Leaderboard

Popular Content

Showing content with the highest reputation on 04/12/15 in all areas

-

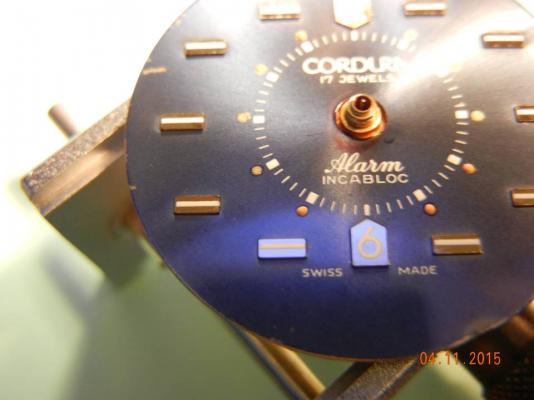

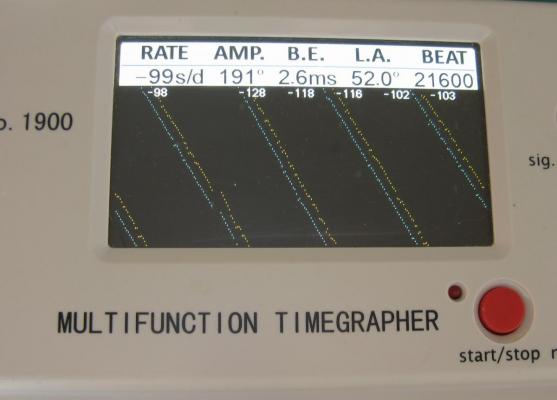

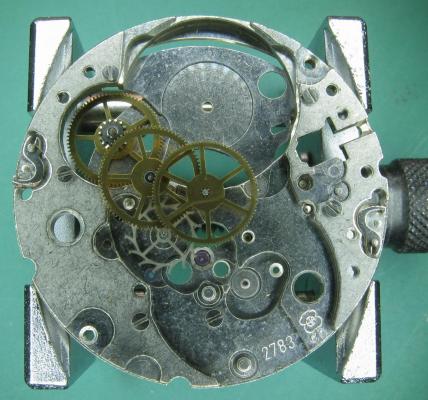

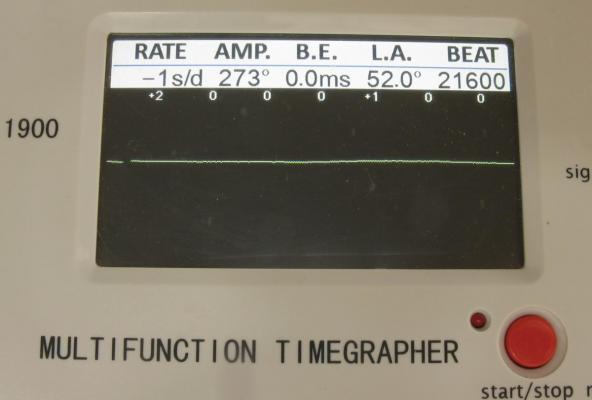

Hello Friends, I want to first thank Mark for facilitating this wonderful forum to explore and develop my watch hobby, and for the numerous suggestions, support and insights I've gotten from its members--Thank you. I haven't posted an overhaul/repair in a while, and so I thought I'd show a wrist alarm that is unlike the ones based on AS movements. If you are like me and din't have the resources to get you hands on a JLC, Vulcain, Omega, you can still get something cool. Seiko, Bulova and Poljot all have nice wrist alarms, but this one is a Cordura I got for $38.00. I also managed to get another for $15.00, so we're talking cheap here ok! The movement was running and didn't look like someone took a butter knife to it. The alarm wasn't working, but the stems were OK... The Ronda 1243-21 has 17 jewels and runs at 21,600A/h. I read somewhere that these 1200 series Rondas were one of the cheapest mass produced Swiss movements--just for information. with the dial removed the alarm complication is exposed. There is a little hammer and bell and it has its own mainspring: The mechanical overhaul was straightforward. I'll just post the abridged version and come back to the alarm in a bit... With the movement done and working properly, I turn back to the dial side for the rebuild: I can see that the alarm wheel has three slots that allow the same spot on the hour wheel to pop through and sort of lowers it to activate the alarm-- The alarm mainspring and its trigger level go on-- With the alarm setting lever and crown in, I can see and feel that the little mainspring is engaging. The alarm lever is suposed to hold the power in check via the intermediate wheels until the alarm wheel drops down just a little and this disengages the setting lever and releasing the wheel and the hammer strikes the bell and it goes off until the power is spent--10 seconds BUT it is not properly meeting the wheel. In the picture it looks like it is, but its not and when I try to wind the alarm the power goes straight through to the bell. I tried bending the alarm setting lever, but it doesn't work so I replace it with another I have from a non-working sears alarm.... and it works! I give it a final adjustment and recase it. Its keeping time very well--No it isn't a pin lever it has a real Swiss lever in there! The alarm functions great and sort of buzzes really. To set it you turn it counterclockwise to where you want, and then wind it. You can pull out the crown to prevent it from inadverdentlychanging but thats it. The rest of the features are pretty straight forward. The watchcase is the usual Funky-d-lite 70's look but I like it. The overall layout of this movement is the same in Sears alarm and a bunch of other makers too. The only difference is that those are usally one jewel pin levers. Hope it inspires you to try out a wrist alarm!2 points

