Leaderboard

Popular Content

Showing content with the highest reputation on 01/06/23 in all areas

-

While I have not posted here in several years , I see some old friends. And from what I read, there is good representation worldwide with many solid answers and suggestions that make me rethink why I do some things the way I do. Thanks. Attached is paper I wrote a couple years ago for customers and people interested in pursuing precison timing but who do not the opposrtunites to attend a formal course. I would like to point out those who contibuted in the acknowldegements at the end of the paper. I hope you find it helpful. Regards, Dewey Clark 1941670032_WatchAdjustment.pdf4 points

-

There's just a novelty to being able to do this that is so cool. Plus i think ti's gorgeous. All oem seiko parts i got for practically nothing here and there when I saw them. Movement is another 7s26 from parts from a handful of my donor/junk movements. Slightly used dial, new case i got for 25 dollars and some beat up old hands i had to do a little work on.3 points

-

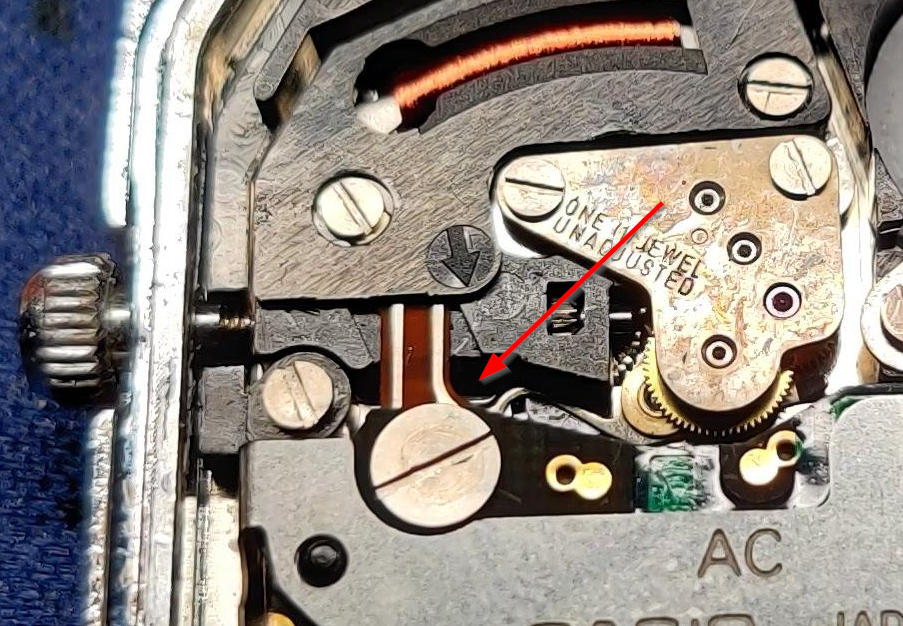

Thank you I didn't want to feel stupid by asking what impulse jewel is. Here's a question what if we were talking about o'clock would that change the answer? Now you have to go into the clock section and ask what's the difference between a lever escapement o'clock and in a watch or I might be nice and answer the question below but clock people do oil the impulse pin in their clocks especially if it's brass or maybe steal I can't remember it typically don't oil the jewels but maybe they do some clocks they seem to put a heck of a lot oil on them. One of the problems we have with rules on lubrication is they will date back to organic lubricants where as they go bad they can get sticky and sticky like pallet fork pivots that are sticky that's bad sticky roller jewel's very bad but what about modern oils they don't get sticky? Even make oils for my quartz watches where the wheels have to revolve superfast when there engaged seems like they might be good for the pallet fork pivots? Epilam on the pallet fork? Even going back to the 50s for Omega they recommended not treating the pallet fork at all because they were concerned about the pallet fork sticking to the banking pins. I'm snipping out the page on epilam from 1957 you'll see the recommendation and why sticky. But also notice other things they recommend not treating like the basically the entire pallet fork. Then of course they recommend the balance pivots which is what eta has been doing for years on their watches you just typically don't see it you have to look at the manufacturing information sheets because it's not normally in the technical documentation. Then yes there is a big debate at least with the older versions of epilam where the solvent evaporates incredibly fast and causes a cooling effect that causes moisture in the air and rust. I've also heard a suggestion that the moisture could get trapped under the epilam when it's busy cooling I'm not sure how true that was but we both seen pictures somebody posted of rusty roller jewel's claiming it was the condensation formed when it cooled. Except the new epilam is supposed to be environmentally friendly and that's not supposed to happen. Then for clock people a lot of times there pallet fork is made out of brass. Then instead of having a nice Ruby jewel they have a brass pin and apparently it's better if that is oil as otherwise brass on brass they claim is sticky. At least that's what the clock people claim.3 points

