Leaderboard

Popular Content

Showing content with the highest reputation on 12/30/18 in all areas

-

I'm starting again. Anyone who would like a copy of the Bestfit Catalogues Vol 1 and 2 You will need this pasword to open each volume. tickandtock Links https://www58.zippyshare.com/v/BGNuxKTX/file.html https://www105.zippyshare.com/v/xrUeOPSy/file.html4 points

-

...and make sure those tweezers get cleaned before they go back into the theatre! In fact, I would be inclined not to use tweezers to hold the logo in place. Dials are incredibly easy to scratch and impossible to touch up. They also show up fingerprints so I would use finger cots to avoid marking the dial and hold it in place by hand. Superglue will dry quick enough that you won’t be there for long and as HSL says, apply with a small needle or pin - you really need just the tiniest amount. If you don’t have finger cots then maybe you could track down some surgical gloves from somewhere... Not sure if it is clear from the posts above, but the pins should really be glued from the back of the dial. That does mean hands and dial off the watch, which is fiddly, but relatively simple surgery and there are some good videos on line. If you aren’t up for that, then the tiniest, tiniest drop of glue in the holes before you insert the pins should be ok. If you try to put the glue on the pins it will likely scrape up them and end up spreading onto the dial.2 points

-

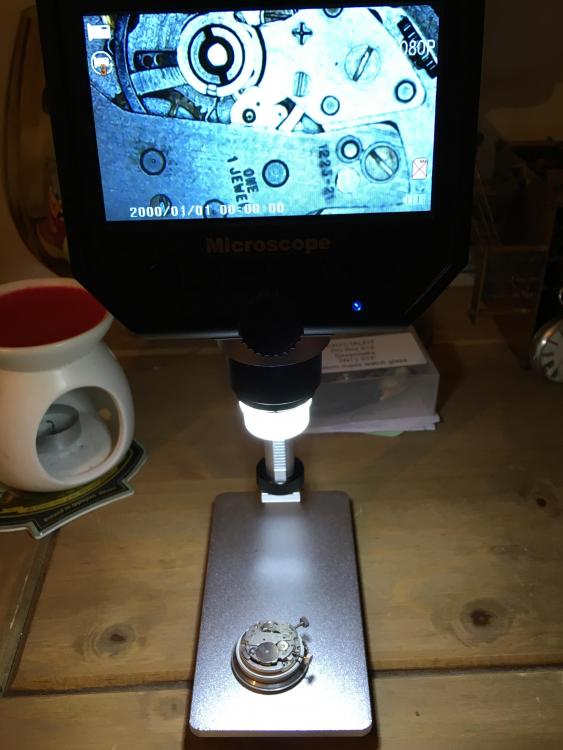

Well gents a couple of weeks ago I jumped on a post about microscopes, at the time I had just ordered from AliExpress one of these, a 600x mag with built in screen etc etc. well it arrived and it’s great, it really is, the screen picture is very clear and the height of the screen and microscope are adjustable to the height where it is easy to manipulate hairsprings with tweezers in the vertical position. For jewel inspection etc you can lower it down to take advantage of that 600x mag and get a proper look at jewels and staffs etc etc. all in I’m very happy with this as it saves me having to have a laptop on the bench with leads etc getting in the way and also finding a program that works with the microscope. This one accepts a memory card and will take stills and 1080p HD video aswell all in one unit so it’s ideal. It’s light and as you can see quite compact, it’s powered by its own internal battery that has a 6 hour life before charging is required , a plug ( albeit a Euro 2 pin one ) and a usb lead is included for charging purposes. my only gripe is that you don’t seem to be able to turn off the led light when it’s switched on, but that is the only one so far. Well with the £40 and 3 week wait for it to arrive from China.2 points

-

1 point

-

Here are two new links. I bought both so they are mine. https://www.mediafire.com/file/mz809lm3bms8zk3/bestfit_part1.pdf/file https://www.mediafire.com/file/eqbhdor949r0ilp/bestfit_part2.pdf/file You will need this pasword to open each volume. tickandtock Sorry I didn't know zippy was now full of crap. If you have adblocker you might need to disable it for mediafire. These are safe I have tested them.1 point

-

th The belt drive is superior for this type of lathe. Mine was a originally a Ward Leonard drive, the tubes you mentioned came in later models. Unless the drives are scrap, most guys chose them as they are superior, the tube drives more so than the WL drive imo because of noise. None of the common drive replacements equal the performance of the original DC motors - they were a large diameter with a huge number of poles so very high torque could be had a low RPM. Of course with a machine tool, you want torque to go up as speed goes down (so power stays the same) and mostly you have to accomplish that via a mechanical transmission, it was one of the features of these lathes that it was done so electronically over an impressive speed range (10-4000 rpm). As mine didn't come with a drive, just the backgear, I'm using a 5hp motor, the back gear and VFD to get the range of speeds. I'm sure my approach will be fine as I don't really need it to run at 10rpm with full power, as I have the DSG goes down to 17 and as its geared, you get full hp at the lower speeds I make it, homemade 10hp rotary phase converter, 240 1P in, 240 3P out. A lot of my machines, like the DSG are 600V so I also step the homemade 3P up to 600V 3P. For the 10ee though, I'm going to use single phase 240 into a VFD; an over rated VFD with 1P in will properly drive a 3P motor. Ideally I'd have VFD's on every machine and do away with the RPC (tired of the background drone, and having to move across the crowded shop to turn it on when I want to run a machine), but vfd's are expensive for high HP's and you need one for each machine. Mike1 point

