Leaderboard

Popular Content

Showing content with the highest reputation on 05/21/22 in Posts

-

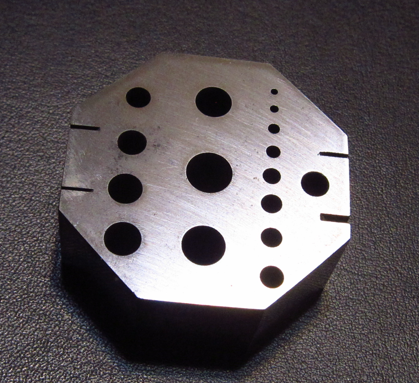

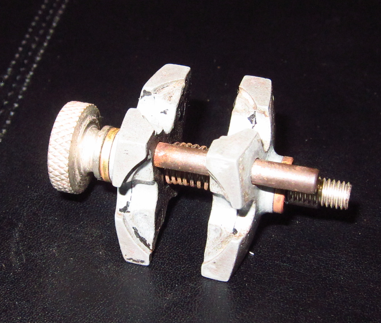

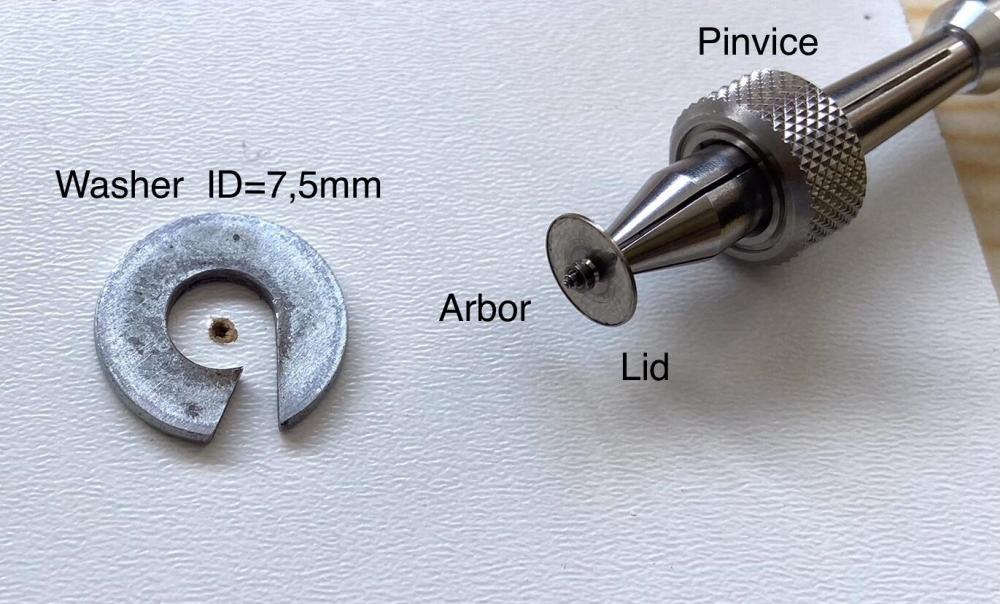

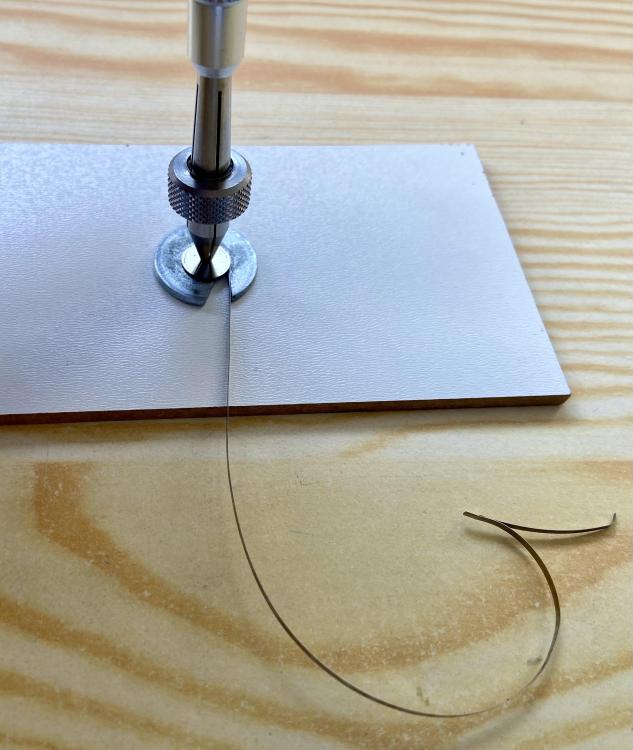

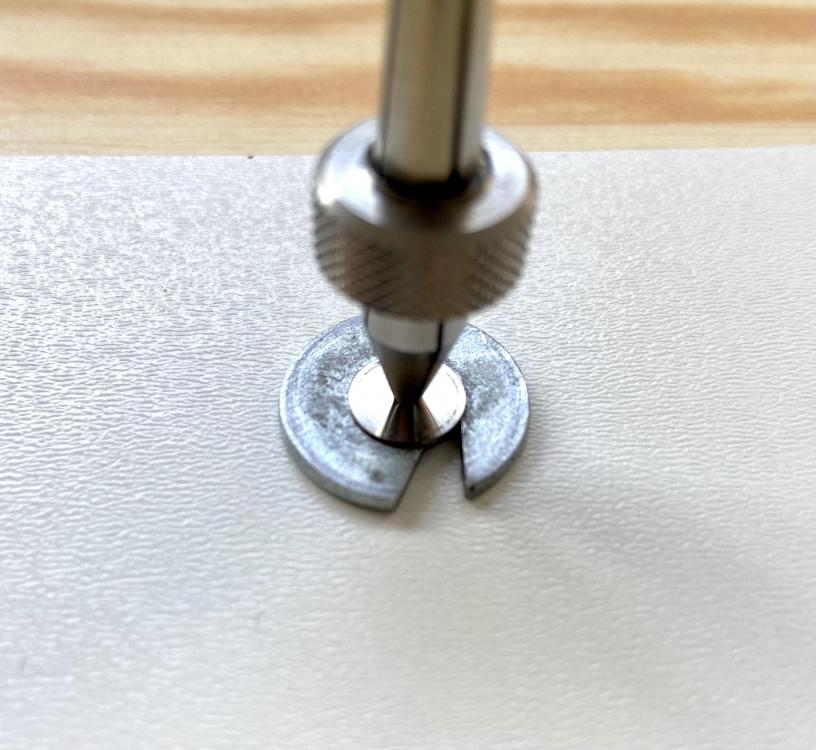

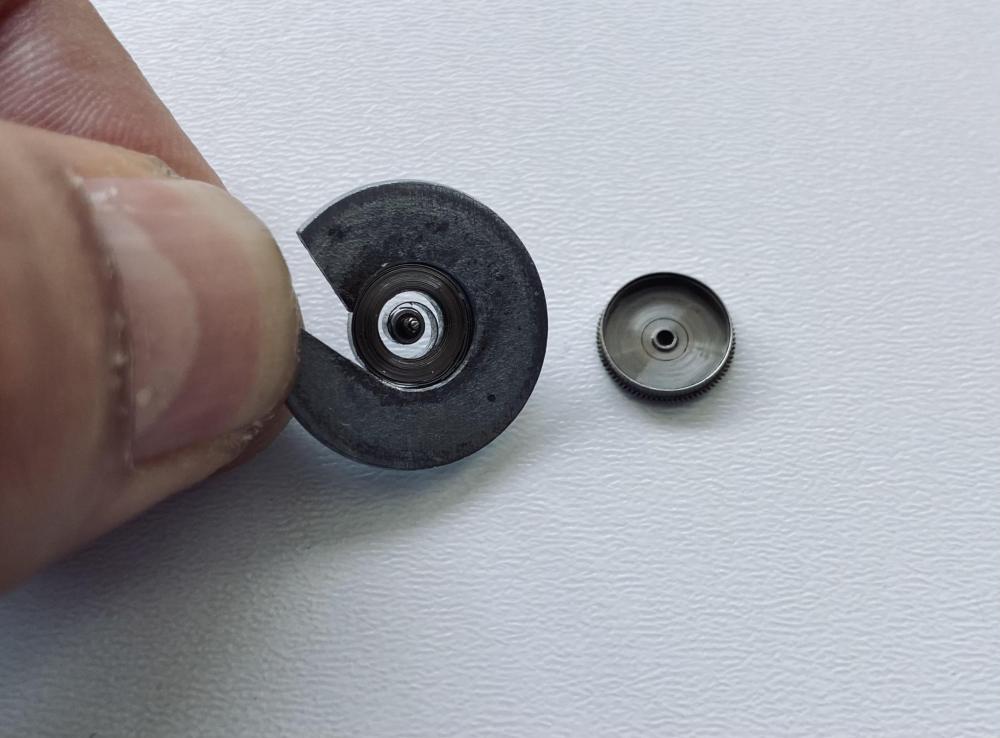

Inspired by the Mastercraft winder I tried to use its principle for a „quick and dirty“ mainspring winder. The spring I used for testing has an arbor diameter of 2,2mm (left wound) and the barrel has an ID of 8mm. The mainspring has a hight of 1,2mm. So I found a washer with the right thickness of 1,2mm, drilled it to 7,5mm ID and cut a slot in with my dremel. Then the washer was fixed to a board with three tiny drops of super glue. I used the original lid and arbor and my pin vice to complete the tool. The rest is selfexplaining looking at the pics. Any thoughts?2 points

-

Many of the minute hands on these clocks are fitted with a friction tight square center and they become loose, so the clock appears to strike slightly off the hour or half hour. There is a tool you can buy which is a waste of money. What I always did is use one of my square needle files and hold it in my bench vice so it points upward put the minute hand over the file and move it slightly to the correct passion. Be very careful not to bend the hand and check first that it is friction tight and not just a bent minute hand. When in the correct passion just give it a few taps with your bench hammer so it doesn’t move again.2 points

