Leaderboard

Popular Content

Showing content with the highest reputation on 08/08/23 in all areas

-

Some of these 2 hand ladies movement do not "tick" every second like larger gents watches to conserve battery power. Instead, some only tick once every 10, 20 or even 30 seconds. After a new battery is inserted, you have to watch the rotor very patiently or if you have an impulse tester, you have to wait at least 30 seconds for an impulse. Another way to test is to put both hands at 12 and see if the hands move apart. If the gear train is stuck, just applying new oil will not solve the problem. The entire movement has to be disassembled and cleaned. If this is the first time you are working on a ladies quartz movement, this is not an easy task due to the extremely small dimensions. Best to work on a less expensive movement first to gain experience.3 points

-

Funny that you should mention this. It's probably off topic, but I've had a fascination with high voltage electricity from young. I've worked on many high voltage equipment over the years, from vintage valve equipment, electrostatic air cleaners, photo flashes, induction furnaces and xray machines. Got zapped countless times. The scariest thing I've worked on was a dental lab induction casting machine. It had a vacuum tube the size of a gold fish bowl. The ceramic capacitors in that thing was the size of door knobs. The working voltage was 1500V with sufficient amperage to melt non-precious alloys up to 1500°C.3 points

-

2 points

-

Look out, here comes the other perspective, taken from practices used in the restoration of art and decorative objects. Since it is just the look that concerns you, here are some thoughts: 1) Do nothing, if possible, especially as you are inexperienced; (I can tell this is not an option for you); 2) The eye always goes to the greatest line of contrast, and your greatest contrast so far is the dark dial against the silver bezel and case. If you can minimize the defects' contrast, they will be not noticed in context. 3) Consider the final context: If you are wearing it with a suit, other lines compete, like shirt sleeve under jacket, both maybe over watch edge; then the room in which you encounter others, it also escalates the contrast line war (Dark moldings, light chairs, etc. If you left it alone, I doubt it would be noticed, nothing like stains on a suit. 4) In plain English, you might be slightly tripping if it is about being seen, because in context it is next to impossible for the eye to register those defects. 5) If you want to diminish the problem, and I would because I am obsessive, I recommend a manual approach. If you take a Dremel to the case, and you never have done so before, you might be opening a large can of whup a**, as we say in the South. 6) I wish I knew the name of a powder I use; I think it purports to have diamond dust. Or the green stick you have could work, if reduced to powder or shavings first with a razor. Stiff polishing cloth or felt pad, use a bit of normal polish like Flitz dipped slightly into the abrasive and work to feather the edges of the defects. Buff. Repeat as needed. You can do this manually. A Dremel cannot repair the edge divot anyway. Rember that you are looking to reduce contrast, not repair the defect. 7) Try it out, in semi-context such as suit shirt and jacket. Get close to a mirror and see what you see. Voila! I know it's a bummer to get a watch with dings, but it is yours now and it is handsome as heck. In time I doubt the defects will matter.2 points

-

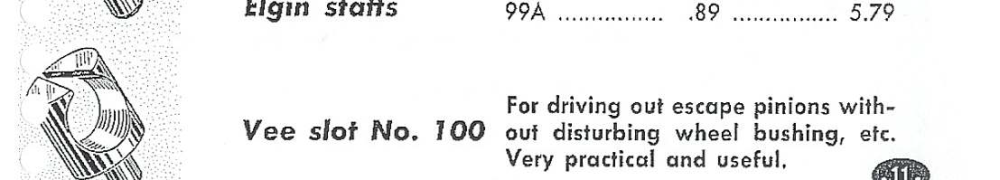

your box definitely looks much much nicer than mine at least on the outside. Mine looks like it's been well used as held together with screws. Then yes typically was staking a cents if they've ever been used there will be? I know what work with time punches seemed to go missing and then they also end up not being in the right place which is what happens when others use the set. well the answer is the question I had. What I'm curious about the staking set punches themselves. Why if you look at the end that you whack with the hammer what is the shape of that? Then yes and being cryptic with my questions deliberately I'm also curious about the punches themselves when you compare them to the others sat do they actually look the same? That's because somebody else sent me a picture of their set and even though it looked much better than what I thought it should look compared the descriptions I've had of other people. Although the other person apparently they didn't have one of these sets they had the stars set from Switzerland and in that set the punches were not finish still need to be finished. But the person that had this that well basically I be curious if you start comparing the punches side-by-side how they compare. but unfortunately you're not quite there yet. it looks more shiny than the one that I have but it looks fine? Is snipped out an image of the catalog just in case there's something I'm not seeing perhaps?2 points

