Leaderboard

Popular Content

Showing content with the highest reputation on 06/12/20 in Posts

-

If the goal is better isochronism with a modern unbreakable/back curve mainspring by mining the archeological depths of horology, you might be better served with a Geneva stop. The whole point of the metallurgy and geometry of the modern mainsprings is to compensate for torque delivery differences across the winding length of the spring. This obviates the need for a fusée and the Geneva stop for practical purposes, but if you're trying to get super accurate isochronism on top of that, your torque delivery error zones are still at the ends of the spring, and the middle is pretty flat. A Geneva stop removes those error prone regions from play, and is much easier to make. Old school Geneva stops would allow something like 4-5 turns of the barrel, but a modern spring would allow a bit more since the error prone regions are much tighter at the ends.2 points

-

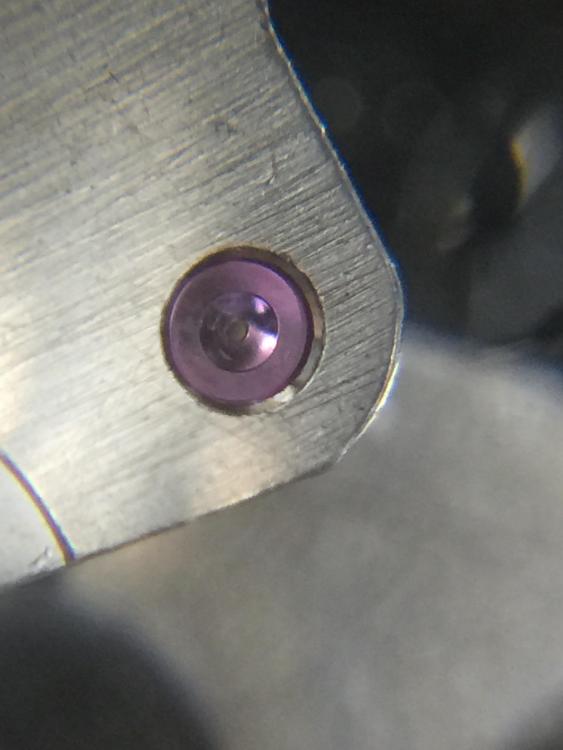

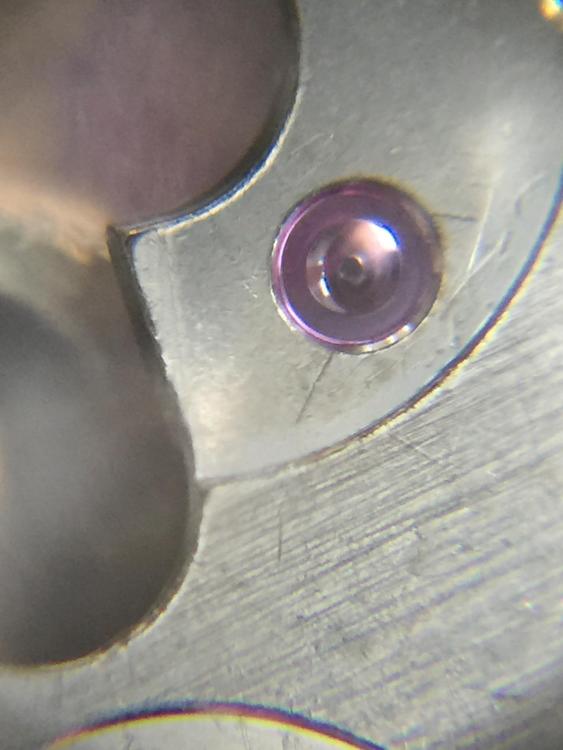

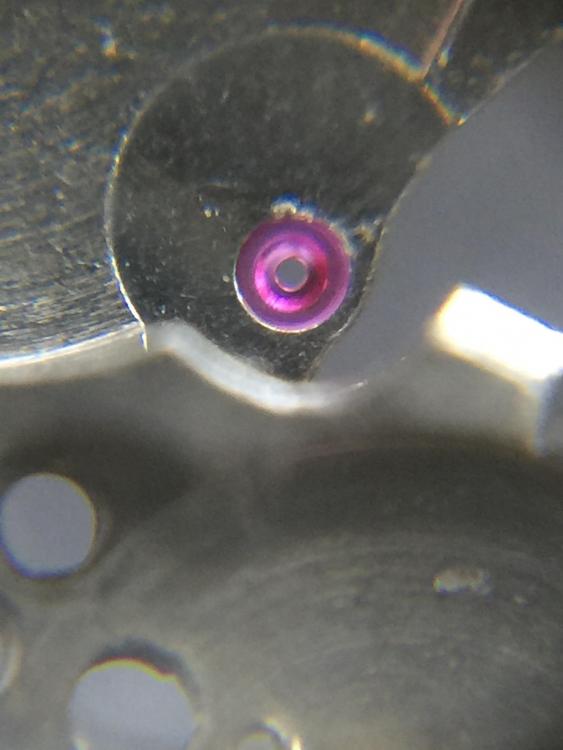

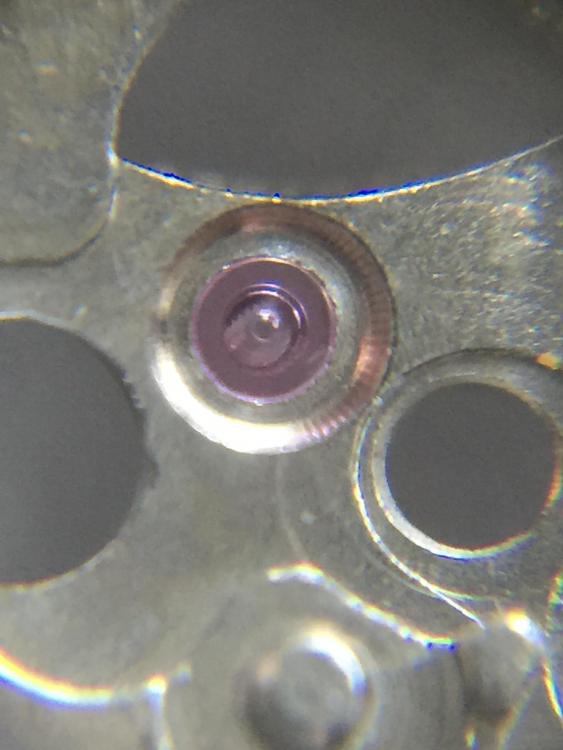

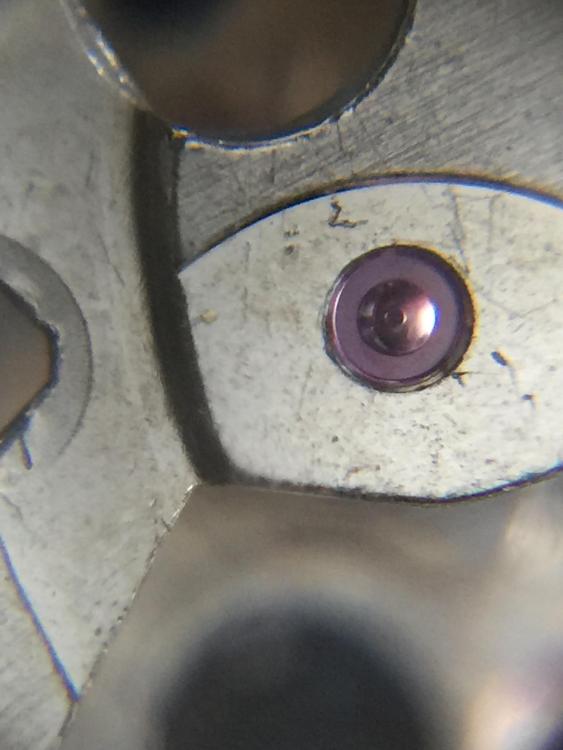

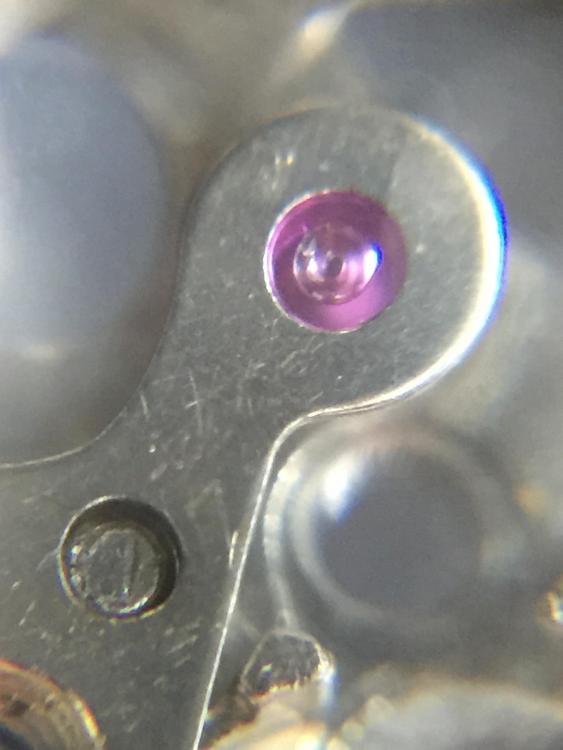

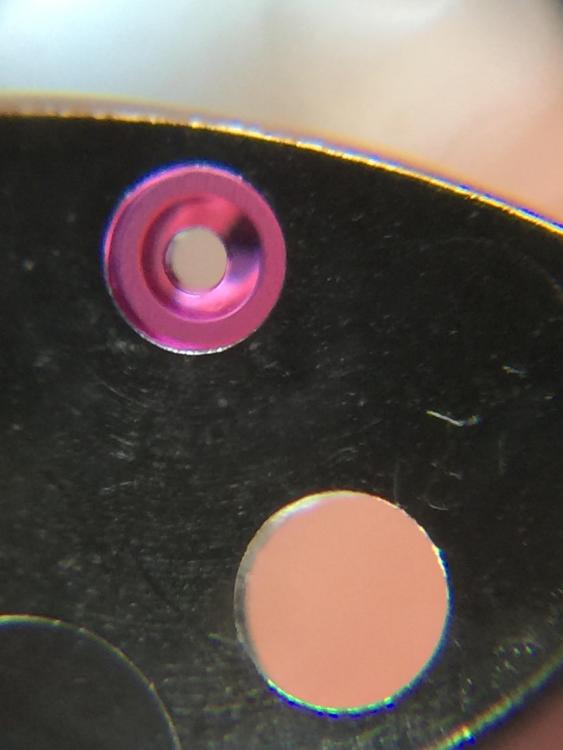

That would be anything but a hack job. No need to glue (Loctite), just a good friction fit, but doesn't hurt to add a little if you want. The whole cylinder can be pressed out of the balance, making it easy to hold in a collet, also, the lower part of the cylinder is rather flimsy to start drilling on with all the cutaway material; in a collet it's well supported. Make sure to note its position in the balance, the balance has a stop pin to prevent it from turning