Leaderboard

Popular Content

Showing content with the highest reputation on 06/08/20 in Posts

-

2 points

-

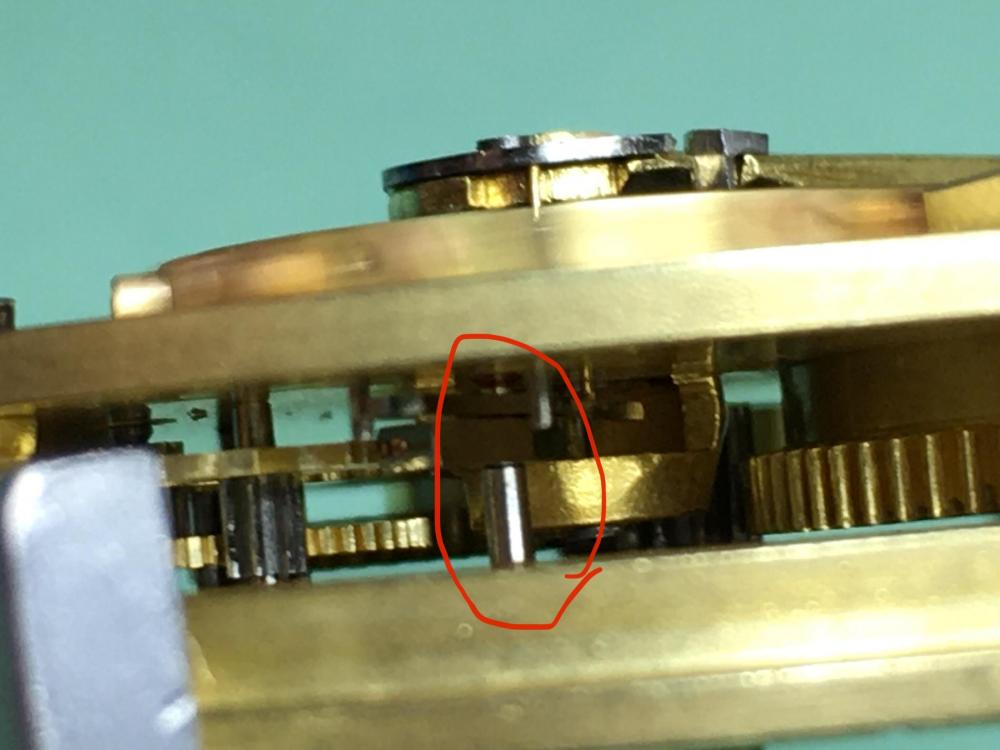

I bought a load of old Accurist ETA movements on eBay for practice (all reported not working in listing) 4 of them are ETA 2390 with small variations (different balance settings). These arrived yesterday morning. A couple of them run at least for a few minutes, but I decided to tackle the 'worst' one first, I figured it would be easier to see if I had made a difference. (It wouldn't 'start' at all despite being fully wound). It had a fair bit of corrosion and was pretty dirty. Photos show a summary of strip down and cleaning. I manually cleaned in a small jar with horosolve, removing corrosion as best I could with pegwood and fibreglass pen, the end result is far from perfect but a massive improvement on how it started, and joy of joys, on reinstallation of the balance it started running! I got quite emotional! I did a reasonably thorough job, relubricating as I went through reassembly, only 'shortcuts' were that I removed the barrel lid and checked spring for damage, but didn't remove it, and I didn't tackle disassembly of the balance as it seemed too much too soon (really should since this doesn't have a shock setting so balance disassembly is required to clean and lubricate top setting) I gave it a brief go, but after failing to get at the tiny screw on the stud after several attempts, I had fears of ever being able to get it back together if I did manage to get it apart. Anyway, on timegrapher the initial readings on a full wind were amplitude of around 240 and beat error of 1.5ms, rate anywhere between -3 and +20 depending on position, so not brilliant, but I'm happy enough given it is a scrap movement that didn't run at all yesterday. I cannibalised one of the other 2390s from the lot for its hands (this one was missing a minute hand) and reinstalled the dial so I could pop it on my desk under a glass to let it run for a couple of days and check its rundown and timekeeping over a longer period. With the experience gained on this one, hopefully I can get the 'nicer' ones from the lot working a bit better!1 point

