Leaderboard

Popular Content

Showing content with the highest reputation on 10/03/24 in all areas

-

As you might have guessed from my username, I brew beer for a living. This weekend I was pouring beer at an outdoor Oktoberfest event, and I noticed one of my 20-something customers had a watch ring on. Of course I had to ask about it. "I got it at a thrift store for a couple bucks. It doesn't work. I'm sure it just needs a battery." I asked to take a look and noticed the "SWISS MADE" mark at 6 o'clock, so I asked him if I could try something. He handed it to me, I wound it up, and whaddya know it started ticking away. I set the time, gave it back, and he was amazed.4 points

-

To answer a question from above: The original tool shows very little wiggling, a bit more when the threaded range is involved. But for this tool a tight tolerance of the arbor seems not essential. Frank4 points

-

Sounds good but I don't agree. Giving so much info will put people off and people at times can hatch things up.3 points

-

Chinese tools is a regular debate on this forum. In my experience having purchased some they are OK BUT there is a compromise in terms of build quality and materials used to make them. For an amateur they are fine but for a pro who will be at his/her workbench all day accurate quality Swiss tools are essential. Fiddling with a tool to make it work is just not an option.3 points

-

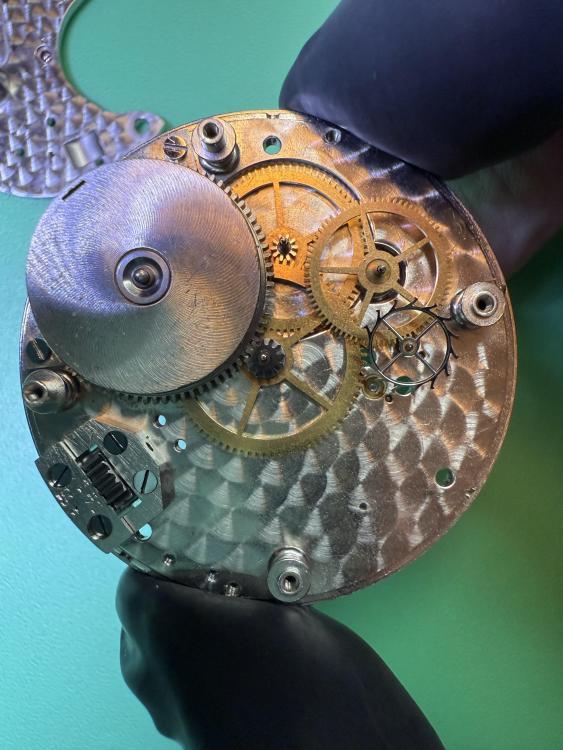

Hey it's been a while! I've been so busy this poor guy has just been sitting on my bench, cleaned and ready for assembly. I tried a couple of things in a corner of the dial, and no, the yellowing is not coming off. I did finally get the mainspring wound and installed, and the train side together. At least to the balance, which started up immediately and beautifully. If you take a careful count, there are 6 pivots in that bridge. You can't see the jewel inside the tube for the center seconds arbor. It's a testament to both the quality of the movement and my patience that I was able to get it assembled on the first try.3 points

-

Just finished up my first repair attempt on an 1939 Omega 38.5LT1 GSTP watch. Bought it as a non working watch for $80 Usd and was pretty happy I just had to replace the mainspring with one from a parts watch (Still took 3 hours though) The barrel had some very rusty looking oil on the arbor, so I cleaned it and the mainplate/bridge pivots with Naptha. Took me a about 2 hours just to rewind the donor mainspring. my conclusion is the 3D printed winders Aren't the best for pocket watch mainsprings. So I'm going to buy a bergeon winder Since I expect to be working with this calibre quite a bit. Once I get some proper oils and cleaning fluids I'll go through again and clean everything. And probably replace the crystal once I decide how I'll deal with the lume. But for now I managed to get a watch to run within 10 sec/day without causing more damage, so I'm perfectly happy with it as is.2 points