too far and this need to be positioned correctly in relation to the cylinder (and hairspring). You'll need to find or make an relieved punch to press the cylinder back in, as you can't press on the lower end- unless you want to make a cylinder. I've made a few cylinders, and it's not really a fun job. A friend of mine is working on a Breguet with ruby cylinder at the moment, and I would hate to have to make one of those! Well, if time was of no importance it would be a lot of fun, but I imagine it would take a few weeks to get something that passes for original. Wouldn't be surprised if the original was made in just a couple of days, of course without electricity, or industrial diamond, etc. etc. It's always awe inspiring to see some of these old pieces.2 points

-

Hello fellow watch lovers, I have just completed a build from part sourced from various sellers. It turned out to be the best build for me yet and I have really amazed myself and the skills I had to exercise on this timepiece. I have impressed myself with this one and it is a stunner with a salmon dial. The NATO strap is very lovely on this timepiece. I apologize for the lack of details on this beauty, Enjoy1 point

-

I agree stopworks are a great way of keeping power pretty even. But the timepiece has to be "globally" designed for them; a typical watch has 6 turns of wind on the barrel to give a power reserve of perhaps 40-44 hours. A typical ratio from barrel to center pinion is 7.5, i.e. 7.5 hours per turn of barrel. The most often seen stopworks do 4 turns, so that gives a relatively small power reserve of 30 hours. Generally in a watch equipped with stopworks the barrel:center pinion ratio will be upped to 9, giving 36 hours- but