Leaderboard

Popular Content

Showing content with the highest reputation on 04/05/22 in Posts

-

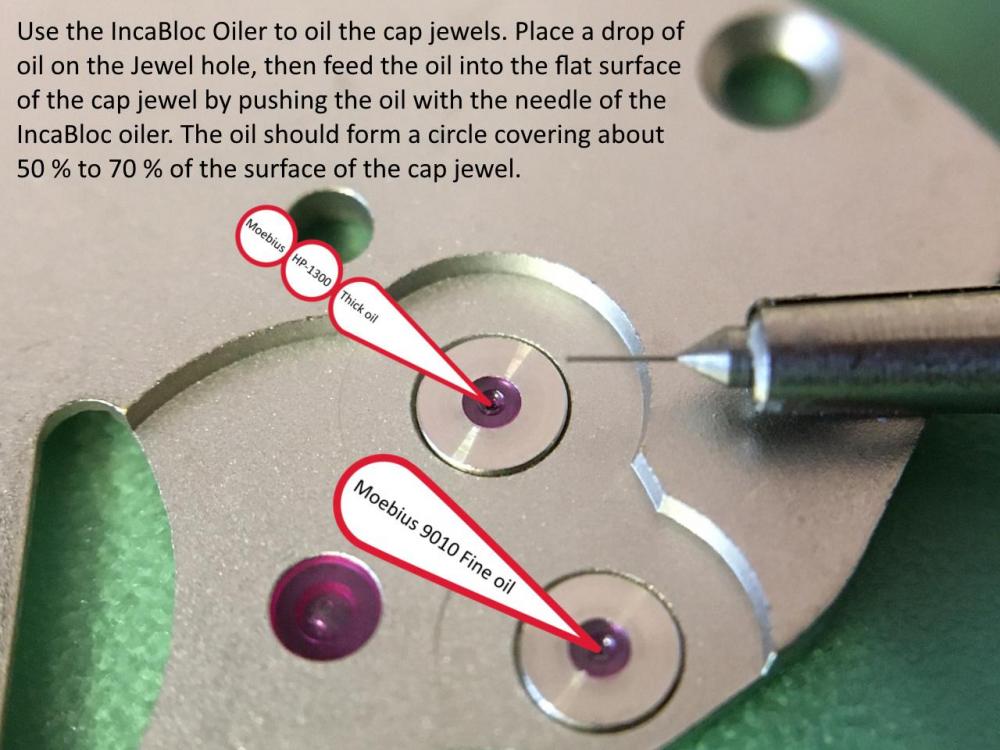

I used to have a Bergeon automatic oiler, but it has long since disappeared. I didn't like it as I could never be certain how clean it was at the tip. For jewels such as these, or old fashioned assembled cap and hole jewels as one might encounter in any watch made before Incabloc or Kif existed, I put a small amount of oil on the hole jewel, then push it through to the cap jewel. There are specific tools for this you can buy from your supplier; I use tiny taper pins that are intended for hairspring pinning.4 points