-

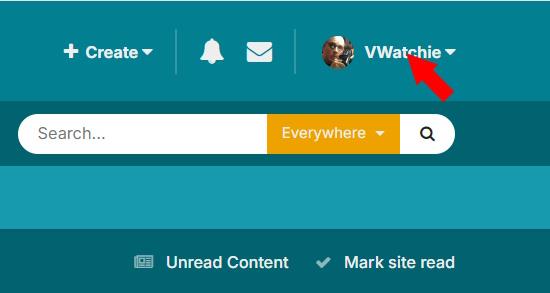

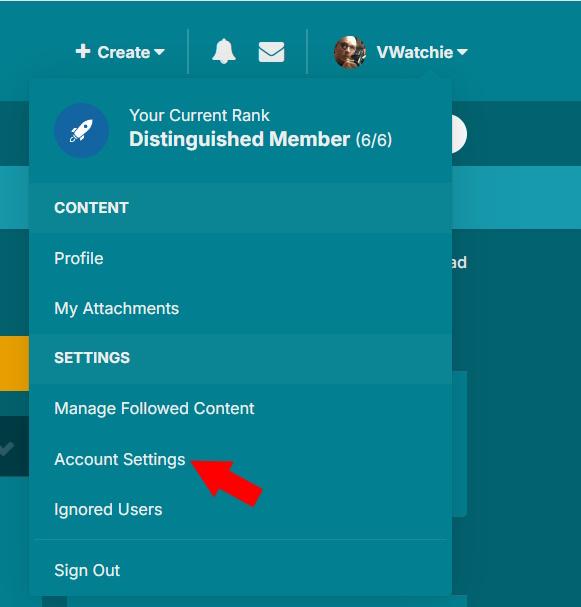

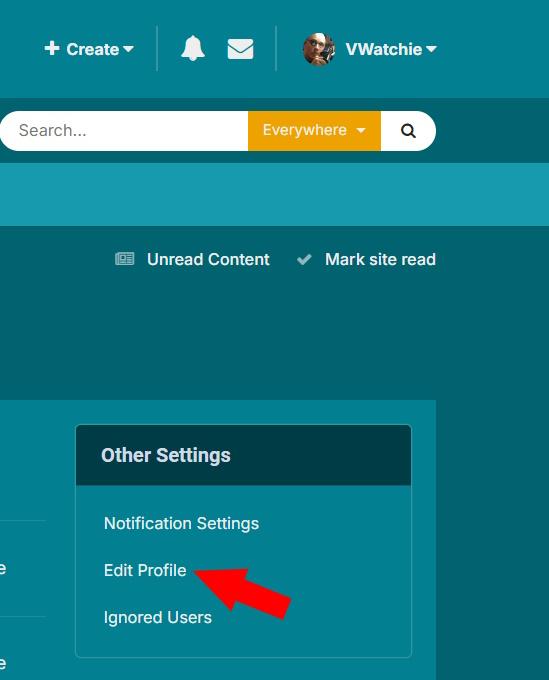

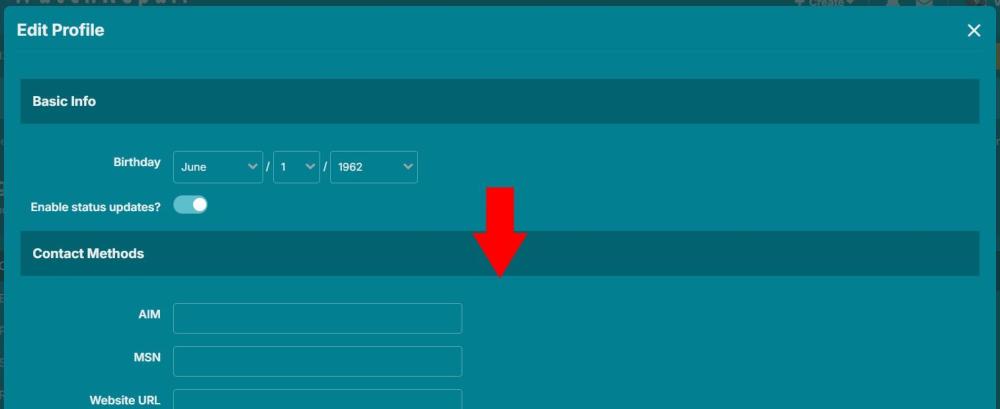

What I really appreciate is when members take the time to introduce themselves on the "About me" tab of their profile. All you need to do to write an "About Me" is to follow these steps: 1. click on your member name at the top right of the page. 2. then click on "Account Settings". 3. click on "Edit Profile". 4. Scroll down the page until you see... 5. ... "About Me" Now all you have to do is write something about yourself and then click the "Save" button. You can always go back and update when you wish to change something. Now other members can click on your icon or name anytime, anywhere, and get some information about you, which is both nice and useful. For example, you can tell others that you are a beginner, which allows other members to customise their answers for you. And once you've warmed up, just update the "About me" section. If I could make a wish, I would like all members to write an "About Me"!2 points

-

Is the following so obvious it's not worth mentioning? Maybe. Nevertheless! Should we understand that as you never lubricated the impulse surfaces of the pallet stones? Lubricating the impulse surfaces can make a dramatic difference. I would clean the pallet fork (peg between the fork horns) and properly lubricate the pallets. I would also re-clean the escape wheel and the balance to make sure the dirty pallets didn't contaminate them.2 points

