Leaderboard

Popular Content

Showing content with the highest reputation on 08/31/18 in all areas

-

That could be hard to tangle out. Think it could be easier if you remove the bridge. Or put an oiler where the crossing is and move it upwards. Hopefully untangle the hairspring. Other then that you will need to find a new balance.2 points

-

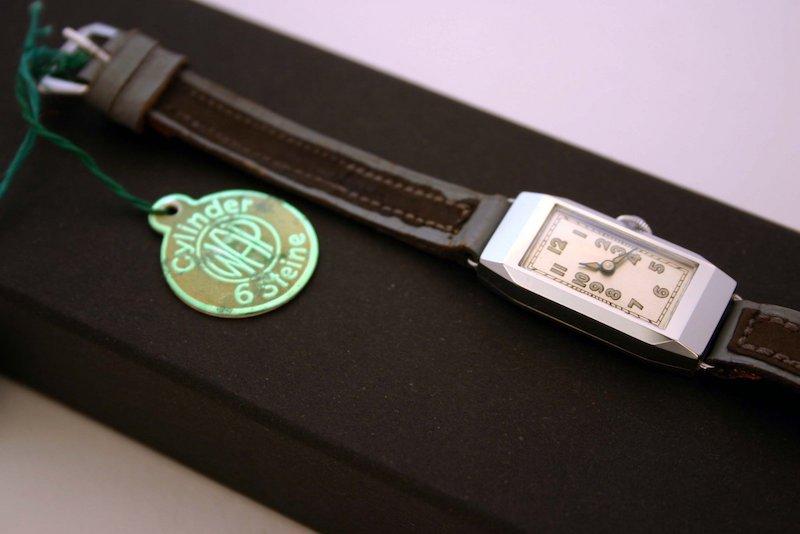

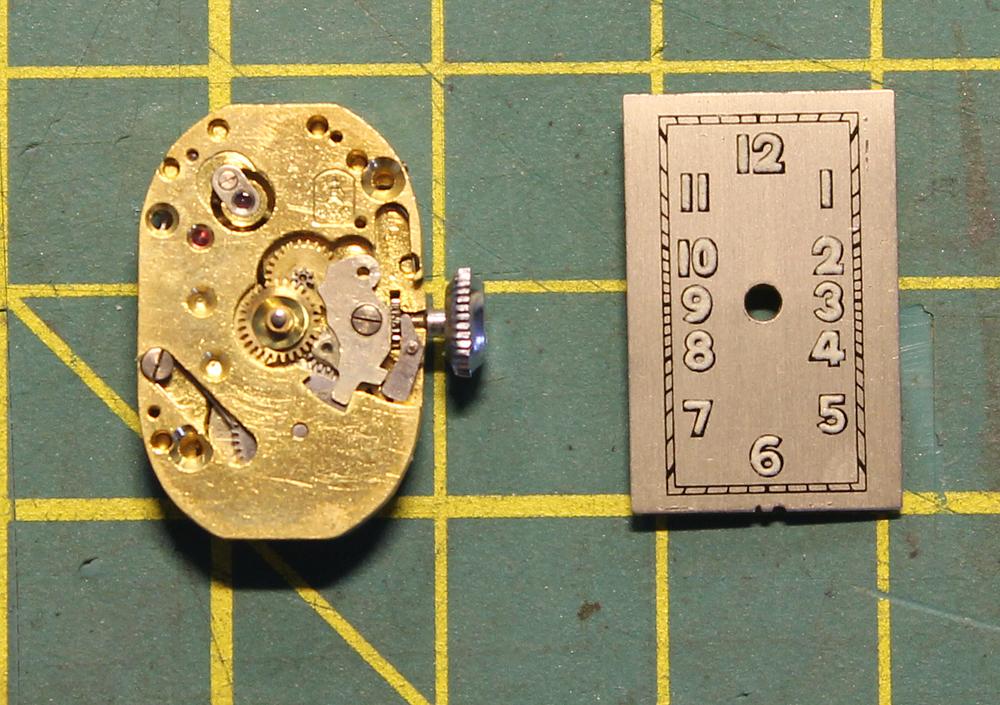

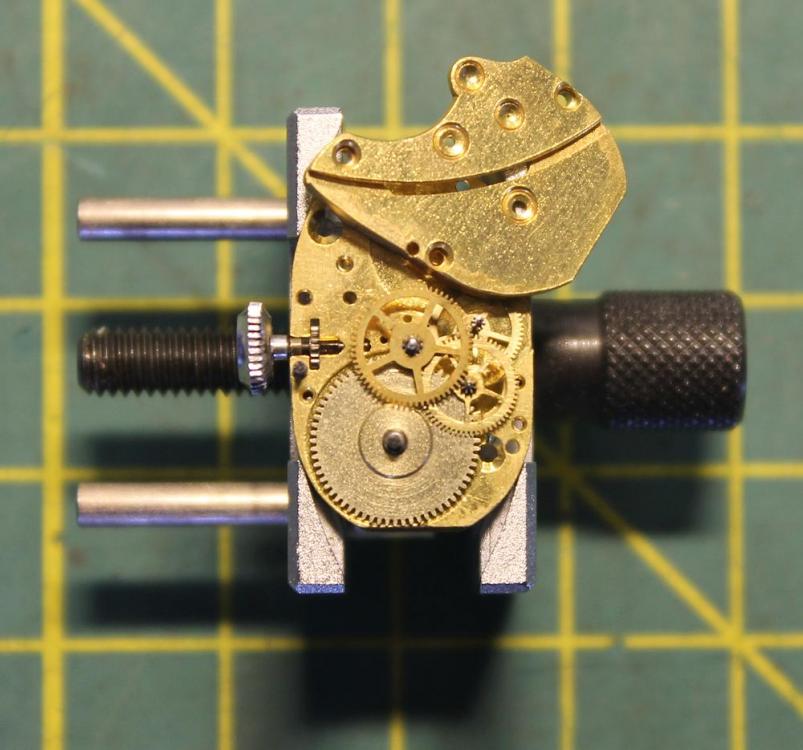

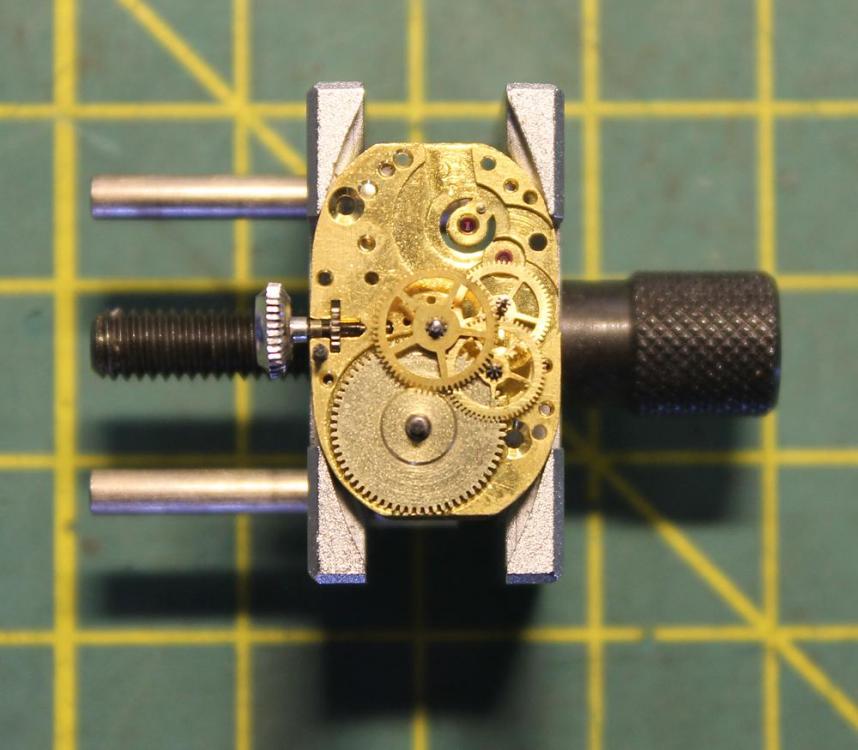

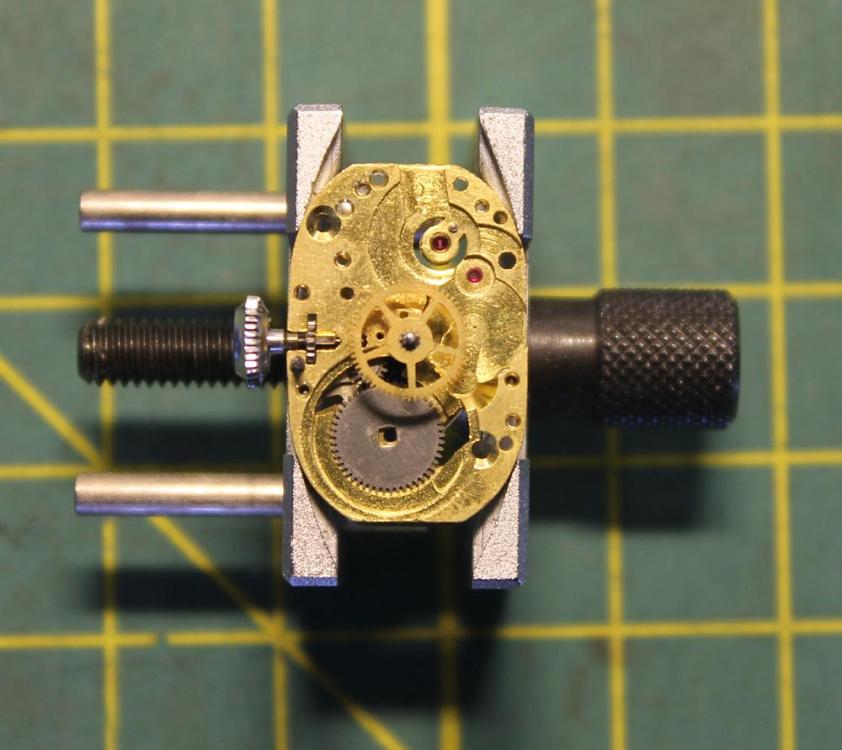

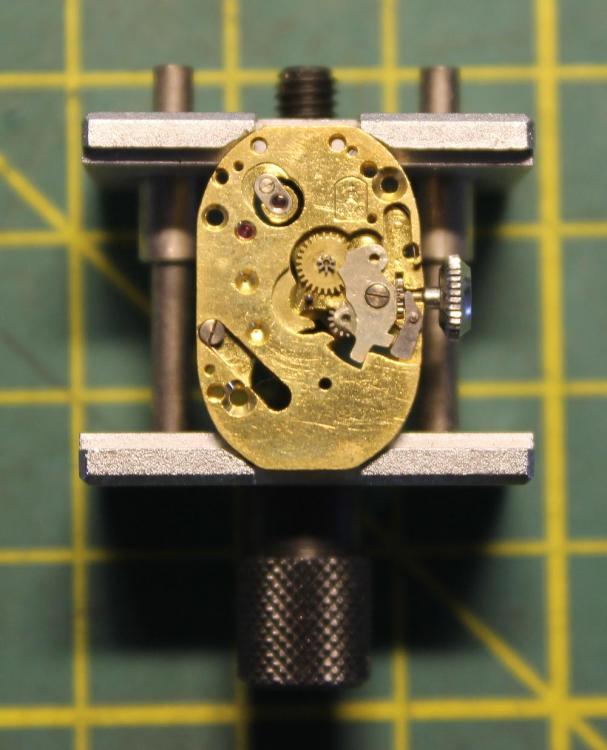

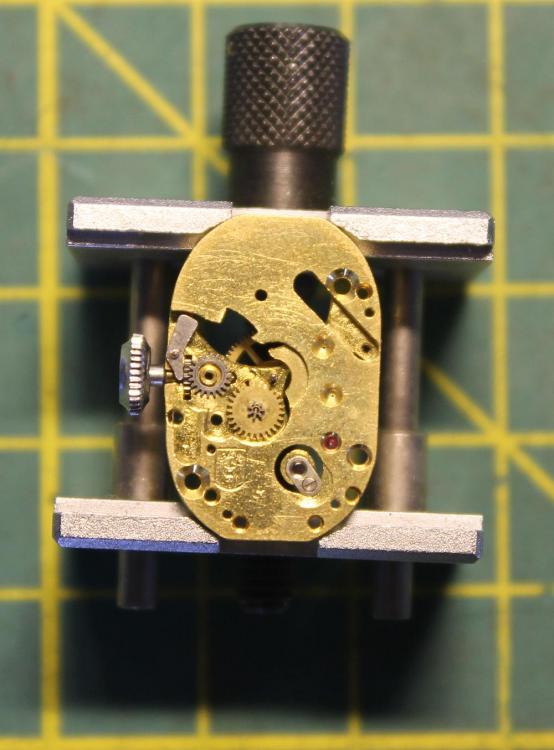

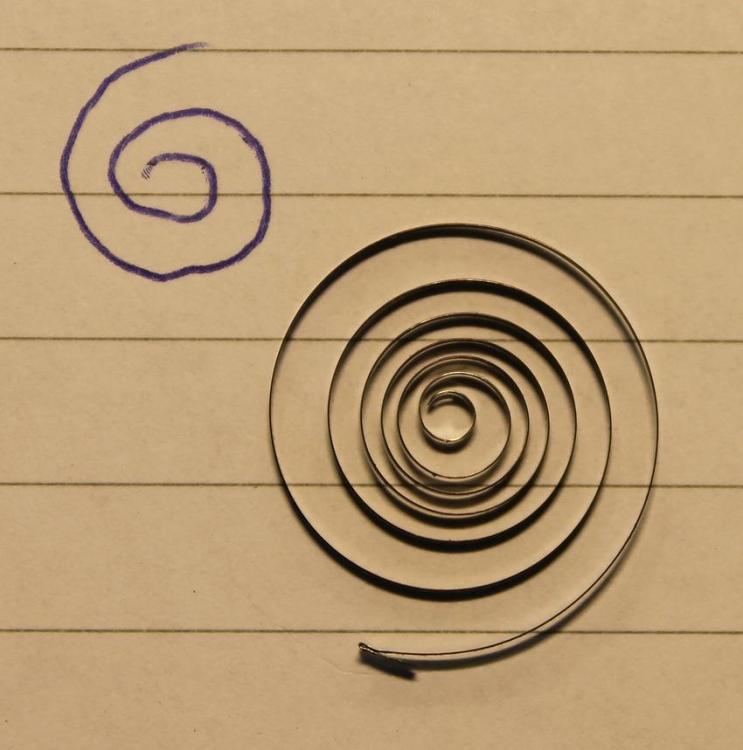

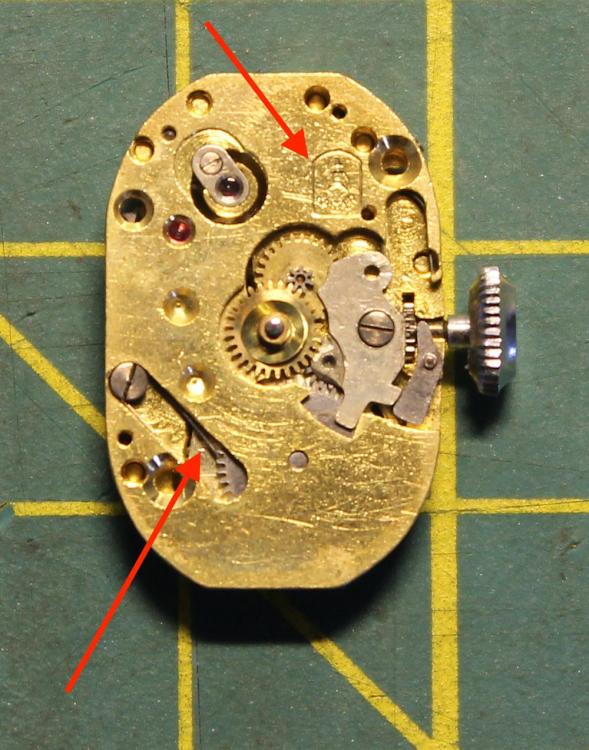

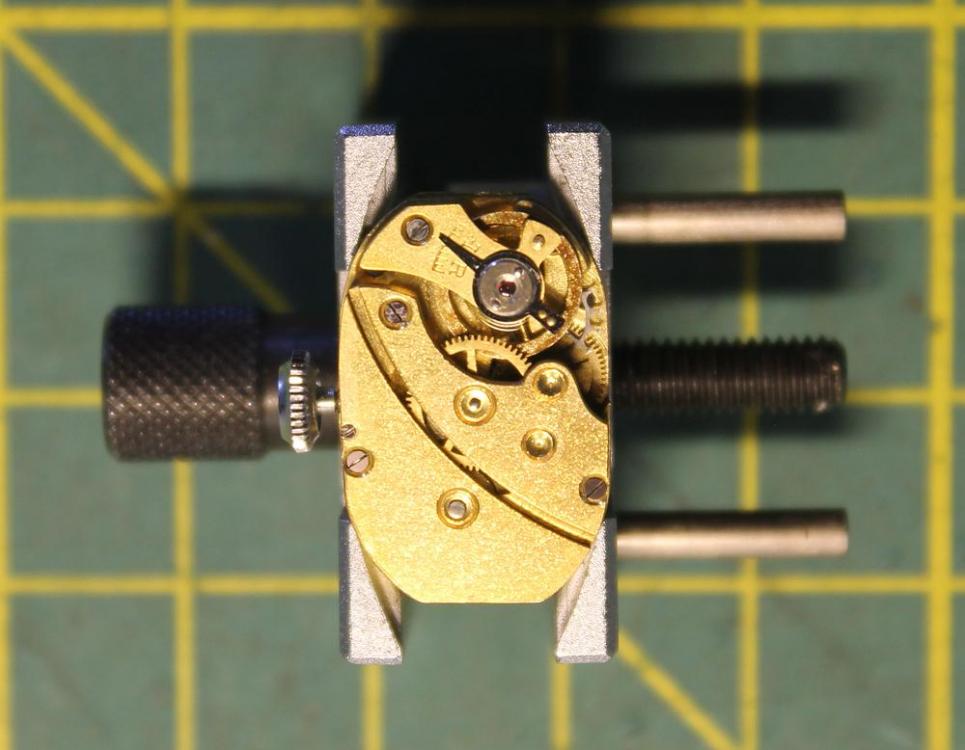

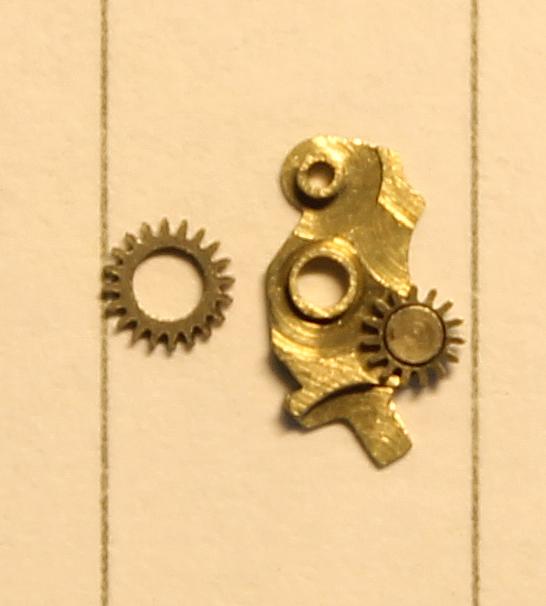

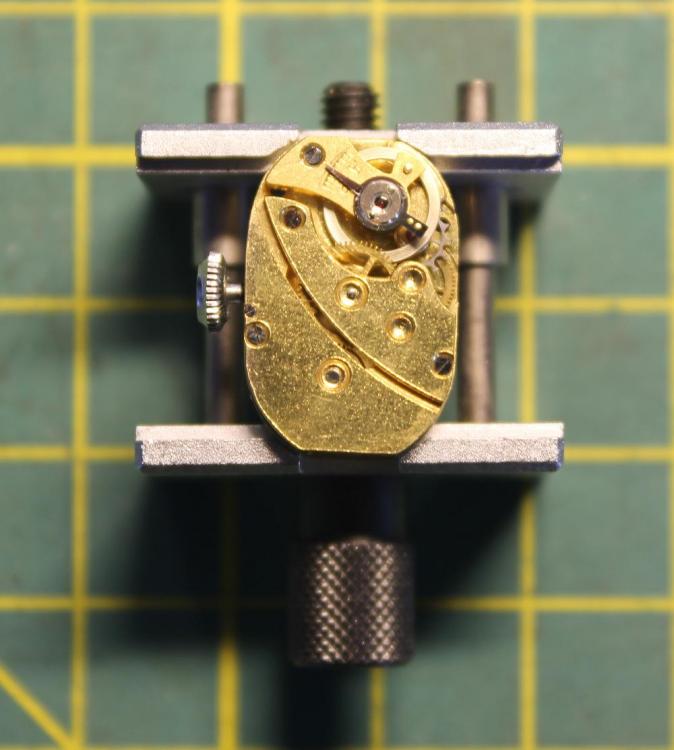

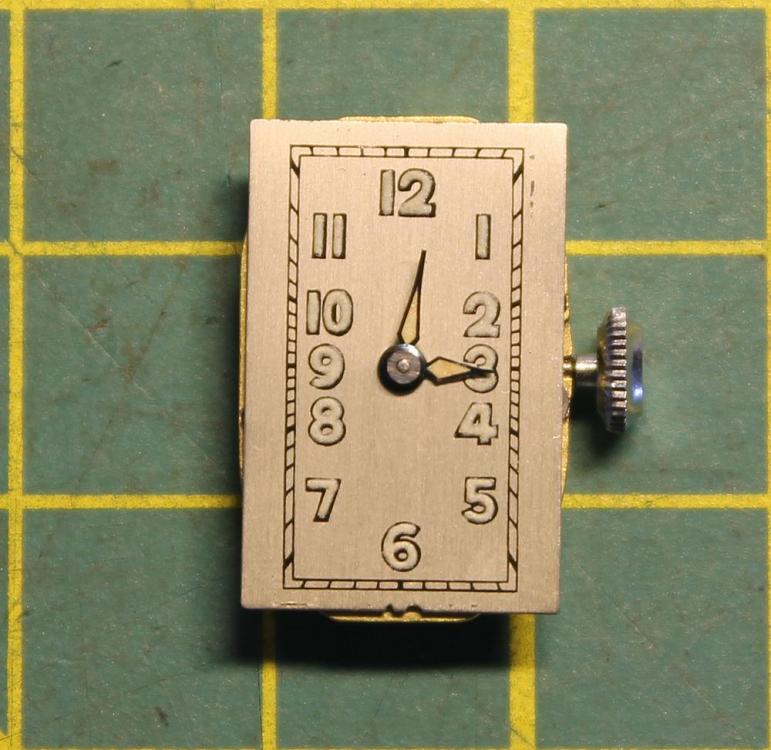

Hello All; I stumbled on eBay over this little N.O.S. 1940's German Art Deco ladies watch. Cylinder escapement, 6-jewels. It looked in good condition and I couldn't help myself..... Upon reception of the watch, it looked different than on the sellers