-

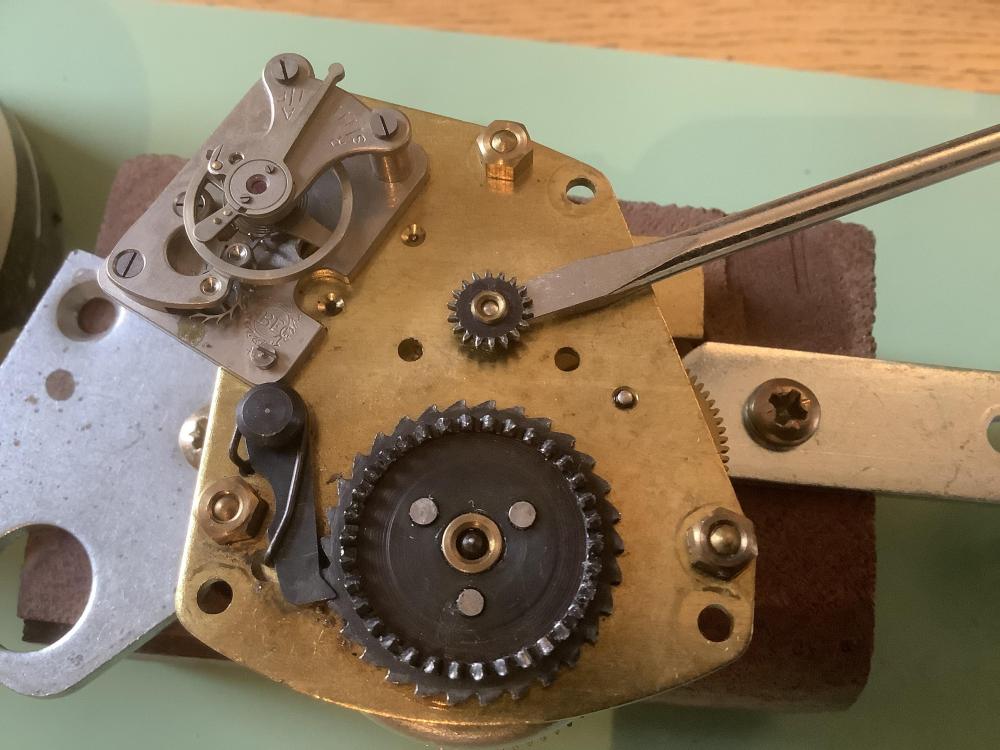

Here is a project that is been going for several months. It came from my box-o-watches. It had a broken staff and a rusty stem and no crown. I cleaned and staffed it--got it running fine. Later on, I noticed there was a problem with the mainspring. It was slipping. I could not tell what was going on. I found a NOS mainspring on Ebay and installed it. Still had issues. Finally discovered that the issue was me. Not gonna air out my noob mistakes, but once I decided to focus and use my problem solving skills, I figured it out. The final thing to resolve was the stem and crown. I could never figure out if this case needed a case tube. I decided to put one on. I had some case tubes in the watch bench, but none fit perfectly, so I put one that was close on the lathe and turned it down to size. Found a crown among the watch graveyard that would work with the stem and the case tube. Oh, long time back, I found a crystal in my stuff--perfect fit. Today it is all together. I am a little concerned about the tube. I may need to put a dab of superglue on it. The hands and dial have radium. I wash my hands after working on it and frankly not worried. Nevertheless, I found an identical NOS dial and have ordered it. Maybe I will swap it out...maybe not. That is TBD. Pictures below.1 point

