Leaderboard

Popular Content

Showing content with the highest reputation on 03/21/20 in Posts

-

Sounds to me like the pallet fork is not interrupting the escape wheel. This would mean that as you wound the watch everything would spin, and no power would be retained in the main spring, so nothing would happen when you tried to let down the main spring. When you have the crown in the setting position the canon pinion has enough drag to also transmit torque back into the train, so once again everything would spin.4 points

-

You have a little special construction on this movement . With a friction drive on the intermediate wheel . Instead of a normal cannon pinion. Should think that is why it moves the barrel to . Put the pallet fork in. Or the automatic bridge. This wheel turns the barrel . And has a friction like a cannon pinion.2 points

-

Happy to report that all the items mentioned have been shipped to others that expressed a need for them. I'm glad these resources did not go to waste. Hope everyone is doing well... Stu2 points

-

Today we have a Baumgartner 844(CLD) based Ingersol with date, from some time after 1975. This one was a little tricky to get running nicely, as it is similar to the EB8800 and Baumgartner 866 in terms of construction, and the resultant faffing about necessary to get all of those little pinions stuffed into their respective holes at the same time without breaking or loosing anything. The main issue was old oil which had set like varnish. It took a couple of cleaning runs. After the first one, it would run nicely for around five minutes, then stop dead. A second clean and some careful tinkering and it is now going very nicely indeed, considering its somewhat rudimentary 2 jewel pin lever construction.2 points

-

Sounds like the keyless work. Does the clutch engage and disengage when the crown is pulled? Is the stem the correct one for the movement? Can you provide better pictures of the keyless work in both positions?2 points

-

2 points

-

A normal canon pinion would move things too, but good catch. That micro canon pinion should be disassembled and greased like any canon pinion though. All things said, with pallet fork out, setting time or winding will have a similar effect if the fork is out.1 point

-

If you can get a slightly better picture that might help, but zooming in on the first picture, however those clips appear to slide on to the pegs, so you probably need to wiggle the module right, then down slightly to free the top PCB from the lower one. However I would start by checking that the gear moves freely, and perhaps by dropping a couple of drops of lighter fluid on the mechanical parts and trying it again.1 point

-

I cna't sepll ta eht bset fo tmies tub I acn sitil mkae teh pdenaitc udnretsnad !1 point

-

1 point

-

1 point

-

Rubbing alcohol (which I believe is isopropanol aka IPA), denatured alcohol and naptha should all be safe on PCB material and etch resists and solder masks as generally these use fibreglass bonded with epoxy, so they are impervious to solvents. IPA is used as a board cleaner in industry (as indeed were things like trichloroethane and other nasty solvents until relatively recently). If you do find something that dissolves epoxy, or printed circuit boards, that isn't nitric acid, I'll be impressed. Occasionally you may find some older and/or cheaper PCB material that is SRBP -FR2, but generally quartz movements use fibreglass FR4 Whichever type is used, it will not be harmed by most "mild" solvents. Acetone, alcohol and IPA may dissolve shellac, which is used in mechanical watch movements, so avoid using them on balance forks or where an item is fixed with shellac. Acetone may dissolve cyanoacrylate, (superglue) which is sometimes used to fix wires on small coils, it will also damage acrylic/plastic watch "glass". The other solvents mentioned should be safe on these parts.1 point

-

I found a lot of 7 NOS oscillating weights with this type of bearing on eBay advertised as for "ETA 2783 2789" and according to the "JBC Watch Parts Database" these should be interchangeable with my 2772 calibre. So, I've ordered them and hopefully at least one of them will be performing well. Keeping my fingers crossed. In correspondence with the seller they have never been used. The seller only wanted £25 incl. shipping for the entire lot from Portugal to Sweden. So if they're good it will be a bargain.1 point

-

The leaking battery can cause thin layers of oxides and other insulating stuff to form on the contacts. It can also etch away the PCB tracks, as can dampness so give everything a clean with isopropanol or contact cleaner, and inspect for damage. Those little dendrites can form in all sorts of odd places due to off gassing of the initial leak, or high levels of humidity. They look pretty under the microscope, but they don't play nice with the PCB or the mechanism.1 point

-

You probably have a really good technique. In my experience, filling the sink doesn't come close to making the right sized circle under the cap jewel. If it works it works!1 point

-

It works, but when you check the oil quantity and it's lacking it's more of a pain than using a pin. Or you leave it lacking. When I was working in a trade shop while in school I did the way you describe but I was getting 10 USD for a manual wind, 11 for automatic, in 1998, not 1950 hahaha. Had to make some concessions. The boss cleaned assembled, barrel out (opened but spring in), then pulled the balance and ran through a second machine with "lube" in the final rinse. I skipped the second machine, disassembled all the movement (he'd leave cap jewels assembled too), did train freedom check etc. I didn't have one comeback. I'm sure the time he saved with the cut rate measures cost him more in his comebacks. Not trying not harangue, it's an old school technique you describe, but pushing through with a pin is a tiny extra step to ensure proper oiling to get it on the cap correctly before assembling.1 point