pictures. That is to say, my wife (for which I bought the watch as a little present) thought it was too small for here liking For me on the other hand, the condition was even better than on the pictures. After opening the back-lid I though it was a modern, recently made watch. A few surface scratches on the outside of the case but inside, it all looked like brand new !! Listening carefully and one could still hear the sounds of the factory echoing in the watch case. The surface rust on the balance was negligible, the seller must have taken that picture from the worst possible angle (perhaps he is a very honest man ) A few winding's and there was life in the balance, be it hesitant, but life nonetheless After the disappointed that my wife didn't like it as much as I did , I did set off to strip this little gem. The watch case consisted of two parts, the upper with the crystal and strap-lugs, and the bottom "box" in which the movement houses. It's a press-fit case. The hands and dial came off without major problems or any damage. The dial had two feet and was held in place by two dial-feet screws (bottom left, top right) The hands were lumed, so were the numbers on the dial. Not sure if this lume is the "bad-stuff"?? With the dial off, the movement finally revealed some of its secrets; First, the ratchet wheel and "the click", the latter consisting of a small wire spring which engages in the ratchet wheel teeth; bottom left arrow. Secondly, the maker of the movement. It turns out that it's made by a company called "Kasper & Co", founded in 1911 in Pforzheim, Germany. Initially the company made elastic bracelets for watches, later added manufacturing of watch cases and from 1932 they produced complete wrist watches. In 1955 they produced their first automatic movement cal.1000, followed by their 2nd automatic movement, cal.1450 in 1964. In ca. 1970 the company ceased to exist. Here their logo from 1939 onward, printed on the front face of the main-plate, top arrow pointing to the logo on the watch; However, the watch was sold under the name "WAP" (?) , as shown on the paper-label. So far, I couldn't find any information on "WAP". Most likely this watch is out the 1940's era ..... First I made sure that any residual tension in the mainspring was removed. Failure to do so and the chances are that the escape-wheel takes off as soon as the balance is removed, potentially ruining the movement. Removed the balance and escape-wheel; both being jeweled on either end. The wheel-train bridge and the barrel-bridge consisted out of one piece; I wasn't able to remove the center wheel as the cannon pinion was still attached to it on the other side. To see is the ratchet wheel and the click on the right; With the main plate flipped over, stripping of the key-less works. The key-less work works quite simple. The winding stem is hold in under spring tension and when turned, the main-spring gets wound. When the crown is pulled & hold out, the hands can be manipulated. The winding stem pops back in once released. The main plate looks in very good condition. Last action for today, removing the main-spring from the barrel; At first glance, all looks in perfect condition, no wear nor any tear ..... This was the easy bit, tomorrow the tricky parts; cleaning of the balance wheel and the cleaning & oiling of the cap-stones....... I hope this all goes well and then the re-assembling .... To be continued .....1 point

-

1 point

-

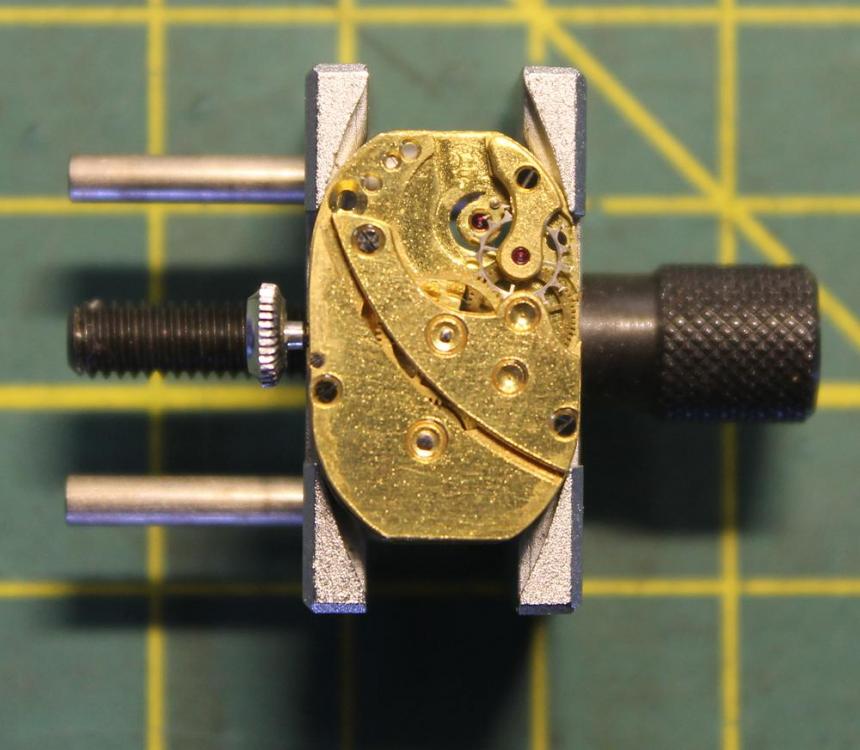

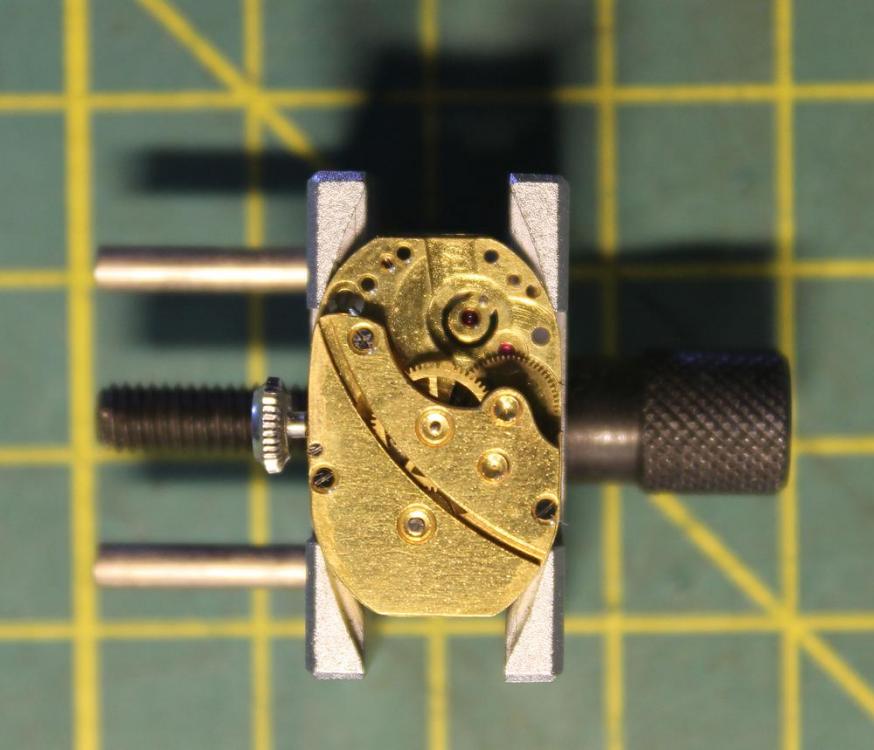

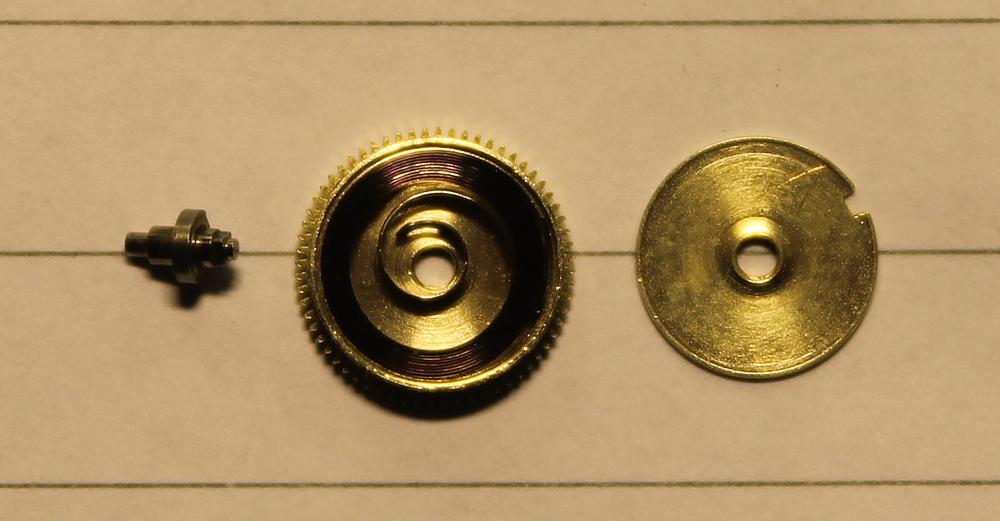

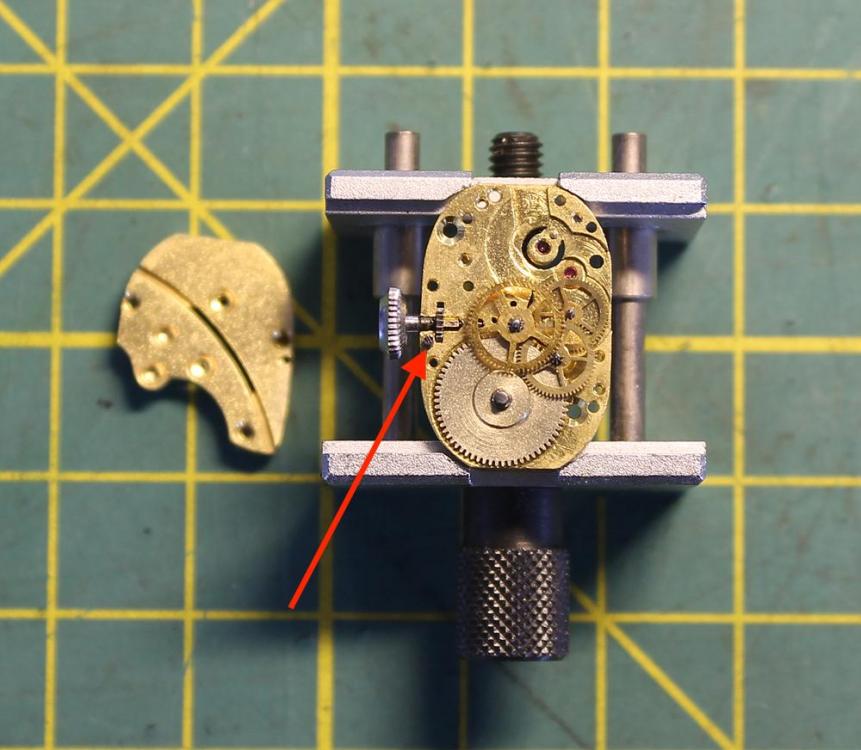

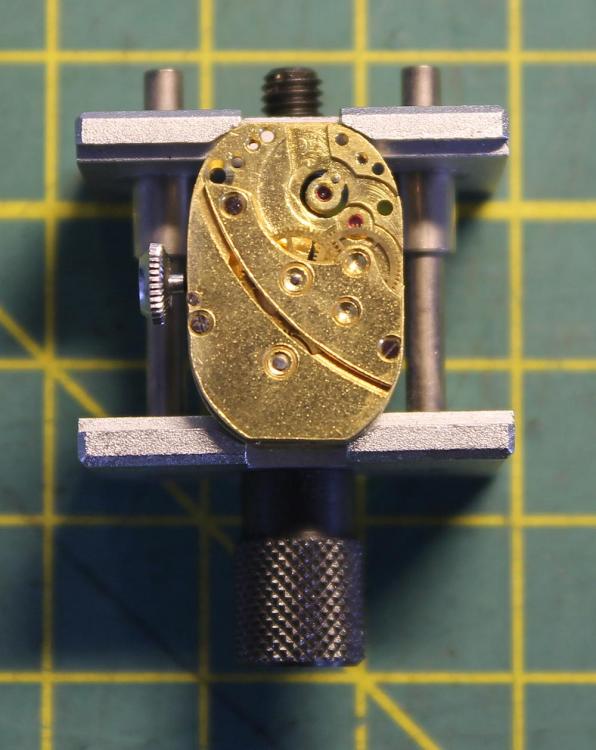

Through the night I left most parts submerged in Zippo lighter-fluid. This should give the decades old oil a chance to dissolve. All the pivot holes and jewels were separately cleaned with peg-wood. All the pivots, teeth and balance cylinder were inspected with a 10x eye-loupe. Remarkably, after 70 years in storage, everything was 100% ! First up was to re-wind the main-spring back in the barrel, oil the spring, grease the arbor and assemble the barrel. I always hand-wind the main-springs. The top of the balance had some surface discoloring (see picture at the beginning). I remove this by gently stroking the surface with a glass-fiber brush, while the the balance was suspended from a balance-holder. I didn't take any pictures as I didn't want to get distracted during this very delicate operation..... sorry ...... It took however only a few stroke to remove the discoloring. Next up was another delicate operation, the oiling of the balance cap-stone. Two screws on the underside of the balance cock had to be removed without damaging the hairspring nor the very delicate balance-staff pivots. On the left the already cleaned capstone, ready to be oiled. For oiling capstones I used to use a very fine dip watch-oiler, but now I'm using a 0.1mm Rotring pen. This works very well for me, very precise and controlled. With all parts cleaned, inspected and both cap-stones oiled, it was time to demagnetize. I made demagnetizing, after some hard lessons learned, a standard procedure. Of course, a German watch runs best on German oils .... Dr. Tillwich is the name; (BTW; the Swiss- and Russian-watches also seem to like this stuff ....... ) Time to assemble the ratchet wheel underneath the barrel, the wheel-train and a part of the keyless. Don't forget to insert the little screw (or sometimes a push-pin) which goes underneath the barrel-bridge: see the arrow. Won't be the fist time that you