those are good hours. Upping the ratio effectively decreases the overall power delivered though. If going with a 5 turn stopwork a thinner and longer spring will be needed to avoid the dead and super charged zones at each end of wind (develop 7 turns of wind). I worked on a small series of watches where the (very clever) designer used a barrel with a spring that developed 15 turns of wind, and quite unique stopworks that allowed 7.5 turns for a 60 hour reserve. The result was a watch that had a difference of amplitude of 5 to 10 degrees between one click of wind and full wind. Effectively a constant force without resorting to remontoire d'égalité systems or special escapements or fusees.1 point

-

1 point

-

1 point

-

Yeah the old watchmakers would often specialize in one aspect of the total timepiece and make the same parts all day, every day, finely tuning their hands, much like stone setters, engravers and so on in jewelry production. This is still the case in some of the big name facilities. These days the market has forced many solo watch makers and repairers to either become generalists or be dissuaded from going very deeply because of the vast rabbit holes in the trade. As for the ruby cylinder, that sounds like a dragon to kill another day. The extent of my ability to cut anything like corundum is entirely in the realms of gem faceting. I think my best course of action will be to attempt a re-pivot on the tampons, and if that fails I can still punch them out of the cylinder and turn some new ones. Of course, we'll see if any of that works, but I think it's a good opportunity to learn a few things while I have a patient and understanding customer. Thanks again, guys! -Dylan1 point

