Leaderboard

Popular Content

Showing content with the highest reputation on 12/19/24 in all areas

-

4 points

-

Maybe a little misunderstanding here about the title, I think Ross ( who worryingly hasn't visited the forum for quite some time considering he throughly enjoyed his watch repair, such a lovely gentle natured guy ) was asking if cleaning in an ultrasonic has a detrimental effect on watchparts. A fair amount of the movements he was working on at the time were suffering from low amplitude, and we were trying to get to the bottom of why it was happening regularly.4 points

-

You have the third option of replacing the escape wheel with the correct one, if thats an expensive option then personally I would make space for the pivots using a jewelling tool, this is much quicker than the adjusting of the pivots route, fully adjustable and also reversible. Where as cutting the pivots back and shaping them will be more time consuming to get right, a modification to a consumable part that really has no business being in this movement.4 points

-

3 points

-

…my version is old and crooked, sometimes shakes and sheds all over the dial. Is there a cheap Chinese clone available?3 points

-

3 points

-

HWGIKE#32 Omega 354 Bumper Full service, new mainspring, new glass, new setting lever spring. Main spring arbor bounced and went silence, landed in my pocket unnoticed. A cleanup in my room, moving out stuff including printer, boxes, cables, stuff then hours of head scratching, magnet fishing and knee surfing for nothing, then I checked my pocket the third time and there it was. By the way the top of our grandfather clock fell on my head last weekend glass in front which was shattered into hundreds of pieces on my head then was sitting on my head like a crown, a pretty heavy piece and i survived with a very tiny almost invisible scratch. I also add a picture of my crown. No glass now.3 points

-

Yes, it is undeniably sad when members we almost perceive as friends suddenly stop showing up, and we have no idea what happened. I truly hope everything is fine with Ross and that perhaps he’s just taking a break. I really had hoped that more of us would have joined our email list so we could simply reach out to each other and check in.3 points

