Leaderboard

Popular Content

Showing content with the highest reputation on 08/06/22 in Posts

-

The bottom line is fitting a new balance staff can be troublesome anyway trying to fit a used staff just adds to the possible errors.2 points

-

Intro A while back I successfully made my first attempt refitting and adjusting pallet stones using shellac. It was something I had dreaded doing (it seemed difficult) but in the end it wasn’t that difficult at all. Having gathered experience from a few years of handling tiny watch parts using tweezers and having developed some left-hand dexterity as well (I’m right handed) probably helped. Anyway, I thought I’d share the experience with anyone who would be interested and hopefully there’ll be some other WR-talker, now or in the future, who’ll find it useful. If you’re new to this topic you might find this page and this video on the watch repair channel a good start. As I didn't want to risk ruining my Gaston tool I melted and prepared the small pieces of shellac on a chisel tool (my improvisation) that I happened to have in my tool box. However, the chisel tool had a very tough plastic y surface but I was able to burn it away to expose the bare metal with my alcohol lamp before melting and forming small pieces of shellac on it. However, the pieces of shellac needed were much smaller than what they looked like to me in the video. My way of making even smaller pieces was simply to poke the small pieces that I had made with tweezers once they had cooled and were hard. Setting and adjusting the pallet stones was easier than I thought it would be. I didn't realize the fork slots for the stones pinch the pallet stones (Vostok calibre 2414) and actually keep them in place before the shellac is applied. So, I could replace the pallet stones and then check and adjust the locking depth to the escape wheel teeth before applying the shellac. A bit fiddly yes, and you do need to develop some dexterity with tweezers before you try this but not to the point that you break a sweat. Anyway, thank god for my stereo microscope! Anyway, it was my first attempt, and as is common when you try something for the first time, I made a mistake. Despite very consciously applying what I felt was a little too little shellac it still flooded the stones and a large portion of the fork when it melted. Also, I applied too much heat so that the shellac started boiling creating bubbles. So, I decided to start all over. Fortunately, the “industrial isopropanol” (so called on eBay) that I have is very efficient so no problem removing the shellac from the stones and the fork. The second time around I only used a minuscule amount of shellac. Also, I heated the Gaston tool holding the fork in short turns, just so that the shellac would fully melt without staring to boil. Much better! The following is what I would suggest based on my first experience: Basically, follow the video I linked to above. In the video, Mark pokes and scrapes the fork and the stones with tweezers to get rid of old shellac. I tried that, but it wasn’t very efficient. Instead I would let the pallets soak in industrial isopropanol for about 10 minutes and then use a paintbrush to brush them clean. The shellac dissolves completely in the isopropanol and the stones can then be easily removed and further brushed if required. To insert or slide a stone back into the fork slot I found holding the fork by the end of the slot (opposite side of where the pallet stone is inserted) with tweezers (left hand) was giving me the most control. I placed the pivot of the fork (guard pin up, of course) in a small hole in my staking block while inserting/sliding the stones with another pair of tweezers (right hand) into the slots. After having applied the shellac Mark suggests re-heating the shellac to adjust the stones. I was worried that it might result in a mess if I tried it, so I decided to do the adjusting before applying the shellac as shown in this video. The slots for the stones pinch the stones pretty well so if you're careful while you're testing the lock to the escape wheel teeth this method works well and won't dislocate the stones. However, to make sure, double check the positions (depth and angle) of the stones before applying the shellac. Now, the tiny piece of shellac should be placed on the rear section were the stone meets the fork. Mark is clear about this in his video but for some reason it completely passed me by when I made my first attempt. In my second attempt I followed Mark's instruction, but the piece of shellac, being very asymmetrical in shape, was difficult to place in the right spot. However, after warming the pallets to the point that it had only softened the shellac a bit, I discovered, to my surprise, that I could manipulate the shellac into the perfect spot with the tip of my tweezers, without the shellac sticking to the tweezers. Of course, as I've come to realize, every repairer must find his or her own way, but hopefully you'll find my "discoveries" useful. Above is a picture of the result. It's not perfect but still worked very well. The amount of shellac on the entry stone is a bit too little, and there is a < 1 degree tilt on the exit stone (which, of course, can’t be seen in the picture).1 point

