Leaderboard

Popular Content

Showing content with the highest reputation on 10/19/16 in Posts

-

No, the 'tick' sound of a watch is actually a combination of five different actions and sounds from the escapement, starting with the impulse pin striking the slot of the pallet fork, next is the escape wheel tooth falling off the locking plain of the entry pallet stone and striking the impulse plain, third is the opposite side of pallet fork slot striking the impulse pin, fourth is the escape wheel tooth hitting the locking plain of the exit pallet stone, last sound is the fork striking the banking pin but there are as you can see lots of actions taking place to create the sound that don't include the banking pins. Hope this helps a little, the escapement is a fascinating subject. Brian3 points

-

I don't think that is so. I would have thought it could be to do with the case a thicker case will be better then a thin one. A square case can never be as secure as a round one.3 points

-

Thanks for the info Marc it certainly brought back some memories when I came across it, I can still remember my mum handing it to me outside the jewellers shop.1 point

-

It's not a 47. Very different chrono bridge. Key difference between 48 and 54 is size, but they share many parts. 148 and 248 are later variants of 48. If you are planning to tackle it yourself, you will need this... http://shop.joseph-watches.com/joseph/members/FMPro?-db=joseph_archive.fp5&-lay=web&-format=esemblo_details.html&kategorie=esemblograf&-recid=12607829&-token=002&-find1 point

-

Just because the inside of the watch isn't marked doesn't mean it hasn't been serviced. It depends upon the policy of whatever serviced it. It seems be the most common things I've seen are scratching variety of secret codes. Felt pen as it's not supposed to be permanent but recently frowned on because supposedly it admits fumes bad for the watch. Or some repair people do not mark the inside of the watch at all. So markings on the back are only a general indication perhaps. One of the nice things with early organic lubricants is they would gum up with time. This means the watch would come to a stop before bad things happen. Modern lubricants chemically can do just about anything over time or possibly might last forever perhaps. Moebius who makes lubricants used to run interesting advertisements that there oil in this case synt-a-lube/9010. Does not gum up, does not spread and does not evaporate unaffected by atmospheric conditions so we can assume that basically last forever Although they don't actually say that. Strangely enough the new bottles you purchase have dates saying when it expires? So for instance let's say your watch has never been serviced and Seiko used the same lubricants recommended in the service guide. So looking at the service guide they're using a mix of Moebius Oil in this case synt-a-lube/9010 their oil S-4 and a Moebius grease. Then as the common trend was using light lubricants where as today we would use heavier lubricants. So as far as lasting forever goes Moebius has a lubrication handbook with specifications and interesting information that applies to this discussion. So synt-a-lube/9010 is supposed to never evaporate but it can spread itself to the point of appearing to evaporate. I've noticed this in watches I've serviced over many years it just disappears. So the recommendation to prevent disappearing is surface treating which usually isn't mentioned in tech sheets which is why typically it's not done plus there is a cost factor. So I was looking up the Watch Tuner Timegrapher app Looks like an interesting program. When you get that we can go back to testing your watch. Amplitude is a real clue of how well the watche is working and looks like timing app has this plus the beat of the watch. So wind the watch up then let it run 15 minutes to an hour to settle down. Usually recommendation to let the watch settle down when it's wound up especially on Non-automatic watches we can put that extra little bit of power which screws up timing results specifically too much power. So you want to time for 24 hours to prevent external influences from changing things you'll keep the watch in a stationary position except when you're timing it. Then for timing pick one position only to make things simple unless you're obsessed. Do not time in either dial up or dial down as they represent your least friction just pick a crown position Crown down 12 o'clock up something you remember. Then we can look at the before and after typically the watch companies time wound up and 24 hours later. But because you've got a nifty app there's nothing wrong with multiple timings during the 24 hours. Then in the above paragraph Were taking a simple approach to timing the watch companies do time in multiple positions at the start and the end to figure out what's going on but I thought we can start with something simple.1 point

-

With a new mainspring you simply press it in. A used mainspring you start by fitting the end into the barrel depending on what end fixture you have, an eye end you hook it on the inside piece, normal bridle close to the inside piece so its resting next to it, then you simple feed it into the barrel using your fingers.1 point

-

Looks almost definitely a snap back as the case is plated and the back appears to be stainless. The case looks pretty filthy so you may struggle to find the cutout to insert a case knife. If you carefully roll a scalpel blade round the join and look hard with a loupe you will probably find it S1 point

-

I too have recently started in this watch fiddling game, and there are two items that I can't imagine living without, and they are, Timegrapher and Demagnetiser. Without these you will end up chasing your tail all day long. Timegrapher first, is essential for general fiddling.1 point

-

1 point

-

welcome to the forum. cylindar escapements are very, very, bad when worn out. i dont know anyone who has restored one. i have a couple in silver cases [non working, but nice looking]. they also have (button set ?) for the hands. it would nice to know the history of that mvt.. vinn1 point

-

A cylinder consists of three pieces two ends and one center, the two ends are taped into the center making one whole piece and this is then taped into the balance wheel. You have to make sure that when the hairspring has been fitted it is the correct distance so nothing is fouling. Balance staffs tend to have two ways of being fitted and they are a single piece, riveted in place or tapped in. I did not have a cylinder watch yet. Is it possible to remove the balance wheel, broken tampon/tampons and finally anneal the staff to make it less brittle? Then insert new annealed tampons and harden the assembled three parts together? