Leaderboard

Popular Content

Showing content with the highest reputation on 11/18/16 in all areas

-

Most of you in England are maybe familiar with this movement but for me it is the first one with a fusee so i am so excited of this new gem3 points

-

2 points

-

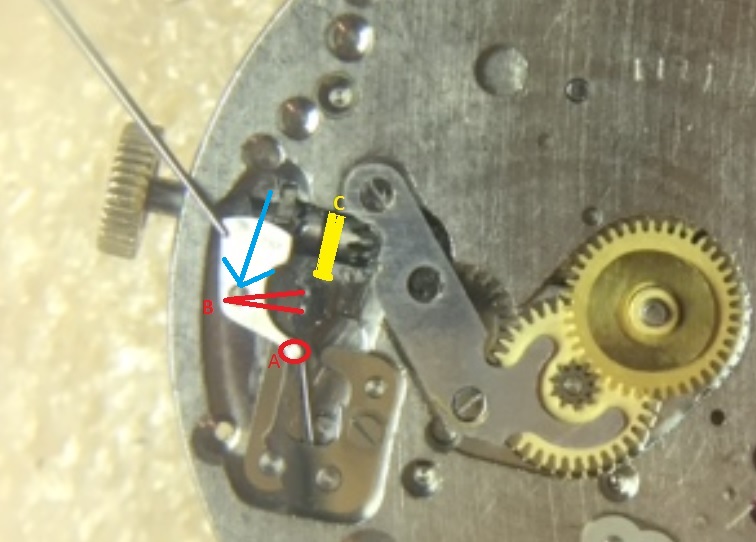

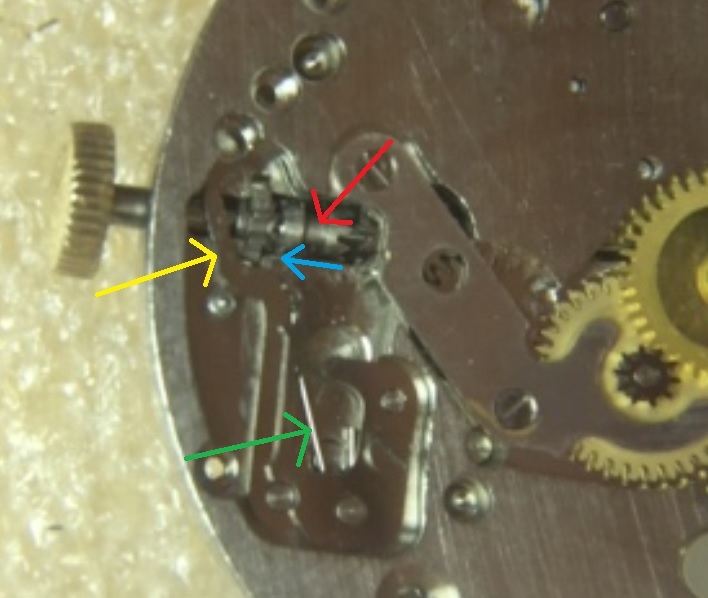

Hi Bill, The way I see it, the little post (A in red below, called the set-lever) needs to be under the 'set-lever spring' so that it rides in the two troughs (B in red). There seems to be a part missing, you would usually find the yoke fitted in the slot marked in yellow below, The Blue arrow is the end of the screw from the other side. I'm not too familiar with this movement but I think the part indicated by the yellow arrow below could be the yoke. Can it be moved so that it sits in the slot I mentioned earlier (red arrow below). The yoke spring (indicated by the green arrown below) will need to apply pressure on the yoke so that the winding pinion (red arrow thing) is pushed in the direction of the blue arrow. This will allow it to engage the clutch wheel (sorry no more arrows). The set-lever piece (which your oiler is indicating) is usually installed first, followed by the yoke-lever and yoke spring. Then the set-lever spring/bridge (part indicated with the red B in the first pic above). Hope this sorts out your problem. Anil2 points

-

Do you intend to repair the chain or try for a replacement. Repairing the chain is not an easy task, if your not careful you will do more damage then you already have. You might need to take the fusse apart to check the teeth on the ratchet, also you will be able to grease the ratchet.1 point

