Leaderboard

Popular Content

Showing content with the highest reputation on 04/28/19 in Posts

-

1 point

-

1 point

-

Very well done. On the Unimat 3 right? I suppose you left the toolpost lose and slid by hand? I'm awaiting delivery of a lathe like that, for casework. Can't wait and I become a bit fixated about.1 point

-

1 point

-

1 point

-

I don't know if the difference in clocks is the same as it is as in for example ETA movements. ETA claims their movements come in four grades; Standard, Elaborated, Top, and Chronometer. The biggest differences in these are the quality of the shock resistance , the balance wheel ,hairspring , the regulator , pallet stones and the mainspring. Other features one can see is them being decorated and in the amount of positions they are tuned; the decoration was made to prevent oil from escaping to other parts of the watch but with the introduction of synthetic oils its more of a decorative feature. The more expensive grades has a Glucydur balance instead of a nickel balance; Glucydur primarialy are made of beryllium, copper and iron and is said to resist deformation from temperature change and shockbetter than the ordinary balance wheel in nickel. You can identifie the Glucydur balance by its radiused spokes; the nickel balance has straight spokes. The hairspring in the lower grades is Nivarox hairsprings and in the higher they are called Anachron here the difference is also said to be the alloy used. The difference in jewels is in the manufacturing process, the cheaper is pressed out of a finer material while the higher grade jewels are said to be cut in the traditional way. Then there is the shock protection system, Novodiac verses Incablock , hard to say why one should be better than the other. The regulator in the higher grades should be a micro regulator making finer tuning possible. By the pictures abowe I would Imagine the same theories would apply here.1 point

-

That's a pretty great rate, but there is a little error, more evident as would be expected at low amplitude. Just try out moving the spring in the direction to get it centered and see what the effect is. If it were me I would leave it, I would bet you are at a similar delta and overall rate as your full wind at 24h. Plus it's an auto so it spends most of it's life far from the 24h mark. But it looks like a very slight poise issue, and would require just a tiny removal of material. One problem with chasing "perfection" is every time you manipulate the balance, there's a risk of introducing a new error, from slightly tweeking the hairspring to a microscopic piece of dirt getting in a pivot, or on the roller jewel, or the lower pivot brushing the fork slot (oil on the slot), to a half a dozen other things. 7750 is pretty robust and tolerant, it's worse as you get smaller (0.06mm pivots can drive you to drink).1 point

