Leaderboard

Popular Content

Showing content with the highest reputation on 08/15/22 in all areas

-

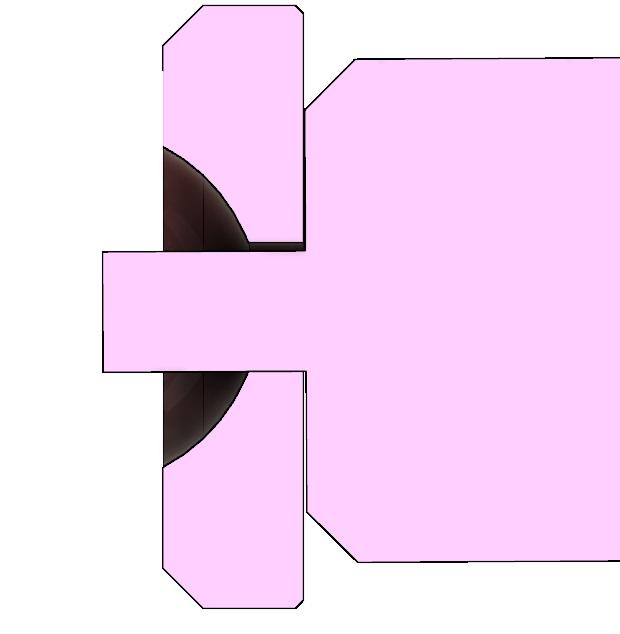

Here's a cutaway with close ups of the two ends. The sideshake is 0.01, which is about right for a 0.15 pivot (this size). If the arbor is under tension, it will generally want to tilt- like when you try to wind the watch with the wheel train in but haven't put the bridge yet- everything tilts . With a very small but existant endshake, the shoulders of the arbor can touch both flat surfaces of the two jewels at the same time. With a little more endshake, as the tilt is restricted by the pivots, it will become possible for one shoulder to touch one jewel (and is almost certainly the case 99.999999% of the time), but both shoulders can't contact both jewels at the same time.4 points

-

Just a PSA for archival purposes. Bought the Esslinger cheapo chinese version of the bergeon #2 presto https://www.esslinger.com/watch-cannon-pinion-and-watch-hand-remover-tool/ It's a high quality tool that needed a bit of shaping of the jaws as the gap was too big for a seiko cannon pinion but it works great and it's about 1/5th the cost of the bergeon version.4 points

-

Typically this thread is for showing one's achievements. I marvel at the ability of some of those here, and hope to one day have the ability to do the same. Well tonight I had an achievement, I lost 2 parts and broke another. That's a personal best for me in one evening! I was working on a cool little Seiko Lord Matic with a 5606A 25 jewel movement. The scape wheel and 4th wheels both have capped jewels on the bridge. While reassembling, I managed to lose both jewels. Not at the same time mind you, no no... I lost one, then miraculously found it, then lost it again when it sprung out of my tweezers after oiling, never to be found again. The same thing happened to the other one about 30 minutes later after I gave up looking for the first jewel. Now I'm down 2 jewels for the bridge. Whatever, I decided to carry on, and managed to accidentally get my hairspring pinched beyond my ability to repair. I decided to remove the hairspring and see if I could sort it out. I've done 'minor' hairspring adjustments with decent success previously, so I thought I'd give this one a go. After about another 30 minutes, it was worse off than when I started. Sometimes you have one of those days where your hands don't do what your brain tells them to do! Today was certainly one of those days for me. I decided to put up my tools and just walk away for the night. Thankfully I have a donor movement coming in a week or two. When inspecting the watch upon disassembly I found some bent teeth on the barrel and 1 broken tooth on the 2nd wheel. It looks like I'll have more parts to use off of that donor when it comes in. I think I'll just put this Seiko LM in a drawer and leave it out of sight until the donor 5606A arrives. Just the thought of it right now is aggravating! This watch has potential. It has a gorgeous green dial and a faceted crystal, and I'd really like to get it back up and running. It has fought me every step of the way though. LIke I said in the title, it is an achievement, but I'm certainly not happy about it! Part of me just wants to go on ebay and find a couple of old Swiss manual watches with no complications and just work on those. There'd be less stuff for me to screw up and I'd get a few 'wins' on the board. I think I've just had bad luck on getting old watches in for repair. I haven't had an easy one in a while (my definition of easy may vary greatly from others on here!).3 points