-

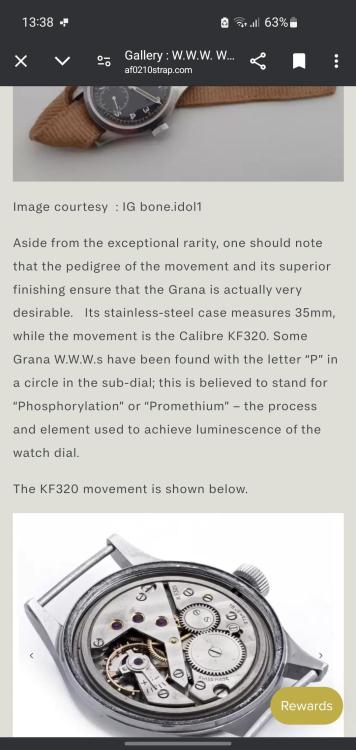

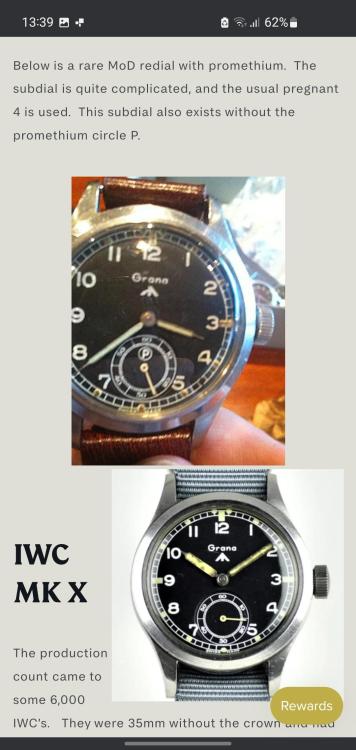

Hello all, I'm moving onto this thread from the introduce yourself one as this is the more appropriate one so for a bit of further reading on this watch have a look at that. My first military watch, and if everything is correct, not bad for my first. Grana DD. So there has been a bit of speculation regarding the dial, from the limited information and internet sleuthing, I believe it's a MOD re dial, when they did away with radium, for a short time they used promethium then went onto tritium, hence the circled P. So does this mean this could be a scarce example of an already scarce watch? The hands look correct but not sure about the colour. I suspect that when they were sent for repairs if it needed hands it got hands. Would be interesting to know if when they re dialed a watch they got replacements from the manufacturer or just cleaned up all the old ones and re print them MOD style and not Swiss style, hence the more chunky and crude quality. Of course you have to consider if this watch has been faked, but if faking a dial I would have thought the standard original layout would have been used and not the hardly seen P dial. So all I have done is clean up the crystal a little to make it more presentable, I haven't gone to town and there are still plenty of dings around the edges, I didn't want to go rounding off the bezel edge. What I hadn't noticed before is the wear on the back from the strap, hopefully that comes out in the picture2 points

