people that collect watches are you manned up with having too many watches so why do you want to go back and read lubricate the watch was seven years ago when you have all sorts of other fun exciting new things to service1 point

-

1 point

-

1 point

-

I didn't know a hairdryer could get hot enough to that kind of damage. But aren't hairdryers made of plastic nowadays? Are you sure you didn't pick up your hot air gun by mistake?1 point

-

What amazes me is there was absolutely no attempt to "sanitize" or hide anything. The setup looks like it was from the '80s. Except for the part where they were using what looks like China made timegraphers. I can't wait to see the insides of a Chinese watch factory.1 point

-

Same with me Graham! Welcome to the forum. Me too. Have you opened it yet or did you just get the movement? Do you know what grade your movement is? My first (and second) were grade 313. It did finally have life however I had cobbled it together by attempting to use components from the second movement and they aren't 100% compatible. I learned a lot. I've got the Elgin Material Catalogue and portions of several other grades. I have 5 other movements (actually 4 and a watch) that are in the queue. Enjoy the forum!1 point

-

I remember reading on the machinist forum about a guy carrying out a punch and die set, setting it in someone's trunk, and the set slamming closed as he set it in. There was a mention of "popping grapes" which horrified me but apparently the bloke made a full recovery. I'm eternally terrified of punch sets.1 point

-

Yes, on a machinist forum I frequent someone wanted to sell some small presses and there was a unanimous cry "if they were made after 19xx they're scrap". Presses scare the bejezus out of me.1 point

-

welcome aboard! IMHO and from what I've learned is that pocket watches are an excellent place to start. that's where I did. i love working on them. Elgin is a great choice and has a rich history. be sure to learn about that history as it'll help you appreciate them even more. another good thing about American pocketwatches anyway, is that even though they don't make them anymore, there are an abundance of spare parts/donor movements to get parts from. it's half the fun. They're not too hard to find. Have fun!1 point

-

I subbed and also have been watching the bearded one for some time also. hi guys!1 point

-

I find the video hysterically funny in a way. It looks simple doesn't it? It's actually quite an amusing video. what if you had a vibrating tool when it look as simple as this? Oh unfortunately in this next video he doesn't give the plans a way that's very sad I believe he sells the school and no I don't know how much it costs but once again look how simple it is https://youtu.be/htckrH3ae54 now the reality is this would be a nice tool to have because notice it displays the beats per hour as opposed to looking at the master balance wheel in the platform which can be it interesting singular. Oh and if you look at all of his stuff he's using an optical method if I remember right user picking up off one of the arms which is nice as you get rid of the sound aspect but companies like Greiner they make a really nice machine that none of us can afford that vibrates hairspring it might even do the terminal curve at the same time not sure about that there is a YouTube video that has that's of somebody really wants it all track it down for you other interesting video in the news as reference to wostep at the very beginning of the video because at least at one time they afflicted pain and suffering on their students by teaching them how to vibrated hairsprings. https://youtu.be/M5LEN66vxgc now in this last video ever notice that the hairspring doesn't have a stud like the other videos. so here the student had to take the collet hairspring pins raw hairspring form of the terminal curve temporarily pin it to the collet. He has just temporary that's a school that likes to teach perfection C have to go back and do another step in unpin do some other complicated stuff was just skim over. The temporarily penned put it on the balance wheel you make sure it's centered and flat and then you can vibrate and notice he has some extra hairspring because you need at least one full turn at the top to do the other steps. The reason I bring this up is the previous videos started with the hairspring it was already pretty darn close what if you hairspring is not close long did it take you to get that hairspring to look like the last video then of course I'm the bearer of bad news in order to learn how to vibrated hairsprings you need hairsprings and we've discussed this before but I will remind you in a way the Swiss no longer make raw hairsprings. It used to be they made hairspring is with the CGS specification and they would send them out and companies variety people to buy raw hairspring is and of course you can vibrate them. But the Swiss have consolidated manufacturing why make a whole bunch of generic hairsprings when Dell just make the hairsprings you need. Or even better yet send your balance wheels to hairspring company and they will they hairsprings for you which is what they do. The consequences are those little packets of necessary raw hairsprings that the students like to go through it a huge quantity because it's not easy to get to the point of that one video and up damaging a lot while you're learning they no longer exist. Now is the bearer of bad news as much is one of vibrated hairspring probably isn't going to happen because you don't have any hairsprings the vibrate you could try looking at eBay if you're lucky you might find the packet or to look at oh and of course the other videos with the stud those of already been vibrated so course it looks easy and simple because that's a finished product I know somebody who has a hairspring vibrating tool and he can never figure out why a comment that vibrated hairsprings is a total nightmare the pain in the ass to do because he's done that very thingies but the balance wheel then he puts in your the stud and markets vibrating about how close it is a different story for starting from scratch takes a long time to get to close to being vibrated here's a website where he shares his fun of vibrating Springs http://www.bobinchak.com/watchmaking/2017/4/26/hairspring-week-vibrating-the-hairspring yes additional tool is expensive but there are as some of the video show other ways to do it the Microset timing machine has a accessory for vibrating hairsprings. One of the old paper tape machines had a holder for tweezers so you could get the to the balance wheel spinning it would no action move up and down these time went up and down a tap on the microphone so you'd use the timing machine to do it don't know how well it worked but that was accessory for the machine so there are some other ways to do it of course you still need hairsprings not what I was looking for but you might find it interesting https://watchmaking.weebly.com/hairspring-vibrating-tool.html okay found it can't buy it from here though but you can see what it is the other material houses should have this. If you raise your hairspring up with the glass in the center is for the collet so they hairspring reflash is a lot easier to see the hairspring that is when it's flat on something https://www.amazon.com/HAIRSPRING-HOLDER-simple-spring-support/dp/B01NCN45S91 point

