Leaderboard

Popular Content

Showing content with the highest reputation on 03/25/15 in all areas

-

Hey all, got another new addition today. I am well pleased with how it looks and it is currently ticking away. I know 99% of these vintage watches from India are refinish/redial, but I am still quite pleased with it. HOWEVER... This simply will not do. Those circles spots are honest to goodness rust. I knew the condition of the inside and case back when I bought it so it isn't a surprise. I figured it would be a good opportunity to see what I can do to fully service it and clean it up. I will let everyone know how it goes.2 points

-

Just finished refurbing a tired Smiths TY believed to be from 1965: Before: After: Case, dial & hands cleaned. Crystal polished. Movement serviced & broken click spring replaced (thanks to John at Obsolete Clock & Watch Parts). New strap. The timegrapher readings were a little variable, however it kept good time all weekend. I am getting a bit of a thing for Smiths (the watches, not the designer-misery band from the 1980's) and have got myself a 1960 Astral to do after the next Seiko.2 points

-

1 point

-

Last weekend, I completed my latest watch project, a(n) homage to the Omega Seamaster 300 Master Co-Axial, based on a Russian Vostok Amphibia, case style 120. I replaced the bezel with one from Dave Murphy that accepts Seiko-compatible inserts, added an insert from Dagaz watches, relumed the hands with a slight patina, and then made a new dial to match. Here is the finished result: Here's a before and after picture: The process for making the dial differed slightly from my previous project, where I had printed the artwork on photo paper which was glued to the dial blank. In this project, the artwork was done using transparent waterslide decal paper, applied in two layers to give a sufficiently dark black. The decals were applied on top of a layer of luminescent tape.1 point

-

1 point

-

Hi all, I am a newcomer in the watchmaking world, and was introduced to his fantastic world only a couple of years ago, when I decided to restore my late father's Seiko 7A34-7010 quartz chronograph. After learning from other forums and reading a lot online, and 6 months of try and error, I finally managed to fix it. This started the hobby, basically, and since then I bought several watches on eBay (at the start mainly Seiko quartz chronographs from the 80's) and restored them, one by one. I then decided it was time to go a step higher, and bought a working Landeron 248 movement, without a case, which was in poor condition. I am still in the process of restoring it, since I still need to find some parts for it, but in the meantime I also bought, and restored, several mechanical watches. Lacking space, and willing to make this hobby fund itself, I then sold some quartz watches and mechanical watches on eBay and other platforms, and have not receive any complaint yet, which makes me kind of proud of the work I've done. I also started receiving requests of friends and relatives to repair their watches, something I am still not so sure I should, since my knowledge is still limited, but nevertheless, I did take some works since it was a simple matter of service/clean/oil. Results were higher than expectations, actually, and everybody was happy, so I was happy. During all this time I decided to document my steps, and my restorations, with a blog, that you can find here: <<forum rules please>> I also launched my youtube channel, but I must admit I am not as good at making videos as our own Mark. Nevertheless, I decided in 2015 to dedicate more time on this hobby of mine, investing also some more money I manage to "hide" from my wife :P and by the end of 2015 I am planning to attend an online course, not to be certified, but just to get the basics right. Since this is an expensive hobby, I launched my own Patreon page: <<forum rules please>> which I really hope will work out somehow. This is my story, up to now. I will be reading the forum, and participating as much as I can, and I hope I didn't break any rule linking my sites. Regards George Clarkson1 point

-

1 point

-

Great thread & very informative. Finally picked mine up at weekend. Received new basket & collar today. Oh I also replaced the lids as the Cork on the underside was looking abit tatty. The fluids I've gone for are I'll be using the l&r extra fine in pot 1 & the the No3 in pots 2 & 3. Any advice before I do my first clean?1 point

-

Radio 2. Ken Bruce in the morning - then Jeremy Vine. Sent from my iPhone using Tapatalk1 point

-

1 point

-

1 point

-

Nice but Cafepress might take issue with you using it [emoji6] Edit: Scratch that. The druids might. Didn't realise it was a pagan symbol.1 point

-

1 point

-

1 point

-

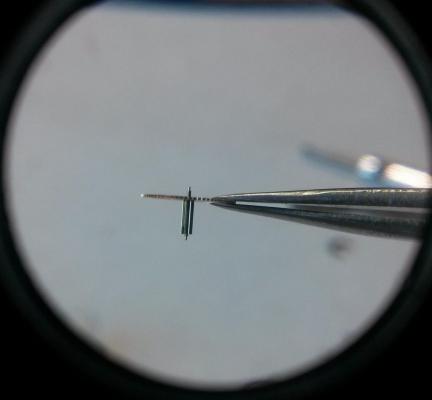

Repair and restoration of a Tissot pocket watch The watch arrived with a number of problems, the crown wheel was missing and so was the barrel arbor. The barrel arbor is a difficult part to make, because it has so many things all contained in a very small space, so I think my first task is to make a new one. Here are some of the critical parts of a barrel arbor: square boss has to have a hole drilled and tapped to accept the winding wheel screw a hook needs to be made on the arbor to fit and hold the inner part of the mainspring allowing the spring to be positively secured and the required clearance to the coil so it doesn't touch the hook there are numerous pivot surfaces, 2 to fit into the mainplate and barrel bridge, 2 to fit into the barrel the dimensions of all the pivots and spacing is critical if the arbor is going to fit and work properly the arbor needs to be hardened and tempered for strength and durability, and it's friction surfaces need a high polish and burnishing to reduce friction to the minimum Whenever you are making a part from raw stock, you have to have a plan and logical approach. My first task was to drill and tap the hole for the screw. Once that was done, the next step was cutting the 4 faces that would secure the arbor to the winding wheel and allow the movement to be wound up. I made these with a very slight taper, so that as you tightened the screw the wheel would be held more securely. Here is a view of the winding wheel being test fitted to the arbor. The next step was to fabricate all the various pivot surfaces and make sure that the heights were correct so that it fit into the barrel as well as between the mainplate and the barrel bridge. Here's the arbor ready to be parted off and the bottom pivot finished. Once the bottom pivot was finished, the arbor needs to be hardened, it is coated in boric acid to keep the oxygene away during heating, heated to a red heat and then quenched in water. Here it is after quenching. Next it gets a polish so that I can see the colour change as I temper it to a blue hue. Now it needs another polish of all surfaces, and I burnished the pivot surfaces for durability. [/url] Now the big test, fittin it into the barrel and the mainspring, it fits perfectly. And next is the installation of the cover, which also is a perfect fit. Moving along the whole assembly gets installed into the movement, end and side shakes are checked and corrected if needed. And finally I am able to re-install the winding wheel and it fits perfect with the required clearance to the barrel bridge and no end play. With that out of the way, my next task is the making of a new crown gear.1 point

-

1 point

-

the difference between the watchmaker and the repairer.. thanks for sharing.. keep it coming!1 point

-

I have no idea to be honest. But I do know it never ends :) Very true! I have mild tinnitus, but it seems extremely loud at night sometimes, I found this app for my iPad which just plays for the amount of time you specify a particular sound you choose. It is a real big help and gets me to sleep most of the time.1 point

-

1 point

-

1 point

-

Finally came around to getting a donor for my Helbros Invincible "Lorsa P72" movement off ebay for $5 free shipping. The donor is a P75 movement and I went straight to work, cleaning and lubricating all the pivots and jewels. Bobm12, you are right I do feel proud of the accomplishment...best feeling ever! Thanks guys for all the encouragement you have given me. Geo, your acetone method worked like a charm....thanks! 2nd project complete.1 point

-

1 point