-

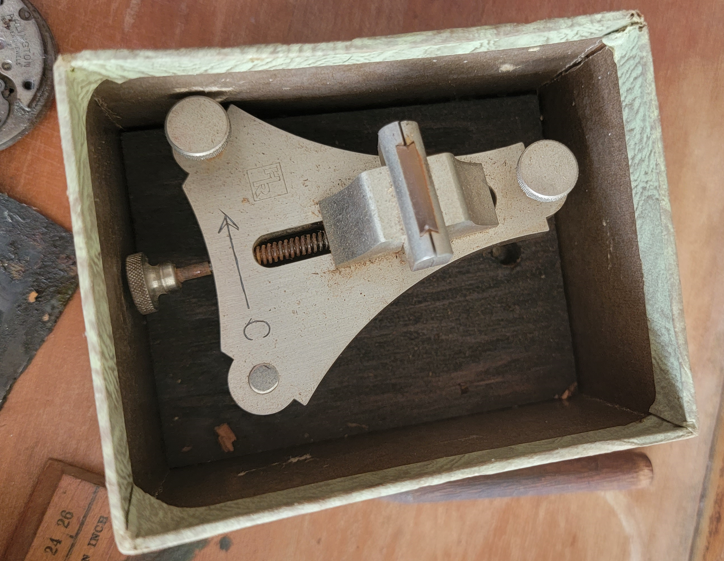

I saw an old watch bench pop up on FB marketplace and it was about 50 miles away, so this morning I was on a mission to get it. I did for $250!! It is not in great shape, but it will be an easy restore. Then I started opening the drawers. Wow. I am showing just some of the things I found. The two watches: one is an omega, and the other is an A-11 military watch. The name on the omega face is odd, but I opened the watch and it is an Omega movement. There are no chips on the poising tool!! I found WW collets (some rust but can be refurbished), a genuine Crocker sharpener. There must have been a lathe but it was not in the bench. I have asked the seller to look for it, so maybe there will be more to come!1 point

-

Yeah, I know I don't have to say that...but... Heading out for my annual trip to the Boundary Waters Canoe Area Wilderness. Will miss this forum and my watch shop but will exchange for the solitude in God's creation with no modern distractions (well, I am taking a SATCOM device, otherwise my lady might not let me go). Be back online sometime early June. Keep on ticking!!1 point

-

No calibre list that I know of for vintage Timex.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. No questions are silly Adam we all have to start somewhere1 point