-

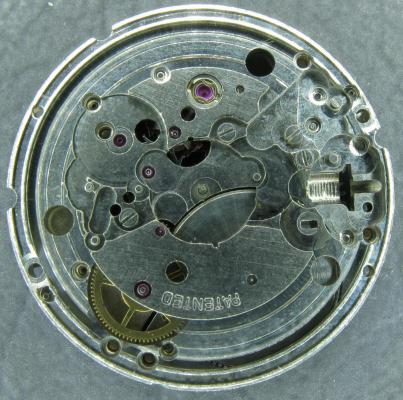

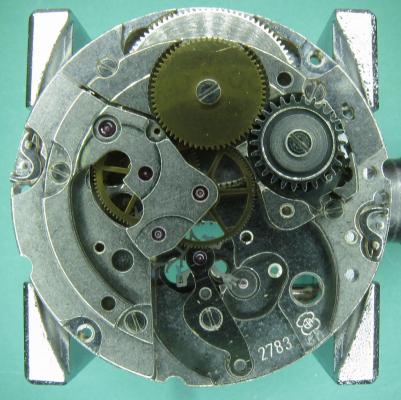

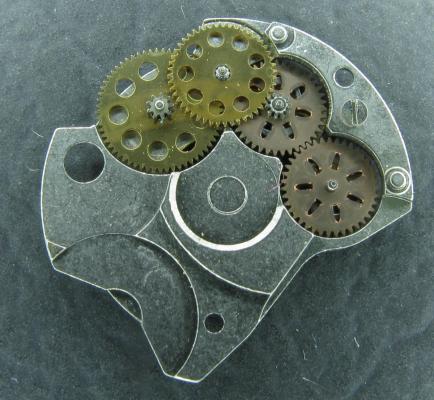

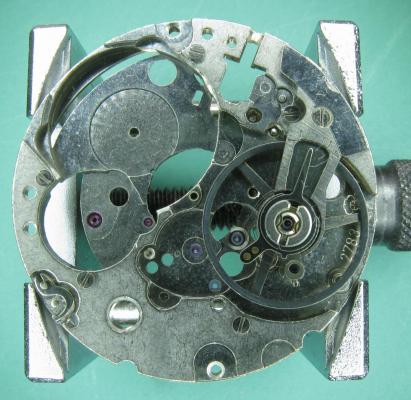

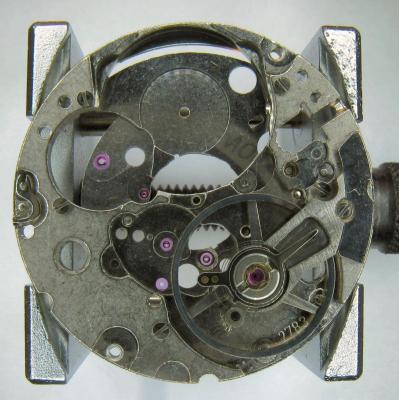

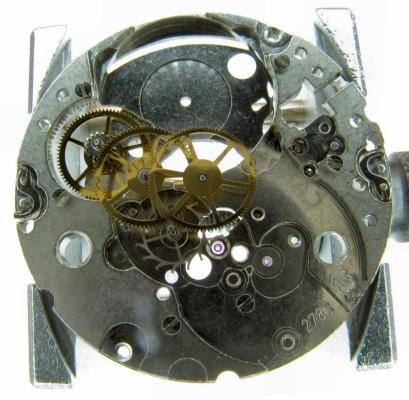

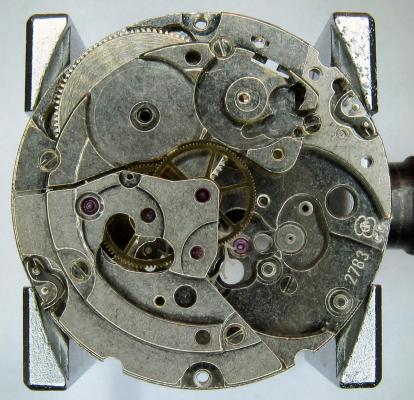

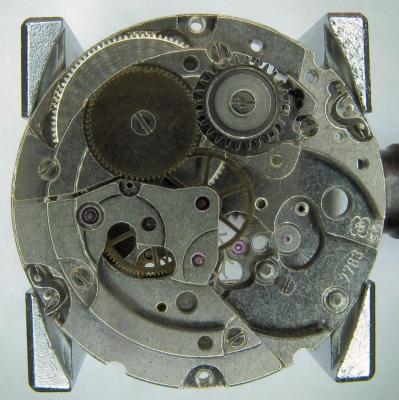

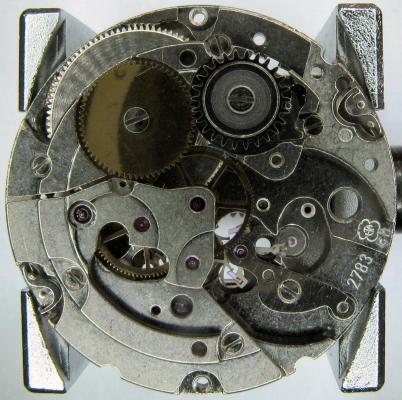

This is one that I picked up a while ago to restore and send on its way. A Cortebert 25 jewel auto probably from the 70's or early 80's. As you can see it was in need of a little TLC on the outside.... And by the look of it on the inside too. With the back off the movement looks pretty clean. It's an ETA 2783, a good solid workhorse, and apart from a couple of light scratches to the rotor and auto wind bridge, it doesn't appear to have been abused. With the auto bridge off the scratch can now be seen to extend to the ratchet wheel as well. Looks like someone slipped undoing the rotor screw and skated their screw driver almost to the edge of the movement. They must have been pushing quite hard. I guess they didn't get as far as trying to remove the dial. All pristine under here. Calendar works out of the way and layout of the key-less works exposed. Dial side stripped out. Just the balance pivot setting to come out. Flipped back over now and the balance and cock removed. With the remainder of the bridges, and the barrel out, the going train layout is revealed. This is the under side of the auto bridge with the reversing wheel cock removed to expose the two reverser wheels on the right, and two reduction gears on the left. The fully stripped auto bridge. I think that this might be the missing centre post that Tim was referring to in his post on the ETA 2873. And the balance and cock go back onto the main plate (minus the jewel settings) ready for the Elma. That's everything out of the cleaner and ready