-

Depending on the sideshake and diameter of the arbor at the pivot, you can have a situation where the shoulders at both ends are making contact with both hole jewels at the same time if the endshake is very small. It can be exacerbated by very short arbors too, particularly the pallet fork*. 0.01mm is hard to visualize, I made a sketch of an arbor with jewels and exactly that much endshake to illustrate. *Troubleshooting a new-build tourbillon a few years back I had a situation where the fork was ultra free, with "feelable" endshake, but the watch was having amplitude issues- ended up adding 0.01mm endshake fixed it.3 points

-

Hi My pleasure as I think we can all appreciate we get days like that. Have a beer kiss the wife and pat the dog and relax2 points

-

Nice CAD work. VWatchie, also remember that Nickelsilver probably also modeled those parts in theoretical perfection. All dimensions spot on, lines that should be parallel are, all angles are accurate without internal filleting or external rounding, concentricity or T.I.R. zero. Which is all easy to draw, very (impossible) to obtain. Watch parts (even "cheaper" mass produced watch parts) are probably closer than most but will (on average) deviate from print. That's called acceptable tolerance. If you don't want to hand fit every part in every assembly, you assemble using fixtures adjusted for parts assuming the widest possible "acceptable" deviations. And as Nickelsilver said, while under torque is not the same thing as when it is free wheeling. Shane2 points

-

Head up Thor we have all been there and some times it happens again, walk away have a coffee and sooth the nerves and pick it up in a day or so and it will be fine. when working with the likes of jewels and cap, springs try to cut down the eacapees by using Rodico or a sticky stick to pick them up. Not being under pressure if the fall off the stick they dont go far2 points

-

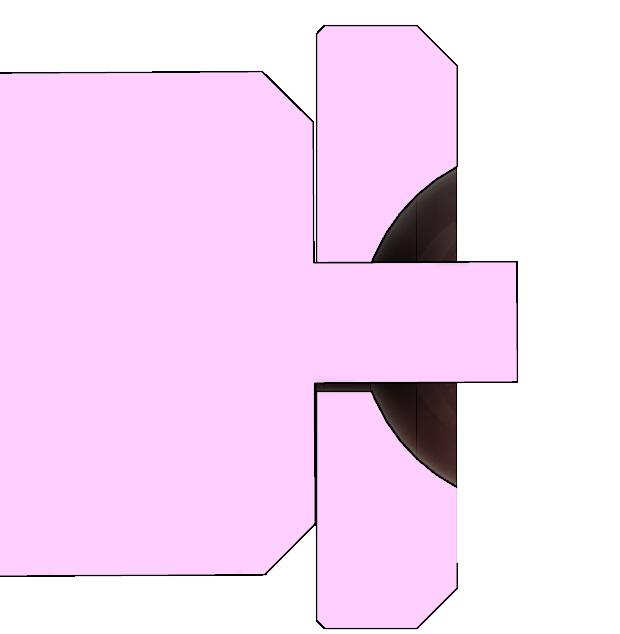

With out seeing the movements identifying is almost impossible. We need to see photos of both movements. Due to experience I'll have a shot. The dials give it away for me. I expect to see what is called a 5 bared movements and the escapement will be cylinder. Winding and hand setting is from the back by means of two squares so a pocket watch key is needed. They come with some very fancy looking dials right down to just plain. These movements all though can look identical I can assure you parts are not interchangeable. They were made on the Swiss French border and the time period is from the 1800's most likely the middle to late. Here is an example of what I'm describing. This one does infarct have i d marks.2 points