-

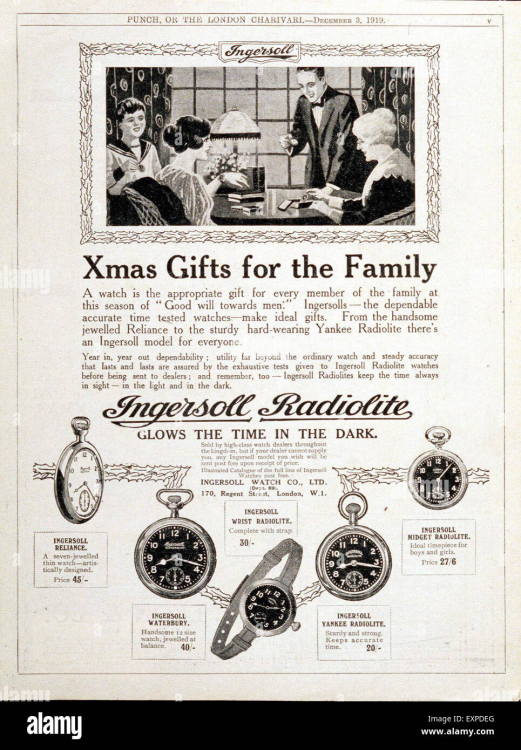

Hi @Edifred I've used some lateral thinking and gone Sherlock for you. Note the 170 Regent Street address for you watch. Here's an advert from 1919 clearly showing that address: Now forward to an advert put at 1922 (https://www.ebay.co.uk/itm/INGERSOLL-Radiolite-Pocket-Watches-Xmas-Advert-Original-Antique-1922-Print/154979300906?hash=item24157c762a) They've moved address by the time of this advert. I think your guess at (early) 1920s is pretty good based on this!1 point

-

Hi They are lovley old clocks, I did one for a retiered fisherman whose boat was being decomissioned. The movement was an Elliot very nice and its hanging on his wall going well. Jealous.1 point

-

Brilliant way to emulate the Mastercraft winder! Nice idea taking advantage of the pin vise versatility. However, what was your experience when pushing out the tail of the mainspring? It is quite a stubborn part to push out. It gets stuck between the plunger, causing the inner spring to coil over and leave the tail end sticking out of the mainspring barrel. Modern winders have very tight fitting plunging mechanisms to avoid this from happening. I built something similar to this in the past and faced this issue.1 point

-

Hi You might find the attached sheet handy for locationg parts etc. as Olh Hippy said the wheel is the wrong way up. How come they were loose. Was the plate undone / loose. and are the pivots ok. 2797_Swiza NEW (1).pdf1 point

-

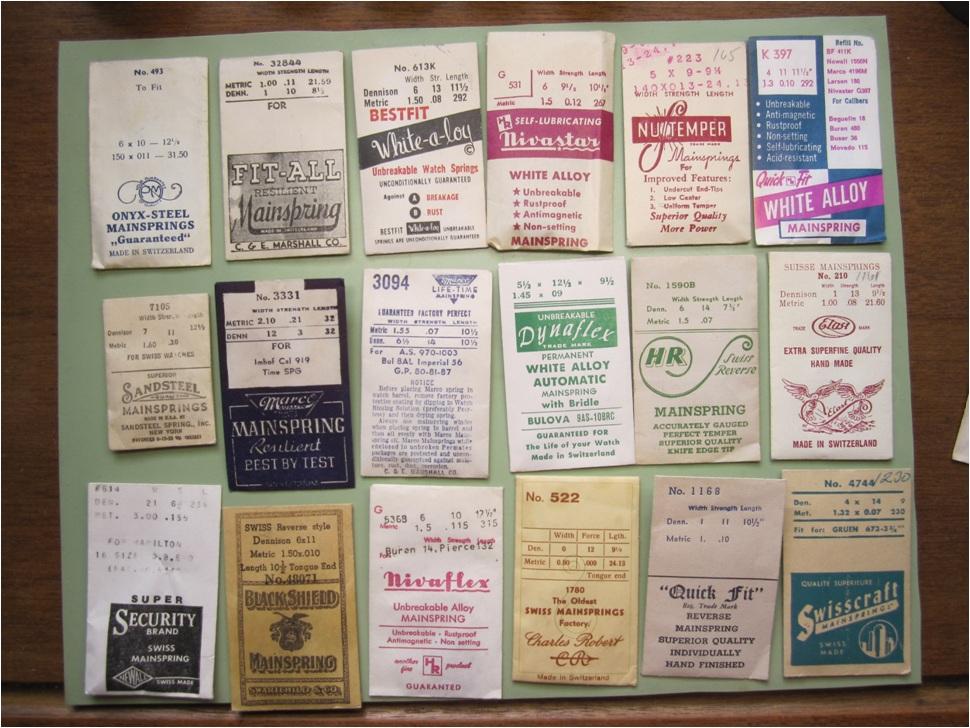

Hi Looking at the label , all prices in old money 40s 50s at a rough guess.1 point