line everything nicely up only to discover that you have to undo your hard work again ..... Barrel-, and in this case also the wheel-train bridge back in place, all pivots engaged and lubricated. Here a close up of the back-side of the yoke including the setting wheel; Assembled the keyless works and ratchet "click". Tested functionality ..... Time to install the more delicate parts; the escape wheel and the balance ........ Lo and behold, after a little tension on the main-spring the movement started to run ...... It seemed happy so I decided to go ahead with the dial and hands. There was no work to be done on the dial, so it went straight back on. Replacing the hands was no problem either. I don't expect to get a COSC certificate with this movement, but I hope that, within the next few days, I'll to get it run within a minute per 24 hrs ....... or so ...... As a side-line remark; I found it difficult to get a descent grip on this movement using the Bergeon 4039 movement holder. But it is also the first time I'm working on a tonneau shape movement of this size, so it may well be me ........ Anyway, I managed to get this little gem serviced without doing any damage. Better be, because there is nowhere on this planet a shelf full of spare-parts to be found Now, it's to hope that I can find a lady who is willing to give it wrist time and can appreciate this little 1940's "time capsule". Obviously it needs a new leather strap, but that will be to the new owners taste .... I'll hope that somebody will have some benefit of this write-up, at some point in time .....1 point

-

1 point

-

Thanks I enjoyed that, and only the tiny little tool they think was to hold a balance was the only tool I didn't identify1 point

-

I have also seen the tool for pinning the H/S to the collet used at BOVET. Different looks briliant design manually operated. Once you see that, you wouldn,t attempt using other tools.1 point

-

This tool punches a dot on the balance wheel where the hairspring stud shall be located. Keeps impulse pin - stud a constant angle. Used in serial work, as mentioned earlier. Frank1 point

