Leaderboard

Popular Content

Showing content with the highest reputation on 09/07/17 in all areas

-

Was talking yesterday to a friend about types of screwback case tools. He said his biggest problem was getting the back to catch it's initial thread. So thought I would pass on how I do it. It's back to my dirty old piece of rodico (might invest in a new piece one day) break a couple of pieces off, attach to the back. Your fingers grip the rodico, then you can rotate the back until you feel the thread bite. Then tighten. See pics Sent from my SM-G920F using Tapatalk2 points

-

How can this work? It may help in grabbing the bezel, but the strength of a normal man is not enough anyway to pull it out. Unless we're talking about $10 Chinese watches.1 point

-

Zugfeder (mainspring) 873 on Flume https://www.flume.de/de/zugfeder-zf-873-1-30x10-00x0-110x320-00mm-718008731 point

-

I don't know if these MS are the same or different but I can tell you that spare part prices have little to with the part itself. They can depend by unfathomable reasons, can be stale hence cheap, or driven by demand or rarity, so very expensive. The thing one can do is decide if worth the price for the project a hand.1 point

-

That is about $4.99 too much. You can buy genuine quartz watches in lots on Y! JP for less than $1 each, all they need is to replace the battery. Or on Ebay from Ramon like many here have done. Granted, you get a pile of junk but at least is authentic or almost.1 point

-

Thank you. In fact, I was really looking for Seiko, but all I've found is this one and one that read (I am not sure if it's genuine) Seiko 7123-8510, since I am really new to this hobby I am trying to play it safe, but aside from cheap Chinese dead watches these two I've bought, looked a bit more decent.1 point

-

1 point

-

The one shown would be very simple to make, but as you point out its missing a great deal of the Feintaster's functionality. As well as the table, "claw" and complexly shaped contact points, there is also the lever controlling the plunger - a very important bit of kit on a comparator. I agree with you those extras are quite tricky. The parts should be hardened and achieving perfect alignment so all surfaces are the same distance apart is far from trivial. In making a gauge you need accuracy and precision, and you must work to a higher standard than .01mm if its expected to be reliable to .01mm As for what indicator, I'd thought a mitutoyo digital reading to .001mm would be good (and I have an extra lol). There is a convenient hole to use with a lever to actuate the plunger (as these indicators often are used on comparators) and with the press of a button you move from metric to imperial (while watchmaking might be all metric, most of other things in North America are still imperial, so for me there's an advantage in both) You also have instant zeroing which is convenient. I'm 60% through drawing a Feintaster with the view of making one, but secretly hope I stumble over one as there are some challenging bits and pieces. For anyone interested in having a go at it, here's a close up of the contact points - a unique design so you can get part of say a balance staff i the V and measure the rest of it1 point

-

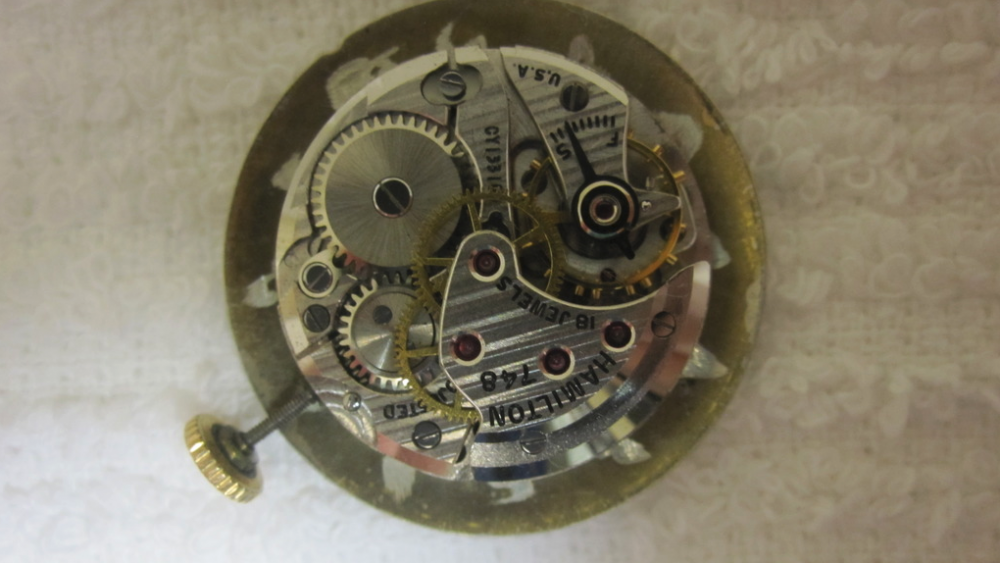

A few weeks ago I was following the auction on a very Minty Hamilton "Rodney" watch . This watch has what is called a Quadrant colored dial which I am partial to . I shared this Bulova Royal Clipper on this post a while back that also had a quadrant dial.... The Hamilton Rodney finally sold to some lucky bidder for $300 . A few days later another Rodney came up for auction but the dial looked dark and the quadrant didn't show up very well in the pics . I figured that there was a gem hiding in the darkness so I got the watch for $74 . After I got the watch I took the movement out and cleaned the case and crystal in my ultra-sonic and indeed , the dial had a smokey dark look to it . I took a BIG chance and decided to try and clean up the dial knowing full well that I may do irreversible damage to it . I am talking from more then 1 experience here ....... First I said a little prayer ,..."Oh Please Watch God , don't let me mess this dial up....Pleeze "...then I proceeded . Well somebody up there must like me cuz it came through the operation OK....Whew !! Feeling ahead of the game now , I ordered a nice retro looking Hirsch watch band to compliment Rodney ... Looking pretty Spiffy if I do say so myself .1 point

-

Just to update. Though the watches that I mentioned previously showed no visual signs of in letting water. Now I have a pressure tester Out of 4 of the watches tested just using the ball to fasten the case back, 3 failed a 3 atm pressure test ! They were fine once screwed fully home. An additional test on a Rotary 3 piece case with a snap back that at some point in it's life had been mullered. Also I have replaced the crystal, passed the test with flying colours . I expected this watch to fail. In conclusion I've changed my opinion as just using a ball to tighten, even on a watch used daily in dry conditions, as potentially moisture could still ingress. From the above, a watch that is of value, it's well worth having it tested and changing gaskets at the appropriate service interval Sent from my SM-G920F using Tapatalk1 point

-

Just polished this stainless steel bezel using 1 micron diamond paste. 5 minute job and has removed 90% of the surface scratches Sent from my SM-G920F using Tapatalk1 point

-

Out for a test drive... Just finished putting this one together... The movement is a dual train design. Basically, it's two movements on one plate.. The left side train just runs the left balance wheel while the right side side balance and the motion work. If any one is curious, the extra function of the motion work does reduce power to the balance wheel. The left balance wheel has an amplitude of approximately 310 degrees while the right balance will has an amplitude of approximately 285 degrees. For some reason I was not equating this difference to the motion work and thought there was an additional problem. I spent a good amount of time looking for the cause and after switching all the components from left to right I got the same result, lower amplitude on the right side with the addition of powering the motion work as opposed to the left side that just had to transmit power to the balance wheel..1 point

-

Found this excellent vid on what to look for when purchasing a watchmakers lathe.1 point