Leaderboard

Popular Content

Showing content with the highest reputation on 08/18/22 in Posts

-

5 points

-

Ulatrasonics have been used for watch movement cleaning for more than 60 years. I have no idea why Chronoglide says not to use it. I know he shows the aluminum foil test at some point, where the US will perforate the foil if properly powerful- in 25 years of only using ultrasonic machines I have never seen damage and never heard of damage from the many watchmakers I know. The Watchmaster cleaning machines were only ultrasonic, no agitation, and my old Greiner Ultrason U2 is ultrasonic, no agitation, and uses isopropyl alcohol as the rinse for the water based cleaner that machine uses. Lititz Precision Products makes a professional modern version of the Watchmaster (their Matador machine) currently. Isopropyl will dissolve shellac, in time. In a minute or two it won't. Water based cleaners will not rust steel parts (someone will say they do), as long as they are rinsed and dried correctly. Drying parts cleaned/rinsed in solvent based cleaner in room temperature air can easily cause rust, due to condensation on the parts as they cool from evaporation.3 points

-

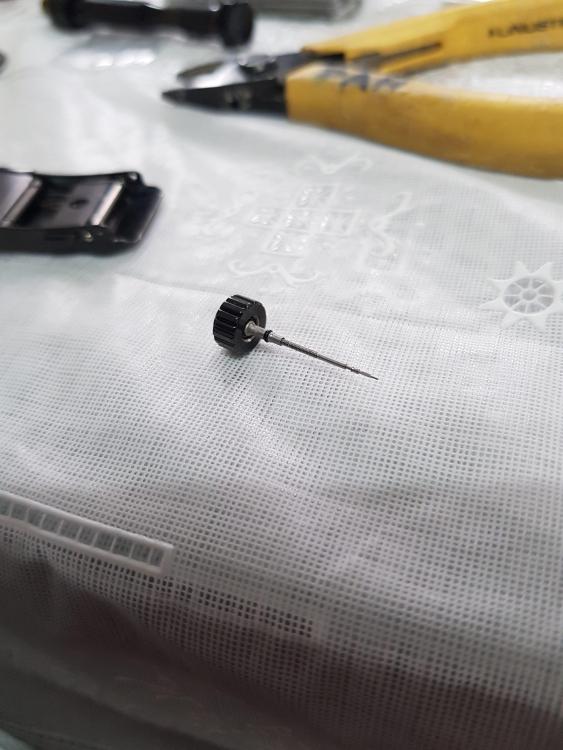

I recently purchased a watch off eBay with broken stem I have cleaned and then dissolved stem in alum powder and replaced with new stem movement is e168 so stem not to hard to find hope you enjoy the pics Watch back with broken stem dissolving stem in alum powder mixed with water put this jam jar in pan of boiling water on cooker ring and 10 hours later over 2 days you get a crown minus stem if crown is stainless steel. Old stem and new stem next to nice clean crown and clean crown crown with new stem cut to length and tested the loctite thread seal used and seals put back . case back cleaned and seal lubed. The watch was cleaned in ultrasonic bath before reassembly. watch all back together happy happy hope you enjoyed2 points

-

Here is a bunch of pictures of one of my recent "ebay barrel scraping" purchases. A Swiss/German "Gallone" style cylinder escapement 80% silver cased pocket watch. At a purchase price of a fiver, it doesn't quite make it in to the 404 club, but maybe we can give it honorary membership. The lack of other bidders was presumably due to the poor condition of the watch, and the fact that it didn't run. The case has a small crack in it, which I may fix at some stage with low temp silver solder and a small patch, however someone has attempted a repair with what appears to be lead based solder, so that may complicate things slightly. The "Gallone" style as far as I understand it refers to the rose gold plating over silver that would originally have adorned the front bezel of the case, some of which is still visible. Inside, while there is no obvious makers mark, there is in addition to the "Gallone" stamp, a German "Moon and Crown" silver designation and a more typical Swiss "0,800 Silber" hallmark. The watch may therefore have originally been sold in Germany, although the stamp also appears on watches exported to other places. The main reason that it refused to run or wind was that the movement retaining screw had fallen out, and jammed itself into the gap around the mainspring barrel, wedging everything solid. Once that was removed and re-fitted things started to tick, all be it somewhat sluggishly, so a quick clean and rebuild was all that was required to get it running within +/- 30 seconds a day or thereabouts.2 points

