Leaderboard

Popular Content

Showing content with the highest reputation on 05/26/18 in all areas

-

Do you have watchmaking tools ? (for this one you're going to meed a lot more than a loupe and screwdrivers) Do you have experience with repairing watches ? This job is pretty difficult so a beginner can't/shouldn't do this.2 points

-

I think Mark and us mods could discuss this. I have contacted Mark and the other Mods to seek their views.2 points

-

Gents, I picked up a lovely French mantle clock the other day, as can be seen from the pictures it has a lovely brocok escapement, my question is this, what’s the best course of action with lubing the escapement, and what oil to use? also the alabaster housing is in need of a clean, I’m doing lots of research into this as the wife wants this on the mantle in the living room.1 point

-

Omega did did change some stems on earlier calibers during their lifespan, but I’m only aware of them changing the threaded diameter. Not sure why they did that. If the stem is “correct” then you could get someone to turn down the end section on a lathe. Good luck with the other part.1 point

-

1 point

-

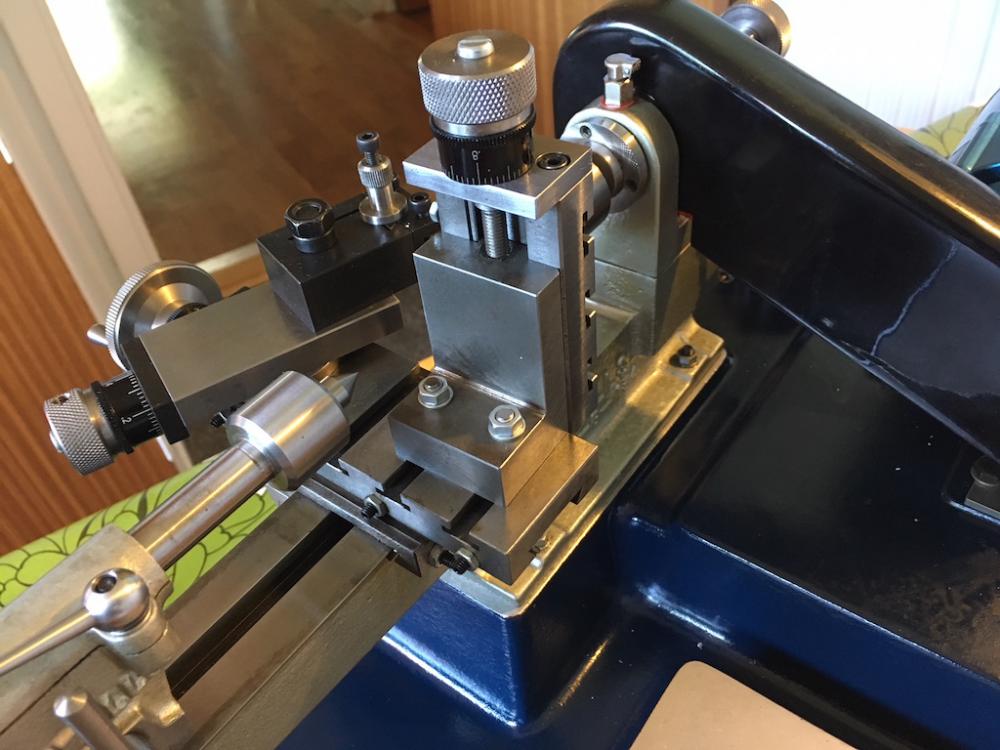

well gents, it's been awhile but work has been quite involving as of late,I managed to do a lot of research on cleaning alabaster stone, I stared with just brushing the dust of, then went to town with a damp cotton wool ball covered in baking powder, then I managed to get hold of some borax and stared to use abit of that. Many years of nicotine and obvious soot from a fire place or two it started to come up reasonably light in colour. It's still not as good as it could be but I think without professional restoration it's not going to get any better. For super shiny brass plates I discovered the use of French chalk, I used brasso on all the parts then without polishing them off I washed them off in lighter fluid, once dry I got my clock brush (found in a box of bits from an auction ) gave it a good rub on the French chalk and then gave it a vigorous brush over each part, if you've never used it before the please do try it, it brings the brass up really nice. As for the running of the movement, I found it had had a repair on then pendulum, not to bad I thought, but after Ihad cleaned and lubed the movement and refitted it to the case it kept running slow, so I kept winding the bob up the pendulum, then it got the repair and I unfortunately wound the bob onto the join at the repair and twisted the repair and in the process cocked up the thread!!!!!!, I was kinda stuck then as the bob was just not staying where it should in the pendulum, a quick think and I pooped into work to the metalsmith and got him to cut a few pieces of my brass plate so I could attach one of them to the pendulum, that ideas was good but you cant thread a flat bit of brass can you! Another moment of thought and I pulled my lathe out and grabbed some 3mm brass rod, turned it down to 2.5mm, I really would like to get a cross slide for my lathe as turning down 6cm of rod by hand is quite a feat. I didn't have but now do have a lovely tap and die set of super small proportions, biggest size is 2.5mm, I got from the shop toolstore for £35, its a lovely set and I can see it being put to use quite often, anyway I threaded the rod and tapped the bob I then had to file off a good section of the rod to make it flat so I could solder it to the remaining part of the pendulum. Movement refitted and it started staright away, but it kept losing time, every morning I would turn the bob one turn for every minute it was slow to speed it up, I even wound it quite a few more turns than was required but still the next morning it wold be slow again, then I noticed it, the bob due to the nice new threads was working its way by itself back down the pendulum. So out came my brass sheet and drill and a small hole was drilled and tapped and then cut out and filed into a rather fetching nut shape. I done this to use it as lock nut under the bob, so far today it seems to be slightly fast, I'm not worried at the moment just keeping an eye on it to make sure its a constant gain meaning that when the bob is lowered and locked I should have a very nice mantel clock.1 point