to go back together. The mainspring was in really good shape so after a very light application of grease, and a few dabs of 8213 in the barrel wall recesses it goes back into the barrel. The balance jewels are then installed with a bit of 9010 and the free movement of the balance wheel checked. Also the state of the hairspring and it's proximity to the balance cock is checked. All is well here so the balance and cock come back off and go to one side whilst the rest of the train goes together. Going train back in. I just love how bright and shiny it all comes out of the wash. Barrel and bridges back in place. HP1300 for the barrel pivots, 9020 for the second wheel, 9010 for the rest. With the ratchet wheel, crown wheel, and click in place I can now check the recoil on the escape wheel. All good. Pallets back in place and lock and draw checked, then a touch of 941 on the exit pallet, transferred to the escape wheel teeth by gently working the pallet fork manually. Then drop in the balance, and off she goes. It's then just a matter of reassembling the calendar works, key-less works, and the auto wind module, and the mechanics are done. And there's a nice drop of ETA goodness to confirm that all is well. A very gentle clean for the dial and hands, polishing of the case, and a new armoured crystal, and things look a whole lot better than they started. I hope that this proves useful to somebody. This has now had a 24 hour test drive and has managed to stay within a couple of seconds of spot on on the wrist. I really like the look of this one and it's a very comfy size, I almost decided to hang on to it but I just can't justify another at the moment, so it is now on eBay. If anyone is interested I will post up the item number although it should be easy enough to find. Marc.2 points

-

1 point

-

It should still pull out just by playing in the force either way, correct?1 point