-

1 point

-

Cleaning the mainspring in situ is a really bad idea. Where does the old grease & crud etc go if the spring is still in the mainspring.1 point

-

You do not necessarily need to winder to place back a mainspring into the barrel. If in doubt, leave it alone, it's not something that crucial especially for a beginner.1 point

-

1 point

-

Well, I've made a little progress, in that by some fluke, I've managed to reset the chronograph sub-dials to Zero. Not as the eBay seller stated in his description, using the 10 o'clock pusher, but in a method not dissimilar to the way you do it on a Seiko 7Axx - with the crown at the first setting position, then using each of the three pushers to reset the sub-dials in turn. The difference with this movement is that it seems to need to be in a setting mode as well, which more by luck than judgement, I found by holding in the 4 o'clock and 10 o'clock pushers in together for two seconds.1 point

-

1 point

-

Also the set-lever may be flipped over. The post 'A' could be the stem retaining post. You may find another post on the reverse of the set-lever. Anilv1 point

-

1 point

-

Determining the lift angle & setting the timegrapgher to correct setting will only make a marginal difference to the readings. I very rarely bother to adjust from the standard of 52 deg.1 point

-

1 point

-

Ok. I made the first pair of tap and die. It is M0.9, important for winding stems The other hole has the tip of the original M0.9 tap so first i made a new tap with the original die from the set. Then i made a new die with the new tap1 point

-

Got timed out on the edit. I was going to write: Text on the bottom of the bezel is Russian for Mission Antares. As worn by French astronaut Michel Tognini for Soyuz TM-15 in 1992.1 point

-

My first clean + assembly went quite well, all the parts are now in place but unfortunately some of my tools got magnetised so I am now waiting for a demagnetisier. I will probably face an issue with putting hands back on, because I don't have any tool for it. What hands fitting tool is ok to use and won't crack my budget? Some photos:1 point

-

Thank you Anil, I will probably use lighter fluid for most everything. I happen to have a couple of bottles around. I will not use the ultrasonic though, I was thinking more on the line of cotton swabs on the big parts and the agitation as you described for smaller ones. The balance wheel and pallet fork I usually clean normally and by themselves. I rather spend a little more cleaner on those than risk damaging them, the expense is minimal. I'm glad you told me about the date wheels! Just in time my friend! Robert1 point

-

Dear Bob, I wouldn't use anything flammable in the ultrasonic as it generates some heat. Apart from that use the same caution as you would handling thinner.. don't breath the fumes, dispose properly. On using them for other parts, if they're steel then its ok. But if the parts have shellac then these fluids will melt the shellac. Specifically the pallet fork and balance wheel, the pallet jewels are held in by shellac and if you use thinners/petrol the shellac will soften and the jewels may get loose, and you have to reset them. Likewise the roller jewel (that wot drives the pallet fork) on the balance is usually held in place with shellac as well. Naphta (lighter fluid) is quite cheap and does not affect shellac, if the watch is unusually dirty I would soak the whole movement in it, agitating it slowly. Dials and datewheels are not cleanable with fluids.. Anil1 point

-

Thank you Anil, that's good advice! I'll definitely use some of the fluids you suggest for a good pre clean since they are cheaper and readily available. And, no, I quit smoking a long time ago so there is no problem there, thanks you. By the way, would gas/gasoline/petrol (different names for the same thing) be suitable too? Do those regular solvents can be used on other watch parts for pre cleaning?...also in the ultrasonic machine (always for pre cleaning)? Sorry for the many questions but that's the price I pay for learning at a risk of being too much! Robert1 point

-

My first teacher during my apprenticeship never removed the mainspring when servicing (unless it was broken). Over the following years I found this to be bad practice and I always open the barrel and remove the mainspring prior to service. I have found many broken or almost broken mainspring hooks as a result and I suspect this has reduced the amount of return jobs significantly. :) Sent from my iPhone using Tapatalk1 point

-

Hope this works have found this Moebius oil lubrication chart. moebiuslubricatingchart.pdf1 point