-

1 point

-

1 point

-

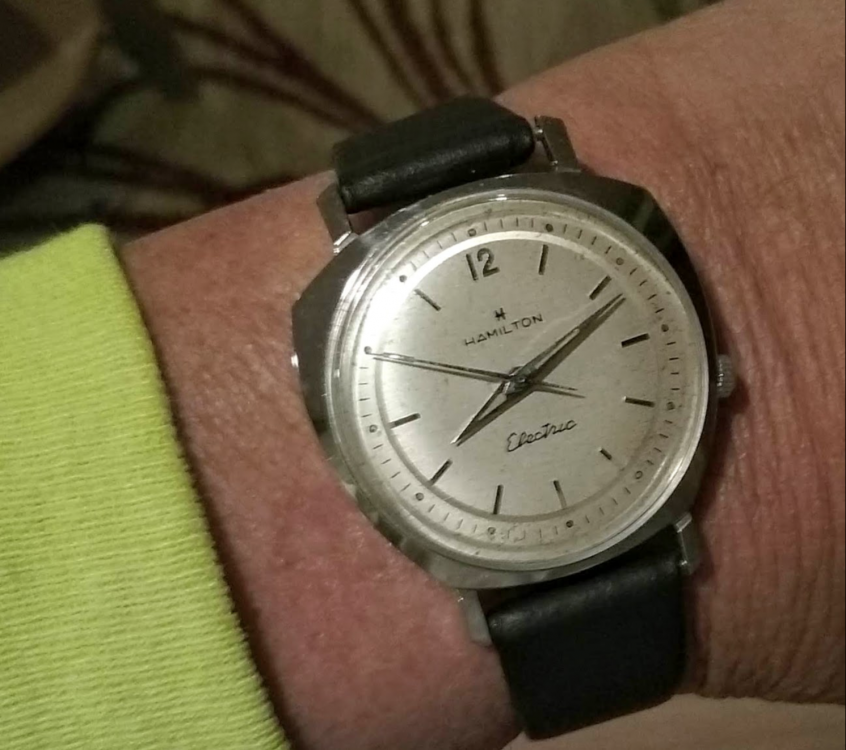

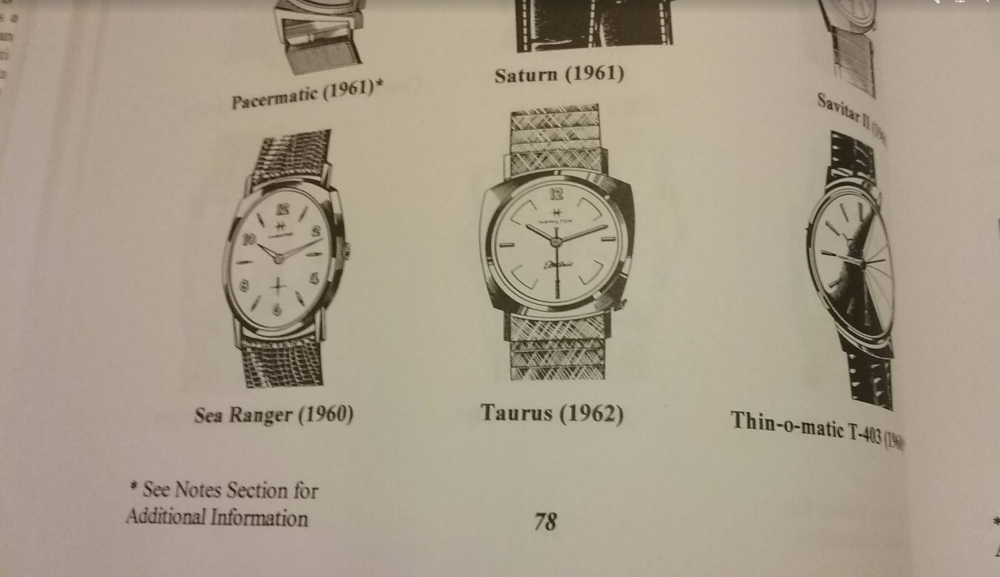

I wouldn't call it a "Chick Magnet"....But as I know so well , "beauty is in the eye of the beholder"...1 point

-

I'm not sure.. does "cheap and bizarre" also count as irresistible? Today's WOT is a Q&Q with their plastic jeweled movement, which is bizarre enough in its own right, but coupled with this face... what can I say. In my defense at 0.99p, non running, spares or repair, they don't come much cheaper. A quick slungify and some light luber-mikay-shun and away it merrily ticks. I didn't go for the full tear down, partly because these Q&Q mechanicals are a little fragile, and partly because it didn't really warrant it.. well that, and the fact I was too lazy/busy to do so. Now if anybody can identify the slightly unsettling cartoon character on the dial I would be interested.1 point

-

I agree. Pocket watches, mechanical alarm clocks and desk clocks are good, as they have nice big components and are less likely to be damaged. You might also like to look on ebay for the really cheap basket case hand wind watches, or perhaps some second hand Chinese mechanicals. The big skeleton movement Chinese manuals and automatics come up regularly, and I've picked up a couple of the last few months for less than £4.00 each. Citizen and Seiko manual winds and automatics are another option, but they tend to be slightly more pricey. Also worth considering are Indian HMTs which are a bit of a favorite of mine can be had for a few quid. The ones with the most hideous repainted dials from India, often go for rock bottom prices. The HMT manual and HMT automatic watches are clones of some of the good quality Citizen movements, and they are pretty robust mechanisms to play about with. Quite forgiving, and not much money if you come a cropper while learning on them.1 point