-

Watch this. The case restoration starts around 19:05. He even restored the box in this video.2 points

-

You could experiment with some old cases to give you an idea of how much pressure to apply to different types of wheels charged with different cuts of polish.2 points

-

I'm sorry to have kept you in agony for this long which must have given you many sleepless nights, but finally, to my great joy, I have identified and fixed the source of the low amplitude issue, resulting in excellent improvements. Upon close inspection (40X magnification) I found some very slight rust and oxidation on several of the train wheel pivots. Don't know how I missed that when I serviced the movement the first time around (really a bit embarrassing). Perhaps I simply wasn't looking close and/or long enough, and no, the rust didn't get there after the service as I wasn't wearing it due to its poor timekeeping. So, my beloved Steiner Jacot tool to the rescue and what do you know, amplitude in the horizontal positions is now slightly above 300 degrees and around 275 degrees in the vertical positions. I'll never get rid of my Jacot tool for as long as I'm able to breathe and am capable to use it! I haven't had the time to fully assemble the movement yet, but for anyone interested, I get back with the measured amplitude after 24 hours of fully wound.2 points

-

out of curiosity when you're building and repairing your electronic things do you charge for the service? Then if you repairing something that was 100 years old would you charge the same price versus something modern? The problem with vintage is it's hard to get replacement components. It is also hard to find somebody who can actually do vintage because that is a specialty in watch repair. the problem with working with miniature electronics is it doesn't have the fun that working on high voltage electronics does. in other words you need to follow a procedure or it will be very unpleasant if you accidentally discharged something through your body for instance. Watch repair has similar procedures like disassembling you should remove the power and typically you would disassemble after you took the movement out of the case. unfortunately it's hard to evaluate a watch that's partially disassembled. Uh-oh and typically if you take partially disassembled watches to watchmakers they should charge a heck of a lot more because they have no idea what they're dealing with. So you're now the watchmaker congratulations and you have a book and this helpful website. important lessons to learn would be when not to repair a watch. For instance does this watch have any sentimental value to anyone in the universe and will they be unhappy if it never runs ever again? Usually we discourage working on family pieces. But sometimes we don't because it does make for a good lesson of well kinda like the lesson of which end of the soldering iron should I grab. in other words you're not paying attention to reach over for the and you grab the wrong end. everyone will have a little different procedure for your particular situation. to reassemble the watch in the case is going to be very undesirable. basically after assembling the plate you would want the movement out of the case and the balance of the pallet fork out to make it a lot easier. So let's start with the basics of getting movement out of the case. You should build a remove the front part of the case is holding the crystal and it looks like you're chasing screws or outs the movement should push out? Hard to tell with where the crown is I don't think it's Columbian issue can't really see the keyless mechanism from your photograph.2 points