-

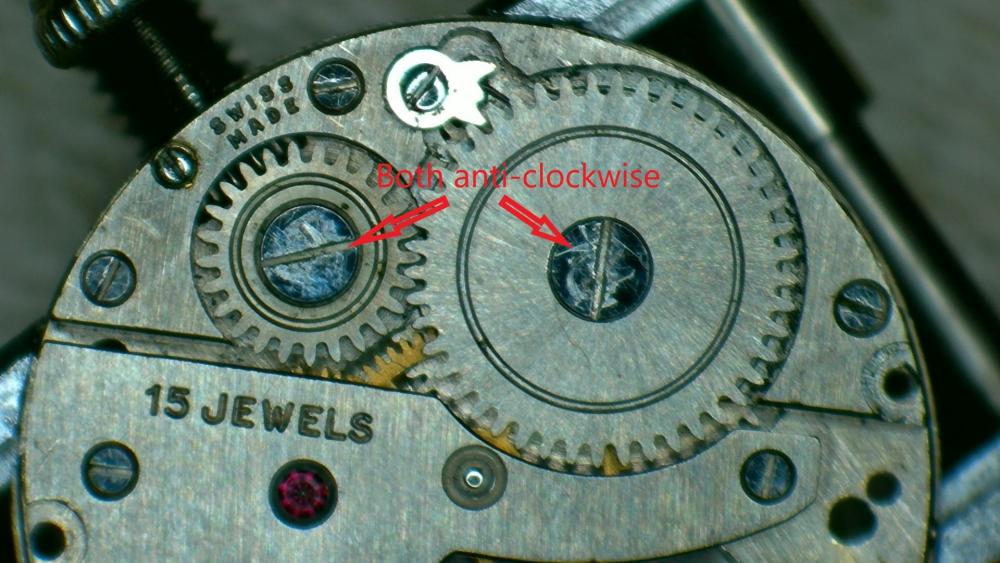

Yes. I have come across several movements (recently a A Schild 984) where both the crown and ratchet wheel screws are reversed. Why? I don't know. Of course, I made a note on the pic for future reference. As @HectorLooi says, if the screw seems tight, try turning it a little the other way. Even if it's not a reversed thread, this can help free the screw.2 points

-

The secret is not to use brute force. When I'm unsure, I turn the screw a little both ways to see which way has less resistance. I've come across watches with both the crown wheel and ratchet wheel with left hand threads. And yes, they do unwind themselves.2 points

-

I‘d like to send greatings to all members and moderators here. My name is Karl and I enjoy my retirement after many active years as a mechanical engineer. My first steps in servicing watches as a hobbyist are about 30 years ago. At that time I had to learn from books and by doing (and destroying…). Meanwhile I watch the fantastic youtube tutorials which brought my interest in watchmaking up again. After successfully servicing a Citizen ladies automatic and a Rx 3135 clone I started servicing my JLC with the 889/1 caliber. I stranded yesterday with oiling the combined bushings in which the escape wheel is running. This problem lead me to this forum and to my first question that I will post in a minute. Regards Karl1 point

-

I adapted a tool to allow me to repivot a balance staff on a watchmakers lathe…and it all worked. Here is the video.1 point

-

I suspect you'll get some better answers but you want to clean off dried oils and grease. Grease and oil become softer/more fluid when heated which would subsequently make the ultrasonic wave cleaning easier more thorough.1 point

-

It'll work great. Lots of us just have heartburn about how many more tools and watches we could buy with the money spent on lubricants.1 point

-

1 point

-

I suppose that was to save one tool change and one different screw at manufacturing.1 point

-

1 point

-

Couldn't the tip just be pushed into a clean piece of pith wood and then be blown off (like an ordinary oiler), or am I missing something here? Anyway, a disadvantage of the the automatic oiler that I have, the Bergeon 1A, is that the diameter of the tip is too wide for some very small jewel holes, like the those for the capped jewel holes of some Seiko and Orient watches (3rd and escape wheel). In those cases an Incabloc oiler (or similar) is really what's required. For anyone interested here's my video review of the Bergeon Automatic Oiler 1A. Here are some pictures of it:1 point

-

Back to your question, after you have cleaned the entire bridge/plate with the bushing jewel, you can oil the cup in the jewel on the opposite side with a normal Oiler. You then have to use a needle or a sharpened Oiler to poke the hole jewel through the oil cup, wicking the oil from the cup to the gap in between the hole jewel and the endstone.1 point

-

You have to try the L&R cleaners. They do such an amazing job that even fully assembled incabloc jewels come out clean.1 point

