Leaderboard

Popular Content

Showing content with the highest reputation on 12/02/16 in all areas

-

I've been working my way through the various chronograph calibres over the past year and picked up this beautiful Favre Leuba off eBay just a short time back. The movement wasn't named but I figured it was a Valjoux VZH and I haven't had the chance to do a Valjoux service just yet. Turned out to be a Valjoux 71 which is the older bigger brother of the famed Valjoux 72. I couldn't be happier- this one is going to clean up nice I think.2 points

-

Put down your hammers and back away....Just kidding . Some members have stated thar's how they service Timex Watches . I picked up this Timex Electronic , back-set , front loader at the swap meet for $8 . It wasn't running and had an AG10 battery still installed , but with no visible damage to the movement . This one has the M87 movement with the date . This is a late 60's model called " The Blue Nebula " with a West German movement that was produced by the Laco watch company that Timex acquired when they bought Durowe-Laco at the end of 1958 to get into the electronic watch arena ..... http://electric-watches.co.uk/makers/laco/ I got home from the swap meet , opened the watch up and installed a new battery . The watch would only tun for a minute or less . I did some reading on this movement and started to disassemble it for a service . If you have ever tried to service a Timex you know why the hammers are used . I got as far as taking off the magnet and then the balance and then a voice from above said , " don't do it . Don't go any further "...so I didn't . What I did do was to clean and tighten any electrical contacts that I could reach , and put a light oil on any jewels and bushing in reach and assembled the watch again . At that point it would tun for an hour or two , and stop . I would shake it and get another couple of hour worth of run time . I left the watch under a light bulb for a while and it ran for approx. 24 hours . Back to the light bulb treatment that I may patent and the watch has been running for 5 days now and actually keeping very accurate time .....Honest . I had a watchband in my stash but have had to file some areas where the lug area of the watch was binding . I still have to smooth and buff those areas so it has a better finish .1 point

-

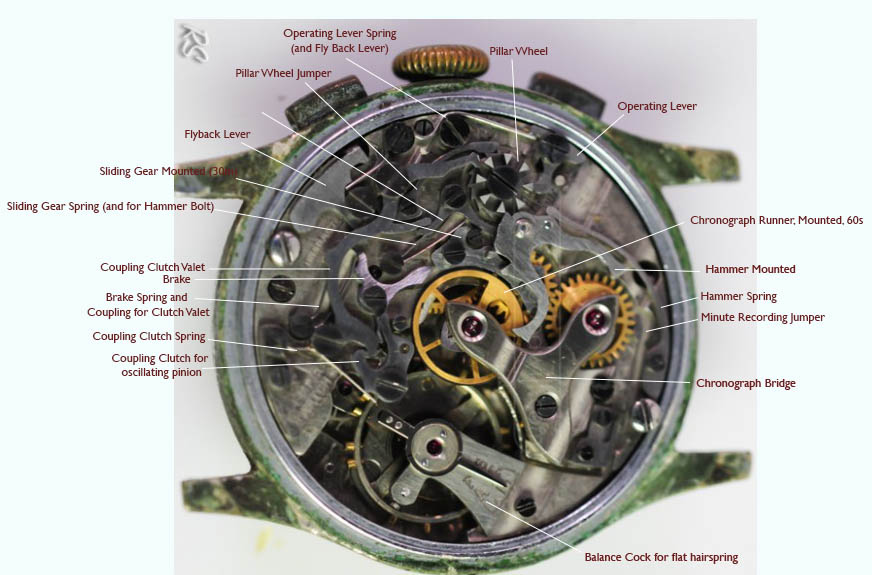

I recently serviced this Jardue with a valjoux 72 movement. I had intended to take more pictures but watch was in very bad shape and I got involved in repair a bit more than I thought I would. Watch did not run at all when I first got it but with a bit of manipulating I got it going except for when I engaged the chronograph. There were several things wrong with the watch. It had been serviced before by someone who thought that the more oil you use the better, it was soaking. Then the trigger for the hour recorder was bent, the hour recorder hand was floating around in the movement and the chronograph coupling clutch was hitting on the pillar wheel which prevented it from engaging chronograph runner wheel properly. By that I mean that when you engaged the chronograph the clutch would hit on the edge of the pillar wheel which prevented it from touching the eccentric next to its mounted wheel. Anyway I thought I would post what pictures I did take in case they could be of use to anyone. Watch is running now after a service and keeping good time. One thing that I enjoyed about this watch is the chronograph plate itself. It is engraved "Pilgrim Electric" I'm still trying to find where battery goes. Maybe it took a drop cord.1 point