-

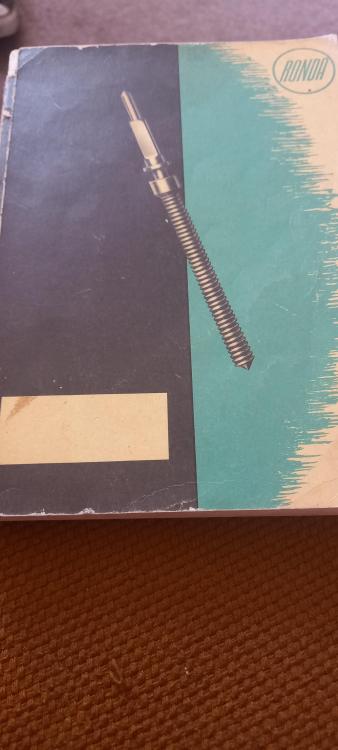

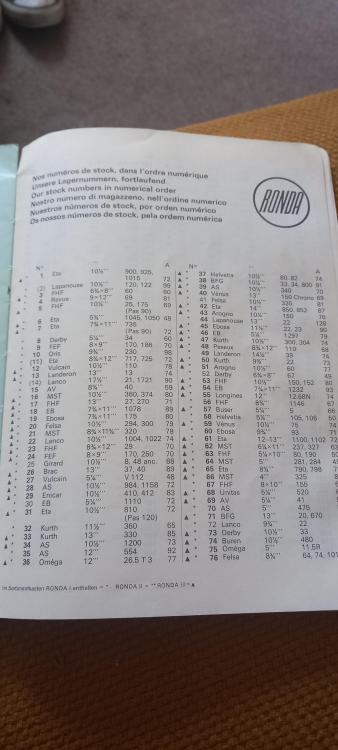

Eyup watch peeps. I have just received another useful book addition . There are sites containing this information, one in particular is the balance staff and stem .com site. A very handy database when searching for information on sizes. But it is an actual retail site so may not be around forever. If you google ronda catalogs there are also pdfs that you can download, i will add a link, but the stem pdf are not complete to the book. Everything is there but only is alphabetical order of make. Not grest if you have a stash of stems by ronda number order which i happen to have. This book will save days if not weeks of searching and identifying ronda numbered stems also unknown stems. https://vintagewatchparts.net/ronda-winding-stem-catalogue/1 point

-

I have a small buffing machine (will take a 4"/100mm wheel) but as several people have mentioned its easy (too easy) to round off sharp corners, our old friend Kalle Slaap of chronoglide just did a video series, see link below, on buffing and polishing which is good and Michael of My retro watches also does a good video on the subject- but to be honest for such a small area that you are looking at with sharp angles, I think there is a great danger of rounding something off and spoiling the look of the watch. When I'm in this situation (and i'm no expert by any stretch of the imagination) I prefer to use disposable buffing sticks (see Amazon screenshot below), the lollypop type, as these give you much more control and are a flat surface so you reduce the risk of rounding. It does take longer, but you keep the control, I just start with the lower grits and work my way up, by the time I get to 12000 grit its a mirror finish. These also have the advantage that they are waaaay cheaper than the mechanical tools. My go to when I need to keep a sharp edge:1 point

-

Oh gosh, I wrote it in the wrong place, Haha an embellishment of frustration. I gave an example earlier of using my power tools, highly unrecommended1 point

-

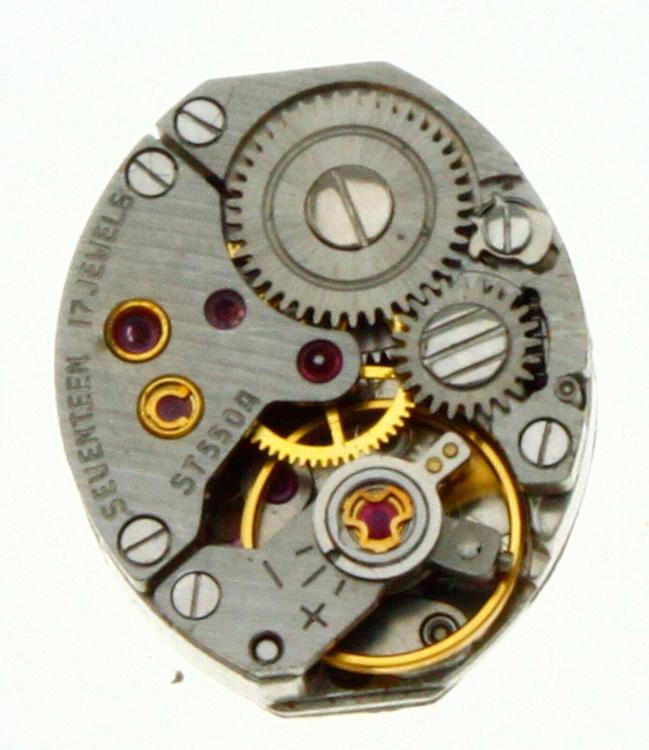

Got yourself a real Frankenstein there, I think that perhaps the dial and the case-back are Seiko and the rest is from something else. It does remind me of an Orient movement (below) with the weird button to set the day, but as @JohnR725 points out the balance protection looks Swiss and not the triangular (ish) shape you tend to get in older Seikos and Orient. Also, I've never come across a click quite that shape/design before, its a mystery! Can always look at as you have a unique one-off watch I'm also curious about the rippling effect circled in red in the middle at the bottom - is this real or just a trick of the camera?1 point