-

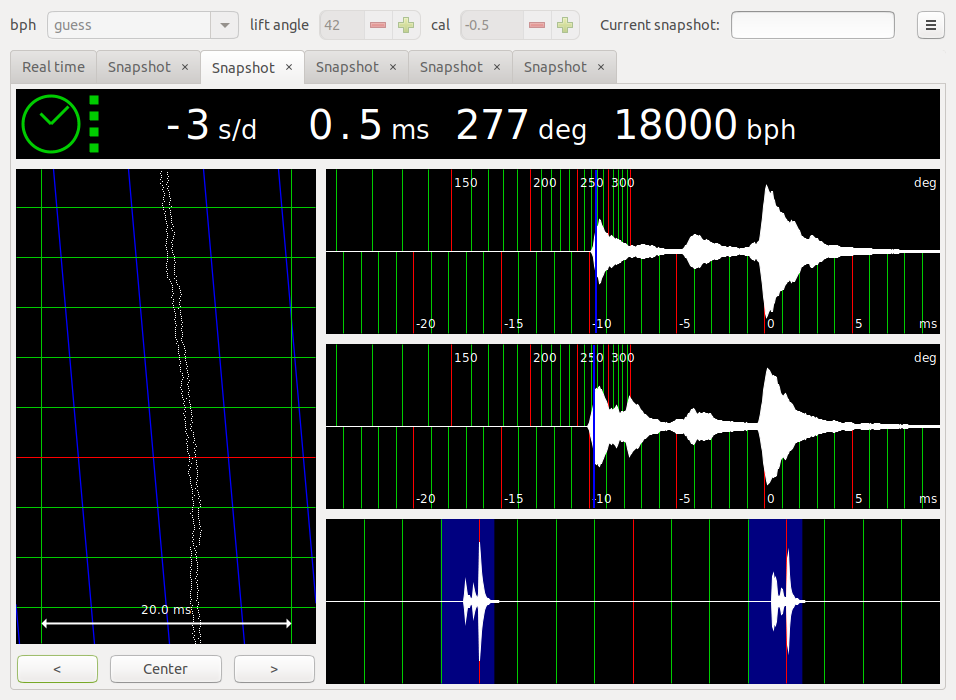

Looking at the first video, showing the train without a pallet-fork, just the escape-wheel rotating; I can't be impressed with the way it rotates. Not sure either what you are doing; tapping or rotating the crown. If it was tapping and that caused the train to continue to run again, that seems suspicious, i.e some additional friction/drag or additional power-release by the mainspring(?). I can't see any escape-wheel recoil either ? The timegrapher lines seems pretty straight.1 point

-

1 point

-

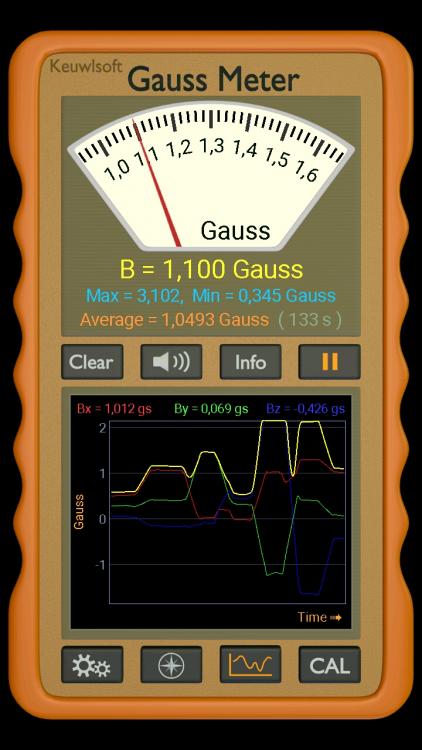

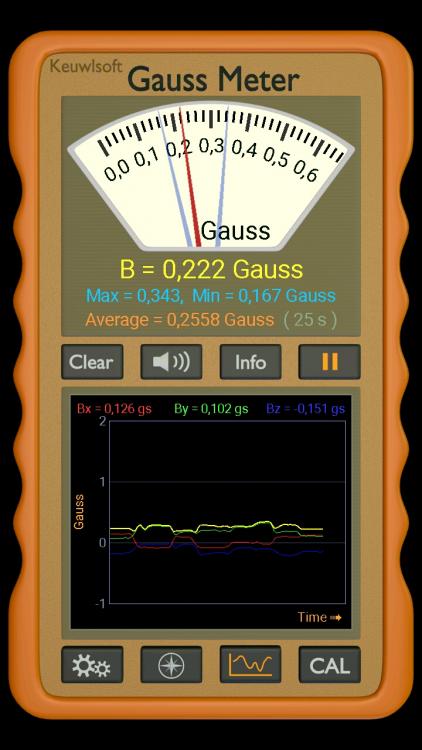

I am working with an NMR spectrometer which is 94000 Gauss Sure my watch was magnetized, it even stopped once i forgot to take off before going close to the magnet. Since i had a suitable transformer and remaining wire from generator rewireing decided to put together a demagnetizer yesterday. Used the middle of an empty bottle as the coil shape, it is big enough for all sized watches, even for my Roskopf pocket watch The 230V/60Hz main current is transformed to 12V/60Hz with a toroid transformer. The wire is 0.7mm in diameter and four layers were wound. It is connected directly to the transformer... well, burned some 800mA fuses when connected to quickly with a switch but working fine with a crocodile forceps. The copper layer under it is for cooling. It is heating up over 60 Celsius in 30 seconds. Before demagnetization the gauss meter (android app) shows up to 3 Gauss. The peak is only 0.34 Gauss after demagnetization The rate increased by ~10 s/d, amplitude is the same and it is more stable in the different positions. Finally demagnetized all of my steel tools. Never again sticky screws1 point