-

Try checking the amount of play the hairspring has between the curb pin and boot in dial up and down, then check if it's the same in crown up and down. I suspect not. It might be the hairspring is ever so slightly out of true, therefore the hairspring has no movement off the curb pin in that position, or too much. I couldn't tell from your reading if it was gaining or losing in vertical position1 point

-

A video on all the steps needed to make a balance staff for a vintage Waltham Pocket Watch Sent from my iPhone using Tapatalk Pro1 point

-

If the train is free, balance pivots and hairspring in good condition, and still low amplitude, I check the escapement. First of all absolutely peg the hole jewels for the fork, and clean the fork slot in clean pithwood, make sure the roller jewel is spotless. If all that is in order, you may need to reduce the lock if possible. I actually do on probably 30% or more of the watches I work on.1 point

-

I used to use a manually operated machine for measuring mainspring force, can't find a pic but nowadays there are more compact electronic devices for that. You might notice a trend in some modern ultra high end pieces using fusees. The fusee form is noticeably less conical than the old ones that worked with steel springs. The old fusees all look more or less similar, they figured out a general form that worked most of the time and used that. In a special piece the fusee would be adjusted to the spring; here, a bar with a sliding weight was fixed to the square on the mainspring arbor in lieu of the ratchet and click. The arbor would be turned to the desired pre-tension, then the bar positioned horizontally, and the weight moved to a position that maintained the power in the barrel (a "gravity click"). The fusee would then be wound. If the form was good, the bar/weight would remain in position. If the bar lifted up, the fusee needed to be cut down there. If the bar went down, the fusee was too small there. Obviously this was a tedious process and would have been implemented on only the finest pieces, or when developing a new fusee. In modern times, to make a fusee is fairly simple if you have a screwcutting lathe. The cross slide screw is removed and a tracer attachment is used to determine the conical form. No need for a dedicated machine.1 point

-

On rare occasions the cylinders, the tampons, and the whole thing assembled with the brass collet have come on the market. Making the cylinder itself would be a real challenge. But if you're in the challenges why did she go for making the Ruby cylinder that's even more fun. Although I think in Daniels watchmaking book he tells how to make the Ruby cylinder. Then look what I found on eBay? https://www.ebay.co.uk/itm/Watchmakers-Cylinder-Tampon-Plugs-for-Vintage-Swiss-Pocket-Watches-i19-/2239869584141 point

-

There's another minor problem with this. Properly made modern mainsprings have a back curve. My understanding is the back curve is to equalize the force to give a more constant running as it unwinds. That means your not just dealing with a strength issue you're dealing with the curvature of the mainspring changing things. Then the principal should still apply you should seek out the books of John Wilding they're not on watchmaking there on clock making. The reason is a couple of his books tell how to make a fusee. Then I have this vague memory that one of my books has the device for measuring mainspring power but conveniently I don't remember which one. But one of the other books does show a chart and suggests that you need a force gauge or a dynamometer Conveniently no pictures provided but there is a curve but it doesn't say what kind of a spring it is.1 point

-

Hi From the net you will find out all about him , He runs and owns a company in Manilla "The Big Tic " I think they call it and a watch repair training school. The whole thing is afilliated to AWCI so he is no duffer. His story is worth reading. he has a range of his own analysers and associated equipment. Glad the information was of some use to you Cheers1 point

-

Hello and welcome to the forum, I have attached a couple of PDFs for your interest. The witschi one may be a bit over your head at the moment but will give you an insight to the complexities of watch repairing. enjoy cheers TZIllustratedGlossary.pdf Witschi Training Course.pdf1 point

-

Well, its not coming it arrived and I am elated! A 1958 CK2990 Ranchero case with its original box! Although not technically a Ranchero, collectors call this particular 2990 a 'Seachero' due to the fact that they share the same case as the Ranchero. It sports a 267 Cal. And is 36mm wide. The watch is virtually untouched - all but the band. Original polish and movement. To have the box is extremely rare as they were only made for 2 years. The previous owner's DNA and grime is still on the caseback and lugs. Timed it and it's running slow. Will service the movement.1 point

-

Great Video JD bags of machine skills there, By the way would you be Canadian the accent is cool. Reminds me of a Guy on Ice Road Truckers from Alaska.1 point