-

1 point

-

There are some differences in techniques between manufacturers, on most vintage Swiss they are riveted in place with those two pins. But now I have looked at two Seiko Kinectic and on both they have been glued from behind. A small dropp of some kind of superglue have been applied onto the pins keeping the logo in place. I guess that's why it gets loose when the glue degenerates. I would probably do the same again since the pins are too flimsy with too little material to rivet with. So with a small needle apply a really tiny drop of superglue from the back of the dial.1 point

-

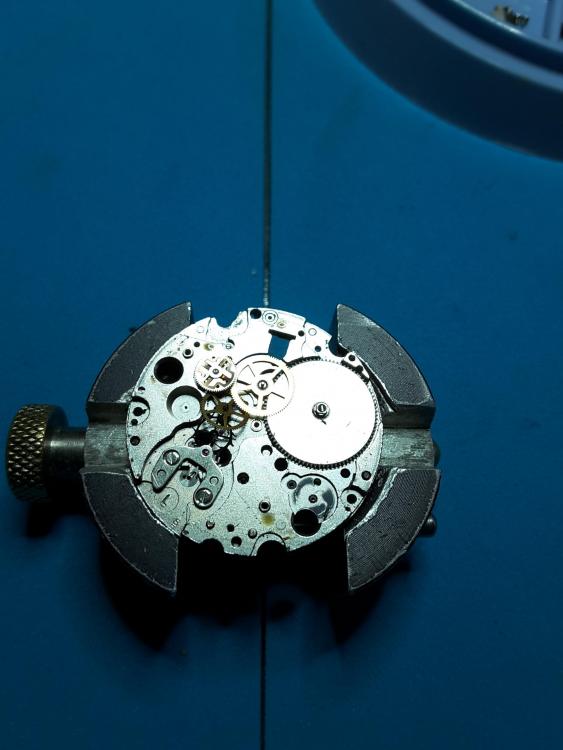

Thank you for that, excellent video! I have been trying to eliminate being on the wrong side of the fork with the roller jewel by positioning the jewel between the two forks. In some movement its hard or impossible to see but in this case, I have a clear unobstructed view. I was led to believe you could do this to prevent overbanking if you do not know what side to place the jewel, left or right. This does Segway to the question of how does one know from caliber to caliber if your to position left or right? I have noticed a “L” stamped into the base plate (framework) near the pallet fork and was wondering if this was a indicator. Photo of “L” attached note the "L" below the pallet fork bridge. Thank you for your response, I will study this area a bit closer.1 point

-

lol, here's the big one....obviously not watchmaking, but I gets use to make tools and stuff for watchmaking and smaller equipment so I justify its inclusion. To continue the car analogies, this ones sometimes called the Rolls Royce of lathes. its a '68 Dean Smith and Grace (DSG) 13x42" weighing in a 5100 lbs and 7 1/2Hp. I once took a 1 5/16" DOC with a .005" feed in steel just to see what would happen and it didn't even groan. right off the gear box you can cut metric, imperial, diametrical and modular pitches and up to 8 start threads. Its such a nice machine, its become almost an emotional attachment lol1 point

-

not really, I'm a beginner at it as well. its essentially a lap which I've a fair bit of. The right way to work with a lap is change a lap by pressing abrasive into and it becomes a cutting tool. You only ever us it for a single grit/type of abrasive and use with a bit of oil. You usually work by moving up in grits. My plan was to make a set of tools for it as I've no idea whats there. That's based on lapping knowledge though, not specific knowledge for this tool....we'll have to get those recommended books! Levin - Practical Benchwork for Horologists Archie B. Perkins - Antique Watch Restoration1 point

-

Just to clarify: the roller jewel is meant to enter the notch of the pallet fork and begin to force it to snap over to the opposite banking pin when the balance rotates. Does your roller jewel do this? A trivial fault can be if the balance is inserted with the impulse jewel sitting on the wrong side of the pallet fork. I’m guessing you already know how to do this. This video provides a nice explanation of what I was describing, ie. over-banking: Slightly more complex is the finer details of the “safety” features of the Swiss Lever which prevent over-banking. A relatively common issue here is a bent guard pin, so you can remove the pallet to check this if need be.1 point

-

I think between the 10ee and HLV the 10ee is nicer just barely, but its like arguing about Ferrari and a 911 turbo, they're both friggin awesome. Very often though, the HLV is the nicer one you come across as they tend to newer than the 10ee's and they do have that nifty threading feature. The last 10ee's made a few years ago were reported sold for $100,000! A 10x20" lathe weighing 3000lbs, 10 -4000 rpm and 5hp, its a beast. Both (like most high end tool lathes) are belt driven to minimize vibration that can show up in the finish. Here's my '42 round dial (my second biggest lathe lol) with the gearbox torn apart. just so you guys can see why I'm not getting more watch work done. Also had to make a new drive for it, by adapting a 3P 5hp motor to the backdrive (2 speed gearbox down below), a work in progress1 point

-

Cousins probably just took a dislike to you. Don’t take it personally I usually enter the bare minimum of information, i.e. height and end type and see if any of the results are workable1 point

-

Minimum beat error should in theory result in better amplitude. It may be that when the beat error is significantly wrong then the timegrapher gets confused. Remember that it's only an estimation based on the sounds heard from the escapement. You alos don't need to go OTT with the beat error. For 18000 trains, keeping it in the low number of mS is good and sub-1mS is excellent. It does not have a significant effect on timekeeping as I guess you may already know.1 point