-

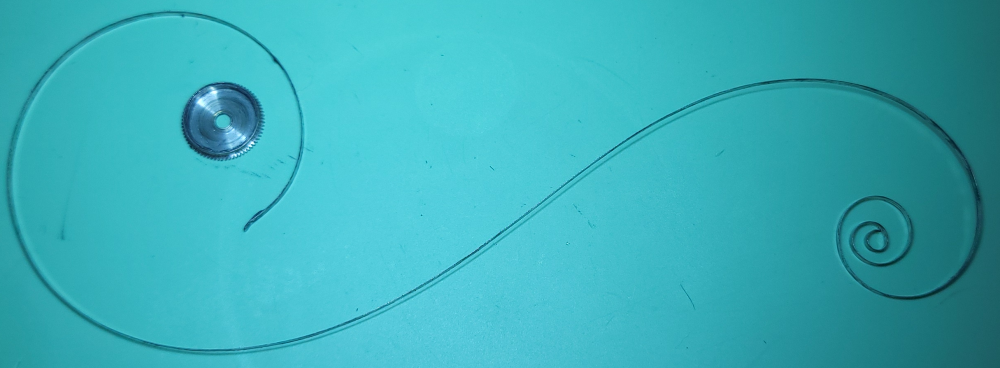

Proper cleaning using ultrasonic and L and R ammoniated cleaner and rinse. Followed with hairspring cleaning and demagnetisation in Essence of Renata. I put a bit of that in the Renata screw cap with the balance and hold over the demagnetiser for 20 seconds or so that agitates the hairspring in the fluid. Seems to work well. I did initially have sticky hairspring outer coil that was causing ultra fast rate when the amplitude went over 310 degrees (which happens on wrist at full wind). That would cause sudden random shifts in time keeping. Remove wear from barrel arbor port (with staking set and smoothing broach). Chronoglide call this 'Hammer Time', I love that. Make hairspring true in the round and in the flat with proper shaped end curve. Narrow the space between the regulator curb pin and boot so that vertical position rate doesn't drop drastically due to the reduced amplitude. Then just regulate at around +2 SPD DU as a starting point and cross fingers. Fine regulation is difficult and I find the tiniest movement of the regulator arm can change the rate by about 7 seconds. Really though if you want to see how the Pros work then take a look at the Chronoglide channel, I promise you will be hooked.3 points

-

We were taught in school to never oil the impulse jewel, and I never have. There is some debate over what effect epilame would have on a fork slot to impulse jewel, and I have seen pics of rust there attributed to the fork slot being epilamed. But it was taught for a long time to epilame the entire fork, and many still do this, apparently with no ill effect. One possible explanation for the rusty fork slot (rust being where it contacts the impulse jewel) was that the fork wasn't allowed to dry in warm air after epilaming; this could cause condensation to form, initiating the rust. To be safe I just epilame the pallet jewels. Of note- it's also a no-no to oil the teeth and impulse jewel in a chronometer (detent) escapement, where the escape wheel delivers impulse directly to the roller. I have seen cases where those were oiled, and in every one there was excessive wear on the teeth. There is a tiny bit of sliding when the tooth gives impulse, but it has always been considered one of the best escapements of all time in part because it works fantastically without oil, and the variables oil there can induce over time are eliminated. Other pieces I've seen that weren't oiled have been in perfect condition after a century or more of use. So I tend to listen to the collective wisdom taught in books and schools, no oil on fork slot/impulse jewel, no oil on chronometer escape teeth. Oil on the fork pivots is a matter of choice, the only down side I see is a potential drop in amplitude, and the drop increasing over time as the oil degrades.3 points