-

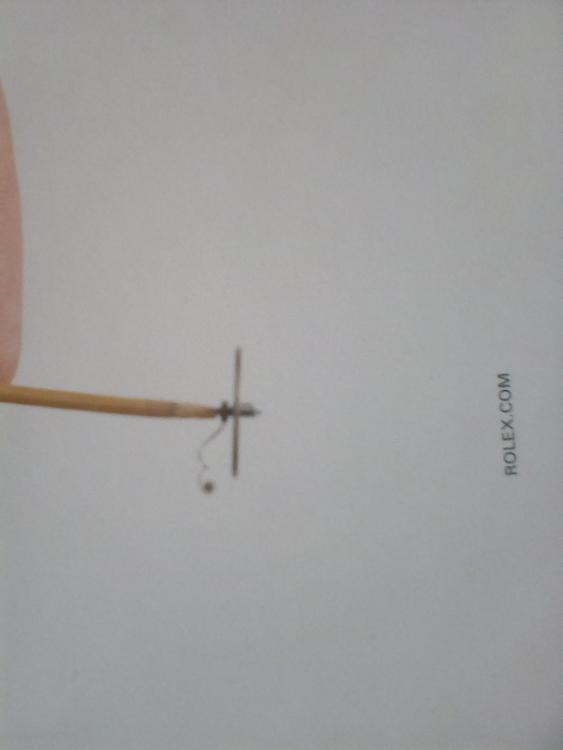

You can unlock shock springs, pop the jewel assembly out ,into a jar, stick a tooth pick onto pivot, turn the BW, this pegs the hell out of the pivot. Repeat . Good luck pal.1 point

