Leaderboard

Popular Content

Showing content with the highest reputation on 04/18/22 in Posts

-

Morning all Well I'm feeling quite chuffed with my self. I wasn't getting on with my stainless steel tweezers so I bought some AA brass tweezers. So armed with these new tweezers I have stripped down the date side of my Salav 2414 movement and NOT had a single part enter the unknown area that's call the floor. I can also twist the smallest screw 360 degrees with out a single "ping" where did that go. This may sound very basic to veteran's but to me it's a mile stone won. yes I know it's early but I was up at 5am and decided after putting my bins out I would dress my screw drivers under a loupe with a diamond oil stone 600, 1000 also while I was at it I started a spread sheet for screw drivers example Black 1.0mm length in jig 23.22mm Length in jig is so next time I get the same angel when it come's to redressing that screw driver. I'm also getting into the habit of taking a photo before and after removal of a part. I don't expect to reassemble the movement as it's a watch that doesn't work also it's been butcherer before found sealant as a o'ring and the dial is very bad shape looks like it's been hit with a hammer in some places. BUT I haven't loss any parts I'm going to clean parts and then keep as spares. Happy Noobie Monday3 points

-

3 points

-

3 points

-

2 points

-

1 point

-

So I was on youtube and this came up. I thought it was amazing so I thought I would share. I love watching stuff like this amazing hope you enjoy1 point

-

Disassembly sequence here (Please sort by name in ascending order) Assembly sequence here (Please sort by name in ascending order) The watch is an Enicar Star Jewels Ocean Pearl from the 1970s A bit of background I bought this watch on tradera.com (Swedish eBay) listed in the category "Klockor/Renoveringsobjekt" ("Watches / Renovation items"). It was listed as "working" despite lacking the winding stem. I bought it for three reasons. I wanted to try my hands on an inexpensive watch in visual need of renovation. I was curious of the Enicar brand and their in-house movements, and I thought the blue dial with its applied indices had potential. It was clear that the watch needed a new winding stem, crown, and armoured crystal. I found an original stem on eBay from Spain for less than €10 including shipping (a bit of a bargain I think). I bought a bunch of inexpensive waterproof crowns from CousinsUK.com so that I could select the most comfortable and at least somewhat nice looking. I also bought a couple of inexpensive Sternkreutz armoured glasses from CousinsUK.com Overall the movement looked pretty OK except for a third wheel pivot that was rusty. Removing the rust (using vinegar essence) the pivot became Coca Cola bottle shaped so I burnished it and in the process had to remove approx. 2 to 3/100 mm. This in turn created too much side-shake so I replaced the jewel as well. The mainspring looked pretty OK too so I kept it. The cannon pinion also needed a bit of tightening. I guess the friction between the centre wheel arbor and the cannon pinion really can't last forever when a watch is being used for many, many years, perhaps even for decades (looking at the case back of this watch it has seen massive use). Anyway, to tighten the cannon pinion I first tried with my Seitz jewelling pusher and stake for lanterning cannon pinions, but it feels like the edges of the pusher and stake are somehow too blunt or perhaps not designed for wrist watch movements?! So, I resorted to my cannon pinion tightening tool (Bergeon 4733) which is really a bit scary to use but works very well once you've destroyed your first two or three cannon pinions learning how to use it. The trick is not to alter the position of the screw (unscrew it) once it reaches the inside of the handle. As soon as the screw touches the inside of the handle it's time to press. That will usually tighten the cannon pinion the required 1-3/100 mm (I would guess). To give back some of the luster to the dial and hands I simply used a Dial & Hand Cleaning Pen from CousinsUK.com. It worked better than I had expected. The old lume was partly missing and what was left was completely crusty so I simply scratched the remains off and didn't bother to replace it (the blue colour shining through the hands looked pretty great and I don't care much for lume anyway) Despite throwing everything in my arsenal of collected knowledge and experience on the this watch I couldn't get it to run perfectly. The amplitude (as well as the rate) in the horizontal positions fluctuates between 260 and 280 degrees but mostly stays around 260 degrees. I did adjust the curb pin as the hairspring was pinched between the boot and the curb pin and made sure it bounced evenly between the two, but the effect was only marginal. I suspect that the hairspring touches the lower part of the boot. Anyway, I decided to wait with further investigations, put it together, wear it and enjoy it. Despite this shortcoming it performs very well as a daily wearer, only varying in rate between about +1 and -1 seconds per day.1 point

