Leaderboard

Popular Content

Showing content with the highest reputation on 02/16/23 in all areas

-

Due to the persistence of some friends of mine, I finished making my first ever watch repair video. Talk about a learning curve! I have zero experience with filming, editing, etc., so this has been quite the undertaking. I wanted to make very detailed videos, so I made the first video (on a Seiko 6139-6005 'Pogue') solely about the disassembly process. It ended up being almost 28 minutes long, but I think it went into detail on some things that I hope someone out there will find useful. It's rough, lol, and you can tell my inexperience creating videos, but I think that the technical info is solid. It's been a fun process. I'll remember not to drink a bottle of Coke before filming the next one. Shaky hands at first, haha! I would really appreciate any feedback you may have. If there’s something I can do to make the video better either with filming, editing, or otherwise I would like to hear your thoughts. I am limited by only having one regular camera and a microscope camera, but I think it turned out OK considering my lack of experience. It really taught me to appreciate the quality of videos that Mark has created. I didn't realize just how much work was involved in creating something presentable. Kudos to him!2 points

-

Hi Probably just use a burnisher to smooth out any imperfections and maybe a small brass brush nothing too harsh.2 points

-

The screws used in Swiss watches (since the last 100 years or so?) are standardized, to NIHS norms. If you have a look at the Asco-Schurch catalog in the cutting tap section they show all the thread diameters and screw pitches (and tap drill sizes, really handy catalog). So if it's a Swiss watch, once you know the diameter, the pitch takes care of itself. I don't know about Japanese watches, and American stuff is all over the map. Antique stuff will often correspond to a Martin screwplate thread, which for the most part, in small sizes, tend to actually be quite close to the modern Swiss standard. Asco-Schurch2 points

-

If you have a tendency to lose springs, it will be a good idea to learn how to make your own springs. My mentor taught me to use guitar strings to fabricate my own springs. It takes a bit of practice but it has saved me hours of floorwork.2 points

-

I'll try that. I have a spare spring. These are a great idea, they come in 2 sizes, ok for tightening up a cannon pinion as well. They have curved shaped cutting ends that are easy to sharpen with a miniature drum sander in a dremel tool.2 points

-

Retired I.T. Director, likes to work with electronics (3-D printer) and Model Railroad (N scale, very small). I got hooked on some watch repair videos on YouTube, and my son, who has been an amateur watchmaker for several years, got me started with some tools and a few watches to work/learn with. I'm enjoying the change from electronics; and having worked as an apprentice machinist years ago, I'm awed and thrilled to be working on these mechanical masterpieces. I expect to post lots of questions here!1 point

-

EDIT: Sorry, didn't read your entire post. Thank you for the link, that is helpful to know. What if the watch is not Swiss and/or is it over 100 years old?1 point

-

Watch parts obey quantum mechanics, there's only a probability of them being anywhere.1 point

-

Haha yes it happens the moment you take your eyes off, the little buggers make a dash for it. I had two children like this so i grew a third eye in the back of my head. When i remember i place something over the springs location if i have to look away. How about creating a perimeter magnet field net with a series of magnets surrounding the bench's edge ?1 point

-

Wow, Looks so nicely fitted. I hate to risk with any future work.1 point

-

1 point

-

1 point

-

1 point

-

I use a Lulzbot Mini which I bought about five years ago. Have been very happy with it. Print ALL the time. It is a little pricey. I suggest you consider a Prusa. The product line is well received and is very economical.1 point

-

My son owns the printer, I just feed him the drawings and he works his magic. I'll see if I can get any advice from him and pass it along.1 point

-

___________________________ Update. Well, I had this collection of plate jewels (thanks Pop!). The closest one I had was a little bit larger diameter. I nudge the plate metal to get it to fit, but there is virtually no metal left to rub in. It is in snug now, but I dont trust it. Appealing to the horological gods for wisdom. Again...there is no downside since this is a donor...just hoping to learn and get another notch on my gun.1 point

-

My normal method. I removed the ratchet wheel. Saw the spring. Oh good! Ill pick up the peg wood. Spring. What spring!! Oh heck.1 point

-

1 point

-

1 point

-

As they're so fine, you can cut them many ways, I have - pliers, scored with a knife ,or fine file, and snapped. The main thing is secure it so it doesn't ping off. Something soft like Rodico stops it pinging off. I also recommend using Rodico when removing springs - stick a lump of Rodico on one end and lift with tweezers. The Rodico damps the "ping" and stops it flying.1 point