-

Welcome to the forum! As you may (or may not) realize, even among Swiss watches, Ulysse Nardin isn't among the typical "top ten". I don't know (but strongly suspect) that the production volume for any particular watch is very low as they seem to specialize in really exotic builds. I'm not at all surprised that they no longer have parts. I further suspect that their assumption would be that anyone buying one of their watches would have a fair number of other (expensive) watches. They do have a few offerings in the 4 figure range but they're mostly known for watches that sell for $50,000 USD or more. Depending where you are located, your best bet may be to find an actual watchmaker who is capable of making whatever part may be needed (which won't be inexpensive). It would also help the rest of us to see a photo of the watch in question. Good luck!1 point

-

Lol, you noticed my earlier double entendre then Rich ? I did the same with a variable speed bench grinder with 75mm mop wheels. It feels a bit big after using a small rotary tool. I've tried a few compounds the last ones being from cousins, big blocks that had some super heavy cuts. I really like the Polinum for a final polish, superior to anything I've tried up to now.1 point

-

The bigger the better for polishing ( I'm waiting for @Neverenoughwatches to lower the tone, hehe. ) I bought a cheap bench grinder, circa £35 and a conversion kit, circa £25. The conversion kit has the required spindles, various mops and compounds. I have various compound brands, seem the same to me.1 point

-

1 point

-

yes that doesn't look quite right at all I circled a few things typically with Seiko they use their own balance protection system and that looks Swiss to me? Not that Seiko and the Japanese the Swiss don't work together for things but that's definitely not quite right + circled the things on the case those don't quite seem right either oh and looking at the picture my bad I forgot the circle something which I didn't notice until now notice your ratchet wheel missing teeth? But never mind it's not the right watch anyway here's a link to what the picture the watch should look like and this one is definitely not it. So looks like someone did a retrofit upgrade and the case isn't writes because as a button pushing something and yes definitely not the right watch it all https://17jewels.info/movements/s/seiko/seiko-6119a/?ref=mizeni1 point