-

I printed this up over the weekend and got a chance to sit & try it out a couple times now. I knew I needed something, but holy cow, it really helps me find what I need easily and keeps me way more organized while I'm working... Duh. Also, behold the dirt cheap collection of (mostly) junky tools this beginner is working with here! The screwdrivers are better than they look. I have some titanium rod and I was thinking of machining my own screwdrivers from some of that, just to be different. I figure just delrin for the heads, which seems common. Anyways, I'm guessing most of these tools will be upgraded over time, but enough about the future. This uses a lot of plastic and of course it fits my tools and maybe not yours, but I uploaded a "step" file in case you know how to customize it for yourself. Yeah, tool blocks baby! We expect them for our screwdrivers, why not everything else? https://www.thingiverse.com/thing:57618302 points

-

Seiko 7005-8042 April 1972 Revisited this watch 2 and a half years after I first serviced it. Never ran as well as I wanted it to with poor amplitude and timekeeping. With the extra experience I've gained over that time I have managed to get it running really well. Running consistently in wear between +0.5 and + 1 second per day. Dial up/down amplitude 280 degrees 1 hour after fully wound. Not bad for a 50 year old Seiko. Thanks must go to Kalle at Chronoglide watchmakers for all his great teaching via his YouTube channel. If you've not seen this then it is wholeheartedly recommended, especially the live streams every Tuesday at 8pm.2 points

-

2 points

-

Here's the bulova 23 model history I referenced above (source: NAWCC 2010 Bulletin Authored by Bruce Shawkey). Bulova 23 History.pdf I normally don't take out the bridle--I just soak the barrel in napha and clean with a soft paint brush before putting into ultrasonic. Like I said, whichever one of the cases/movements you decide to not to use as a whole I'll take dibs. Jay2 points

-

Some more testing and progress. I've typically aligned the top of the basket with the top of the heating chamber and ran it for about 5 minutes or less. Never had any issues running the ABS plastic that way. I tried pushing it deep into the heating chamber. This time it melted pretty good. I took some more measurements, and it looks like it can get to 100C in there. So conclusions: 1) If using ABS don't put it deep into the chamber. It's plenty warm enough to evaporate any IPA even if it's not all the way in. 2) Ideal is to print with even higher temp materials. That's what the photo is. The black basket on the right is printed from Nylon w/carbon fiber. Should be able to withstand 160c. Also made the basket a bit shorter since I'm using 1/2 baskets now. Happy new year!2 points

-

Having had a few drinks with family this past Christmas and discussing Ali Express watches, I drunkenly made a bank breaking purchase of an $8 fashion watch because dagnabbit the thing is hilarious. This.. item.. has inspired me to start this thread, which is a dedication to ugly watches. It's a Binbond (I thought it said Binbono at first) quartz movement in a timeless stainless finish. The bracelet is chintzy and cheap feeling, and the watch itself whilst being the size of a dinner plate is next to inscrutable when it comes to actually telling the time. It is a conversation starter much in the same way a bin fire on your street might be. I have absolutely no idea when I might wear this thing in public, but I know for certain I would never wear it if visiting a circus as I would likely be mistaken for a clown. 11/10 amazing timepiece. Got an ugly watch in your collection or seen something online that burned itself into your retinas? Post em up!1 point

-

That is actually an excellent press and most of the negative reviews are from people who have not actually used one. You can tell that because the most common complaints are the the L bracket and the two uprights bend under pressure, and once you get one you realise that no mere mortal is going to be able to bend either part, they are just too thick to bend. And yes the L Bracket is like that for the watches bracelet to slide under.1 point

-

Hi LWS you are a brave man, but I bet if you do it will be the one time the wife checks the bills. anyway its out of stock, now does that mean they dont sell many or have they sold out of what they had or are they order only ? Hell you only die once and if she misses you have another chance.1 point