-

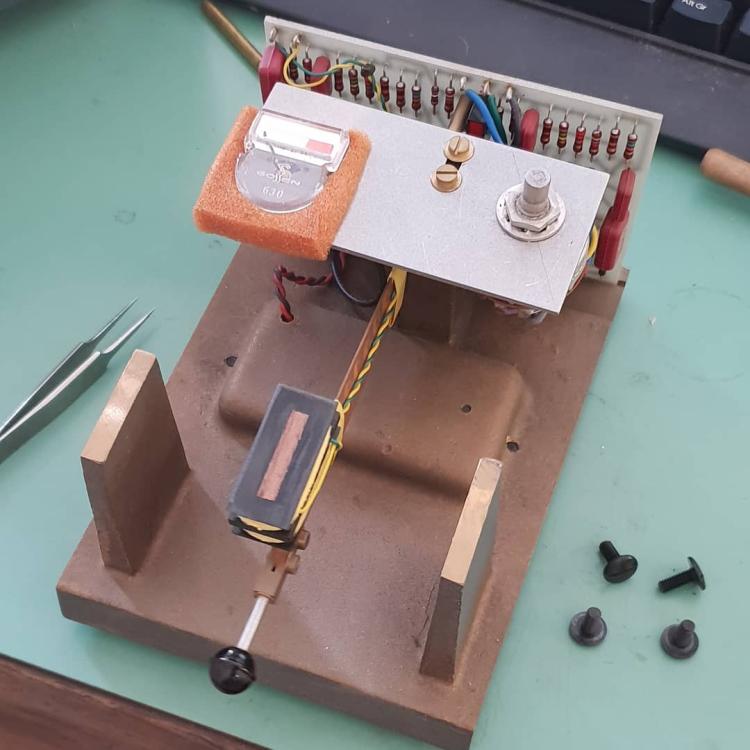

You are a microphone reminded me of something. The actual microphone parts where you put the watch I have one of those just not the rest of the unit. I used to like to buy surplus stuff surplus electronic stuff when we used to have surplus electronic stuff stores. I purchased something ones that had that microphone and to really big coils which thinking about it now it must've been for picking up magnetic fields or maybe it was for generating fields I don't remember I think the coil is buried someplace in the attic I'll never find it in the machine knows where that is it's probably been disassembled centuries ago. I basically just wanted it for the microphone. Then yes it's a bit odd that something like that would show up in Seattle. I have seen that app before and it looked very promising for detecting magnetism. I find myself that I don't really like smart phones I really enjoyed my flip phone because it could stay in my pocket off it was only for emergencies but the world forced me into a smart phone and android which is typically it's off. But when I got it I looked into's and found the one at the link below it also has a timing machine section but it wants me to plug in the sensor. I don't know if it's smart enough to know the difference between any USB sensor or whether it has to have its specific sensor. But the magnetic part does work when I bring it near anything that's a magnet it definitely response to that. https://play.google.com/store/apps/details?id=com.appnroll.accuracy1 point

-

Yes, I have a Magnotest, too and wonder how its old electronics still works fine. Its action is like a generator or a bicycle dynamo: a magnet passing a coil will generate a voltage. I used it to show that Nivarox hairsprings can be magnetized here. Frank1 point

-

Here is the .stl file for the movement holders, just change the file extension from .pdf to .stl MultiMovementHolder.pdf1 point

-

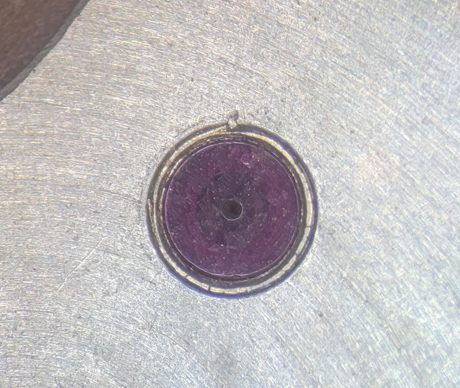

I've never really gotten the compass as a magnetism tester either, but I think it's a matter of knowing what you're looking at. As I understand, it's generally held over the balance, and you see the needle dancing if the watch is magnetized. Otherwise, back when the Magnomatic was designed Greiner also made the Magnotest, a really cool device that will detect any magnetism at all. It's so sensitive that even "fully demagnetized" steel , even a tiny steel hairspring, will register something at the high sensitivity level. There's a modern version, Magnotest II (not cheap of course), and a slightly cheaper one from Horotec, about 650 / 450 respectively at Cousins. The current Magnotest says in the manual to turn it on for 20 minutes before use; I imagine so that it zeros out to its environment or something?- but the old one, with it's massive bronze core, works instantly. You put the part on the window (where the dime is, dime for scale), then flick the lever at the bottom, which passes a coil back and forth under the part/watch. If there's magnetism the meter will indicate it, at level one it should remain motionless. Any magnetism will show as it rises toward the red. At level 2 it will register a little for any steel- I think it's to help see through thicker cases or something, but not sure. I'm sure Frank or Littlewatchshop can explain what's going on. B is battery check, for the 9v battery it runs on. Heaven forbid it get's left on, battery dies in a day or two!1 point

-

I've never seen somebody jump start a mechanical watch before. Have you got the polarity the right way round?1 point