-

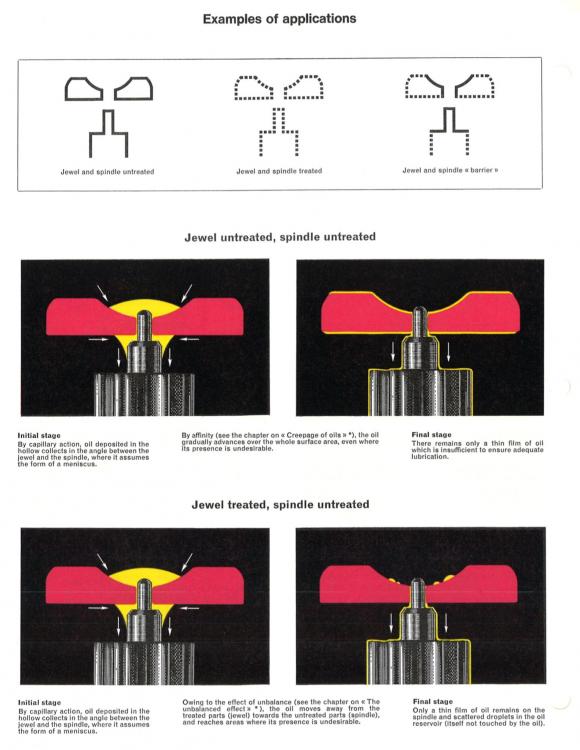

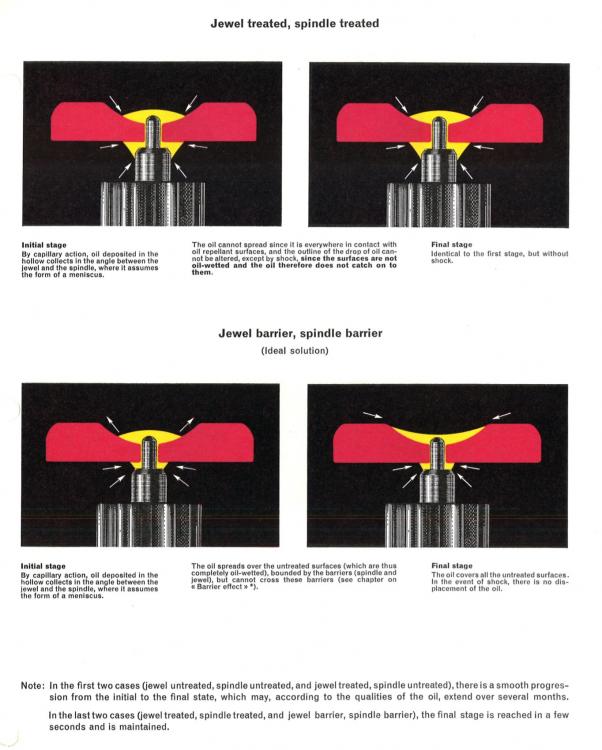

I think if the entire surface is epilame treated, oil deposited will stay fixed in position. If there’s a surface that is partially epilame treated, oil will migrate from the epilame coated surface to the untreated surface. This means that the epilame is oil repelling, but if the entire surface is oil repelling, the oil will not migrate.1 point

-

1 point

-

I ultrasound them in L&R #111 cleaner, rinse twice in #3 Rinse and finally benzine. I also place a drop of oil in the jewel hole and use a broken oiler, which I sharpened to a needle point, to wick the oil into the setting.1 point

-

I could be very wide of the mark here but I don't think that epilame needs to be hard wearing, in fact I'm not sure that it doesn't need to be fairly easily abraded in order to function the way it's supposed to. The idea is that it is an oil repellent. you coat the parts with it, then run the watch for a short period without oil. That way the the epilame gets quickly worn away from all of the points of contact. You then oil the movement in the normal way but the oil can only stick to the contact areas where the epilame has been eroded, and it can't spread beyond those areas because that is where the epilame is still intact. The result is that the oil stays where it is supposed to and doesn't get wicked away into the rest of the movement.1 point

-

Are you holding down the ratchet wheel firm with a piece of pegwood, then unscrewing either clockwise or anti clockwise gently to see which one loosens it? Also, you’re going to face serious issues lubricating the balance jewels. You have to release the balance wheel first.1 point