-

.01 - .02 mm / .0004 - .0008 in, is quite small. Some mechanical assemblies require a higher degree of clearance do to a wider acceptable tolerance within all the components making up that assembly. Once you pick a design philosophy, you need to keep with it all the way through the assembly (assembly is being used as both a noun and a verb). Dimensional and angular deviations abound, total indicated runout of the shafting and the pinions and pivots machined into them, as well as the ID in relation to the OD of the gears those shafts are pressed into, the engagement between the involuted gear pairs, times how many pairs within that gear train. Not to mention, if the pivots are at the end of a tapered shaft, you have also restrained them all radially as well. It's hard to say what the problem or problems might now be but if it was running better before you tightened it up, is it really perfectly free now? It sounds like you will need to loosen it back up. Let us know how you make out. Good luck. Shane2 points

-

Hey guys, I've got a weird one here, see pics below I'm thinking 60's but it uses the FHF66-9 movement (quite a pretty adjusted movement, hence my interest) that's apparently from the 50's? There's no info on the interwebs that I can find, but this appears to certainly be before it was sold to an Asian company. If anyone knows a little something about this piece or any other interesting facts I'd be grateful.1 point

-

Their websites out there that will cross reference parts for you. You don't want to do a visual mixing and matching if that's what I'm interpreting you do because there could be subtle differences that you may or may not see. Crushed probably isn't quite the right word broke off would be better. Or in the process of crushing they broke off that your pivots are definitely missing Because of the way the watches laid out it's usually very difficult to start on one side and slowly put the pivots in one at a time as you tighten screws. Usually end up almost having to put all the pivots in that the same time or at some sort of random order of whatever goes in goes in until they're all in. Sometimes it's literally as simple as putting the plate on top other times you can struggle for quite some time it just depends on the watch.1 point

-

Good advice, thank you.1 point

-

I have been retired for many years. I'm a fully qualified watch & clockmaker with around 30 years’ experience. Had my own business working on high grade clocks mainly restorations and also valuations. Also worked for a top Antique shop, giving advice on what to buy at auctions when it came to clocks. Eventually having to retire due to poor health. You can only learn so much from books, they don't tell you how to overcome many obstacles. The best way of learning is to get your hands dirty (I say that all the time when people ask me) If you can work for yourself that way you reap all the rewards yourself and if you are good at your work you will never look for work. The best form of advertising is word of mouth. When you have decided where you would like to start up your business do some research as to what to expect when it comes to repairs, such as is it place where it is full of clocks and good antique type, or is it a place where some cheap store just sells cheap watches and jewellery, poor or good stranded of living. Hope this helps a little and good luck.1 point