-

Thanks, it has been really satisfying, I had 4 of these arrive in a joblot from eBay last Saturday, and I've now rebuilt 3 of them, it has been kind of an addiction! the 4th one has given up its balance and a shock setting spring to the cause of the other 3 so it's not going to make it sadly, all the other 3 now run to some degree or another though (See my other thread on timing weirdness on one of them!). I do have the going barrel from the 4th one that I could swap in as a test to see if it makes much difference but I think it is likely I just over oiled this (only 2nd watch I had tried a rebuild on outside of the practical bit of Mark's course) or missed something during rebuild, and it was really filthy and corroded when I started on it. Like I said, with the experience of the other 2 behind me now, I think this one was a bit stiffer to turn the train... The other 2 would literally spin the train under the puff of a dust blower... The barrel is an easy swap so I will try that first. It's really not worth buying a mainspring for it. This, 5 other movements and a case only cost me £12 all in for something to practice on. I will do my best on the 3 I have and build the best running one into the case when I'm done, I've done a trial build in the case now and it looks pretty neat!1 point

-

1 point

-

was that for me mate? no supplier for new parts on the pocket watch i am working on, its approx 100 years old so its good old love and care to get things slrted, look at my post "broken pivot" ans youll see what i mean1 point

-

1 point

-

experience mate, also check out marks videos on youtube, i believe old hippy put a link up on another thread with an interesting video ref hairspring manipulation. Ive just spent the best part of a day getting one flat and coils evenly spaced, nightmare but got it done in the end.1 point

-

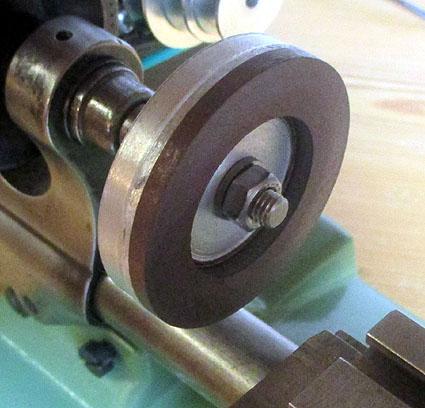

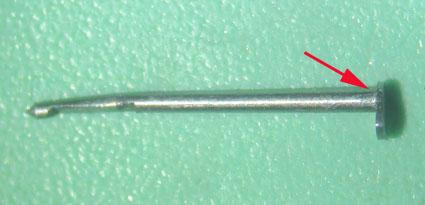

Gentlemen and ladies ( if we have any ) I do believe I have some success. A day of manipulating the hairspring and lots of coffee we have the results of my endeavours here for you to see. Thanks to everyone that gave advice and hints and tips and the asked for criticism, all very much appreciated. There were many failed attempts at making the pallet staff and some very successful ones that I broke the pivots off when burnishing them, I have learned a lot about turning by hand on my very old 6mm Lorch lathe so I’m happy with that, even happier that I’ve also got quite handy on the Jacot tool, so another skill learned ( still a long way to go on all fronts though ) but i am after all just a tinkerer and not a skilled watchsmith. Enjoy my failures, there’s a picture of most of them sat in tray, I’ll keep all them as reminders that you just gotta keep trying. IMG_7131.MOV IMG_7132.MOV1 point

-

I liked the dial on this, and swithered about buying it, as I have quite a few other projects in the pipeline. However since I picked up a bunch of Sekonda corpses with these Slava movements in a while back, some of which had trashed dials, I have a bunch of parts for this scrapper, including a clean, almost new looking case, a number of suitable seconds hand and a balance, so it may not need too much work to bring it all together. At just under four quid, the price means it just squeaks in to the 404 club. It is heading my way from Ukraine, and surprisingly the postage wasn't too bad. I've had local sellers charge more, but who knows how long it will take to actually get here, when you factor in snail mail from Ukraine with coronavirus restrictions. Ouch... I hope that isn't blood, and I don't hold out much hope for that hairspring. Although this might technically end up as a frankenwatch, looking online at similar examples, the case I have means it should be pretty faithful to the original. The only missing ingredient here, as usual is going to be "spare time" to actually get it torn down and built into a working watch. I will of course keep you all posted if I make any progress.1 point