-

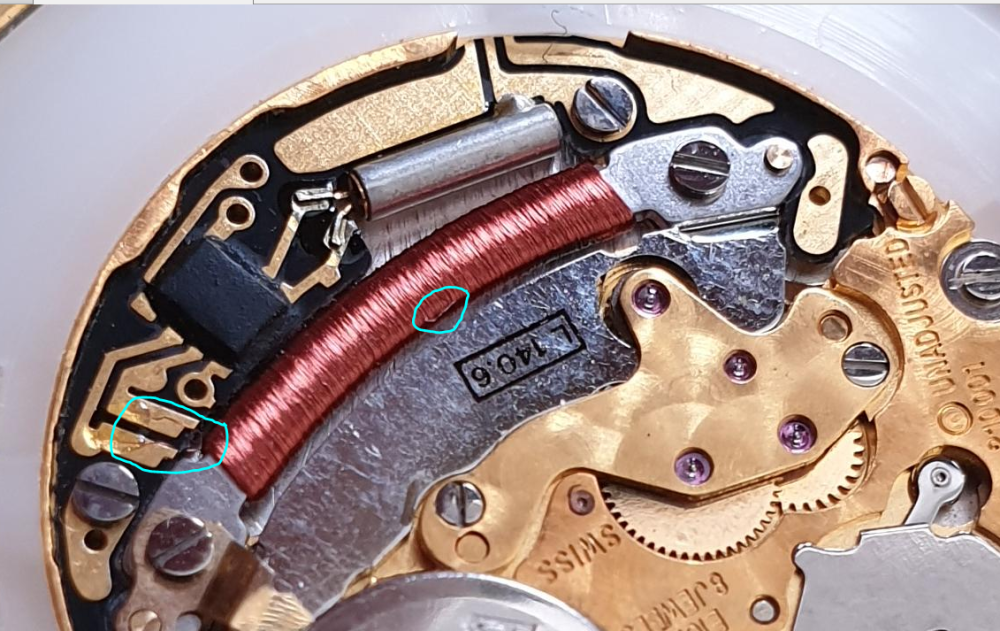

when you are changing the battery did you make sure that the battery insulator on the other side is still in the correct location? then for troubleshooting you really need the technical sheet which I've attached. Then you also need some electrical test equipment. PDF page 14 as the diagnostic information but it does require the test equipment that you probably don't have. then if you look at the tech sheet you see that it should impulse every 20 seconds or as they state three times per minute. then test equipment like measuring the coil resistance to make sure it's not damaged. Being careful when you do that the stay away from where the leads actually touched the circuit board because you could damaged the leads right there trying to test. I've circled where you want to stay away from for testing and I circled something in the middle the coil which looks suspicious maybe it's just dust particle then personally for me I like to test the current consumption but that requires a micro amp meter and a suitable power supply. we've had different experiences. Some quartz watches will run without lubrication others will not. Dirt particles dust falling of the watch will definitely cause an issue. but I usually find a holder quartz watches the lubrication's gone bad and typically it's sticky. Sticky lubrication a quartz watches is bad the watch really needs to be serviced that means complete disassembly just like a mechanical watch. CT_210001_FDE_502580_09.pdf1 point

-

I don't know any source of info for pivot sizes, with the exception of some old info on American stuff. If the jewel fits, but doesn't want to tilt at all*, I would go to a 0.10mm hole. Manufacturers did indeed use half and even quarter sizes (0.095mm for example) for jewels, but in a case like this going up to 0.10mm with a 0.09mm fitting "snug" should be just right. *With a proper balance jewel, the hole will be olive shape, and even if very close in size should allow a surprising amount of tilt.1 point

-

If you have a jewel that is a loose fit in the mainplate/bridge, you can theoretically close the hole a bit with a convex punch. But it usually doesn't work that great. Better, as Waggy said, to open the hole to the next size of jewel. So if you have a 1.30mm diameter jewel, and it's loose, open the hole for a 1.40mm jewel (which the reamer in your jeweling tool will do, to the proper interference fit, meaning the hole in the plate/bridge will be 1.39mm). The only thing affecting the hole size of the jewel where it pivot fits is the hole size of the jewel. The jewel in non-compressible. If this were a thin walled bushing in brass, yes, the hole for the pivot might compress a bit, and need broaching to final size once fitted. If the jewel is a loose fit, and the hole won't close enough with a convex punch to hold it, and you don't have a larger jewel to fit, you can make a thin walled bushing and fit it to the plate/bridge, and fit the jewel into that. There's a limit to how thin walled the bushing can be though- about 0.2mm wall thickness. So for a 1.30mm jewel, you would need a bushing with a diameter of 1.70mm. This may be too big for the part you are working on though. In that case, if going the jewel-in-bushing route anyway, it's worth looking for a smaller jewel, so the bushing can be a reasonable size. Ideally you would have a lathe to make the bushing too.1 point

