Leaderboard

Popular Content

Showing content with the highest reputation on 10/13/22 in all areas

-

Cousins has them, they are listed as clock pins. You will want to get a few sizes, probably the 3 smallest ones. https://www.cousinsuk.com/product/brass-clock-pins-by-size2 points

-

did you know a very long time ago dials didn't have screws to hold them in. The dial flood came up into the plate and a tapered pin was shoved in a hole in the foot. Often times a pain to get out and sometimes had to be replaced as are in really bad condition. Then the miracle of dial screws but not all dials have screws. Modern dials have other things like this watch. sometimes if you have the service bulletin or even the parts listing get a clue bike the PDF attached which was found at the link below then an image your image notice I circled something I wonder what that is? I did manage to find you an image it really sucks but on the sides the things that I circled in your image you'll notice a little not she push on the notch it's a pivoted lever basically it will slide out or you can read the description of the pictures civet sounds better than what I'm saying they case the thing as to rotate worst case you can't figure it out just take the watch apart with the dial in place you'll see them once you see how they work the really easy. There are very common method on modern watches so they don't have to have screws are a lot simpler to make https://www.cousinsuk.com/document/search?SearchString=6922 3804_Longines 6902-6972_Smaller.pdf2 points

-

I would clean everything by hand. Spray down everything with WD40 and leave it overnight. Then take everything apart abd clean off all the rust with a wire brush. The headstock and cross slide would probably need the most care. Don't go crazy with cleaning or you'll lose the tight tolerances. There have been a lot of nice lathes on eBay recently. I mean complete sets, with all the accessories and in a wooden case.2 points

-

Hi when you look at the front of the clock the lever at the top right (the one with the hole) when you lift it does it release the rack and cycle the strike. Its a substantial clock going by the plates and the chime barrel. If you can get you hands on a copy of De Carles book Clock and Watch repairing Chapter VIII gives a detailed description of the workings and several warnings regarding the power held in the fusee spring which is enough to break fingers so be very careful I have attached some of the information from the book for you . Scan.pdf 1.pdf Scan2.pdf1 point

-

if they have assorted sizes sometimes that helps because they don't always seem to be exactly some size. This is where access to a lathe is nice because sometimes you have to make the pins.1 point

-

the problem is you're looking for a bolt let's see what the Internet says a bolt is so you can see a bolt is another name for screw except that's not what you're looking for you're never going to see this picture is really clear and the thing that I circled is really clear but you're still looking for something that looks like a screw and that means you're never going to find it. now I snipped out another image for you from your picture. Look at your pictures you have two of them out a snipped out the other one. The other two mystery items don't you what are they? Now in the image I snipped out below I have an arrow pointing at something all you have to do is wish right where they arrow is and you release your dial flight you'll need to do it on the other side. If you don't believe may just take the plates apart you'll build the see them much better you take the plates off still definitely be visible. then they're not always push type like this some of me have to pull out but with the picture I gave before it clearly shows pushing not unscrewing the bolt. okay I had another thought let's go to the tech sheet notice the parts cross reference we know the part is called a dial bolt so let's see what it is and will get a part number. according to the parts reference it should be part number 934. Then if you look at the pictures we see 934 which looks really weird doesn't it? As you see it does not match the description of the dictionary of what a bolt is at all other than it's used to hold the dial on. So it is a fastening device it just isn't a circular thing with threats. It snaps on a post in the center which you can see in the picture below and it rotates if you push on it. One direction pushes and releases the other direction pushes and holds. But if still confused just take the watch a part it should become very obvious one holds the dial on https://fastenerengineering.com/what-is-a-bolt/1 point

-

I've found that jumping in at around five seconds out can sometimes work. It can stop anyone upping their maximum bid at the end.1 point

-

I can program though. Signed up for the eBay Developers Program now, will see if there's any interesting API endpoints that can be... leveraged...1 point

-

Hi to everyone, I've been reading a lot from this forum for a while now and find this place very useful and informative. As I now have questions of my own I thought it would be a good time to join. Hopefully in time I too can make some valuable contributions.1 point