-

I am going to try a product I have used for other things outside of watches. Its called EvapoRust. Its different from Acid based products (of which Vinegar is one). It works through a Chelation process (its molecules attach to rust molecules and detaches them from the ferrous material) so no change in theory. Its water based and enviromentally safe. So I dont think I have much to loose given the condition of the spring. I may take out the regulator pointer first (or whats left of it) and just brush it clean.1 point

-

I know that before I disassembled the watch even with the rust, the balance wheel would run for a few seconds when pushed with air. I failed to check the fork after I removed the balance wheel. So dont know yet. You are correct, its whats left of the regulator pointer :-). It looks like it had broken off and that piece missing I found inside the case. But the regulator actually still seemed to work before I pulled it. It moved at least left/right.1 point

-

If the balance wheel tilts when upside down, and the balance wheel pivot is located in the hole jewel, it COULD mean that the hairspring isn’t flat. This MAY potentially affect the amplitude of the watch in the vertical positions. But getting the hairspring flat could also introduce a lot of other problems and is not meant for beginners. I would recommend you look into other potential issues before even thinking about this. I didn’t mean that the pivots were broken causing the lower amplitudes in vertical positions. Since the shoulders of the train wheel pivots rest on the upper and lower jewels in the vertical positions, the increased friction in the vertical positions cause lower amplitude. If the increase in friction is too much, such as due to insufficient end shake, or pivots not polished, the amplitude drop would be larger. But such adjustments would require expensive tools to fix, and special care to diagnose. When you install everything except the pallet fork and balance cock, and try winding the watch, all the train wheels should spin. Does the escape wheel spin change direction of spin at the last moment? This can be a good indication of train wheel freedom, since it means that all the wheels have very little friction. This is known as back spin, but not all movements may show it. Have you tried timing the watch again after 24hr at full wind? Is there any difference? How did you lubricate the pallet fork? I hope you didn’t lubricate the pallet fork pivots.1 point

-

Finally the case. This was never going to be perfect. I started by gently cleaning it with white spirit and one of those green pan scourers. This removed the filth and didn't abrade the surface to harshly. I have seen a number of clocks where it looks like someones taken a belt sander to it. This was followed up by applying a 50/50 mix of white spirit/boiled linseed oil. Forgot how many coats I put on. Then finally applied the boiled linseed oil oil neat and wiped off any excess after allowing time to dry. Then is was two/three coats of clear wax and plenty of elbow grease. I'm no furniture restorer, but I think the results are pleasing on my humble little clock.1 point

-

Scrappers break my heart sometimes. A few of them have ethics, and they try to ensure that the watch they scrap is a non-runner that is mostly beyond hope. But some I swear will scrap a watch that may only need a good cleaning. Either way, OH says it better than I can. Even if we locate a latch spring that could possibly fit and may do the job, it will almost certainly have to be modified in some way. I've only gotten lucky a couple times, and I still had to file down a couple surfaces and drill a new pin hole before the spring was set to do the job. It would have only been *slightly* more difficult to make a new spring. That's the sort of task you'd be facing.1 point

-

This will be like looking for a needle in a haystack no two are the same. I have seen them on ebay in collections of old watch parts. One of the reasons you find they are without the case is the cases get sold for scrap and all parts that are not silver or gold have to be removed because they add weight no matter how little. You might find one you can adapt but getting it to fit correctly and the screw hole to line up will be hard I don't know of a tap that small that you can buy and I haven't a clue what thread it would be, something odd that's for sure.1 point

-

Let others feel free to answer also, because I can make no promises, but I possess a bunch of old latch springs. I could send you a private message, wherein I would request the most accurate measurements you could make (thickness, length, width of latch section, etc) and a tracing on paper of the spring which you could scan and attach or mail to me, and high resolution photographs. Don't stop looking though. There are a great many different kinds of latch springs.1 point

-

1 point

-

As far as I know, nothing has happened. I'm guessing Mark just doesn't have anything new to post at the moment. He has already covered a lot of ground in previous videos and his lessons. Sooner or later I suppose you run out of things to say, plus you are just too busy with other stuff (like running this forum, for instance).1 point