-

…something I said to myself last month while adding a new Seitz flat pusher to my cart…2 points

-

2 points

-

When buying second hand you need to make sure all the punches are in good order, not chipped or blocked up. There are a lot of stumps missing. Also does it all line up, in some cases the staking tool has been dropped.2 points

-

Ok, I'm going to have a go at the crystal today, if it doesn't come out very well than like mikepilk says, a replacement shouldn't be a problem, with the current state of the crystal I've nothing to loose. Also this would mean I have done something with this watch that would bring satisfaction. I am not going to service the movement, this is potentially a highly sought after time piece (obviously professional authentication will be needed at some point so until then will always treat as potentially), and I as a novice am not immune to easily avoidable rookie mistakes and this isn't the watch to take those risks. As to what I'll do with the watch I've had a think and for now I'll just keep it as it is and enjoy being in possession of such a watch. Ultimately though, will probably eventually getting it properly authenticated and serviced and if all correct selling. I do collect watches but not military watches, this is someones (potentially) holy grail watch but not mine and if this completes someones collection and I make a couple of quid then its a win win. But like I say, for now I'll enjoy having it and continuing reading up on these watches with one in front of me. When I've had a go at the crystal I'll put in a picture but as I'm still on the introducing myself thread I'll move it over onto the show me your military watch thread which I think is more appropriate, I think I've said hello now. But now is a good time to say this is exactly what I needed from the forum and I appreciate your knowledge and responses.2 points

-

I totally agree with you @clockboy. If I was doing this for a living, I would be buying better quality tools. For the likes of me, time is not money, I enjoy fiddling and fettling tools. So for a case removal tool, which I may only use once a month, I'd rather fettle a £60 tool than pay £1200.2 points

-

...A Hamilton 940 just finished for a friend. He was a helicopter pilot in Vietnam and closing in on 80 years old. This was his father's watch in Kentucky USA. No charge for military but I may try and weasel some KY bourbon out of him... Flabby before it was missing the hour hand and the story is the brother opened it up and broke it- I'm certain his brother tells the EXACT same story if you know what I mean. Hands for these are around so hour hand no problem but it also had a broken spring what holds the setting lever open. Most of them broke long ago and spares are nowhere available- keep 'em if you have them! Otherwise the movement was in good condition, just dirty and a few service marks. Lots of watchmaker runes carved into the backs on this one. It has the unusual 'motor barrel' so a little more fiddly to deal with the spring but it didn't take me too long to wind it back in...2 points

-

Hi folks. I was given a non working automatic bulova that was acquired by my partners thrifty uncle for £20 from a charity shop. I foolishly declared that I would fix this watch. A year later and the Watch has been stored beside another two non working bulovas. i realised I would have to start at the beginning and have been gathering tools and Seiko movements to practice on. I do a bit when I have some spare time. Eventually I’ll bring the Bulova back to life and my partners sister will ‘steal ‘it from me1 point