-

Hi this is an old book but the principals remain the same, hope you find it interesting. TheWatchAdjustersManual_10245884 (3).pdf1 point

-

1 point

-

I think you might find their website Moebius below helpful.They even have a nice PDF lubrication chart To download. Then it would be impossible for any horological company not to have 9010 because everyone in the universe except me uses that for the balance pivots. It's just about the universal one that 99.9% of the world recommends is 9010. You could use the 8000 except it's a natural or mineral oil it's not synthetic. Although it's much cheaper you really want to get the 9010 so you can be with the cool kids of the world. Then you're right I've done a really thorough search because it's impossible but they really don't have any 9010? You really want to look at their website Moebius look at the tech sheets 9010 and 9020 are not the same thing. 9020 by Psalm is now considered obsolete. When I was in school it was the universal pivot oil of course yet 9010 up for the balance of light stuff. So it's basically just heavier 9010 and it seems to stay in place longer. As typically I'm doing pocket watches it's my oil a choice as the light oil. Then when purchasing a horological stuff it's very important to shop around prices can vary considerably. So I have a link to eBay below they have a variety of oils and the seller is in the US. There was another seller in France it might've been cheaper but I don't know what shipping's going to be or whether you even get anything from France right now. Then the D5 is a mineral oil The suggestion is to replace it with HP 1300 9104 I have a link below for that. Slightly cheaper than your D5 Then the last link is another seller and if their prices are up to date they look pretty good you'll just have to scroll down the page for the various lubricants. http://www.moebius-lubricants.ch/en https://www.ebay.com/itm/Moebius-Oils-Lubricants-Greases-for-Watches-Clocks-Repair/172671249074?hash=item2834022ab2:m:mXVxMGZkUfPs7aD9W88bz1A https://www.esslinger.com/moebius-9104-synt-hp-1300-synthetic-watch-oil-2ml/ http://www.ofrei.com/page246.html1 point

-

Esslinger has a nice tutorial on SS polishing. I have this polish i cant remember the name of it and its not in my possession but it cost me $30 and its the same used by omega when they polish cases. There are so many different compounds out there it’s basically a matter of preference as to what you like to use what’s more important is the type of buffs and polishing pads you use. For removing scratches very quickly you could use compound used for platinum you have to know what you’re doing to use it because you can really dull the facets. Red water soluble rougue is great and makes easy to clean case in ultrasonic. Just a mask and eyewear. Whenever i use red rougue my face looks red except around my eyes and mouth lol. As what most people don’t realize is buffing could take as long as 30mins its not a once over type of deal. AND BE VERY LIBERAL WITH THE ROGUE. Once it starts to disappear add more to the wheel. This is what i use: Buffing Hard felt for buffing deep scratches Muslin 3 rows of stitch for light scratches (I use 2-3inch hard felts buffs you want to cover the entire area you buffing with the wheel, this wide diameter comes in handy when doing watch faces and backs. Quite pricey though) Polishing Muslin buff with no stitching I use a dremel to get to the hard to reach places. Things like 3m pads and emory cloth also assist in removing scratches before a buff. Polyimide tape is a must for protecting facets and edges especially when trying to achieve a statin or brushed look combined with high polish. Sent from my iPhone using Tapatalk1 point