-

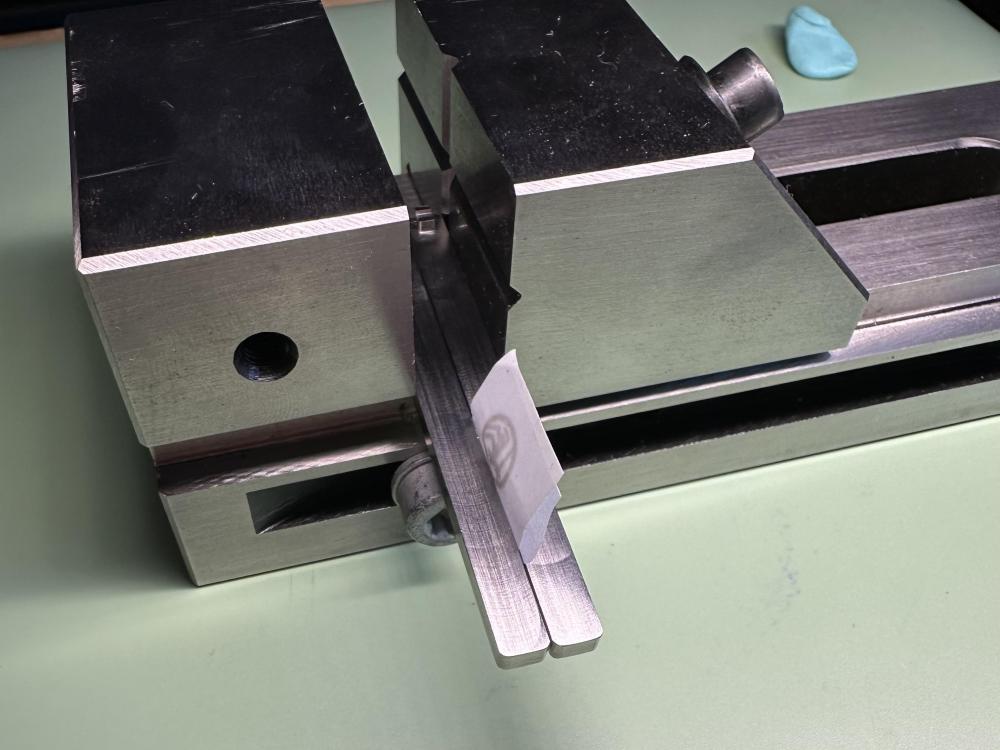

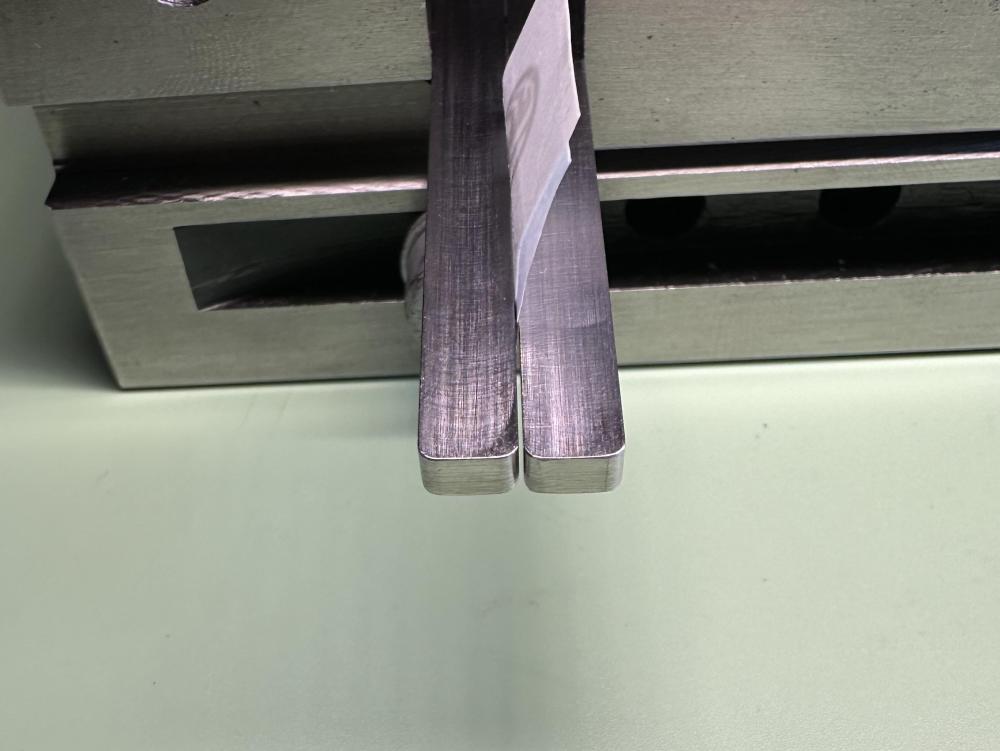

So there might be someone out there who has the same trouble as me aligning the chronograph second hand exactly pointing to the 12 index. Yes, I use a special holder, I press and hold the reset while setting the hand and I use a hand setting tool - but always the same trouble: While pressing down the hand the last 0.2 mm it rotates a tiny way and doesn't line up with the index. Absolutely no idea where this rotation comes from, maybe dark matter from space. After many frustrating chronograph services today I tried a new setup and for me it worked - so I want to share it here. I use two pieces of steel, rounded and burr free, with some paper between them so there is a gap as wide as the hand is. I put them in my vice and adjust them to a height in which they guide the hand but do not touch the dial. With the left hand I move the holder to the right position so the tip of the hand is guided and pointing exactly to the 12 index while the thumb of my left hand is holding the pressed reset button. With the right hand I press down the hand - done. I use a free hand tool here as I have better control but maybe a press works too. And of course everything very careful and slow to prevent damage to the hand and dial.2 points