-

Hi When cleaned up just check its not pinned before trying the lever off, Never come across sush a daft design, may be peculiar to the Gilbert.1 point

-

While digging through my dad's boxes of watches that customers never picked up, I ran across this Jubilee diver. I wound it up and monitored it for many days--it was keeping great time. Then I noticed that the date was not changing. Long story short--the date cam is made of plastic and had broken. I found another movement on Ebay (BTC 7422)--got it, and I replaced the cam, polished the crystal and now it is as good as new (almost).1 point

-

1 point

-

1 point

-

1 point

-

Pretty straight forward really. It came to me because the customer had had winding issues and the two piece stem had been pulled all the way out, so liberating the movement was just a matter of removing the crystal and it fell out. I don't know if they are all like this but the crown on this one had a very light line etched across it in the same orientation as the connector in the split stem so if the crown is still in situ all you have to do is align the line on the crown vertically and the movement will just fall out, no pulling with pincers to separate the stem. The movement is an ETA 2372 which is a straight forward manual winder. This one had issues though. It had an incorrect spring for the hack which was what was causing the winding issues, the hack pin which contacts the balance wheel to stop it was bent over flat, I found a paper shim under the train wheel bridge without which the centre wheel bound up tight as a result of zero end shake, and it had the wrong mainspring fitted. I couldn't get a replacement hack spring so I modified the closest replacement I could find so that it works. Straightening the pin was easy, as was adjusting the center wheel end shake with a jewel press so that I could do away with the shim. After that it was a straight forward service and fit the correct M/S. It's a really nice watch actually and I wouldn't mind owning one myself.1 point

-

Just for the record, these are a one piece case, the back does not come off. Split stem, and everything comes out through the front. I have just done one.1 point

-

1 point

-

1 point

-

I learned from @oldhippy that there is a thing called Vapor Corrosion Inhibitor (VCI) paper. Sometimes tools come wrapped with this brown paper that feels a bit damp. Well, it seems that a piece of this paper in the tool box will prevent rust of everything in it.1 point

-

I agree with @Zero. Rust is a serious problem here in the tropics, where the temperature and relative humidity is really high (30 degrees celcius, 80% RH). I store my more expensive tools in an air tight food container box (volume of over 10 liters), along with a CaCl2 dehumidifier. To be safe from leakage, the CaCl2 dehumidifier is placed in a separate plastic dish (IMPORTANT! I use two to be EXTRA safe), while the tools are kept in an uncovered plastic tray, both inside the sealed food container. I monitor the relative humidity inside with a blue tooth digital hygrometer. The relative humidity inside the container is around 20%. However, you should replace the CaCl2 dehumidifier when you see some liquid (CaCl2 solution) at the bottom; in a sealed container it should last at least a few weeks, but depends how often you open it. I don’t recommend refilling the CaCl2 dehumidifiers, since leakage will destroy your tools. The CaCl2 dehumidifiers are quite cheap, but you MUST remember to replace them, if not you will have very serious issues with corrosion from leakage of CaCl2 solution.1 point

-

I thought it was a lack of money was the mother of invention, well it has been for me over the years with some of the gagets I have made1 point

-

Barrel diameter size is only specified for modern mainsprings. Typically on older mainsprings it's never mentioned at all unless? Unless it's made for a specific watch in other words the only time you care about barrel diameter is if you're going to shove the spring in from the holder it's in. Otherwise with holder packaging especially when it's the older blued steel Springs a lot of times they would be in holding rings much much larger than the barrel. Then I have a image here for you here's a sampling of a whole variety of mainspring packages how many of them have the barrel diameter? Then I also have a picture of what the mainspring ring looks like if you're not familiar with it springlike that it billed to just push it right into the modern barrel which is why a lot of hobbyist watchmakers never end up with mainspring winders because they typically buy brand-new Springs and just shove in Microphone off lights in them lot of how to live in by the spring strangely enough it is a spring but it will line of not being used to set spring take them out of the barrel much bigger circular route there's nothing that Mister them back Then the third image mainspring is when their brand-new the top one that some modern white spring you'll notice the back curve it has. Some modern Springs website which back curve they have more back curve the front curve it just depends on who manufactured which watch was manufactured for etc. the spring below strangely enough is a good spring but in my mind borderline on not being good least it opened up. Usually when you take out blued steel Springs their circular they have zero resemblance of the taken aback curve and there's not much bigger than the barrel. They will work they will run the watch but not for very long because it just no energy left is no spring left in the spring.1 point