-

Make sure if its really the balance staff that is the issue. First observe the staff as you wobble it, if the staff doesn't move then the issue is the balance rim is loose on the staff, this can be corrected by re-staking if the hole in the balance is not distorted too badly. Also the wobble may be simply a balance wheel not being level and it shows up as a wobble when it spins. Do not attempt to straighten it with the balance installed, the pivots will break. The balance-spring and roller plate needs to be removed and the staff re-staked. If the balance wheel and staff are solidly affixed, next observe the amount of endplay (ie up down). On its own, too much endshake would not contribute to wobble (as the pivots are a close fit into the hole) unless the pivots or jewels are damaged. Close inspection here will identify which pivot is the problem. Do this inspection dial up and dial down. Next dismount the balance and inspect the pivots. You may find on pivot shorter than the other.. the shorter one is the broken one. If both pivots look ok (post pictures here for comments) then the depth of the jewels could have shifted. This is rare but happens, especially on older watches where the jewel holes were hand-drilled. Reinstall the balance and balance jewels and inspect the roller jewel and its interface with the pallet fork. lift the balance up against the upper (balance cock side) jewel and see if the roller jewel still fits in the pallet fork. If it does then you can try to push the lower jewel (mainplate side) up a bit with a right size bit of rod. (note if the jewel is already flush on the side that faces the balance this will not work. Related to the jewel spacing, check if the balance cock is level with the main plate as this will affect the endplay and if too great the balance may wobble as well. Good luck. Anilv2 points

-

Haven't found the yoke spring yet. Had ordered a pack of assorted shepherd springs from Cousins so maybe I can subsitute one of them when the order finally leaves UPS purgatory, returns to Cousins, then to me. Didn't clean or oil anything. Only manipulated the various parts, learning the different screw types, and how each wheel is oriented in its jewel, how they fit together and spin. Pretty easy to identify each part, even each screw type. Just put it together, sans yoke spring. Getting the setting lever back on its screw took a few attempts. Learned that two hands are necessary when putting bridges back on. Was anxious about damaging the balance but it slipped right in and sprung to life when the bridge was nudged into place. Seeing that balance wheel spring to life was quite a thrill!2 points