-

sometimes the English language can be a bit confusing like I'm not sure the meaning of hatch things up? but skipping over that I'm in 100% agreement with this. Typically all I really would care about is skill set and I like to know where people live but I don't need an exact address country is fine. Then yes we get a interesting problem of putting people off or maybe people just don't like to write up profiles about themselves or for that matter even doing introductions what if somebody doesn't do an introduction should they be thrown off the group? I think the last time I needed to do a profile for something somebody else had to write it up for me as I just didn't well it just isn't what I do. Or for instance introductions I don't do that either and never did one for this discussion group. Somehow stumbled across the group obviously I was not looking for help on watch repair. Stumble across the group liked what I saw jumped in and started helping with answering questions. then to be honest I didn't even know this feature existed. Well it will make you unhappy but it only sort of exists? like probably a lot of things on the message board of if people didn't know it existed then well it doesn't exist sort of. Like newbies unaware that maybe they should give a thumbs up if they liked something. Or if this isn't filled out as I just now looked at a variety of profiles including one of the moderators and if you don't fill it out there is not even a blank tab to look at. But over on the left-hand side there is a public profile that somehow can be filled out but don't worry I have done none of the as is not really my thing to do these things oh and thinking about being put off? Where I work were supposedly attempting to hire people on a continuous basis but they never show up. One day with odd timing management stepped out. Yes husband-and-wife they just go out without telling us they're just gone. A person with girlfriend came in and inquired about a job. I suspect they were in the mall and she suggested why don't you try here? So then he inquires about a job and was told management is yes it's embarrassing if we don't know where management has gone to. So typically I don't talk to these people but I asked some questions. Like did you know what a watch was? Yes we have to start at the basics and yes he did he put together his own Seiko watch. That sounds very promising. I asked about repair experience or basically where is he working now he's working in a cell phone store and he's repairing cell phones that sounds even better. Then we have the icing on the cake sales and he worked in the sales department he sounds like a perfect candidate. About that time one half of management returned and briefly talked to him. Then the other half of management came in and this is her standard profile if you come work here now she requested a two paragraph essay on usually it's a variety of subjects probably one of them is tell me about yourself and why you would like to come and join the team. Then notice I'm not mentioning names the other half of management later on asked if we got contact information and the answer was no we did not. Which was sad because this person seems very promising and of course no essay was ever seen. out of curiosity I asked Dave is a teacher at the community college teaching the Rolex watch repair program. So I asked what percentage of students in watch repair have dyslexia? Or what percentage of your students would like to write a two paragraph essay on. Yes in the technological fields you end up with a lot of people with dyslexia in various forms and asking them to write a two paragraph essay on well maybe that explains why we don't hire very many people at all. So yes sometimes writing up essays profiles whatever just isn't what some people do all we really need for the group is some sort of basic at least initially until we get to know people what their skill set is.1 point

-

I managed to get a replacement high dome crystal. Had a bit of trouble getting it in. Then noticed a piece of lint on the dial. Took the crystal back off, removed said lint and got the crystal back on. Had to use my crystal press to make sure that it was fully seated.1 point

-

Forget all this fandangled stuff, cleaning watch parts is just like cleaning your clothes. Spin them backwards and forwards in good cleaning solutions with some added agitation if required, spin off the excess fluid and hang em out to dry........ah the random shite that us penny-pinchers do to get by .1 point

-

1 point

-

I agree, skill level and location would be really helpful. I think an introduction should be compulsory.1 point