-

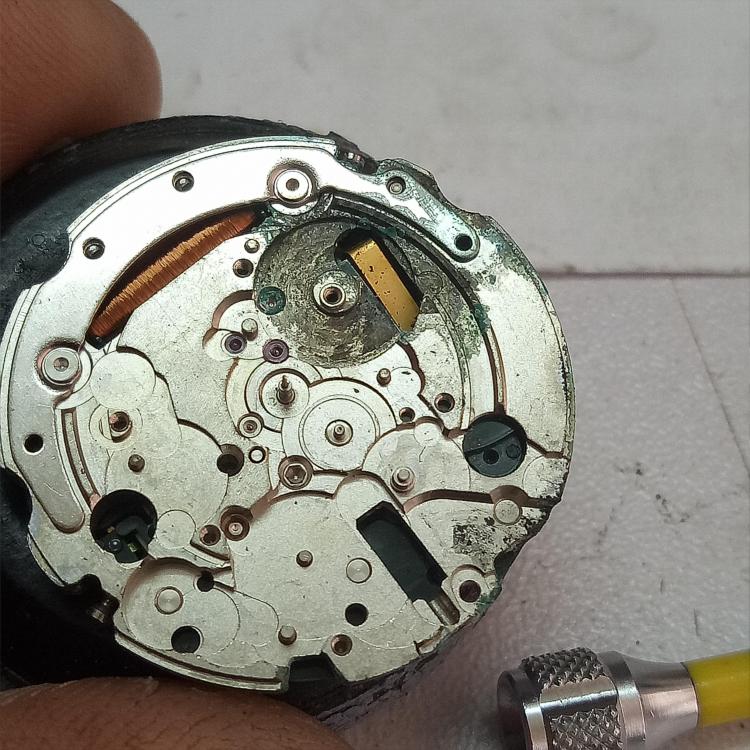

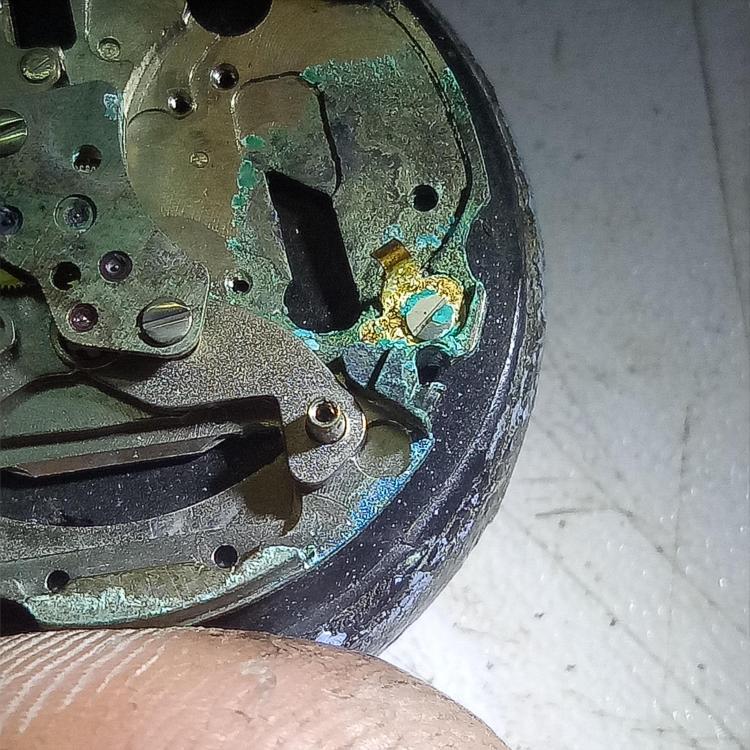

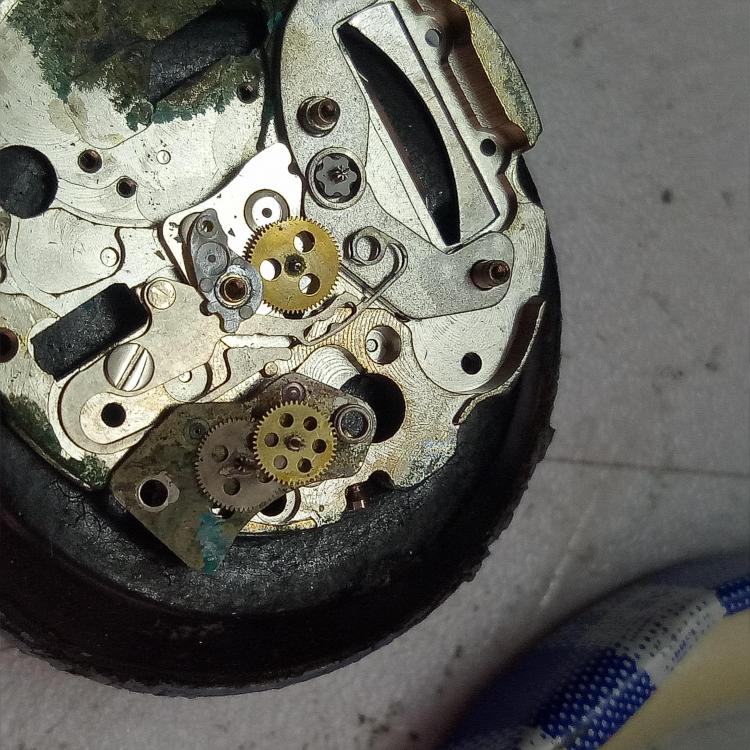

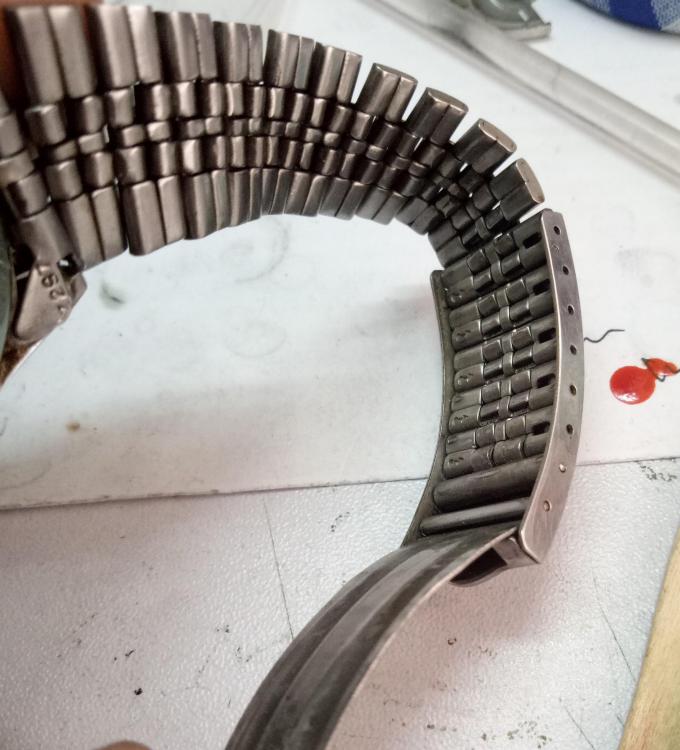

Hi guys.. I don't really like working on quartz watches but I do make an exception for the Seiko 7548. I came across this at a flea-market for MYR20 (USD5) so I figured I'd try to get it working. Its actually a 7546 but theres not much difference. The 7548 has five jewels and the 7546 has to make do with only four. The hands have the usual black stuff which is what remains of the original lume. First thing I checked is if the hands set, unfortunately it only does part of the way. Forwards the minute hand sticks at the 50 minute mark and backwards it gets stuck around the hour mark. Day date sets ok. Typically grotty caseback. This is a 7546-7130 It has a full length bracelet.. that's good! What's not so good is the amount of dirt. Those with a weak stomach should look away now. I finally open the caseback and look inside.... what I see is usually enough to throw it into the bin. The battery needs to be physically pried off as the corrosion has made it stick to the movement. Once removed I find this. The corrosion is pretty bad but I've seen worse. In this case the two contacts for the battery are still present and stand up to the prods from my tweezer. Sometimes they are corroded beyond use and break off. The dial resembles a starry night sky. You'd pay a lot of money if this was a high end swiss watch but this is bassically a reaction from the cases released when the battery acid oxidises. That sh\t wont buff out. The stuff under the dial is the same as on the 6309 automatic movement. Looks good so far. But the hour wheel was stuck to the cannon pinion and thats was what made setting the hands impossible. When this happens the keyless works usually suffer broken/worn teeth as people try to force the crown around. Those parts on this watch look ok. Here we have a picture of the underside of the date advance. The date advance is made of plastic so its in pretty ok condition but the mainplate has a lot of corrosion. Next off is the circuit block. More