-

1 point

-

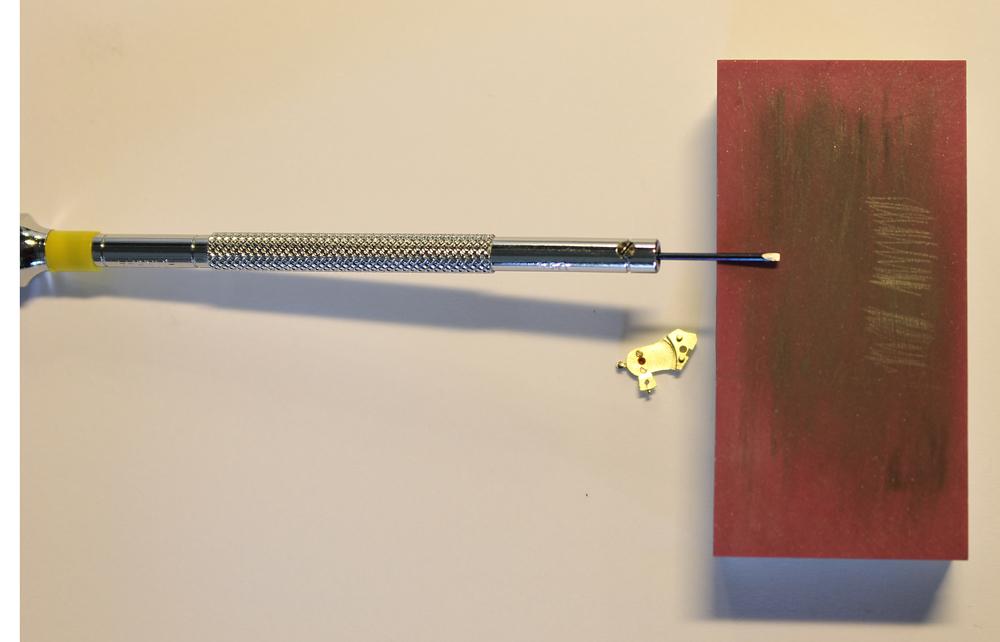

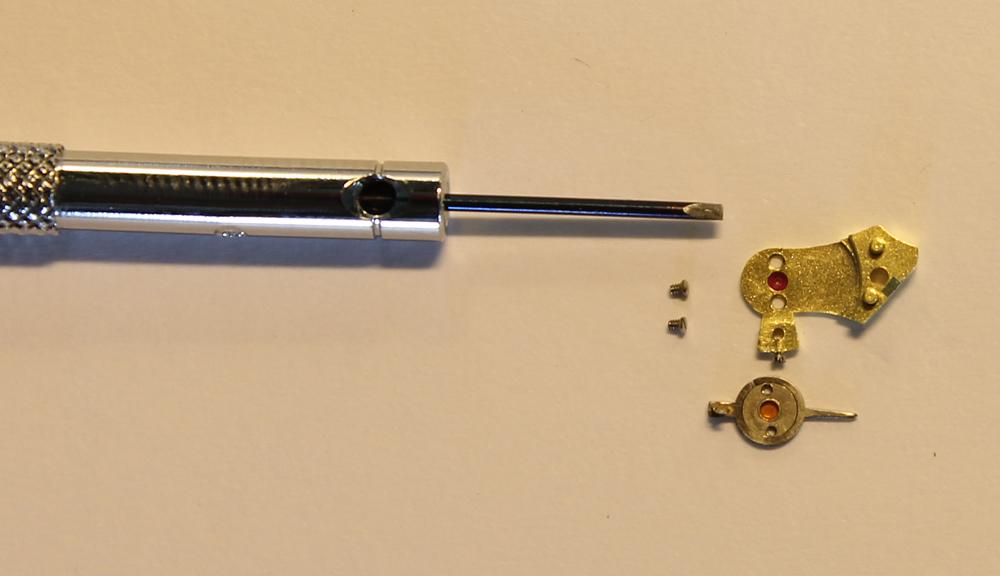

Totally dissatisfied with the results above, I decided to strip the movement again and let the parts soak in Zippo lighter fluid. Old oil seemed to be the culprit and some serious pegging had to be done. This time there was no easy "opt-out", the balance jewel in the balance bridge had to be properly pegged and oiled. I decided to get the delicate balance out of the way first. As described above, the 0.8mm screwdriver was too big, the 0.6mm screwdriver fitted, but proven to be too weak for the task. I decided to customize the 0.8mm screwdriver blade by dressing the sides down to the full length of the screw-slots (about 0.7mm) and flatten the tip of the blade until the blade had the maximum amount of "beef" and fitted the screws-slots snugly. This would give my the highest, and the final, opportunity to undo the two screws. Lo & behold; It worked !! Now I could do a proper oil job, but pegging the extreme small bore of the ladies movement balance jewel was another challenge. My experiences with these tiny holes are that if you get the tip of peg-wood in, it brakes off easily. Next to that, once you got the peg-wood in, while rotating, your fingers slide & rotate down. Once the fingers are to the end of the peg-wood, and some more pegging is required, you either have to pull the wood and try it again or; try with the peg-wood still in the jewel-bore to get your fingers back on top of the peg-wood ........ with a very high probability that the peg-wood tip will brake off; stuck in the jewel Some kind of solution had to be thought of, perhaps this has been done before, but so far I haven't seen it; the screw-peg ® ! I had a small box of toothpicks. The diameter was 1.6mm. One of my screwdrivers is 1.6mm. I removed the screwdriver steel-tip and with one of the toothpick ends cut off, the toothpick is a press fit in the handle. The toothpick-tip can be sharpened multiple times by either a knife or dressing it on a diamond stone. Now, with the peg-wood tip in the jewel, you can rotate as long as you deem required. I also found to have very high control over steadiness, direction, rotation and applied pressure. Works like a treat !! Back to the movement; Pegged & pegged again every hole till spotless. Pegged every pivot. Installed the balance to check free movement and re-check the impulse jewel line up with the center of the banking-pins. With now both cap-stones oiled, the balance rotated freely and smoothly. Same with the pallet-fork; installed the fork and it rocked backwards & forwards on its own weight. The wheel-train run with the slightest touch on the spring barrel. Sounds good !? ....... hmmm, not so........ with the movement assembled, it still doesn't run happy. An amplitude of below 120 degrees is hardly something to brag about. It also stops after a few minutes, continues again after a little shake .... perhaps pallet-fork / escape wheel area ? Still a beat error of over the 7ms, whereas the impulse jewel was spot-on the center of the banking pins ..... Hmmm ....... Being Dutch, I will say: "Luctor et Emergo" .......1 point

-

This well know and done always identically. He lists any possible desirable item by copying the listing with the lowest price, but with a 15% discount. As seller name he places "do not buy - contact [email protected]", that changes often . He answers email swiftly telling that because of a bug Amazon will process the order manually and send an invoice for bank transfer payment. To add a bit of credibility he waits the following day to send the fake Amazon invoice with a reply address as amazon.it.259348523592638952348752892.023789465298359283685922632.com and the beneficiary details IOAN STELIAN MAILAT (a Romanian name) IBERCAJA BANCO, S.A. IBAN ES4920855687250330432670 BIC/SWIFT: CAZRES2Z SPAIN REF: 403-3508465-3272433 That's all I needed to flag domain name to the registrar, and provide the details to Spanish Police. Shame on you Ioan and your accomplices!0 points