-

I've tried that, but the square part of the arbor is was never long enough to get a grip on with the pin vice. Maybe I just need better pin vices.1 point

-

Some slightly beaten up looking parts movements including a Waltham with twisted hands, two Rotary ladies, one Tissot ladies and an unknown ladies pocket watch. All qualify for the 404 club, bit the Waltham is the one I was most interested in. At just over a pound per movement, I'm pretty sure I'll get some value from them.1 point

-

Wow @Kalanagthat is amazing. Mine even has a omega signed crown. BTW, the second link did not work for me...timed out several times. Could be me. Here are some of the other tools. Even includes a cannon pinion breaker! That last tool has me baffled. It is not a watchmaking tool...perhaps for scribe something or another.1 point

-

You may find the right microscope makes a taller work surface unnecessary. You're definitely leagues ahead of most of us amateurs!1 point

-

A "Regulateur" pin set pocket watch (or some bits of one) is heading my way. I'll admit I bought this for the case, which appears to be in reasonably good shape. There is a pretty high likely hood that the worrying collection of bits in that tobacco tin should actually be in the watch. However since it only cost me 0.99p I think its worth the risk that it might be incomplete. Besides I have a fair number of homeless movements, so perhaps one of those might wind up in this case.1 point

-

Hi, I’m new and a beginner but have made some progress with disassembling this clock. It doesn't look damaged but doesn’t go for more than 10 seconds and looks like it only needs to be cleaned and oiled. To get the rear plate off I need to remove the wheel with the screw driver head under it see picture. The axle this wheel is on is captive and goes right through to carry the clock hands and the configuration of the wheels on this axle between the plates means that the wheel I’e identified has to come off. This wheel looks like bits been simply hammered (gently) on. It is tight and levering it off with a couple of hand removers didn’t shift the wheel. so my question is: Should I try harder (I don’t want to bend the plates or the wheel I’m trying to get off, or shift the other wheels on this axle. Or would a gentle bit of heat from a wee torch be the answer as when heated brass expands more than steel? cheers Jeremy1 point

-

I've been using jojoba oil for years in a hand tool woodworking paradigm (same problem, different scale). I made up a little sapele box with a reversible lid. One side of the lid is just french polished, the other side has a small piece of shearling leather glued to it (hide glue for what it's worth). Jojoba oil lives inside, and when I'm done with whatever tool, I drag it across the lightly oiled shearling, and then it goes to its home. The fatty acids that make up the triglyceride that is Jojoba oil are fairly long chain, and fairly saturated (as far as natural oils go), so it doesn't evaporate or go rancid very quickly.1 point

-

This is my collection The lolipop one was the first one which came from my dad's collection of watches he must have taken on trade in. It did not work, so I fixed it. The others, I bought on wild-and-crazy ebay. Some bad buys, but I recovered at some cost. Often the cases are wrong. The uncased watch needs a hairspring which is impossible to find. I recently got a case on ebay that was a good price and I was able to recover one of the watches that came with a faux case.1 point

-

Yes, plus radon gas. However, the risk is very low IMO. I posted on the "radium" thread on this site, a study done that included wearing (in a variety of ways), working on watches both as a professional and hobbyist, etc. The yearly exposure is quite low, even for a professional watchmaker (150 mrem/yr). My own sense of risk is anecdotal. My Dad was a watchmaker and serviced watches 55 hrs/week from 1947 to 1980 and then at about 10 hrs/week for the next 10 years. He died at 93 of natural causes. I am certain that there was radium everywhere at the shop. Nevertheless, I use caution and would urge others to do so as well, because the human body is complex and we are not all the same--some may be very sensitive to the effects of radium.1 point

-

0 points

2Rotarys(ladies)UnknownPW(Ladies)Faces2-l1600.thumb.jpg.7f1a8ba3226dc2083a2b6a02da62c22b.jpg)

2Rotarys(ladies)UnknownPW(Ladies)Rear-l1600.thumb.jpg.62ec3f4ddcea646d0ff25c715cbcc89b.jpg)