-

The 404 club "probably Le Coultre" pocket watch got a little attention yesterday. It arrived stone dead, fully wound, with a half gallon of wd40 on the surface, so I cleaned as much of that off as possible, let down the mainspring and gave it a few clicks of wind and off it went. It will need a full strip down, clean and service, which I will do when I have time to relax and tackle it with no interruptions. Since parts for this are probably completely unobtainable, I want to take a little extra care with it. This is obviously a quality movement and hopefully once I have it apart, there will be a serial number or some way of identifying its manufacturer with certainty. The case appears to be silver, but so far I haven't found any hallmarks or stamps to prove this.1 point

-

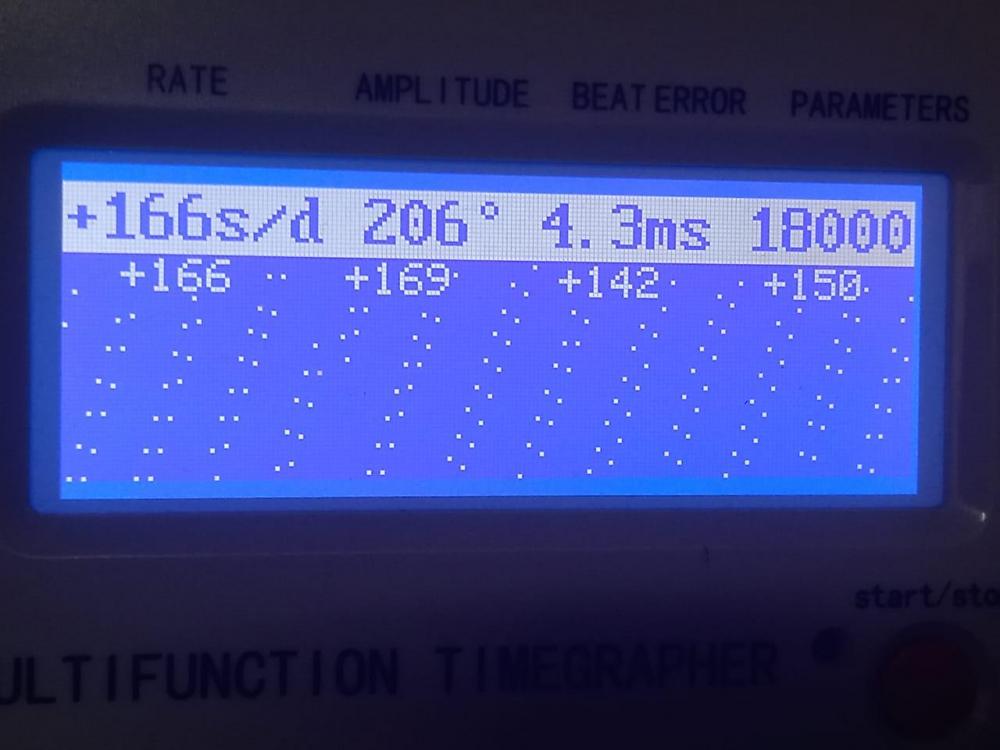

Just bought this neat Omega, it wasn't really cheap but as it wasn't running and there was a lot of gunk on the dial the price was pretty decent. It is a handwinding cal.230 in a stainless steel case with a solid gold bezel. It has its original crown which is gold filled and in good condition. A serial number in the 11.4million dates this to 1947-50. Back when this watch was new it was on the same level as Rolex in terms of cost and reputation. The dial is pretty worn but once I clean up the green oxidization it should be pretty wearable. As always, the camera is always more critical than the naked eye. Nicely signed Omega crown, gold filled. God only knows what that gunk is, but its pretty brittle and comes off easily. Nice calibre 230. No sign of the gunk that was on the caseback. Probably because there was a dust protector which, well... protected the movement! While it didn't run while in the shop, when i reached home I was pleasantly surprised to find it running. I had kept the watch in my jeans pocket and I guess the warmth of my body plus the movement was sufficient to persuade it to run. Looking at the trace it really needs a service but it runs without much variation so that's pretty good. I wound it full and it was still running 24hours later so I'd bet the mainspring can still be reused as well! Will not be able to work on this watch now but will post some more pictures of the teardown and rebuild later. Anilv1 point