-

As long a the primary focus is function I don't mind aesthetics one bit, quite the contrary. It can be extremely satisfying to enjoy. However, aesthetics (like a golden dragon on the dial) without function, no matter how beautiful and well executed, just isn't my cup of tea.1 point

-

That's kind of how I feel about tourbillons. I do however find the rose engine decoration on a dial quite nice. RGM's operation is quite a bit smaller in scale than Arnold and Son.1 point

-

Probably just the fan motor running slow with age, if it had just stopped you would hear the difference in the sound the oven makes. Low cost ones are just not worth repairing these days, even 20 years ago when I worked on them we mainly only did insurance work as the cost of major parts was often more than the microwave cost new, we often just bought a new oven just to strip for spares as it was cheaper than buying some parts, even at trade prices. Glad I am not in that business any more.1 point

-

Interesting. This is why you asked the question the other day then, about wearing Russian, ended up causing a bit of a stir haha. My favourite and first repair watch is a Sekonda 2609ha raketa that belonged to my grandfather. I also picked up a Suba dude a few months ago and my missus bought me a vostok custom diver for Xmas.1 point

-

I learned about it here: https://www.geocities.ws/dushang2000/ It appears to be an excellent site at first glance, and I'll be spending some time there this week.1 point

-

Nice walk-through vw. I've passed up on a couple of these in the past, this has encouraged me to have a pop at one. These are the nice vintage cheapo pieces I enjoy learning on. Love the caseback design and the Enicar Saturn logo, I used to be an astromer. Good looking solid crown choice, I hate the skinny hard to to wind , bit difficult for me to gauge when they're fully wound. Overall nice restoration1 point

-

Thanks for asking! Mostly Moebius! Taking a look at my latest service walkthrough (assembly sequence pictures) should give you a good idea. I believe I get better results (amplitude) with Dr. Tillwich Watch Oil 1-3 for the pallets, but I don't think it is as durable as Moebius 9415. So, I'm a bit split.1 point

-

I think Hector covers all bases ," just keep calm and carry on ". I use the screw mothod as it retains the brigde and tappinf and shuffling usually works. The stubborn ones need a poke so I made some shaped tools from needles bent at various angles to get under the plate.1 point

-

Practice, practice, practice. There is no substitute for actual hands on practice. It took me 45 mins to get the train bridge on when I first started. After 4 years of practice, I can usually get a train bridge on in under a minute. There is no secret technique. Firstly, get all the bottom pivots into their respective holes and stand the wheels as upright as possible. Then take the top plate and orientate the holes to the pivots. Hover the plate just above the pivots and drop the plate on. If you are lucky, you'll get a "hole-in-one". If not, try using the back end of your tweezer to tap lightly on the movement holder. The vibration may jar the pivots into their holes. If all else fails, then you have to resort to the "poke and nudge" technique. Use your pegwood to apply gentle pressure on the top plate and use your tweezers to lightly upright the wheels and coax the pivots into their holes. Start with the bigger wheels first and work your way down to the escape wheel. Sometimes with really stubborn ones, you might have to place some of the screws back in, but do not tighten them. They are placed only to prevent the top plate from separating and allowing the bottom pivots to get out of their holes. Make sure you have good lighting, work at your shoulder level unless if you are using a microscope. Stay calm and breath slowly. Take breaks before you break something. Good luck and enjoy.1 point

-

1 point

-

What I've done in similar applications is get the broach that's the correct range, then find the spot that it's the right diameter with a micrometer. Mark it somehow; a tiny piece of masking tape for instance, or some graphite pencil lead. For larger format analogs (thinking a set of carburetor jet reams), I use paint pen marks that are semi-permanent, and do the full set in appropriate increments with alternating colors on whole numbers or fives/quarters. Then broach up to, or right before the mark, test fit, and go a up to/past the mark as needed.1 point

-

I'm afraid I can't answer your question, but I thought I'd mention that Kluber Chronogrease P125 seems to be a very popular universal(?) braking grease. You can have it from Cousins (5 grams) for as little as £84/€101/$109 including 20 % tax. That is, the price including tax per kg would just be £16,788/€20,257/$21,889. So, better get a kilogram life time supply before it goes up in price!1 point