-

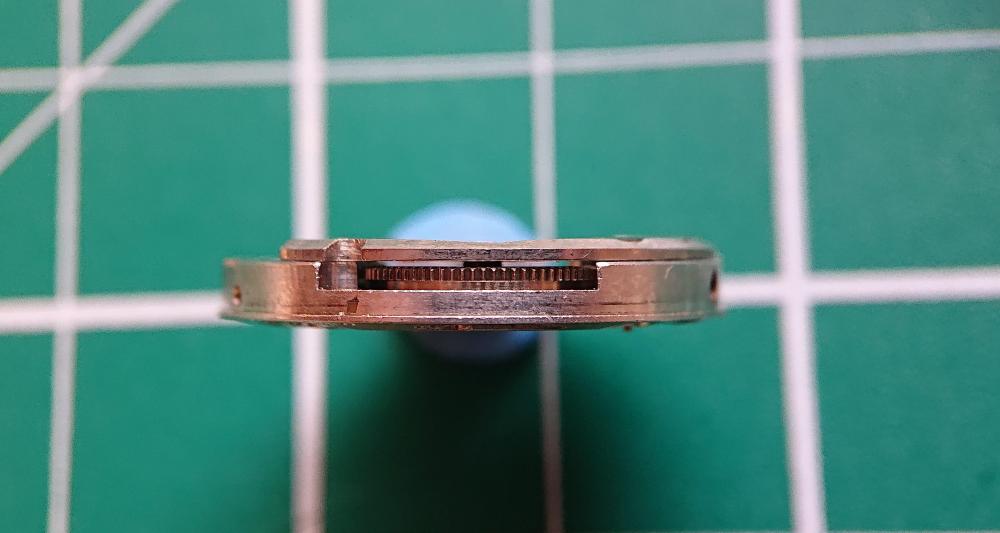

I've taken possession of an Eterna wristwatch belonging to a family member, in need of a service. It's in a sorry state externally. It barely runs and has terrible variation in between positions. It has been serviced in the past. There are four servicing marks in the case back and scratches on all of the bridges. It definitely requires deep cleaning. On examination, I found two significant challenges requiring attention, which are damage to the barrel bridge and the setting lever spring. Spares are no readily available for this movement and donors rarely come on the market. Plus it's time for me to move on from fault finding and parts replacement on to greater challenges. 1: The mainspring barrel bridge pivot hole is ovalised. The barrel arbor is no longer orthogonal to the plate and bridge. There is obvious wear to the upper side of the bridge from the ratchet wheel. I've resolved this issue by fitting a bushing to the bridge. I practiced the technique, refining each time on a couple of old citizen movements before working on the eterna: Having mounted the movement on a wax chuck I centred it on the lower barrel pivot using a wiggle stick, ensuring the movement was fully flat on the chuck: I then fitted the barrel bridge, and bored it out to about 2.7mm to regain the centring. I then bored the hole to 2.99mm using a seitz reamer. Following Perplexr's instructions on youtube, adapted to the tools I have available I turned a brass bushing 3.00mm in diameter and 0.44mm in thickness, pressed it in to place and broached it to size ready for a test fitting. If the fit is good I'l deburr it and re-plate the bridge. Happily the barrel now sits square, rotates freely without side play and with correct end play I then finished the bore with a burnishing broach, deburred and replated the bridge. Regrettably I scratched the surface of the bridge when boring the hole. You can see the scratch running up from the chamfered circle where the bushing meets the original material of the bridge. Oh well, it's only one more of many. It niggles me as I managed not to to do this on the practice pieces. Part 2 of the challenge (the setting lever spring) is rather daunting and I'm struggling to find the materials. I'll post it as a question in the other forum.1 point