corrosion (the black stuff).. it can be scraped off with pegwood. And the coil is carefully lifted out and put away safely. Here we can see the effect of the battery juices on the watch mainplate. train bridge is heavily discoloured and most likely the pivots as well but its in the battery cavity that the corrosion is heaviest. The (+) contact (held by screw) shows sign of corrosion. If this breaks off the movement is not worth repairing. but luckily it comes off in one piece. I finally remove the train bridge and lift it off. I made a mistake here as the stem is out and the movement is 'hacked' with the hacking part contacting the wheel. Mot really a problem but more important to remember this for the assembly. The wheels are stuck in the pivots so thats not good. Need to inspect them carefully to see if they are reusable. Reference pic to show how the various wheels go together. Bare mainplate ready for cleaning So is the watch worth fixing? Frankly no. The dial is beyond salvage, the damage to the wheel pivots may affect the performance of the watch (surprisingly the pivots look good at high magnification) but the most important issue is the coil and circuit board. They are no longer available from Seiko and this particular watch is never going to be worth the money to source one from other sources. Having said that.. I will check the coil and circuit board and if they are in working condition then I will re-install it and use the watch for a while. Even if I do get the watch to work, I foresee that the eventual fate of the movement will be as a donor for a 7548 diver watch as this seems to be the only quartz watch still in demand. Will post updates.1 point

-

Just an update. The repair I did with the jewel seems to have worked. It had been on test since Saturday morning and was taken off Tuesday morning. The jewel is still holding great. I have returned it to the customer giving the customer my reservations. If the jewel does fail I now have a spare bridge. The clip that was missing I purchased from cousins although a few thou under the original spec it is working fine. WHAT FUN !!! ON TEST IMG_0119.mp41 point