-

2 points

-

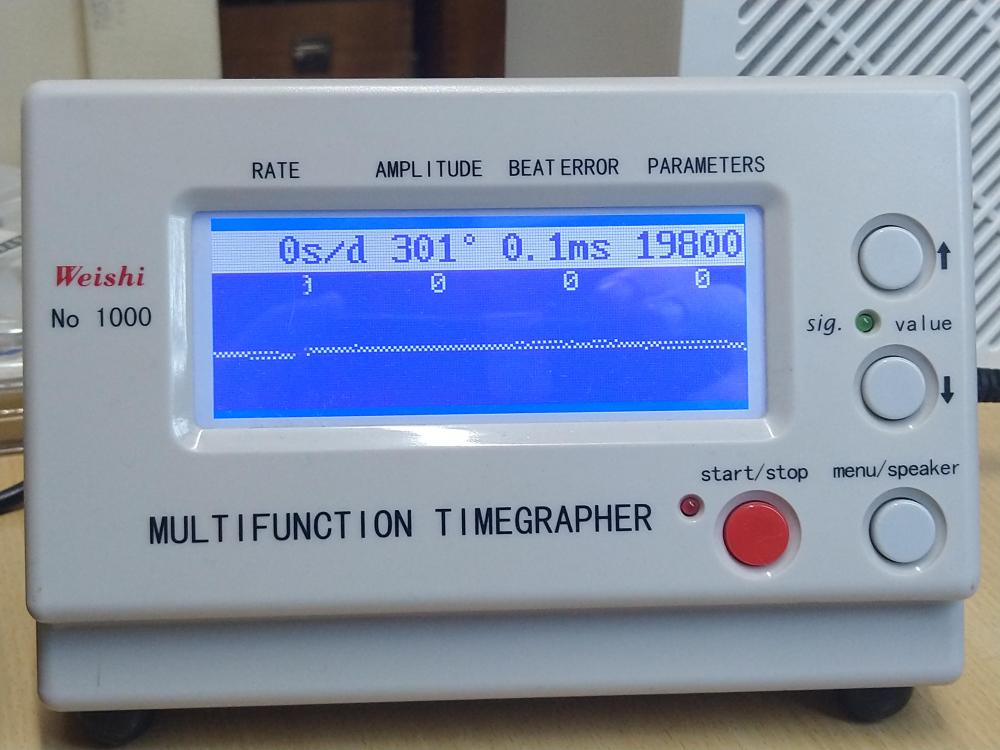

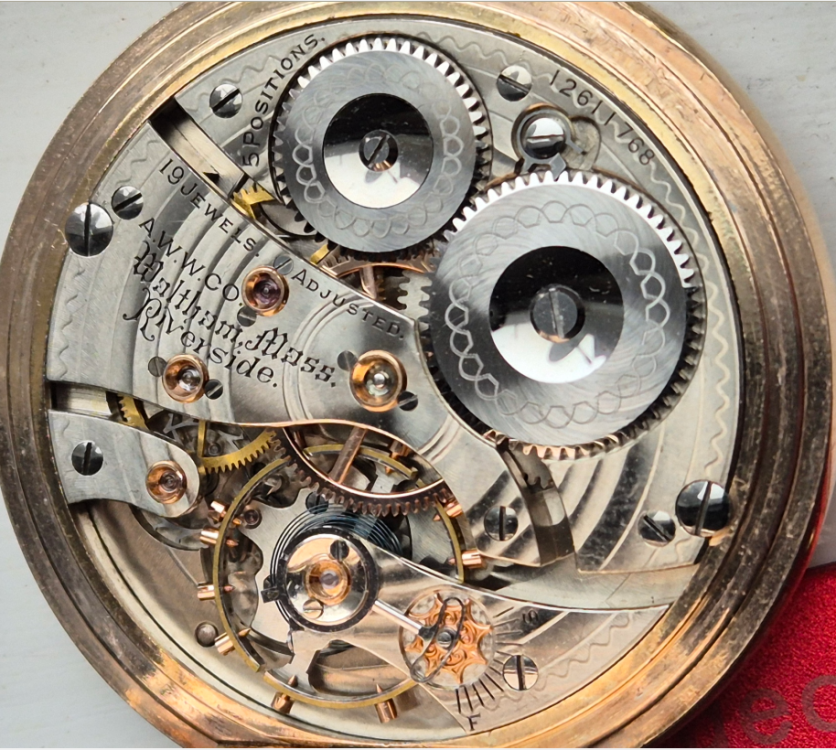

Welcome to the Waltham club Rich ! I started on pocket watches - especially Waltham. Bigger watches = easier fiddling. I have a small collection of eight Waltham, including a 620 like yours. You will be surprised how well made they are, and how accurate they are with those big balances. And push in balance staffs on some, so easy ! As Nev says, the barrel/mainsprings can be interesting. This was before I had a mainspring winder, so I hand wound most in - quite tough on the fingers given the size of the springs. I found the jewels were often broken, but replacements were not hard to find (e.g. Dave's) My favourite is a 1903 Waltham Riverside 19J (you will notice similar features on yours). When I'd serviced it, I bought an Albert chain and wore it to work for a week. It was more accurate than my mate's new Omega Seamaster (which itself was <2s/day).2 points

-

I know H , I just did not understand why it didn't resonate with a lot more of us. I do hope Ross is ok, he was such a nice bloke, no malice in him whatsoever.2 points