-

Usually when you find the used staffs there in bottles of miscellaneous used staffs. In other words the watchmaker usually keeping everything they ever replaced Placed all the Old staffs in a bottle and that typically is for sale. So in my miscellaneous stuff I have a bottle of used staffs. The real problem here is why would you use a used staff somebody replaced it for a reason And your going to inherit their problem. Miscellaneous assortments especially if they come off of eBay are interesting. At work we have a Swiss packet of miscellaneous staffs and I don't think I've ever used any of the staffs for restaffing because they don't match anything I've ever seen. But we were once given a bunch of miscellaneous tools from some old watchmaker in there was a staff assortment. I really wish I can find another one of these it was assortment of American pocket watch staffs and I've used quite a few staffs out of there because they were all usable staffs. I know there were several Hamilton 992B staffs in perfect shape. So somewhere out there that there are really outstanding staff assortments the problem is they existed at a certain time and those assortments do not exist today unless you goodbye old watchmaker's estate in just get really like. I don't think I've ever seen an assortment as nice as this Hamilton Elgin Waltham all-in-one nice assortment. On the other hand when did those watch companies ever exist altogether which gives you a clue of how old these are and doesn't explain why brand-new staffs would be an assortment anyway usually Usually to valuable To be sold an assortment should be sold separately?1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

I have purchased a bulk lot of balance staffs. Out of the 100,s I have used one that I had to modify. Used balance staffs I have never come across. Certainly not worth purchasing as if a riveted staff the rivet will be useless.1 point

-

I can't believe anyone is selling used staffs. As you suggest, I can't see any way they could be re-rivetted*. As for using shellac - possible I suppose, but you'd have to make sure you got the wheel square with the staff. *The first staffs I replaced were Waltham pocket watches which used friction fit balance staffs. Those you could possibly re-use.1 point

-

The side shake is not terrible, but probably worth closing the hole a bit. This shows you how to (I've pasted this a few times recently !) : https://www.youtube.com/watch?v=rshFo-KGgjY&t=3s1 point

-

Unfortunately when they made American pocket watches epilam didn't exist yet. One other thing is you don't know about him pocket watches is when was the last serviced hundred years ago or five years ago you don't know typically. If it's really old organic oil it does take on a interesting smell or at least it can. Although those watches are getting farther and farther apart. In other words organic substances ago bad with time don't always smell pleasant sometimes the lubrication in the mainspring barrel will leak out all over the place of something was careful. There are other methods of lubrication we end up with that all over every place. I was very popular over a period of time will skip over how that works says it's a thing of the past but basically ended up with oil every place. But yes it's usually comment on older watches and oil leaks out all over every place or at least it is every place.1 point

-

Yes it would be better if you could leave the jewels where they are and just move them around. Just a reminder the stones are slightly different angle and you don't want to mix them up. Plus of course you don't want to misplace one as that would be a new fork.1 point

-

Thank you for the clarification, yes it is side shake not end shake. This watch will not be a daily wearer. Truth be told the factory bracelet won’t even fit me at it’s longest setting. It’s more of a project than some thing I plan on wearing regularly. If I do get it up and going though I’ll probably find an XL strap for it and wear it on occasion. You are also correct that it is a 7006a movement. I’ll keep moving forward with assembly and lubrication and we’ll see what kind of readings I get. Thank you for the advice.1 point

-

Hmmmm, that a 700x movement? Looks like it. Your problem looks like side shake, not end shake and it’s certainly showing advanced signs of wear. That said, wear on that looks more like the arbour hole on the main plate, not the top plate (which would be an easy fix but just punching out the bush). The main plate isn’t bushed and staking that is probably not a good idea, but certainly possible. But it’s not ruined yet. I see them with score marks where the ratchet wheel has left marks on the top plate and yours doesn’t have that. You might lose a little amplitude and power reserve but it won’t be the end of the world. If that watch won’t be a daily for the next 5 years you’ll probably not need to do anything. Up to you though. That escape wheel is pretty dirty; looks like someone dipped the whole movement in oil. I would still go ahead with your plan to clean and lubricate, see how it performs and take from there1 point

-

I speak from experience. I have opened watches and other objects which had not been ouched for easily 50, ot 60 years and found "wet" oil, it could have been little or more, but was there. I guess it wasn't aware of its own chemicals characteristics.1 point