-

Having a hard time getting my head around that but glad you made it work. Typically one would use rodico for something like this. When I am installing a bridge, I always install the screws into their holes but do not tighten them in. This stabilizes the bridge. Then I use a piece of pegwood (tooth pick I suppose) to gently press down on the bridge as I gentle nudge the wheels in place. I am not a professional, but this method has consistently worked for me.1 point

-

We started discussing it some time ago but it fizzled out - see this thread: JohnR725's clear advice was to not oil, but didn't expand on the reasons.1 point

-

Hi, VW, Mike , I do oil the impulse jewel, but a wee wee bit. Have heard the same arguement as to why not as you would for not oiling fork pivots, ie; doesn't engage much , only works for a short period, doesn't stay on the jewel and accumulates where it does no good......etc.. Most of its downside might not hold true if epioamed only. You gents have tg and epilame, so its upon you to try epilame only and observe its short term effect. Rgds1 point

-

I did somthing similar using Mahogany with two turn tables for the tools and some holes around the edge for odds and ends not really pretty but practical. Also did an oil station as well using contact lens capsules.1 point

-

Hi. Not exactly a classic and not somthing I like but It may be some ones pride and joy some day. Maybe.1 point

-

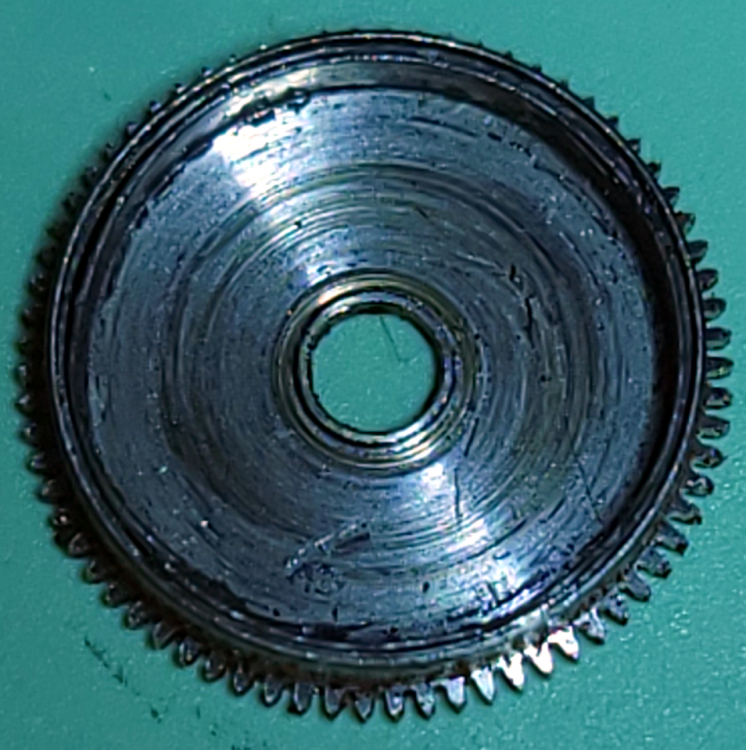

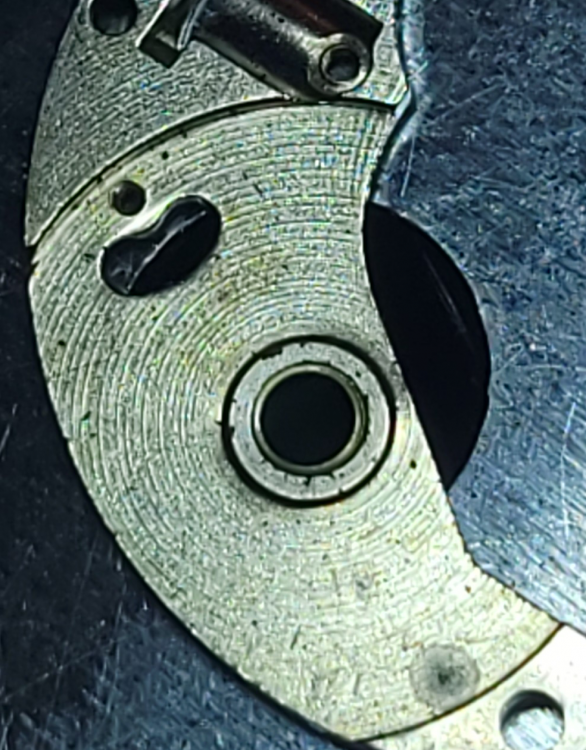

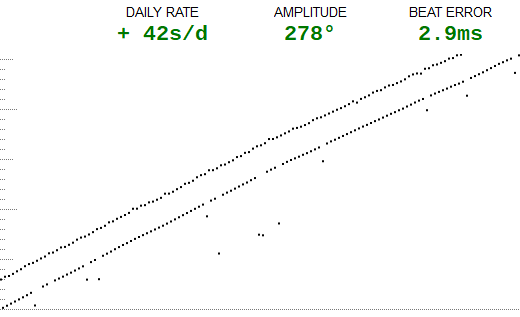

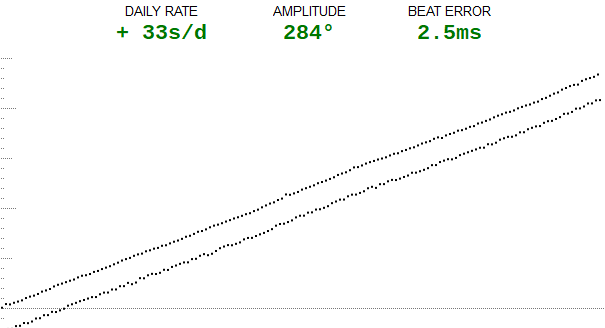

The mainspring looks good to me. It does have a detached bridle. I've had trouble getting detached bridles back into the barrel in the past so I'm a little hesitant to pull it out, but I suppose it does need to be taken out to be cleaned properly. Here's the hole in the barrel bridge. It does seem to have been sleeved, whether from the factory or not--I'll have to open the other one and see. Do you think closing it up with a rounded stake will still work here? Top: Bottom: Well, to my surprise, the watch on the right with the yellow dial started right up and runs strongly. Dial up and dial down: There's almost no play in the barrel bridge. It does look like that bearing sleeve is from the factory: Looks like instead of a parts movement, I've got a fine working one! Maybe I'll swap the nicer dial onto this movement. We'll see how the other one comes out.1 point