-

1 point

-

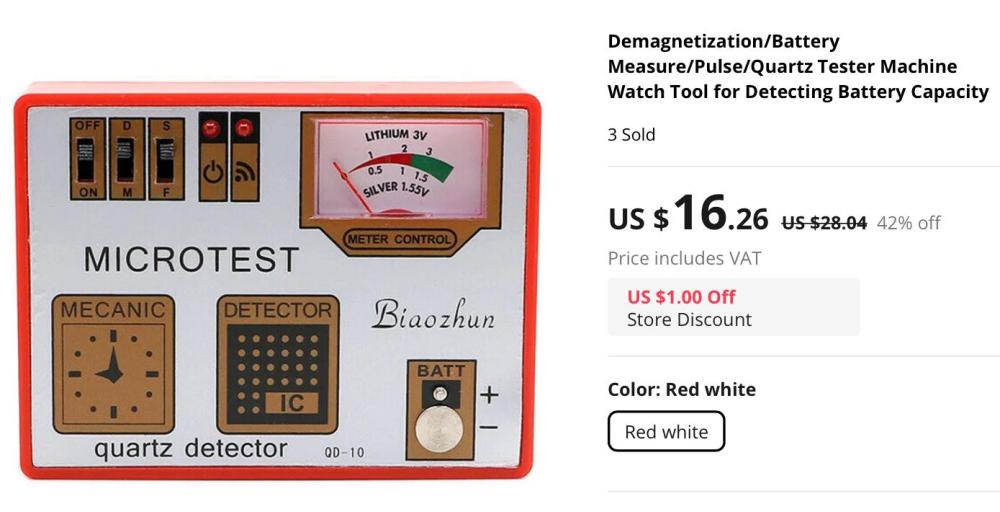

At first you should inspect the rotor with a loupe (see arrow). If it shows the slightest twitch every second there is a mechanical fault most likely. If not there might be an electrical issue. An affordable tool for this kind of diagnosis is this: If you have a watch demagnetizer handy you can use it for moving the train components and hands. If nothing moves the train of wheels got stuck.1 point

-

I assume you mean that your new jewel will not stay in the new hole securely? If that is the case and you can't close it up using the staking set and smoothing broaches (like you would with a barrel arbour hole) maybe you may need to enlarge the hole and insert a jewel with a larger OD (that has an interference fit with the new hole), but the same ID, this time using extra caution not to open the hole up too much. Slow and steady wins the race.1 point

-

I completely agree, i mentioned something way back on this thread about the variables in an experiment. The biggest being the experimenter's perception of the result, no one person is all right, no one person is all wrong. My quote was mostly just a quip, mostly. Some folk seem to have an air of tetchyness if they think they are being questioned . Hey everyone likes to think they are right, right ?1 point

-

I think that the controversy lies in the fact that watchmaking is a blend of art and a science/engineering, hence, there are some clear best practice's and others which are more personal or based upon experience, rather than hard science. To illustrate my point (pun intended) both da Vinci and van Gough painted good pictures, but went about it in their own way. Similarly, with watch repair some practice's are universal and others are more nuanced and personal. Cleaning jewels is a great example, we all know they need to be cleaned, and I myself use post-it notes after a soak in naphtha, then another soak. This is a practical and proven solution for me. However, this may not be the case for someone else, but arguing about it is as pointless as arguing if van Gough or da Vinci had the correct painting style. Just my opinion, I don't mean to 'fan the flames'1 point

-

found a tiny bit parts exist well sort of http://cgi.julesborel.com/cgi-bin/matcgi2?ref=STA_550A then in the bestfit book we get this image basically it's part of the Swiss movements except I don't think it is anymore. If you look at the parts list up above and you look descriptions plus look at the balance completes notice Seiko comes up. Plus the balance jewel assembly looks more like Japanese perhaps so I think it's an acquired brand by probably the Japanese. then I really wanted a much better picture found one and apparently can be purchased. So now we get a much better picture and we can compared to yours at least where the stud and the regulator are they look like they're about in the right place. https://www.ebay.com/itm/174802967828 then the timing machine results. Usually for things to be right visually the amplitude has to agree with whatever the timing machine says. Often times on timing machines if the amplitude is superlow timing machine reads the wrong part of the waveform gives you a much happier number. Then everything on the timing machine has to be functional in other words we should see numbers and I always get suspicious of zero's for instance the making wonder if it really is zero or something else? In the case of timing a really tiny watch getting at the fit in the movement holder can sometimes be problematic. then you really don't want to hold it in another holder to hold it in the timing machine Gazette can interfere with getting a clean signal. Because without a nice clean signal than everything becomes problematic. now I'm going to assume that the graphical display looked right for the numeric readings you are seeing? then reread all the other answers you got because everyone else gave excellent answers. Users scope to look very carefully at the balance and the hairspring. Make sure it looks flat it's in the regulator pins. Visually how does the amplitude luck yes I know that's why we got timing machine so we don't have to visually look. Also take all of the power off a look at the balance and hairspring look carefully make sure the hairspring isn't touching the regulator arms for instance.1 point

-

Excellent idea, and I look forward to it! It's going to be a new experience1 point

-

1 point

-

Was the watch behaving like this before the restoration? Check that the cannon pinion is seated fully and that the hour and minute wheel are engaged properly. If you remove the hands and advance the time, do you still feel the "snagging" feeling?1 point

-

Hi lookforward to hearing how you get on , remember just ask we are here tp help you over the hurdles.1 point