-

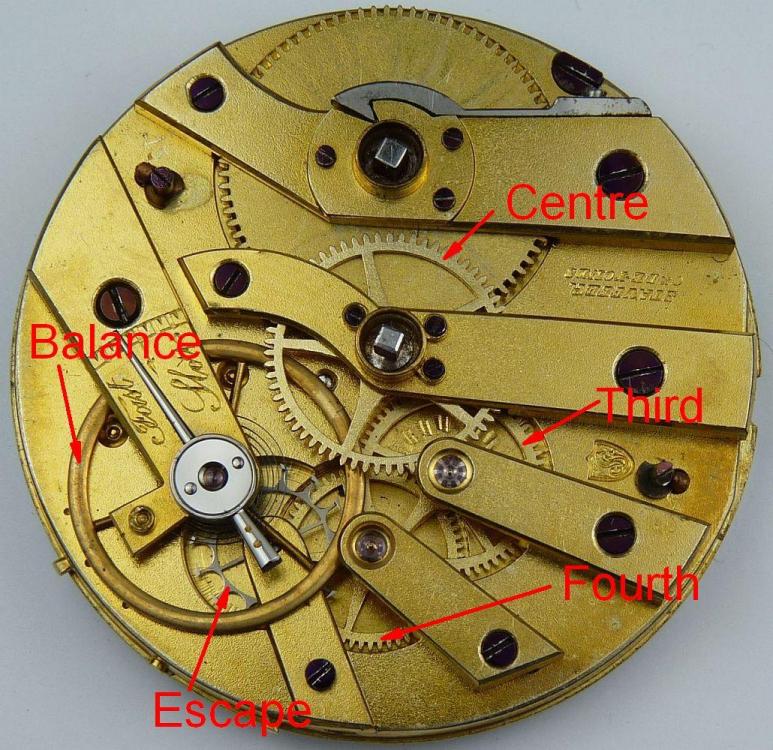

Obviously yes. My own 1st calculation gave the same result as yours, but I felt, this must be too much. The manual of a timing machine (Timomat) led me to the correct calculation. This picture from another forum reminded me of your post. Seems like vertical screen is about 5.5 ms here, so your TG may tell the truth and one line wrapped around once - though it is puzzling. Frank1 point

-

Hi Find attached the service/parts sheet for the BFG 866. It would be helpful if you could post some pictures of the watch indicating your problem, pictures accompanying any query are always a great help to members. thanks. 2529_BFG 866,866.31.7 (2).pdf1 point

-

Thanks to all for spending the time on your answers. I will trying again with some scrap movements. VWatchie, I stand corrected on Mark's course, likely I mixed up presentations from Kalle Slaap on Chronoglide.1 point

-

Abrupt stop usually indicates the balance itself rubbing on something and rarely the fork rubbing on the roller table . Pivot shoulder rubbing on the setting hole might be dismissed since both balances stopped. Regds With AmScope you will easily find whats rubbing.1 point

-

A WILD CLEANING FLUID discussion has appeared. (Pokemon Reference) I'm currently using Zippo lighter fluid and honestly have almost zero chemistry knowledge but I appreciate all your experience sharing. I'll have to get some "Benzinum" and give it a comparison. I suppose I could test the zippo fluid one more time on a spare balance to see if it was the lighter fluid itself or some other mishandling. I'm back from vacation! Luckily, while I've been away the Raketa 2603 spare movements have arrived from Ukraine! They must have more important things to do now than ship me spare watch parts, but alas! Swapping the balance immediately fixes/reintroduces the oscillation issue. So now that it's isolate to the balance assembly I can investigate further. Also, having something to compare against. Yesterday, I did a very thorough rebuild and it seemed to be purring until I flipped it to the dial side and noticed it stopped immediately. It also restarts immediatley when reverting. My immediate thought is the vertical travel on a part near the end of the train of wheels or in the escapement seeing as how quickly it stops. Need to review Marks videos on 'end shake' I think it was. Anyways, will report back. Got a AmScope and I feel like I can ACTUALLY do things versus just guesing ... feels good.1 point

-

1 point

-

Hi there Dmitry ,minutes must be more precisely indicated to give an accurate time reading; simply pointing somewhere between numbers won't work. Therefore, the minute hand extends farther than its counterpart usually to the markers on the edge of the dial so as to provide an exact accounting of the time .With the minute hand being longer, you smoothly travel over the hour hand without it getting in the way.The fact that the minute hand is always longer, and often thinner, than the hour hand, serves a very specific purpose, though. The hour hand doesn't have to point specifically at the hour number it relates to for a person to know what time it is. For example, if the hour hand is pointing anywhere between two and three, anyone capable of telling time will take this to mean it's two o'clock. Probably carried over from early cock days when you pushed the minute hand to set the time so that you would get past the hour hand without touching it . Cheers ,Graziano1 point

-

Hi Murks. Just asking if you are aware that most crown wheel screws have a left handed thread. Sometimes indicated by a line either side of the screw slot, not allways but when that indication is there you know it is definitely left handed. So that screw can occasionally get broken off or the thread stripped, i will assume this is what has happened hear. Post close up photos of the screw and the threaded hole it fastens to.1 point

-

Hi the logo states as you found out its By Thomas Ernst Haller of Schwenningen Germany, The Kienzle watch factory also Schwennigen used a similare mark registered in 1952. 43 C/m is the pendulum length D.R.G.M is a design patent Deutsche Reich Gebraumiester. Trade mark was redistered in 1904. Thos Haller was bought by Kienzle factory in 1928 hence the similar logo.1 point