-

1 point

-

This is one of those massive clock movements, extremely well made many are English. Winterhalder & Hofmeier also made many like this but there is a difference. From the photo I would say this is English. The self correct is not working as it should. The best way to find the trouble is to remove the chiming levers and check all parts. Have you had it apart and now it is causing problems? Any signs of wear on the chiming side? if no then you need to build the chime side and watch the way it works. It takes a lot for a movement like this to miss behave. As its out of its case I would give it a good once over of the complete movement. I would like to see the chime side of the movement between plates.1 point

-

Hi Could you provide some pictures of the back and sides, I think its a Junghans clock but need a bit more information thanks1 point

-

Just thought some of you may be interested in an old Italian watchmakers shop and workshop. He was very shy ( bless him ) spoke no English at all, but was happy for me to take a few photos. Some may not be great as I was using an old crappy phone. I would have bought something but his clocks were around 3 grand, I think he mostly customer repaired and was working on a huge fusee pocket watch wearing a loupe, a pair of tweezers in one hand and the watch in the other hand. I couldn't see a microscope anywhere in his workshop, but then didn't see any wristwatches either. But he did have a multi watch winder so maybe repaired but didn't sell them. He had loads of old tools on display, here are a few.1 point

-

This guy looks like he knows how to make stuff. Nice little table top milling machine there, and I see the end of a Schaublin 102 lathe bed just behind it. Love the display case with all the antique tools!1 point

-

I agree with Hector. This is one area where WD40 is actually one of the best things (or any "penetrating oil" in a can); it doesn't remove rust but the solvents in it really help when going at the parts. I would use a wire brush (hand held) to get the big stuff off, then go at it with steel wool and WD40- keep it wet. I would avoid all abrasives, pretty much period. Levin made easily the best slide rests of any of the makers. Some were chrome plated (really old ones in particular), some nickel plated (yours looks like that), some no plating. If the plating is flaking or worn here or there just clean it up and leave it, don't try re-plating. Yours is inch, which would be a killer for me now as my brain has turned full metric, but is not too hard to get used to. I used to work at a place with two Schaublin lathes, one inch, one metric, and switched between them no problem, haha. I would imagine from the pics that the actual tailstock quill and bore are in good shape, same for the headstock bearings. If so, that's a big bullet dodged. It looks like the bad rust is near the drawbar knob on both. When you get into the slide rest you'll need a really complete set of inch hex keys, good quality. There are at least 3 different sized screws from the cranks to the gib adjustment to the others, and they used really odd sizes not necessarily in basic sets. From memory there are brass pieces between the gib screws and the gibs, with tapered faces to match the gib- don't lose them! This is a pretty late model, so there will be ball bearings in the crank barrels. Don't muck around trying to change them- just clean them up and grease them, and check on disassembly if there are any shims and get those back in as they were. The bearings are normal deep groove, but are setup with preload like angular contacts to eliminate slop there. Great design (Schaublin does the same). As it cleans up you'll recognize the quality difference between it and something like a Peerless... these things are nice.1 point

-

1 point

-

No worries mate, enjoy Rome! Lovely there when it's not 35 C. yup I might attempt to straighten the post at some point but to be fair at this point she's a donor.1 point

-

This is an extremely difficult procedure. Unless it's an expensive, signed crown, I wouldn't do it. You'll need a microscope, old oilers and acetone. The crown has to soak in acetone until the gasket softens into a black gooey mess, then use the oilers to scoop out the goo. Repeat several times until it looks ckean. As the oiler is carbon steel, the gasket seat always gets scratched up and I wonder if it can give a proper seal after that. I've tried cutting off the washer, intending to replace it with a new one, but the lip that holds the washer in always breaks when burnishing to flare it open. I wonder if other members have had better luck with this?1 point

-

My kind of timepiece!! very nice… we’re up to three in our house- the one I wore today, the new one my wife wanted, and one waiting for me go get the nerve to dive in… Based on your pics it could be tough call on the case if the dial is great. Wait till you get the scuzz of I’d reckon…1 point