-

I've used all sorts from Torx Bits to pieces of metal with a point and drifted it out from inside the case. It all depends how well fitted they are as to how much persuasion they need. Is that the remnants of the tube still in the crown? You should measure the internal diameter before you start trying to remove it from the case.2 points

-

Another method described by @nickelsilver is to drop degreaser into the pith wood and then run the pinions into the pith wood. Naturally, this doesn't help much against rust, but it dissolves all other organic or fat-soluble material. I use it all the time. I have restored several movements where the wheel pivots appeared fine even under high magnification in my stereo microscope but still turned out to have micro-rust, micro-oxidation, and small, almost invisible wear marks. While this hasn’t caused the movement to stop working, it has still affected its performance to varying degrees. A good way to thoroughly clean wheel pivots is by using Eveflex, but in that case, only use the softest variant and avoid working for too long, as it may shape the pivot into a cone. The ultimate solution for getting wheel pivots in perfect condition is to use a Jacot tool. There’s no rush to acquire a Jacot tool, but sooner or later, you’ll want to restore wheel pivots to mint condition, and there’s no better option for this. There’s quite a bit to learn to succeed with a Jacot tool, but one vital aspect is knowing how to hold the burnisher and practising this skill.2 points

-

You might need to take the tool apart to clean it. The most important quality difference between these clones and the original however, is in the pushers and stumps. But if you happen to have a Seitz tool, you could use the Seitz pushers. They are usually 4mm as well.2 points

-

This horia clone is not too bad tbf and for the money is worth every penny, but obviously nowhere near the quality of a genuine Horia. The pusher and stump ends will benefit from dressing and polishing. Good magnification is needed when using it to help lining up with the jewels, as the tolerances can leave a little to be desired, yet still a very workable tool .2 points

-

Hey Fred, can you give us more details please. In particular why you want to make this modification, but also which movement you are working on and some pictures to help us visualise want you want to express. When starting to learn watch repair we often make decisions to do things that aren't necessary, that can be achieved in a different and less involved way, that are detrimental to the movement. It can take years of knowledge and experience to learn NOT to make these mistakes. If it seems like a major modification in your head then it probably needs re-thinking and another head to look at the decision in a different way. Not that what you're asking is a major modification, but a simpler answer and process for what you want to achieve might exist.2 points

-

LOL, agree on all points, and I don't service Timex! I actually struggle with larger movements. Have a good one!1 point

-

Last I heard from Ross was that he was taking an extended break due to some of the frustration he was having. I believe he intends to get back into it in the new year. I really hope he comes back, such a nice chap. Tom1 point

-

Rich, I am talking not about the cylindrical part of the pivot, but only about it's tip. For sure the movement with 17 jewels (no cap stones on EW) works fine. For sure friction in such wheel will be more in horizontal, no mater how rough will be the tip that rests on cap stone. By the way, when no cap stones on EW, this helps to minimize difference in amplitudes horizontal/vertical1 point

