Leaderboard

Popular Content

Showing content with the highest reputation on 10/17/15 in all areas

-

2 points

-

Sorry for the delay with the progress report, but this has been one of these three steps forward and two steps backward jobs. It transpired that there were more issues than I first thought. To reiterate the obvious problems:- Centre Second Fourth Wheel - The gear wheel was off the shaft. Escape Wheel - The wheel was off the shaft. Auto Reversing Wheel - In bits. Oscillating Weight Bearing - In bits. Intermediate Ratchet Wheel - Separated. Intermediate Date Wheel - Separated. Lume on minute hand damaged Lume on dial stained with oil. The watch as received. I eventually worked out how so many components were in bits that come assembled from Omega. The watchmaker before me had tried to clean surface rust off virtually everything except the balance assembly, by soaking in rust remover which is phosphoric acid. This resulted in not only rust, but steel being eaten away allowing the wheels to fall off the shafts and pivots having a rough finish and being reduced in size. I had two attempts at assembling the watch, but unfortunately kept finding other damage. The eventual parts list required was:- Escape Wheel Centre Seconds Fourth Wheel Auto Reverser Wheel Bearing For Oscilating Weight Intermediate Ratchet Wheel Intermediate Wheel Escapement Lever Barrel Arbour Intermediate Date Wheel Ratchet Driving Wheel Third Wheel Cannon Pinion With Driving Wheel Mainspring Total Cost £320 (not helped by postage on multiple orders) THE ASSEMBLY. Starting point, the bare main plate. Keyless work assembled. Barrel bridge with wheels and click spring in place. Click plate fitted. Barrel, ratchet wheel, intermediate wheel, and barrel bridge assembly fitted. Escape wheel, third wheel and fourth centre second wheel positioned. Wheel train bridge fitted. Pallet fork and pallet bridge fitted. Date mechanism and cannon pinion with driving wheel in place. Date jumper located. Date ring retaining plates fitted. Wheel train and revering wheel located in the automatic device framework. Automatic device lower bridge fitted. Auxiliary reverser fitted. Oscillating weight bearing fitted. (I had to make a tool to tighten the nut) Oscillating weight fitted to automatic device framework, held by the three screws in the centre. Completed automatic device ready for fitting to movement. Balance assembly and oscillating weight assembly fitted to movement. Dial and re- lumed hands fitted. The new lume certainly works! Movement cased and running strongly. The scrap. The result! That's All Folks!1 point

-

1 point

-

1 point

-

This watch also come together today . Today has been a giant day in mankind :) I finished three watches today . This one got a new third wheel . And it's up and running again . New mainspring and old but good third wheel . Still hate pallet forks :pulling-hair-out:1 point

-

Interesting... I have just such a radio across the room from me as we speak... a 1937 RCA 811K, with a Tuning Eye tube. Gryf1 point

-

1 point

-

Came across this while searching for something to watch on his YouTube account. Very interesting! Ben Heck’s Oscilloscope Watch http://youtu.be/HOqBInoDEhE1 point

-

I don't think a survey will help matters with the supply of parts, but I have filled in the survey it took all of 10 minutes. The only thing that would change the mind of the Swiss watch industry would be if revenues are affected by such decisions. The prices of Swiss watches has been outstripping inflation for the past ten years now, Rolex, Omega and many other manufactures have increased prices beyond the reach of many does this make sense? Rolex manufacture around 600,000 watches a year my guess is they are trying to produce less with out losing revenue if they sell 600,00 watches at a average of £3,000 a watch it makes more sense to sell 300,000 at an average of £6,000 a watch and limit supply and increase the image of exclusivity and maintain the brand image. The industry also seems to want to push independent jewellers out of the supply chain and more brands are moving toward boutique stores and forcing independent stores into expensive refits, if they cant afford it then they lose there franchise. I have had many bad experiences with manufacturer service centres, Omega and Jaeger Lecoultre have both been appalling in the past, they offer poor value extremely long turn around times and are generally expensive. Simple jobs will become expensive. In the past year I have been told by one manufacturer when enquiring about a simple crystal replacement that it could only be done as part of a full service going from what should have cost £50.00 pounds at the most to £400.00 including compulsory service in the end a independent fitted one for £35.00. I have also been told that a steel bracelet I had on my Omega Speedmaster could not be repaired and would need to be replaced at a cost of over £400.00 pounds, The same strap was repaired by a independent repairer for £20.00. I hope that things like this will make the general public think twice before purchasing a Swiss watch from the big manufacturers, because practises like this will be the norm in the future and hopefully the big manufacturers will suffer from there own sharp practice there are plenty of good watches to be had from smaller manufactures and the gap would hopefully be filled by these. At the end of the day it is simply a revenue increasing exercise these manufactures are more interested in selling new watches than ensuring your inherited watch your father wore continues to run.1 point

-

1 point

-

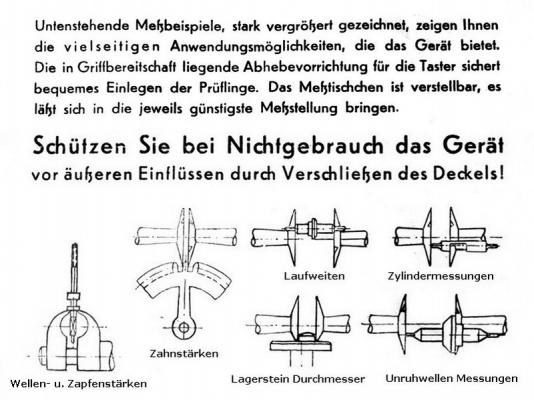

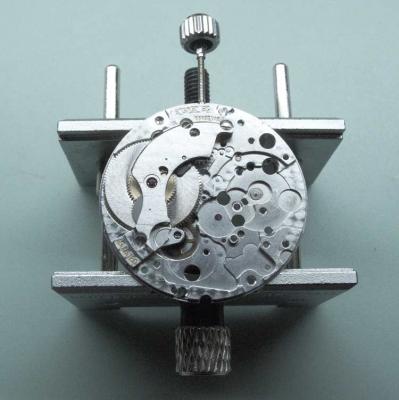

Thanks Chadders I have looked at these but my clamp system works. However a Feintaster is on my future purchase list when funds allow.1 point

-

1 point

-

I can for certain see that 3 coils are definitely touching each other.1 point