-

Because it's a premium mov.t, it's thinner than common others and can command an higher price. You can use the ST18 for complete replacement, but it's kind of expensive too. There is no guarantee that any part, even if visually similar, will directly swap. Beside, no parts are available for Chinese mov.ts. https://www.cousinsuk.com/product/3-hands-seagull#1 point

-

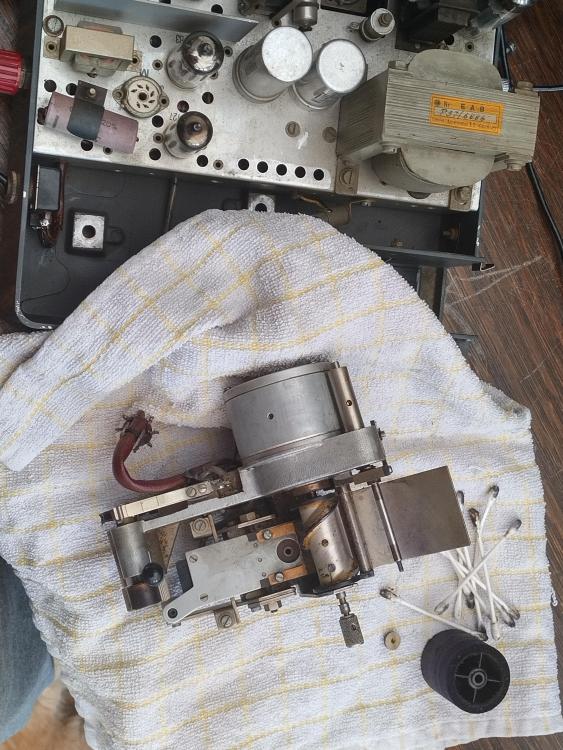

Just when you think your and done...and then... I got another sweep second, broached it, fitted it and installed a new crystal. Then it stopped. Decided it must be the sweep second hitting the inside of the crystal so I shaped it to fit better. No luck. Strange behavior. Seemed to run face down but when I put it in the case it quit. The nature of the quitting was interesting. The locking jewel of the pallet fork was hitting--face on--the tooth of the escape wheel. Was the fork bent? Was a pivot bent. Escape wheel pivot bent? All possible. I removed them all and put them on my poising tool. Maybe, just maybe there was a slight issue with the the escape wheel but could not imagine it being the problem. I had another escape wheel from a donor (which will open up a new can of worms below). I could not see any issue with the pallet fork. I inspected everything under high magnification (40x). All pivots looked fine and polished (i.e., no broken pivots). Put it back together and still having this issue. I had another balance assemble from the donor. Installed it. No change. Still locked up. My theory at this point was that the fourth wheel and the escape wheel were not meshing perfectly at some angle. I looked at the fourth wheel and could not observe an issue. OK...I have a fourth wheel from the donor...installed it. The watch seems to be running properly now, but I am not satisfied. I still need to find the root cause. Gonna take a careful look at the fourth wheel when I get some distance between me and this ordeal. During this process, I noticed that the alarm spring was slipping!! Grrrrrrr!!! It was work...I am sure! This required another tear down to get to the alarm spring. When I removed it there was a reverse kink in it. HOW COULD THIS BE??? Did I do it during the original clean?? No way! I have K&D winders and I know how to use them. Did this barrel get swapped with the donor barrel??? I don't know, but I got the donor barrel and removed the spring and went ahead and cleaned it to be sure. Installed and it is working. So, yesterday was a bad day...well...frustrating is more precise. I love solving problems and, fortunately, this problem transitioned from headache to research (which is just an emotional mental transition). Am I done? Dunno. Watching the watch carefully on the bench. Soon I will put a strap on it and wear it--the acid test. I am working on the Seth Thomas Electric marvel clock today...lol...what adventure lies ahead?1 point

.thumb.jpg.1c99a7476966ab050fc81eae8685d8fe.jpg)

.thumb.jpg.9926a38c71fbf05ea423acf5de580dab.jpg)