-

1 point

-

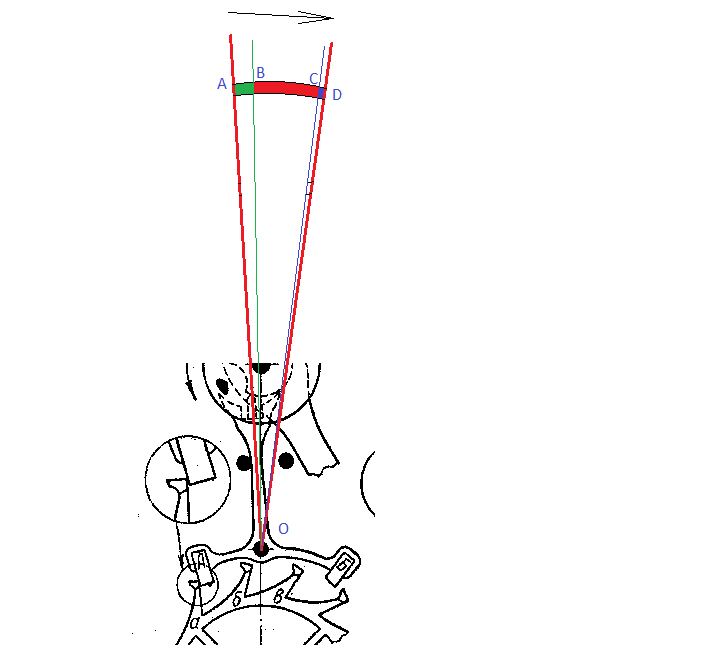

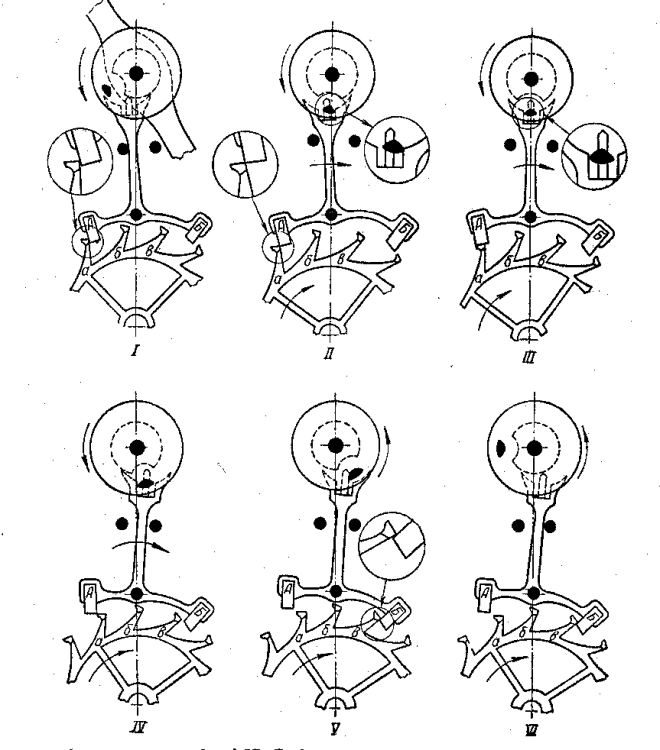

Hi Dmitry, First, a little theory needed here. I will try to present the theory in a little different way, hoping this way is easier to understand it. Look at this drawings: The angle AOD on the first one represents the whole angular movement of pallet fork tail from one banking pin to the other. In the beginning, the tail is in point A, which is shown as "I" on the second drawing. Angle AOB is the rest angle. If moved to the green area, before point B, and then released, the tail will return to A by itself. If the tail is moved past point B to the red area (point B is corresponding to "II" in second drawing) and released, it will snap to the other banking pin by itself. The red area (angle BOC) is impulse angle. The important moment here now is the point C, corresponding to "IV". You will see on "IV" that the tail is not touching the banking pin. This is very important. In the moment when the tail leaves point C and enters the thinny blue area, the tooth "a" leaves the pallet "A" and the tooth "в" falls on pallet "Б" as shown in "V". The movement of the tail from points C to D is RUN TO THE BANKING. Movement C-D and the thinny blue area MUST exist and this is very important. What happens in You case is that 'Run to the banking' in the exit pallet is close to 0. If we look at the second drawing, this is like IV and VI to coincider and in the first drawing - the blue area to not exist. The tail to be already rested on the banking pin, but the tip of the tooth а can't leave the edge of pallet A and there for tooth в can't fall on pallet Б. Of course, this happens only on one or two teeth of the escape wheel, which are higher than the others. And, the drawing is for the entrance pallet, but the problem in You case is with the exit pallet. As I already said, the easiest way to make the watch work is to open a little the banking pin as to allow some healthful 'run to the banking'. I understand that You don't want to bodge with the escapement, but You have to understand that this is what is needed here. What i saw on the last video... See, You show actually nothing helpful. Just endless jerking the brass table of the escape wheel with steel tweezers. This can only hurt the escape wheel teeth, which is something not wanted. The correct and simple way to look for wear of a bearing is to give some force to the wheels repeatedly in forward/reverse direction and see if the pivot moves. Then, the bearing that is actually interesting is not seen in the video, this is the main plate bearing.1 point

-

So that should tell you the issue lies where the Auto works connect to the rest of the movement.1 point