-

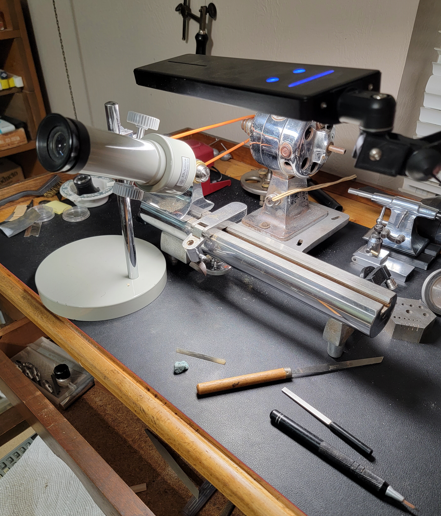

Another thought on this microscope. I have a nice stereo scope, so when I need close up work, it works quite nicely. It is mounted on a large boom and takes up a lot of space, so it is a little cumbersome for lathe work. This morning I had the idea to use the Bulova for turning. I did a test and turned a 100um pivot using pivot steel. It might work. I wish I had a little more working distance, however.1 point

-

1 point

-

Hi T practise makes perfect but on the other hand faliliararity breeds contempt I think we aim some where in the middle well done for not crawling on th floor1 point

-

1 point

-

Just a thought, there are two huge very powerful magnets in the magnetron, never checked so don't know if the magmatism makes it through the case but that would affect your watch if it's was. Will check mine later with the magmatism app on my phone and report back with my findings. Re your microwave cutting out, might be something like the fan not working or the vent holes at the back have become blocked, check the back to make sure they are clean. Or it could be the ghost of your ex-husband playing games1 point

-

You CANNOT remove the hole jewel from the metal housing. In order to clean it you have to use ultrasound and a cleaning solution, or floss it with a thin strand of hair. If you have stuff stuck in the underside, in between the metal housing and the hole jewel, you just have to hope for the best with ultrasound.1 point

-

Too aggressive... I know there are dedicated tools for this but are you guys talking about using tapered broaches by hand? The difference is .01 mm, .0004 in, 10 microns. Potable water filters and automotive oil filters filter out 10 micron particles. Gust thinking about a cutting tool should remove more than that in a softer material. I have had some luck just burnishing small amounts from the back side with a tapered steel pin that I have. I can't say what it was supposed to be or for what purpose it was made but I modified it to fit in my jeweling tool. It has a fine semi satin finish and is held perpendicular to the table. It is a bit slower than cutting but that gives back some extra control over turning a tapered broach by hand to an uncontrolled depth. The jeweling tool gives fine adjustment of the finished depth and diameter achieved. It should also produce a rounder hole than a tapered cutting broach. Just protect the front surface from any damage, put some pressure against it and gently swivel the hand about the pin (if you can't swivel the hand you're pushing to hard). I wouldn't try changing sizes by drastic amounts this way but for small discrepancies or the last little bit after cutting it's fine. Just keep going until it fits. Shane1 point

-

Well OP's post the slot goes over center, so no idea at all, total nmLystrt1 point

-

Esslinger has Stella crystals for hunting case watches in both GHC and PHC styles. It appears to me that GHC is the flatter of the two. I need the flattest style. I have search online for a Stella catalog or some other documentation to explain this difference...no luck. Anybody have a pdf stella document? Anybody confirm what I surmise above?1 point

-

If it keeps running in FU and FD positions then pivot shoulder seats are not rubbing on hole jewels, so unless you like to renew the staff, this one still has another decade of life left. I don't think this approach of mine got approval from OH , he once said just put everything back right( he was reffering to my advice I think), but here is what I do and it works. Flip cap jewel over, so its domed side faces the pivot, this will reduce end shake. Oil will stay on top of the dome specially if you epilame treat it. You might need to adjust shock springs to press on cap stones( push on them and bend a tiny bit) so not to have the jewels loose inside housing of the setting. Both lower and upper end stones can be flipped over if needed. Its a lot easier than staff renewal, poise .... Good luck Doc.1 point

-

That's what I'm thinking too. Then someone in an higher echelon identified who theorized that being able to freely add oil without cleaning is a good idea, the additional cost for the special jewels, sent him back to assembly work and the novelty quickly disappeared.1 point

-

The hairspring studs in these balance cocks without a stud screw are held by friction very tightly in the stud carrier. It’s almost impossible to press out safely unless you can find a way to support the underside of the stud carrier, but the balance wheel is in the way. I looked at the Jules database and there’s quite a number of balance staffs listed there for the 2452, with multiple incabloc ones with different pivot sizes? http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_24521 point

