Leaderboard

Popular Content

Showing content with the highest reputation on 03/04/21 in all areas

-

Normally this is done with a studding table, which is a tool that clamps the stud at whatever height you want so you can clamp it with the hole sticking out at table height. Slide the spring in, then insert pin. Most folks don't have that tool, so the next best thing is the cock itself. Fix the stud in place, insert spring, then pin. To press the pin tight it's very useful to modify a pair of tweezers by removing about 0.25mm from the end of one side; now you can rest against one side of the stud with the short end and squeeze the pin in with the other side.3 points

-

2 points

-

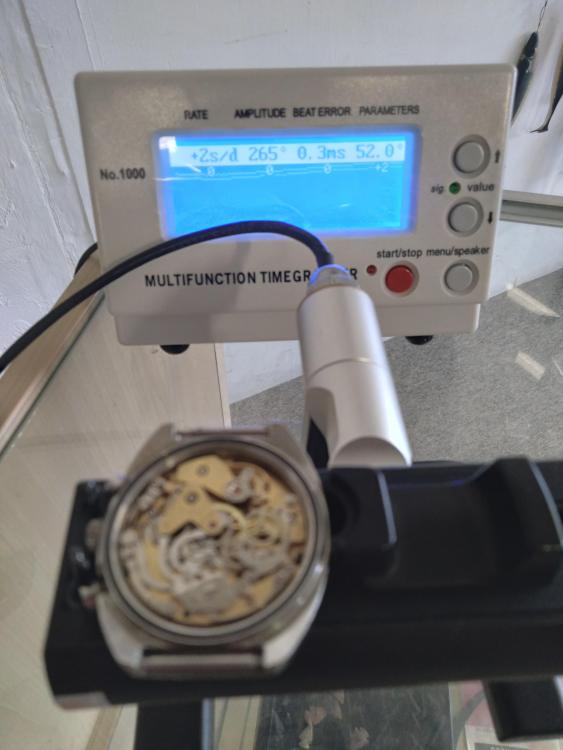

Hello all! This is my first post, and I apologize in advance if this has been covered. I did some searching and reading and still wanted to ask a couple questions. My background - I just started collecting watches last year. I've gotten kind of obsessed with mechanical watches, and really wanted to try tinkering a bit. I recently bought a timegrapher, and I've regulated all of my mechanical watches (all new watches). I managed not to break anything, and I have greatly improved the accuracy of all my watches. I felt pretty good about that, so I started collecting a few very cheap vintage watches to work on. For my next step up in my comfort level of working on watches I removed a few movements and crystals from the cases and buffed the old acrylic crystals and made the old watches look a lot better. That's super simple stuff - baby steps. My timegrapher says the old watches I've bought are in dire need of attention. One is +100 spd dial up and then -300 spd crown down, or something like that. Very low amplitude, 5 ms beat errors, a screen that looks like snow... running, but just barely. With the giant swings in rate in the dial positions, these are obviously beyond a little tweak of the regulation arms. I did the crystals so I can admire the vintage dials, but now it's time to step it up. I've paid less than $10 for some of these, so they will be great practice watches for the next step. So thinking about the next step and trying a service - which I guess would be a complete tear down, clean, lube, and re-assembly - this will take more equipment than I have. Speaking of what I have, I mostly just have basic low-end tools - stuff for sizing bracelets and opening cases. I do have a case press I got when I couldn't get a press-fit case back back on a watch, and I have the generic model 1000 timegrapher. I don't have anything for pulling hands off or re-seating hands, or a movement holder yet - those are basic things I plan to get soon. (Messing with the hands scares me, but I'm going to have to get over it!!) I really don't want to shell out a ton of money on equipment and oils for a first go at a service. After all - I may hate it, or I may find out I don't have the eyes, dexterity, or patience for it... so spending $200 to see if I can improve the performance of a $5 watch doesn't seem practical or smart. I need to do this on the cheap, and if I have success and I enjoy it, then I can maybe get better stuff. If I choose my least favorite and cheapest of these old watches to tear down, is there an alternative to a very expensive-looking parts cleaning machine for cleaning the parts? Can I just throw them in a jar of something and swish them around? If so, what solution should I use? I read a post where a guy said he used lighter fluid, but that seems like it would leave an oily residue.. For an oiler, can I get away with using a 28G hypodermic needle? I've read a lot about the oils and I think I know what route I'll take there to start. OR - maybe as a first step I should just try to take one apart and put it back together without cleaning or oiling? I could do that with the tools I have on hand (once I get something for the hands, and a movement holder). All my old watches are simple with no extra complications. One doesn't even have a seconds hand. They should be good learners. Any advice on the questions above, or anything else is appreciated! I watch a ton of Mark's videos. He makes it all look so easy, and I know that's just due to his expertise. I'm sure all of it will be very challenging! Thanks in advance!1 point

-

Cousins has it. Search mainspring by size, 2.50 height 0.20 thickness and you will get everything that matches that. There's one for a 17mm diameter barrel which is perfect for you, 50 in stock.1 point

-

Hi JohnC, Doesn't look it would creat any noticable beat error, which is a pain to adjust with fixed stud holders. In case you feel no master re-pin ner, I refit the stud with the cock, put em back on the mainplate and just use a bit of epoxy 5 to keep the hairspring in place. Good luck.1 point

-

The bike is now all finished although I will replace the brake leavers when I can find some more in leeping with the age of the bike. I took it for a short test ride tonight and the Sturmey Archer hub is changing gears nicely and no slipping when riding up hill. I'll take it for a longer ride this weekend.1 point