-

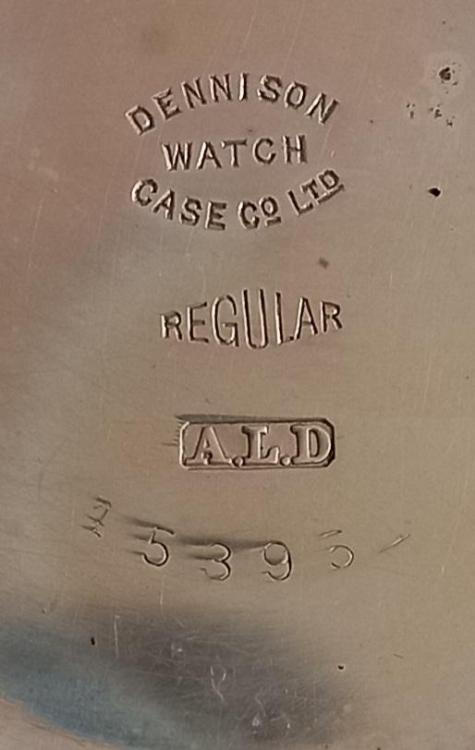

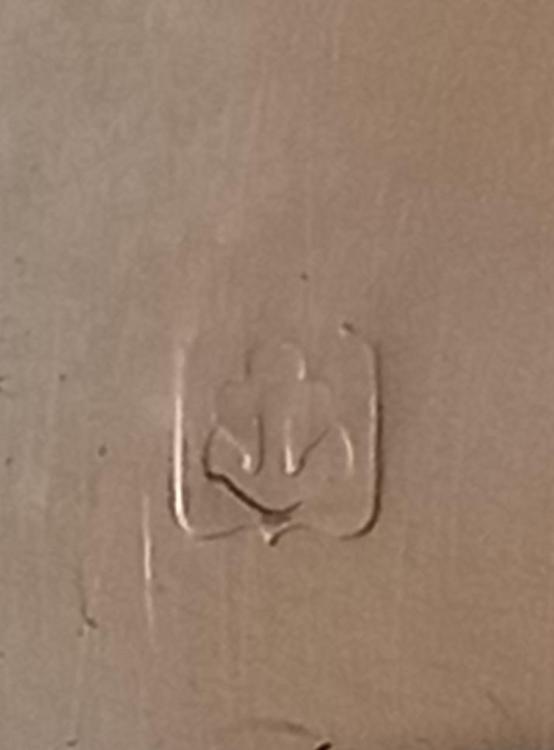

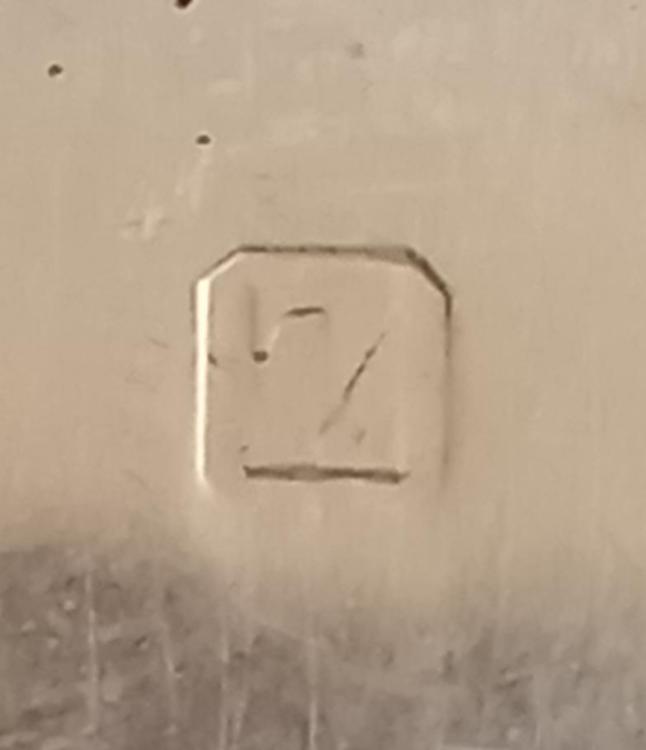

Surprised is not what I think when I think of Waltham mainspring barrel. Then they can get more interesting if it's the Waltham jeweled barrel. What about the hallmarks in the case isn't that more of an English thing also? Both Waltham and Elgin exported oh block of watches especially to United Kingdom where they actually had a distributor. Elgin got even more creative with their exported watches as they sometimes don't look like American pocket watches that are more like three-quarter plate watches. Many times the only have the serial number and on rare occasions the England distributor will actually engrave their name on it hinting that they actually made this watch when they did not. So basically United Kingdom should have a lot of Waltham and Elgin watches if you know what you're looking for. The other thing that makes the Waltham mainspring barrel interesting is the mainspring itself. Yes it has a hole in the end nice and simple except it's not. Rather than explaining I have a PDF which explains the problem. Yes it really is helpful to modify the end of the spring otherwise it's wishful thinking that the hole is going to go where it's supposed to. HT_August2016_MembersOnly The Waltham Hole-p22-24.pdf1 point

-

Yeah, I would've been amazed to be the first to post it here, but I'm pretty sure I searched before I posted... Maybe I used a dumb term or typoed it1 point

-

Another great thing with pocket watches is that they are so easy to re-case. A 16s pocket watch will fit in any 16s case (with a few exceptions). So the case may not be original. Due to the mechanised production methods the US pocket watches were generally better than most Swiss watches of the time. There are examples (quite collectable) of Swiss watches trying to pass themselves off as US pocket watches.1 point

-

There's nothing listed in the Case Parts for the tube so looks like it's a measurement job.1 point

-

1 point

-

Hi Rich, these are nice watches, well made. You will be surprised by the barrel construction.1 point