-

As this is a single roller it was probably held In with shellac at least at one time it's probably washed off or disintegrated with time. Whenever you lose a roller jewel you should always search the movement if you're lucky you might find it. And yes some watch companies much later on like in the 40s when they change the production methods did use friction jewels but not a single roller like this. You also have to be careful with which assortment you get because American pocket watches used two different lengths of roller jewel's depending upon whether was a single roller or a double roller. So basically out to find an assortment that has the longer length of jewels that you need for the single roller escapement's. Which is becoming harder and harder fine for the large size pocket watches. Then just for future reference they do make special tools for sizing roller jewel's. Plus I threw in a few more pictures of what the tools would look like even though you didn't need the tools. More for future reference1 point

-

Hi JoeBirmingham, I believe what you should be referring to are the crown and the pendant tube. The stem does not form part of the screw-down function. That crown looks very much like those used on Monnin cases. These crowns were made by a different firm (either BFG or MF Co.). These crowns screw into a thread cut within the pendant tube. When they fail to screw down, it can be either the pemdant tube thread or the corresponding thread inside the crown. To replace it, you can buy the crown and matching pendant tube from Cousins UK. You need to know the stem thread size (like 0.9mm or 1.0mm) and the crown diameter. You may be able to simply swap the crown and keep the pendant tube as-is. Otherwise, the pendant tube requires press-fitting.1 point

-

@JohnR725 I've swapped the cannon pinion with a spar one I had and the watch is now working fine, it doesn't stop and it keep great time. The only thing is that setting time is quite hard so I think it needs a service but I will use it for a while before bringing it to a watchmaker.1 point

-

Some posts about the supposed advantage of 'hollow ground' screwdrivers has been moved to our pinned topic on the subject below. Incidentally I'd like to inform fresh members that if they can undertake the not so big effort of reading into that or any other pinned topic, it's most likely that their questions and elucubrations have been covered there already in the past.1 point

-

Another "makes it look so easy" video by one of our members @Repivot, this time about hairspring manipulation. https://youtu.be/IoBd-oxpEZ41 point

-

1 point

-

I have no idea, but I am looking forward to the results of your experiment!1 point

-

You completely missed the point of my post The O/P was asking about a low cost solution. And believe it or not water and dish soap does a very good job of removing oils and grease, it's what dish soap was designed to do. It not be used by any watch maker professional or not that you know of, that does not make it any less good at removing oils and grease, I bet the average frying pan is far dirtier than your average watch. I agree it my not be the best and it may not generally be used by watch makers, but that does not make it any less effective at doing what it was designed to do and at a low cost which was the point of the O/P I will step away now. Bye1 point

-

I'm of the (ahem) older generation. My father's famous words if I was going to do something I hadn't done before - "Min' an' use yer heid" - meaning remember and use commonsense. Perhaps my pet hate is the warning you sometimes get over hot taps - "Hot Water. Danger of scalding!" Well, no sh** Sherlock!1 point

-

As the man said there are many and varied opinions, as a starter as we are at the begining you can use Lighter fuel, and rinse in IPA then blow dry carefully. as your skills develop you may wish to go further and get a cheap ultra sonic. They can be had for about £20 used for jewelery, bracelets etc and they are adequate, I have one myself and it does a crediable job. So initially you dont need a great capital outlay at this point. Just take your time and enjoy what you are doing.1 point

-

if its a high beat (28800vph) then 9415 is the correct oil, its an oil that turns to grease on impact, however on low beat (21,600 vph) 9410 is the correct oil which does not have these impact characteristics Pallet jewels should only be lubricated on the impulse faces, not on the top at all. it is good practice to have no visible bead of oil on your oiler when you apply to the pallets, just "wipe" the oil across the face of the jewel, the actual contact area of the pallet with the escape wheel is very small, so little oil is needed, too much just causes drag. there is another method of oiling the pallets, which is to apply the oil to one tooth of the escape wheel, the theory being it will eventually spread this oil over all contact points. The noise you see on your timegrapher can be the oil, if you have not applied too much this noise should settle down after a minute or two, The reason being that the oils spreads over the escape wheel contact points over this period, however another symptom of the noise is the pallets themselves, incorrectly set pallets will generate noise.1 point