-

I noticed that, sometimes, Cousins offers more than one stem for a movement and I once ordered a stem for a Seiko (one of those mass produced and popular caliber movements) and it was the wrong length... So maybe the stem isn't really the right one ?1 point

-

One of the small downsides of moving postings is that it breaks the read/unread feature of the forum, at least on my browser (chrome). If a post has been moved, then that section will show that there are unread posts even when there aren't. Makes the forum look a bit shabby. I know what's happening and work around it, but I'm sure that's not true of everyone. And I agree, stickies can be helpful when people come asking the same question all the time, but they have to be concise. As you say @Chopin, "Quick Questions, Quick Answers". Thanks!1 point

-

Thanks jdm! Hi Dralecmv I myself own a Cowell's 90CW (just got it) and have done some research before my purchase. A Cowell's 90CW has a spindle nose that fits 8mm. watchmaker types B8 (European Schaublin) and WW (American Webster Whitcombe), all this fit in Cowell's spindle. The difference is as you mention the thread. B8 has a thread called 6.82mm x 0.625mm pitch with 55 degree threads. WW collets have 0.275 "x 40TPI or 6.985mm x 0.635mm pitch. The Chinese Sincere uses M7x0.75 on their accessories. However, this is not a major problem. Sincerely can provide a universal drawbar that can be used for your Cowells when that day comes. Someone also feels great pleasure by producing some of their tools. Therefore you can easily find tap and die and make it yourself. Cowells 90CW comes as standard with Drawbar for B8 collets. But as the machines are built to order it will be easy to get it delivered with just the drawbar you want. Even my goal is to make lots of drawbars so I can use what I want. I can not recommend that you buy Sincere collets, as their runout is way too big for watchmaking! "Dear Valued Customer, these collets run out is 0.02mm," If you want to meet small run out for small money i think Sherline is the way ..(however, they are not hardened) If you want to read more about this, Jere Mihalov has written everything about Cowell's 90CW and much about collets treads and other equipment. https://watchmaking.weebly.com/other-lathe-attachments.html1 point

-

Thread unlocked on member's request. Please stay on topic; postings which do not will be removed.1 point

-

It might be bent/warped but can you show us some photos of the hairspring laying flat ? That's how you can best tell... You can let it rest on the balance cock and take a photo of it like that... If you've posted any photos I can't see them... just the video.1 point

-

In my experience, ladies watch bracelets can be very frustrating and because the more complex design of a fashion watch bracelet isn’t always matched by good engineering. If you have through holes in the links, you may find a pin may be less frustrating than a spring bar. Pins don’t have to come from a watch spares supplier. I have used sections of a paper clip, bits of guitar string and bits found in the bottom of that special drawer in the kitchen where you keep the dog lead, bits of string and batteries that might work (but never do). And the gratitude for the repair sometimes makes it all worthwhile! Neil Sent from my iPhone using Tapatalk1 point

-

Wow. We’re putting a lot of thinking into this and the plot seems to be lost. 1. A movement doesn’t know when midnight is in any precise way. Most watches change date between 23:00 and 01:00. Rotating the dial 5 minutes(time not angular rotation) is unnoticeable. 2. The date aperture can be anywhere on the dial. As long as 9 is showing on the ninth, it works. You may need to adjust the printing of the date ring if that matters. 3. The printing of the dial and positioning of the dial feet is determined by the case and movement orientation, not by anything intrinsic to the movement. Naturally you will find some watches that break these rules, but not many. Neil Sent from my iPhone using Tapatalk1 point

-

Spot on and well researched. The conversion is very crude. The other thing that stood out a mile is the so-called pattern that the back plate has. That has been added at a later date, I expect it was added at the same time that converting it to an anchor escapement happened. Fusee clocks, Many run by a chain, they also have steel wire, bronze wire or gut. You might think they look dangerous, but they are quite safe.1 point

-

1 point

-

1 point

-

I'm not exactly sure what you mean but I have been having an idea for the "repair help and advice" section of the forum which you and others might like. What if there was a sticky topic in that section (sticky as in it won't get lost down the page) called "Quick questions, quick answers" where people can ask simpler stuff, maybe even post a photo, and someone can simply reply and then just have someone else ask something else and so on. The advantage of this is that there won't be any topics about "how do I change the battery on this watch?" or "how do I remove this stem" and it'll be a dedicated topic where experienced folk can offer pertinent answers to those trying to solve a simple issue.1 point