-

Oil doesn't dry. Oils, or at least most organically derived oil do dry, persay. It's more like they turn into an organic plastic or polymerizes. It has to do with that oil's ability to uptake halogens from the atmosphere surrounding it. This is know as that oil's iodine value or how unsaturated the oil is. The iodine value also allows you to estimate an oil's density and it's viscosity at a given temperature. It also suggests how suitable an oil will be for any given purpose while at different temperatures and for how long. The higher an oil's iodine value, the more susceptibility to oxidation that oil will be. This is how oil paint works and why butter goes bad without refrigeration. It's also how you season cast iron cookware and why we use certain oils for high temperature deepfrying/cooking. Different oils are good or bad at performing different functions. Now I'm hungry thinking about my wife's cast iron cookware and what she can cook/bake with them. I'm thinking buttered corn muffins.... Conversely, I'm under the impression, petrochemical and synthetics oils are more likely to have their move volitale constituents evaporate, causing them to thicken over time, then to oxidize. Whichever way, within a sealed watch the oil may have a problem doing either... quickly. Food for thought, pun intended. Shane1 point

-

No, I did not. I simply warm the pallet warmer gradually until the shellac melts. If you overdo it the shellac will start to boil creating bubbles. Insightful post! I've also come to the conclusion that the number of parameters governing the effect of IPA on shellac is so great that it's hardly even meaningful trying to discuss it. Personally, and to be 100 % safe, I never clean or rinse my pallets in IPA. Instead, I simply use Horosolv degreaser and it works really well and is just a very minor inconvenience as it would be easier to rinse the pallets in my watch cleaning machine.1 point

-

Thank you grsnovi. I was able to find the exact tool i needed. Bought the tool there and had a great experience with https://www.daveswatchparts.com.1 point

-

Shellac can be a variable substance, but what do you expect from something that is scraped off the bodies of insects? Likewise, the various opinions on its solubility in "alcohol" are also affected by the broad variety of what people may be using, and it can easily become an apples-vs-oranges situation. Even if you are somewhat specific about the base alcohol you are talking about, there is variability. Denatured alcohol is generally thought about as being ethanol, but in some cases it contains significant amounts of methanol and also more water than you might expect, which affects its solvent activity. Likewise, when people discuss isopropanol, are they dealing with 70%, 90% or 99%? And guess what - even if you start out with 99% isopropanol, it's very hygroscopic and can become 90% or 70% over time as you open and use the bottle and it absorbs water from the air. I think this contributes to the situation whereby some people are extremely concerned about shellac dissolving during an alcohol rinse and some others feel it is not a problem. Your mileage may certainly vary depending on what exactly is in your jar...1 point

-

You can try to reduce the size of the hole with a round punch as shown here : https://www.youtube.com/watch?v=rshFo-KGgjY&t=3s It looks like someone has already tried that. You could fit a jewel if you can find one the right size1 point