-

1 point

-

Mikepilk!!!! Eureka,I removed it!!! I used the razorblade method you recommended! I followed your instructions. I inserted the razorblade at one point and slowly worked it around one half of the case (boy was there a lot of gunk -60 years worth, lol) and it popped off! I was nervous, my wife thought I was crazy standing at the window wearing a loupe (to minimize any scratching if any at all) with a razorblade in my hand, lol! Thank you for walking me through this procedure!!! After further inspection it seems that there is no real gap, so patience is required and gunk does not help, lol.1 point

-

1 point

-

1 point

-

Good news! I just heard back from "perplxr" with the following message: "Hi, we are working on that. Please stay posted for further information about our videos - we are currently revamping our social media. Thank you so much for your interest and concern!"1 point

-

Hi watch repairer people, I've just inherited these two watches from an elderly family member and I really don't know how to go about identifying them - apart from the main makers marks? Could any kind soul shed some light on either of these lovely timepieces and maybe an indicator of resale prices? (I have no other information apart from the fact that my elderly family member is VERY old and they received them from someone who is ancient :-) Regards Steve1 point

-

Boy, did I ever get lucky! I went back to a local antique mall (more of a flea market, really) early this morning to buy something I'd seen several days ago. And it was still there! And this time, I had money! A Girard Perregaux Gyromatic. Not running, so they weren't asking much. I bought it and went straight home to my bench. Cleaned, inspected, oiled, regulated, and now it runs quite nicely. Fitted with a nice patent leather strap, and I've been wearing it this evening. I often turn about and sell many of the watches I rescue and repair, but not this one. Not this time. I took a liking to it rather quickly. Addendum: it has a 17j GP 21.19 plated with gold. It's a jem to look at. And a 14k gf case which took a nice polish. The original crystal is not too terrible at all, so I'm thinking of leaving it on.1 point