-

Just took apart my very first ETA cal. 2824-2 (17 jewels), and I took a picture of every step. Mark Lovick “assisted me” with a sure hand as I went along (thank you!), so my pictures (more or less) replicate his disassembly procedure. The general idea is that I first take a picture of the part that I’m about to remove (pretty much centred in the picture), and the following picture shows the part along with any screws that held it in place. I’ve used an iPhone 6s with a macro lens to take the pictures and I’ve strived to obtain as much focus as I possibly can so that it will be easier to find the right screws during assembly. The pictures are stored on my OneDrive and should be sorted by name (default is photo date) in ascending order. I’ll post my assembly pictures in this thread once I’m done (waiting for a new mainspring, Moebius 8217, Moebius 8981, and Lubeta v105). Disassembly pictures here!1 point

-

Assembly pictures here (IMPORTANT! Please sort by name in ascending order). So, just finished reassembling my first ETA cal. 2824-2. To be able to service this type of movement was my long-term goal when I started out on my watch repairing/servicing journey a couple of years ago as it is one of the most popular high-quality Swiss movements found in many renowned watch brands. So, feeling pretty good about myself for having reached this goal! Initially, I didn’t intend to include any points of lubrication (there are approx. 70 of them) but changed my mind in the process. I also included information on what parts (according to ETA) should be treated with Moebius Fixodrop ES/BS 8981 which I had not even heard about before I saw it in ETA’s technical communication for the 2824-2. I also mention the use of LUBETA v105 for the reversing wheels which ETA does not communicate. According to ETA the reversing wheels should not be cleaned but replaced if dirty or rusty As mentioned in the title, my 2824-2 is a 17 jewels version whereas most 2824-2s are 25 jewels. I’ve concluded that the difference is the automatic device framework plate (6 jewels) and reversing wheels (2 jewels). Also, my version isn’t hackable as it lacks a stop lever (balance stop), but other than that the pictures should apply to all 2824-2s. I’ve included ETA’s drawing of the stop lever (at the correct place in the sequence of my pictures) and where it is fitted in the movement. I will add a few more pictures in the coming weeks which will show mounting the automatic device framework, the oscillating weight and putting together the entire watch. The reason I haven’t yet done this is that I’m waiting for a new pallet fork as I got a pretty clear indication on my timing machine that it isn’t healthy. I had the same reading before the service but was hoping it was just the result of dirt and/or dried up oil.1 point

-

Eyup peeps, hows everyone doing ? Now i know not everyone likes to admit their mistakes but i embrace mine and find a positive side to everything i do. I'm the product of a poor upbringing and instead of moaning about a shitty childhood my outlook on life has made me the man i am today. A non negative, pick yourself up off the ground and become a something to be proud of person. So that being said, I'm returning to my second fluffy duck up from the start of my repair journey. Here it is an early 70s Smiths diver, not the quality type watches that the Cheltenham factory turned out that summited Everest but the stuff that came from their joint venture with Ingersoll just after the war made in Wales. Making mostly Smiths Empires in a variety of dial designs and a simple movement used in a few other named watches. But its British and so am I ( and simple ) and that will make me proud to wear it regardless of its final condition and performance . So after a service and the repair of a broken click courtesy of a willing donor, everthing was cool i had another fix under my newbie belt . The case was pretty grubby so a quick bath in the US and I'd be ready to dial up then reinstall the movement. Hmm i thought it looks like some water has got under the bezel insert ( a classic newbie mistake ? might have been wise to remove the bezel and crystal before the case clean ? ). Its a diver it will be fine, not really no. A very old diver and a poor one at that and had probably never seen water in its life. It would need to be dried out quickly and carefully ( notice i use the word carefully ) I was going out that evening and had been messing around repairing most of the day and time was knocking on. So drying needed to be speeded up a bit, a hairdryer, a great choice but not when in a rush. After a minute or so nothing much seemed to be happening, time to get a little closer and crank up the heat. 20 seconds later i noticed a strange smell of burning ? Wtf, a second later came the moment of clarity. Too late the crystal was starting to melt before my eyes, picking up the case and hopping it from one hand to the other while running to the bathroom to run it under the cold water tap was a sight to behold. Jackson POLLOCKS ! A melted crystal, a partially melted bezel and two scolded hands, not my finest hour that week. I was gutted to say the least it wasn't particularly a cheap watch, even the GB Smiths divers can fetch around £200 -£300 in fair condition. But it is what it is, a lesson learned and an English diver ready now to go back into service. The bezel is a bit of an issue as I've tried to source one with no luck but something will rock up eventually. The universe is older than time immemorial and i know it looks after me from time to time thats why I still walk this earth. So before i get too emotional with myself here it is ready to be reassembled, the bottom one is what it will look like but with a black face, much nicer imo.0 points