-

Welcome Jason enjoy the forum. The tools and oils for servicing watches are not cheap but you have a dilemma. You can purchase cheap screwdrivers and be selective in the oils but if you get the bug you will have to purchase again. You could purchase used tools from eBay. The two oils you almost certainly need is Möbius 9010 & D5. However there is an oil named “Anchor” which is sold as a general purpose oil watch oil. Sold on eBay and is cheap but it might be OK I have never used it but it is only £51 point

-

That's the same type of machine I had mine had the ultrasonic unit which the machine sits on and you just plug it in. That's the best machine I had using L & R and I had had others in the workshop.1 point

-

My rinse's jug just says L&R Ultrasonic Watch Rinsing Solution. An older one waiting for disposal does say #3 though, I don't know what the difference is. I use the ammoniated #111 cleaner. After the dry cycle, the basket on mine is too hot to touch for a few minutes. I doubt there is any appreciable risk of fire if you are using the solutions meant for the machine. I think we would have heard about it? I will be interested to hear if you determine yours is also wired wrong (or what I call wrong, anyway?) in the way that gives a faster dry and slower spinoff. Oh, does your fan run when the heater is on? It should.1 point

-

Sorry, "You can't" might be a little strong. If you give up on using the electro-mechanical timing and synchronizing system built into the machine out of simple cams and switches, and replace all that with a computer of some kind, you can of course make it do whatever you want. In my opinion that's unnecessary, and unnecessary computers should be avoided in things that I need to rely on for a long time.1 point

-

You can't, the time is fixed because the indexing motor runs a certain speed and it runs constantly until the basket drops into the next jar. You should concentrate instead on making sure the spin-off speed is as high as possible without causing the fluid in the jar to swirl around and splash up and out. All the speeds are controlled together with the rheostat you can set with a screwdriver. But the proportions of the speeds to one another are controlled by the taps on the wirewound resistor that you can move. I forget the exact details ... do you have the manual? It's all spelled out. My machine was wired wrong when I got it, giving a spinoff speed that was slower than the drying speed. The spinoff was useless and the drying would wake the dead. The spinoff is supposed to be faster than the dry, and it works great with that fixed. I have been using it for 15 years now...? Probably ran it six times today.1 point

-

1 point

-

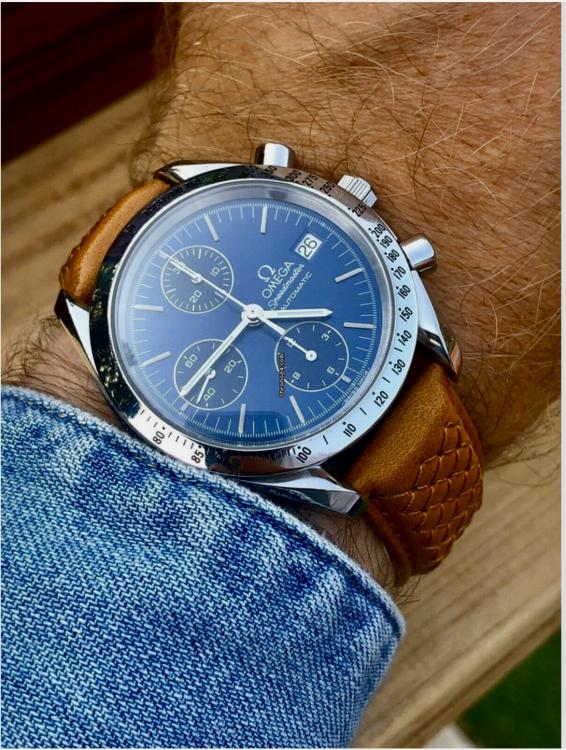

I acquired this watch not running with the stem not doing anything. I called around locally and only one person would service it for $475 dollars. I've always been afraid of working on a chronograph but after that price I decided to give it a go. Some of the keyless was rusted and I ended up breaking the setting lever removing the stem. I ordered a new one and got to work and I'm happy with the results. I also changed out the crystal.1 point

-

OK, what I did was soak it in WD40 for 24 hours. Then, with a tap tap on each side of the handle with a leather mallet, tugging with my hands and a little very careful prying it came of. Then the removal of the brass know was a little of the same process without the prying. Soaked the brass in lemon juice. The brass know is two pieces. I had to drill a hole in a block of wood that was bigger than the insert but smaller than the knob. Then with a wooden dowel, I knocked out the center piece. The center piece should have a spring that keeps pressure on the outer knob. It appears to be complete eaten away. Wow. I will post pictures later1 point

-

If it were me (and you're not, nor should you be), I think I'd take a file/emery stick to the top of the new cam. Original parts are only original once, but new parts can be sourced. You're forced into a new minute counter by nature of the repair, but the others are still original. That seems like the lowest impact and most cautious approach you could take. That said, I'm a dummy, and someone else will be along shortly to prove it.1 point

-

Yesterday I started to work on the case. First some pictures from before: I started with a grid 100 file and that got out most of the deep scratches and dents. I used some water while filing so the removed metal doesn’t settle into the files too much. after that I moved all the way up to grid 12000 and this is how the case looks now: On the top surface I didn’t went up to 12000, because it will be brushed in the end anyway. I think this already is a remarkable improvement. Getting to this point already took me hours. next step will be to polish the sides with a wheel and apply the brushing to the top.1 point