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

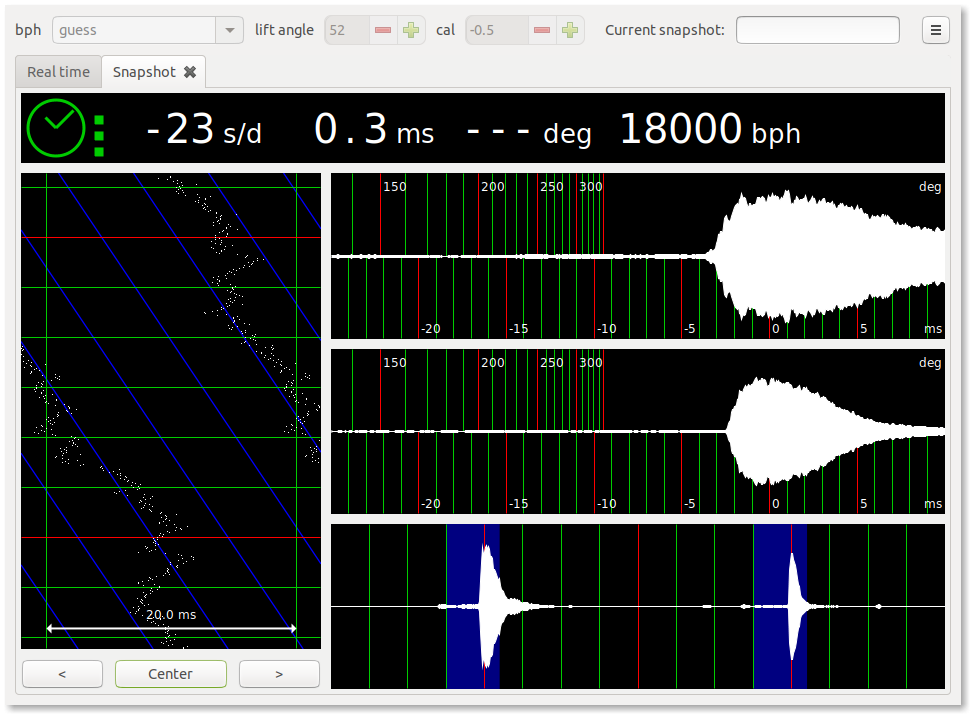

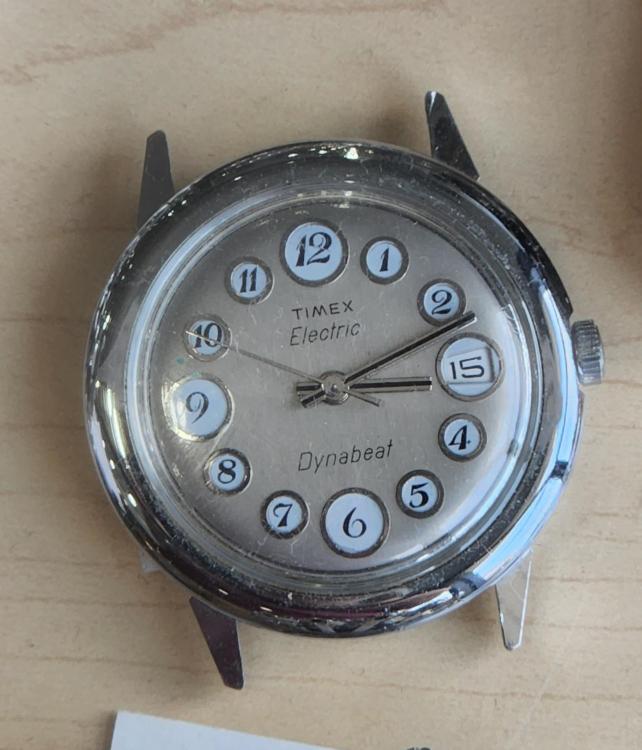

I have a Timex Dynabeat that requires some work. I've had the watch for a bit and the watch has been acting up lately. It developed a loud ticking noise when the dial is face up. When it is placed face down the noise goes away. Plus it will stop randomly from time to time. Although a shake will get it running again. I've taken the watch to a couple of watchmakers near my area. They all said it needs to be serviced but they didn't want to work on it. What are my options as far as getting it serviced? If anyone can point me to someone who can help me out that would be great. Thank you.1 point

-

this is where on a practice watch acquired cheap where you make a decision as to how far you want to go. Also as a practice watch have you been practicing with it? Like how many times have you taken apart and put it back together how good are you at putting it together without breaking the pivots off. When people learn watch repair at least in school they practice a lot at doing tasks they don't just do a one time it's done multiple of times. If you decide that replacing the staff and actually making this watch run is almost impossible it still has value as a watch to practice taking apart putting back together and getting familiar with everything. It's also a good lesson to learn that unfortunately every single watch cannot be restored and made the run again at least not in a practical sense.1 point

-

Sound advice WW. If the staff is ok then besides wanting to identify the movement for curiosity then possibly not necessarily worth the effort. I did manage to download the bestfits from the forum but not through old hippy's mediafire post though. Someone else had posted a link to another download, took me a while. Maybe just worth buying it, i think its a tenner. I do enjoy your input John. You always make great logical sense with your advice that folk can learn from Good positive approach to watch repair charette. Learn from every project regardless of the outcome. If it runs then thats a bonus.1 point

-

brunomartins, Thanks for kicking this back into the conversation. I had previously missed this. I have saved it as a link and will print this off as a PDF and paper copy once back at work. Thanks to Karimn51 for the effort as well. Shane1 point

-

I will try to get some photos of the staff later this evening. I was finding it hard to get the lower pivot through the spring on the microscope, but was pretty sure the top pivot was shorter, had an odd angle like it was snapped off. The case is only a base metal, nothing fancy. Indeed, this was was just meant as a practice and was acquired for very little. It has been a fun process regardless if I can get it to run again.1 point

-

the only problem with the bestfit books are the only cover a specific time spanned and even over that time span they do not cover every single watch. I looked in a different book that goes back much farther and does have some stems like this one as in other words the lack of a stamp and I saw zero reference to this watch which is not unexpected there were a heck of a lot of watches of this type made that there is no identification for this means of the absolutely had to have a staff you have to take it out disassemble measure everything and we do a search to see if we can find a staff if you're really lucky we would find one. Or the likely we might find one that's close and with your lathe that typically people new to watch repair don't have because they become expensive with all the bits and pieces and they require skill set. But if you had the lathe you could either modify existing staff or just make a new one which would solve your problem. But if you still have pivots on that staff then we should find out what the problem really is as opposed to attempting to replace the staff with very likely a custom-made staff either you will spend the hundreds probably thousands of dollars to acquire the tools or you could send it out to have some a custom make staff which is definitely not justified for a watch of this quality unless this was some family heirloom where money is no object.1 point

-

Hi In the absence of any numbers of any kind or makers mark/logo its an up hill task to identify the movement . The bestfit books were put on the site by Old Hippy using "mediafire.com" as he owned them there was no breach of copyright and could be downloaded. In the search box type "mediafire.com" in quotes and it will give you all the instances of the term. I have just checked and they are still there. Unfortunatly the Pocketwatchdatabase.com will not be of any use as it requires serial numbers.. I think before going any further we should determine whether the balance staff is actually broken and requires replacing, is it possible to post a picture of the balance so we can see both pivots. Thank you.1 point

-

Ah ok maybe so. I wasn't aware that this was a pocket watch sorry. But at least you have some good useable information for another project Is the case for this made of silver, if so and has a silver hallmark you can then date the watch providing the case is the original. This then may give you an idea if identification is possible. Can we see good close ups of both sides of the mainplate, train bridge and the dial back and front. One of us may spot something in the way of an identification mark. Good advice anilv, we did discuss most of this on the wobbly balance thread, I'm unsure if the issue was diagnosed though1 point