-

Found this article in todays Daily Telegraph (UK). It appears time us more complicated than we think. IF IT feels like there is never enough time in the day, there may be a reason. Earth had its shortest day since records began last month, with 1.59 milliseconds shaved off the usual 24 hour spin on June 29 – raising the prospect that a negative leap second may soon be needed to keep clocks matched up with the heavens. Usually, Earth’s average rotational speed decreases slightly over time and timekeepers have been forced to add 27 leap seconds to atomic time since the 1970s as the planet slows. However, since 2020, the phenomenon has reversed with records being frequently broken over the past two years. The previous fastest day was -1.47 milliseconds under 24 hours on July 19 2020 and the June 29 record was almost broken again on July 26, when the day was -1.50 milliseconds shorter. While the effect is too small for us to notice, it can accumulate, potentially impacting modern satellite communication and navigation systems which rely on time being consistent with the conventional positions of the Sun, Moon and stars. It means that it may soon be necessary to take time out, adding a negative leap second, and speeding up global clocks for the first time ever. Scientists have been left scratching their heads about the cause, although experts have suggested that a phenomenon known as the “Chandler Wobble” may be having an impact. The speed of the Earth’s rotation varies constantly because of the complex motion of its molten core, oceans and atmosphere, as well as the effect of celestial bodies such as the Moon. The friction of the tides and the change in distance between the Earth and the Moon all make for daily variations in the speed the planet rotates on its axis. The Chandler Wobble is the change in the spin of the Earth on its axis and it normally causes Earth’s rotation to increase, meaning it takes longer to complete a turn. But in recent years the spin has become less wobbly. Dr Leonid Zotov, of the Sternberg Astronomical Institute, believes this lack of wobble may be behind the speedier days. He will present the theory next week at the Asia Oceania Geosciences Society annual meeting. “‘Normal amplitude of the Chandler Wobble is three to four metres at Earth’s surface, but it disappeared’ ” “The normal amplitude of the Chandler Wobble is about three to four metres at Earth’s surface, but from 2017 to 2020 it disappeared,” Dr Zotov told the website Timeanddate. In the early 2000s, the amplitude of the Chandler Wobble started to fall and from 2017 to 2020 it reached a historic minimum just as the length of day began to shorten. Other factors that can have an impact include snow building on the mountains in the northern hemisphere and then melting. Global warming is also expected to have a role by melting ice and snow at higher elevations, causing the Earth to spin faster. But it’s considered to be a relatively small factor. Changes to the length of a standard day were only discovered after highly accurate atomic clocks were developed in the 1960s and compared to fixed stars. The last leap second was added on New Year’s Eve 2016, when clocks around the world paused to allow the Earth’s rotation to catch up. British Telecom’s speaking clock added a second’s pause before its third pip while Radio 4 inserted an extra pip to its 1am bulletin. The International Earth Rotation Service, based in Paris, monitors the planet’s rotation and informs countries when leap seconds must be added or taken away six months in advance. However, the leap second could be abolished entirely next year when the World Radiocommunication Conference will decide whether to rely completely on atomic time. Britain is opposed to the move because it would sever the link with solar time forever. Some experts believe the need for a negative leap second might increase pressure for a move to atomic time.1 point

-

Beginners often ask about where to find this or that crystal, as it happens replacing is cheap and easy as long they are just flat round ones. But the crystal may not be found as generic, or can be expensive, or hard to find. So good old polishing is needed. Here again my technique key points: Crystal mounted on case, that will make it so much easier and safe to handle. Caseback removed, check below why. Jeweller's motor or other rotary tool with a fixed stand. You really want a screen like a carton box. Plastic roundel from a credit card as big as its size allows. 600 grit wet paper. No other grit is needed, as it will lose abrasiveness already after 20 seconds of use and become comparable to finer grades. Try to got directly over the deepest scratches, but without insisting too long (as in 5 seconds max) so to not dig valleys. Find the right compromise regarding the work angle, going flatly is good, but isn't even reasonable to try to sand the entire surface even. Look at the white streaks from inside the glass while working. You will see if you're getting right at the scratch or nick because if so the defect will show up in contrast Be patient with the paper stage. After a while it becomes hard to see if all scratches are gone, but you must remove them all before going to the next step. You should have made a mental note or drawing of where the defects are, rinse it up and observe at different angles. In difficult cases you may need to replace paper once or twice. Crystal will look now very foggy, that is normal Once happy refit caseback and crown, or rodico in the tube. The diamond paste is much more messy and you don't want that inside the case. Mount an hard felt wheel like 7 or even 10 cm dia, 2cm thick, place 1 cm of diamond paste (No. 10 or 14 good, but others work too) on the section toward you while keeping the crystal horizontal. Let the wheel grab the compound one bit a time, keep well pressed up and go over until all paste is used and you can present the entire surface to the wheel, rotate the watch and collect the past on the other side, place it on the crystal again on the other side. You can't do more than 30 - 40 seconds of work before adding fresh paste. Usually I do 4 or 5 passes like that. When working with paste is almost impossible to see the result with cleaning up. Clean with dishwasher detergent, dry it and observe well. Very likely you will notice some small defects, up to you if you want to go back to paper, concentrating on the spot only. Final polishing can be done switching to another wheel and finer paste, no less that 10 as these have no practical effect. Cerium oxide is another option but I didn't try it extensively so far. Below what I did today in about 20 minutes. The central scratch was quite deep. No final polishing or cleaning yet. After:1 point

-

1 point