-

1 point

-

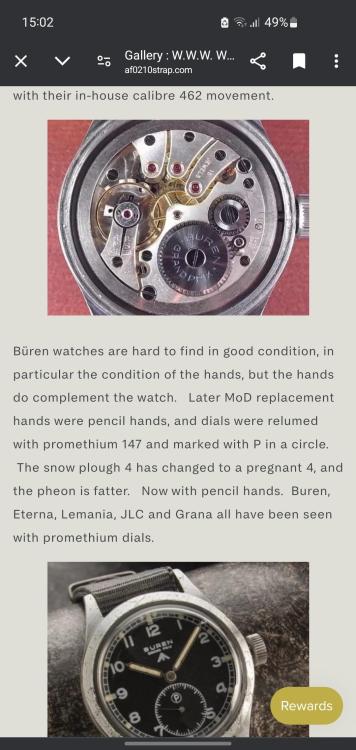

AndyGSi, so far all I can find on this is from this site https://af0210strap.com/blogs/news/w-w-w-watches-on-a-f-0210-straps Pics below including their referece. rehajm, the others? the radio active pocket watch I think I can hear rumbling in the corner? The following pictures of the pocket watches from the same box, to describe the contents, there are many many watches all from the same era, mostly the likes of smiths, roamer, ingersoll and so on. These are the only military ones, the boxes are all very old and I suspect when they were all collected they weren't collectable at the time. Lots of parts, cases movements etc. One of the omegas is not military, two work fine but one has a broken mainspring, can't remember which one Just on that previosly mentioned site ... and this extra info1 point

-

The thing with the P and Promethium is that it wasn't used until the 1960s so not sure how the MOD Redial stands. I think the Serial Number may shed more light on this if you can find another Grana with a similar number.1 point

-

You should really do a systematic check of the escapement function. I wrote this up a while back, it covers the steps.1 point

-

make sure the pallet guard finger [on the fork side] didn't get bent .....you said all worked fine separately1 point

-

As it appears the lever is the naughty one here. The pallet fork ( lever ) has 2 ends that both need to interact with their playmates in a nice way. For one the pallet end must play nicely with the escape wheel, if the stones are locking and releasing as they should then suspect that the lever is misbehaving with it's other buddy the balance. As you have mentioned excessive end shake in the lever........how does the fork'a height lay with the balance's impulse pin ? Are THEY playing nicely or are they rubbing one n other up the wrong way ? As is " Making the right Connection " a key element to a successful business this also applies to repairing watches. Using the word " RIGHT " describes and encompasses all scenarios. A Good connection, a Modest connection or a Non connection. The right connection must fit the right scenario.1 point

-

1 point

-

1966 Timex field watch 1158 2466, 30.5mm just got cased with a new crystal today. This m24 movement had all sorts of problems revealing themselves each time I solved one. Bent wheels, bent fork slot, bent pallet pins, somehow the lower balance v-conic pivot getting pushed out of its friction fit hole (I never gave these any thought before as to their installation on the plate). Luckily I have a sackful of Timex spares and all the parts are interchangeable. I was glad to get this around $20 since they're not all that common.1 point

-

Dmitry, the other possible reason is that the bearings of the escape wheel has worn and as a result, the escape wheel has shifted towards the pallet fork - just a little, but enough to cause the problem, effectively the depth of the escapement is increased and run to the banking in exit pallet is missing. Do not search for other reasons, the problem is in escapement.1 point

-

Sometimes the movement doesn't seat perfectly into the case, affecting stem depth while it still screws in securely. Some cases have more slop than others in this regard but 0.25mm is all it takes to possibly throw off the keyless function. I'm glad it's working better this time.1 point

-

Hi, really appreciate your feedback. Will try it and wish me luck. Thank you!1 point

-

Elliot clocks are English I have many ranging from time pieces to Chiming all with platform escapements they are very well made clocks from the movement to the cases. The coiled spring on the escape wheel should act as a silent tick, that is if it is working correctly. You need to make sure the balance is in beat, if you stop the balance and you have power on the spring the balance should start up on its own. You need to check the balance and the depth of the contrite wheel making sure the teeth engage correctly. No matter what position the movement is in it should work, if it stops the depth will be wrong.1 point

-

I presume it has been serviced, it certainty looks clean. If so it’s a matter of elimination take power off the mainsprings then add a little power by a half a turn then remove the platform escapement and see if it runs . BUT BE CAREFUL don’t let it run away uncontrollably by a finger on one of the wheels.0 points