-

Hi. The way the movement comes out it through the front. Remove the bezel and the glass, You will have to make some small pry levers for hand removal. Put some polythene over the dial to protect it then using the levers gently pry off the hands. Once removed turn over the watch onto a soft pad to protect the fourth wheel extension for the sweep hand, after that remove the two case screws holding the movement into the case (two on the very edge) and the movement will push/drop out from there. At this stage. Check the movement for power and release the click controlling the rundown. Once done now you can dismantle the watch, balance first checking its pivots and jewels for breakages and damage. The watch is a nice one and we’ll worth reviving, its a three quarter plate movement.1 point

-

Usually problems with the hairspring result in low amplitude and faster rates. You say that adjusting the regulator doesn't change anything, which leads me to suspect that the hairspring has slipped out of the regulator. Check if this is the reason. And John says, we relish photos.1 point

-

Hi as Richard said ask for advise first,,!. You will hopfully be lucky that the movement was in a rundown state before you removed the plate as that’s where the click usually is. My advise is to refit the plate carefully not breaking the pivots and then remove the movement complete from the case. The clock on yours might be on the front plate but turning the movement out will displace the barrel if you don’t have the plate ON. Once you have the plate on and the movement out of the case you can start, let down the power ( if any left) remove the balance after checking that is spins in both directions with a puff of air. Removing plates as you have done could suddenly release the mainspring resulting in major damage, teeth off the wheels, broken pivots, the spring it’s self breaking, so if not sure please ask.1 point

-

Hello and welcome. I wish you had asked for advice before starting, the movement wanted removing from the case before removing the plate. I can't see the click, it should be visible once the movement is removed. If you open the other side of the case, the movement should come out. Send more pictures then. You have chosen a difficult movement to start on as it is a full plate.1 point

-

1 point

-

1 point

-

This little beauty arrived today! An Omega "tank" from thr 1930s. Cal 12.6 (or T12.6). I love it and its blued hands. It'll be a birthday present for my mother after I service it. It was supposed to cost 200 EUR - already a great price for such a piece, I find. But the seller admitted that it was running 30-40min fast per day. So we agreed on 160 EUR. Since I wanted to service it anyway, I was happy. Well, when winding it, I immediately felt that the mainspring must be broken. The obvious click-slip sound after every 2-3 turns of the crown. Well, I had already ordered a new mainspring anyway Then on the timegrapher... complete snowstorm. So I demagnetized it. And yes! that created some clear lines and at least some output on the Weishi. But running super slow now. When I looked at the regulator, I saw it positioned all the way to R/slow. The seller must have tried to compensate for the magnetism (making it run super fast). Sliding it back to a more neutral position, I was able to get some more horizontal lines. But still wavy. I will report back after the full service1 point

-

A West End Watch Co – Sowar Prima, Possibly with a Taubert & Fils. Case (I'm pretty certain it has their FB stamp inside), is on its way. I'm not sure of the caliber, possibly a FEF 190-1 I'm also uncertain about the age. The case looks as if it has been restored, or at the very least, slightly over polished. The mechanism looks to possibly be from the 1930s or 1940s. West End Watch were popular in India, but I picked this one up on Ebay in the UK for a bit of a bargain price. Not quite 404 club material, but only a few pennies north of that mark. These pictures from the listing are somewhat fuzzy, but hopefully if is genuine and looks to be in reasonable condition. At that price, almost inevitably, it does have a fault however, but when did that ever deter us?1 point

-

I could not resist this one and hope that it really looks as nice as in the pictures of the seller. I'm salivating over those blued hands. An Omega ref 730.17 from 1939 with the calibre T17 that was record breaking at the time for it's 60h power reserve. In fact, Omega took until 2006 (call 8500) to surpass this number. It has a nice 22mm (without crown) by 39mm (with lugs) size.1 point

-

go back to the homepage of this discussion group scroll down to the section titled WRT LOUNGE look at the various subcategories I think you'll find what you need there.1 point

-

Hopefully, Christian is well and not spending too much time working in isolation. That never bodes well for anyones mental health.1 point

-

I don't have a cleaning machine so I clean all the parts by hand with the use of little brushes. It is a very tedious job but I currently don't have any other solution. First I clean all the parts with lighter fluid, and after that, I rinse everything with rubbing alcohol (except the pallet fork and balance wheel). It is the old way of cleaning watch parts and I have had excellent results.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)