-

There was talk about caseback openers a while ago. I already got the Bergeon copy but because I'm a sucker for old and heavy tools I also pulled the trigger on an MKS 220. The Chinese one isn't bad for the price but this Japanese is like a tank. Very heavy and robust, cast iron frame and the "locking nut" is also steel. Tight tolerances. I'm still waiting for some brand new case holders and opening bits (the tool is still made as model 22020) but I'm already very impressed. I paid like 40€ for the frame and the rest will cost about 80€. Plus import fees and shipping. There's also quite a big difference in size.1 point

-

1 point

-

That’s going to be my approach. Action the switch with some peg wood.1 point

-

Quite right. I misremembered the 99 cents. It's actually only one thousand seven hundred and ninety nine US dollars and zero cents. I'll be buying any individual parts I need separately. The train wheels can be had in Australia for between AU$44 and AU$47 from VTA. The business ends of the pivots actually look clear of rust or I wouldn't be considering reusing the parts. The bits I'm most hesitant about are where there are some tiny dots of rust on the leaves of the pinion on the third wheel and escape wheel. And when I say tiny, I would not have seen them at all before I got my stereo microscope. I am relatively inexperienced. I've worked on a couple of dozen watches all up but that includes a handful of simple quartz repairs/battery replacments. This is my fourth mechanical Seiko, I think. My expectations are modest: I'm not looking for perfection but I want the watch to run and be wearable by its owner, otherwise there's not much point, is there? This is not just a practice movement: if I need to do something to it that I haven't done before I will practice on one of my junk movements first. Thanks, I'll bear that in mind. I can see how that might apply to the washer on the fourth wheel. It's harder to see the point of the washer on the ratchet wheel, but I guess its probably doing no harm.1 point

-

Generally, rust and oxidation have a very negative effect on a movement. In my experience, even the slightest imperfection on wheel pivots (and jewel holes) increases friction, thereby reducing amplitude. How much it affects, of course, varies. Then again, it’s naturally a matter of what demands and expectations one has. A movement can keep time very well even if everything isn’t entirely perfect. I’m not sure how experienced you are, but if you’re relatively new, my best advice is to lower your expectations a bit and try to enjoy the small progress you make step by step as you learn more. Good luck!1 point

-

So You actually need to use 'normal' type pivots escape wheel in movement with cap jewels. You can use grit 1000 or 2000 sanding paper glued on something flat to gently grind the pivot tips (of course, diamond disks, Arcanzas stone... can be used), BUT the best way is to shift alittle the jewel setting(s) in order to increase the axial free play.1 point

-

Pivot length reducing is possible by grinding and then burnishing for example. But, before doing something, please explain what You need to achieve, as may be what You think is wrong and will lead to wrong result.1 point

-

My first thought is “Why?” And my initial response is “Don’t”. Even unbending a pivot, they just break. They’re so brittle. I imagine to do what you’re suggesting will require a lathe and a Jacot tool to reburnish the pivot. I can’t imagine something like end cutters would work (like shortening a stem)1 point

-

It might also be worth trying renaissance wax, it’s a micro crystalline wax designed to conserve amongst other things metal objects in a museum. I’ve found it useful for old tools that I have de rusted and polished. Tom1 point

-

I only see two options, spray it with oil on a regular basis, how often would depend on how quickly it rusts. Keep it in a sealed container with a bag or bags of silica gel.1 point