-

1 point

-

Spring is here in Sussex - bright birdsong, green buds everywhere, lots of sunshine, though still a nip in the air. The old, old tune "The Oak And The Ash" - also known as "The North Country Maid" - slipped into my mind as I walked in the garden this morning. So I got out the Martin and played a few choruses, just for fun. I've put it in dropped D tuning (the 6th string is tuned down from E to D). I dug out my old Sony Minidisc recorder and Sony condenser mic to record this one - just for a change. https://www.youtube.com/watch?v=-f40XSbPk0Q1 point

-

1 point

-

Oh yeah! That's what I'm talking about! Nice set up. Very impressed with the final result! Cheers, Bob PS. Plenty of Californium in...California? I'll stick to Miamium, I think it is expensive enough! :)1 point

-

...or dum dum dudum dum dudumdudumdudum! :) No, just kidding! Cheers, Bob1 point

-

One-Dip is 99.9% Trichloroethylene. So buying the Bergeon branded bottle is probably no different from your other source (apart from price). They are both equally nasty.1 point

-

There's been quite a long discussion about this here in the past. As I've said before, there will be three probable effects (IMO) on the watch world: 1. Repairers will stock s/h parts and the desirability of s/h ETA movements on eBay and other sources will rise 2. Chinese and Japanese watches will kick off in an even bigger way 3. More brand makers will do deals with independent Swiss manufacturers outside the Swatch group. Greed will eventually take its toll...1 point

-

Welcome to the forum...I think we're already acquainted. The Omega is a fantastic piece indeed. I hopr to someday have a Speedmaster to add to my collection--I have no chronograph as of yet. Thanks for posting the Speedmaster IV. J1 point

-

The 4 second ticks is the 955 EOL (End Of Life) indicator. The seconds hand jumps every 4 seconds to indicate a low power state. You need a new battery.1 point

-

Just an update, thanks to noirrac1j I got the KIF Satellor spring I needed for this watch. Just so that it is on the internet, indexed and searchable for all time: The Favre-Leuba 253 Movement takes a KIF 4-3 Satellor spring for the top balance jewel. Replacing this spring was super easy thanks to the clingwrap method.1 point

-

If anyone is a Costco member do yourself a favour and try the Kirkland Bourbon - its delish and slightly dangerous at 51.5% Vol. Just popped in for a browse as I am up to my eyes in prep for my daughters wedding. Will be attending to projects and posting results asap - I'll be back. Cheers, Vic1 point

-

These are the last pictures of some final touches. Tomorrow I will move tools into the place. This is the 'clockbench' shelf. I am not completely happy it needs adjusting but it will do for the moment - will be tested later. Now you don't see it! And now you do! :-) This is the secret draw in which I will keep a lot of small bars of gold, platinum, rhodium (and californium if I can get a few of these) after I make bags of money on watchmaking. :-)1 point

-

1 point

-

I purchased a cheap ETA 6497 pocket watch a while back with a view to making a big wristwatch, However when it arrived the balance was in bits and on assembly the hairspring decide to get itself all out of shape! This was shelved as I had no confidence in correcting the self destructing beast. Until 2 nights ago armed with my new Dumont no4 tweezers and having watched Marks excellent videos over and over, operation Do or die commenced! After a couple of hours of bending ,stroking, cursing and manipulating the little bugger the watch was running...Badly! By 4am the whiskey i had been sipping to stay relaxed had over relaxed me so I went to bed! Last night phase 2 began. A little more caressing and back together, still bad! spring looked ok but no amplitude and the loudest knocking I ever heard from a watch. Further investigation showed the balance wheel spokes were hitting the index pin, the arm had a slight bend which was finely adjusted with a set of pliers! Much better! On to the timing machine and I saw what looked like a blizzard so then decision was made to strip the movement down ready for cleaning today! I ended up cleaning reassembling and oiling and having got to bed at 4am again I left the watch running. It now shows good amplitude. 0.3 m/s beat error and around -10 to +6 secs a day. Happy Bunny. If there's a moral to this it must be never give up and all credit to Mark without whose brilliant videos this movement would most likely have never ticked again. The End....or just the beginning?1 point

-

Well done Blake, you're doing well so far. I have a thick block of cork with a sheet of white paper placed on top when working on hairsprings. This lets me pin the hairspring down firmly to stop it moving when I manipulate it. I use an old watchmakers screwdriver cut down as a tack and push it through the spring collet and into the cork. A block of cork is a very handy addition to your equipment, it's good for pinning down all sorts of odd shaped parts that are otherwise difficult to hold.1 point