-

A job lot of 5 watches arrived today which I bought mainly for a Nivada and a very old Vertex. Surprise number 1 - 4 out of five are running and keeping good time. The 5th one looks like it was given away in a lucky bag. Surprise number 2 - This Sekonda is a minter. Not a mark on it, dial is very clean, 35mm excluding crown and it runs very well. The movement is a 2614 and it does appear to have been stuck in a drawer and unworn for many years. There is also an unfortunately named 'Tempex' watch, which is also in very good cosmetic condition and a really nice case design which I will definitely be wearing once cleaned and serviced. Pictures to follow of them all but, for now, here's the Sekonda.1 point

-

1 point

-

I forgot to quote you first. Usually loud ticking (in this type of movement) is from to much end shake on the balance wheel. You adjust it by tightening one of the screws holding down the balance bridge just a bit more than feels comfortable (checking end shake as you go). It may seem crude not to have just bottomed the screw out and adjust end shake some other way but it is very clever, it works like a belleville spring washer and holds the screw tight against the threads in one direction and doesn't let it vibrate loose. As you tighten that screw and it warps the plate and reduces end shake. Shane1 point

-

1 point

-

If you're not yet comfortable rebuilding your own movement, replacement movements might be available for negotiation. Either way someone here may be able to help. Shane1 point

-

Hello @dadistic, I have amended the instructions (attached)...do you think it's enough? g. ---- @Paul80, I don't know if you are handy (though as a Watchmaking fan you likely are), but the way I'd troubleshoot that is to UNPLUG the unit, open it up and check the resistance of the heating element (which is probably 100W) to see if its resistance is infinite (broken heating element) or really low (like under 10 Ohms). If you can get a measurable (but low) resistance then the issue is likely elsewhere in the circuit (maybe a fuse). Here's a little discussion from Quora about heating element resistance levels and how their resistance changes when they go from "cold" to "hot": g. ----1 point

-

Wow! A telephone dial Dynabeat. I've never seen one of those. Dynabeats are a strange beast. They were pre-quartz era, battery powered mechanical balance watch. Not many watchmakers will take on such a repair. So, what do you wish to do on this forum? Do you wish to learn how to service this Dynabeat yourself or are you looking for someone to service it for you?1 point

-

D5 is way too thick for ball bearings. If anything, a minuscule amount of 9010 would do. However that is not the cause of your problem. If, as correctly noted, the weight won't drop on its own when the watch is fully wound, that is not necessarily a problem, But if that happens with the watch unwound then something is seriously wrong you should take all the barrel and auto winding system apart, inspect and reason on each part and check its function. Since Seiko and ETA use radically different systems it's unlikely that the cause will be the same.1 point

-

Hello and welcome to the forum. You have quite a cross section of watches there to keep you busy/ a little addition to get you started. I should look at the "watch fix " site for the online courses run by our administrator. They will give you a good grounding in the repair of watches. TZIllustratedGlossary.pdf1 point

-

I had this issue with a Citizen and assume that the bridle got slightly deformed when pushed into the winder barrel. The grease has no major influence imho.1 point

-

I have this problem with my Vostok Amfibia. Originally before I used braking grease in the barrel, it didn't have this problem. I haven't tried cleaning out the barrel and using normal grease. I should really do that and post my findings.1 point

-

Is it just the barrel rotating on its own or are the rest of the wheels moving as well ? Barrel on its own, it's not meshing with the second wheel. Rest of the wheels as well, there is an issue with the escape side of the movement. Remember I am a beginner so probably missed something obvious1 point

-

Eyup. Here are 5 Timex watches that cost 23 quid in total so a little over the original 404 price budget. 3 waterproofs with snap on backs so thats non believable for starters. And if Andy's American strap a Timex to an outboard engine propeller, submerge in a large tank full of water and let rip advert is anything to go by then i dont think so lol. An unusual pink/orange dial hard edge cushion case and an m22 W.D.P Cinderella from the late 50s early 60s which my missus really loves and is going to restore herself.1 point

-

1 point

-

I remember one online tutorial that opened with a picture of a watchmaker "smoking expensive Swiss cigarettes and crawling on the floor looking for a part" At least you only lost one part. My last disaster was a parts tray explosion, and it took a looong time to find everything that went walkies. Eventually I found everything except a crown wheel screw, plus I found three mystery parts! Have no idea where two of the three extra parts came from. Sigh.1 point

-

Great check list. I am still not sure how to properly check the condition of pivot or staff tips (how the condition should be). Another point is the prohibitive indication to not put back the mainspring manually. Does it always require the winding tool? I mean those tools use to be way expensive, above a lot of good watches.1 point

-

1 point

-

1 point