-

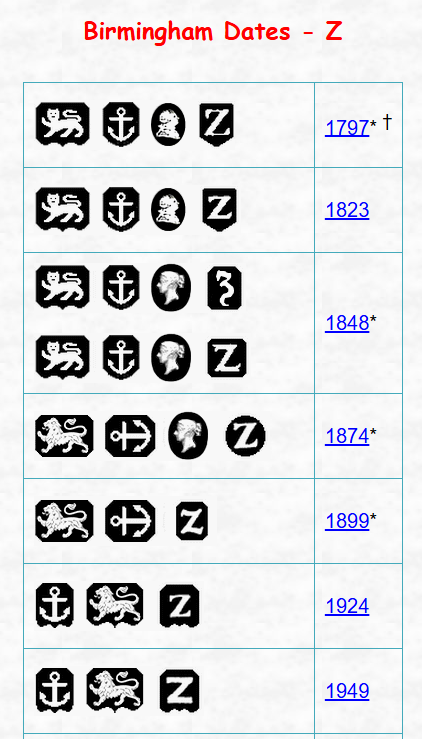

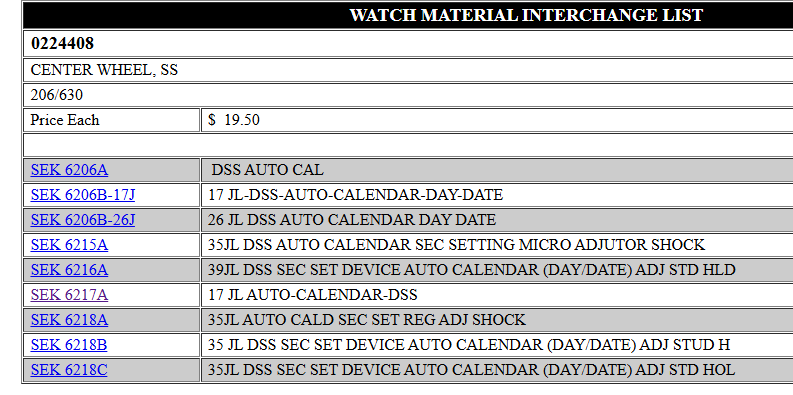

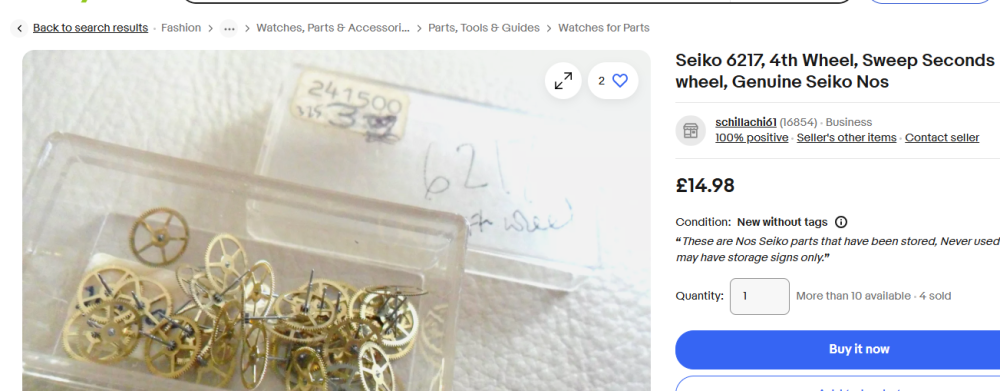

A useful source of service guides (apart from Cousins) is https://watchguy.co.uk/cgi-bin/files As you can see from the first pdf, the base calibre is 6205B. Most parts are shared but the centre seconds wheel (241500) is not. Check in the Jules Borel database to see which parts are common to other calibres. e.g. But it's often easy to find the correct parts, using the Jules Borel database and ebay. Just a quick search in ebay for "seiko seconds wheel" I found this in no time. Seiko 6217A-17j.pdf 6205B-17j-Seikomatic-Selfdater.pdf1 point

-

Okay I have a few GB’s and every one has to have a thinned 0.0045” torsion spring as they are all somewhere between 0.004” & 0.0045” , the book states 0.004” but I have never found one to take that , As your clock is running slow that points to the same wrong torsion spring, I have done a video how I thin a torsion spring along with lots of other torsion clock videos, here is the thinning video. Dell1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

Hi and welcome to the forum. Enjoy. Added a file for your information. Cheers TZIllustratedGlossary.pdf1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

1 point

-

I find this often, however not always so extreme as yours. I use to clamp stem with crown tube in a collet of the lathe and tap strongly on the protruding edge (small hammer and a piece of hard wood between). Not always really successful. Frank1 point

-

Haha, that might be one anxious bride that is not receiving the same amount of attention as the watches eliminate the impossible and whatever remain however improbable is still possible dear Holmes.1 point

-

Hello Louis, The files (and links) have been updated since this post was originally made. You can find the latest version of them at Images Only: https://www.dropbox.com/s/7gh0lsjpkjhs8ut/StakingToolsAndHowToUseThem1910_1200dpi_ImagesOnly.pdf?dl=0 Images with OCR text: https://www.dropbox.com/s/ktjb8j2hy2rlgym/StakingToolsAndHowToUseThem1910FullTextSearchable.pdf?dl=0 Please let me know if you have any more difficulties accessing the files. Best, Tom1 point

-

Just to let you know that even the second mainspring I've ordered from Cousins is being delayed and I therefore won't be able to get this watch done before I go on holidays . I'll post again in early January..0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)