-

Hello , im new to the forum . And new to watch service and maintenance. I have a skx007 and i want to swap the original crystal for a sapphire double domed . The questions are, Is worth it? Will the swap affect the original water resistance specification?1 point

-

OH. the topic refers to the use of a joacot tool. This involves downward pressure on the pivot that rests in the jacot drum. Downward pressure is the only type of force you can use with this type of tool.1 point

-

The first thing you need to do is take the power off, take the balance and pallets out and check pivots and jewel holes on both, make sure the jewels are correct and tight, make sure the pallet bridge hasn't been bent and that it sits flush to the bottom plate when screwed down, if that's ok check the pallet stones, its time to put the pallets in make sure you have there pivots in the jewel holes and carefully screw down the bridge, check for end shake if all is well add a little power and with the aid of your tweezers touch the pallets to see if they will let the power escape? Let me know how things are then we can go into the second part.1 point

-

I have seen pivot holes made of steel on the real low grade pin lever movements but was not aware some Seiko Calibers also have this poor design. I think I see one of Marks vids where he reams out the centre wheel pivot hole & replaces with a jewel. A while ago I did replace a barrel arbour bushing. I had to make the bushing out of brass because although conventional jewels had the correct internal & external dimensions they where all to thick. This is a very interesting vid that shows the method I used.1 point

-

Nice work thus far Scott, I've not seen pushers with screws like that before. Most have a small lip that keeps them in the case although the 1940's were kind of like the "Wild West" days for the chronograph and many manufacturers had different solutions. Possibly this was a fix by a later watchmaker. Here's a pic of a NOS replacement I have although for what chronograph I'm not sure. Regarding the chronograph runner tension spring- that little guy is going to probably give you fits when you take it off. It's extremely light and will take a static charge very well which causes it to become magnetized. It will stick to your tweezers and grab at anything steel when you try to replace it- especially it's own retaining screw. Nothing wrong with that so long as you are prepared for it and remain calm during reassembly. That's good news regarding the lack of rust. Usually if you do find it, it will be in the keyless works or where the pushers meet the actuating levers. On the Venus chronograph I'm working on there was quite a bit of rust. I gave the rusty parts a bath in some vinegar, then polished out any pitting when possible. As you can see below, not all parts could be salvaged though. Keep up the good work!1 point

-

1 point

-

1 point

-

1 point

-

Well after some 30 years without a service this 1977 Seiko was in desperate need of tlc, luckily the cosmetics of the dial and hands are quite good and the inner bezel has aged like they all do . Timing is the same as it was the day it was made New favourite in my collection ( long overdue ) Not quite as nice as that Favre1 point

-

1 point

-

Here is a pick of a Timex that belonged to my wife's uncle years ago. It was missing the crown and the movement wasn't working. Oh yea it was also missing the seconds hand. I replaced the crown and seconds hand from a donor watch and the movement had a broken screw that I was able to replace. The only movement that I have actually taken completely apart and put back together is a 22r belonging to a ladies Helbros but I am waiting for a donor click spring before putting it back in the case.1 point

-

Thanks for the support, everyone. Ry, I appreciate the links. I'd seen the tech sheet, which I used to make this diagram: I'd seen the Esembl-o-graf for sale (as pdf) by hucksters on the bay, but hadn't yet found a free one online, so thanks for that. The scans are really good, too. It's a great document and largely made my diagram redundant, but it was helpful for me to study the shapes and names of the parts in the tech sheet and find them in the watch, so it wasn't a wasted effort. Some notes on further progress I've made. I was surprised to find screws on the pushers, but I guess they're just there to provide a lip to keep them in the case. The pushers have pretty bad brassing. The case itself is not too bad once the green gunk was removed with mineral oil and a toothpick, but I guess if I replate the pushers I ought to replate the case. I'll think on that some. One thing about those screws: they were good practice for me to learn technique and further refine the tips of my screwdrivers before I attacked the movement. I got through the removal of the first few pieces: flyback levers, chrono bridge, and chrono wheels. I stopped before the Second Wheel Tension Spring. Seemed like a good place for a picture in case it needs to be just-so on reassembly. Ry, you commented that the movement seems fairly rust free, and I was pleased by this too (especially with that broken crystal). Looking through the sides of the movement, I can see a bit of oxidation on the barrel, though. It might get a bit messier once I get deeper in. I'm starting to think about oil. If anyone has any tips on best sources of small quantities, and the minimum types I need, I'd appreciate it. Let's assume I'll take the whole thing apart, but feel free to stop me if you don't think it's necessary to clean or oil certain difficult parts (like the balance, haha).1 point