-

The interference fit of the wheel to the pinion would indeed degrade after each removal/re-installation but it would take a good many removals for this to become a problem, and it would be a progressive change. You would be able to tell when you re-installed the wheel if the fit was in any way loose, in which case a quick tap with a hole closing stake solves the problem, and if it is done with care it doesn't damage the hole or the wheel. If the fit is good when you re-install the wheel it will stay good until the wheel is next removed; it won't slacken off a week after re-installation unless something else pulls it off. Given that the OP has stated that he has tried to pull very hard and the wheel won't move it is reasonable to assume that the interference fit is still in good order, in which case there should be no problem with removing and re-installing the wheel as part of the service without any need to close the hole, and as I said, this should be done if the watch is to be properly serviced. The purpose of regularly servicing the movement is to prevent damage through wear and tear. If this wheel is only removed when excessive side shake is found then the damage has already happened, resulting in the need to re-bush the pivot hole in the bridge, requiring significantly more tooling and experience than closing a hole with a hole closing punch.1 point

-

In your pic of the empty barrel and arbor, the arbor screw hole is facing down (so you can't see it) and the hook is facing anti-clockwise, so the spring must spiral in anti-clockwise for the hook to catch, which is how you describe you installed the spring. In your pic of the whole movement you can see the barrel arbor screw hole facing up, which means that the barrel has been flipped to install it into the movement, so if you had x-ray vision and could see the spring inside, it would now be spiraling in clockwise because you are looking at it from the other side. The hook on the arbor will also now be seen to face clockwise, again because you are looking at it from the other side. So although you installed the spring anti-clockwise, when you flip the barrel over to install it, the arbor must turn clockwise to catch the spring. The barrel, the arbor, and the way you are installing the spring are all correct for the way the watch winds up.1 point

-

Welcome to the Forum. Alum may solve your crown problems. See the post I linked above.1 point

-

A lot of videos show how people cleverly walk a mainspring out this is fine for a wristwatch it's not suitable for pocket watch. The springs at least two or three times as wide it has way more force it has to be pulled out but certain precautions are needed unless you're used to doing it. The arbor has to be removed because you don't want that flying around the room. Typically I hold it in my hand and pull it out but I've done enough of them and even though I'm holding in my hand I have my hand under the bench out of my sight just in case it decides to fly away. A better procedure is to remember to put a towel over the whole thing or have your hand buried in a towel just to contain everything. The definition of flying away? Typically we have a mystery here in that it depends upon the condition of the mainspring. Typically blued steel Springs are set they will open up to a relatively small diameter. But if the spring is in good condition it can have a heck of a lot of force and when you pull the mainspring out all the energy releases. So all The energy released means that a lot of bad things can occur if you're not careful. The definition of flying away is literally that it depends upon how big your room is as to whether room will contain the barrel where it's going to hide after it flies away And is never seen again or if they can escape out an open door. I'll skip over the open door Part although it did make a nice sound that was the barrel bouncing off the door disappearing down the hallway. On the other hand it wasn't a typical pocketwatch mainspring it was slightly bigger. So while you can wear safety glasses as recommended above. I still prefer that the process take place out of your visual site so do it under the bench. If you're concerned about your hands you can get a glove or hold the barrel with the towel so the towel is between you and the barrel but the whole thing still has to be wrapped up to contain everything doesn't have to wrapped up Tight it just has to be a will contain when all The energies released.1 point

-

Hi some more information for your interest attached.. Moebius Oil_Chart.pdf moebius-specsbook.pdf1 point

-

1 point

-

No no, do not pull out at once, the spring comes out violently, wear protective galss .1 point

-

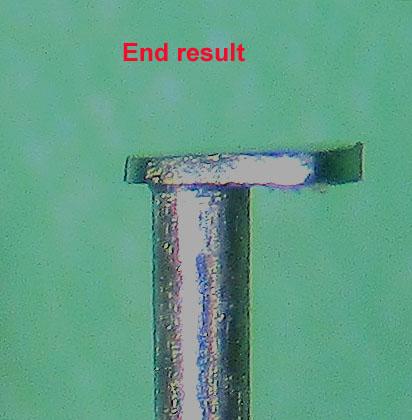

This 1200 grit diamond wheel produced a nice square end to the tubular section. But I then had to countersink the end of the tube by a small amount because the sliding inner part has a radius in the region arrowed. Finally I had to dome the end of the locking screw. As supplied it was flat and tightening the screw increased the gap as it pushed the inner slider outwards. I wonder if these tweezers are second sourced from India?1 point

-

1 point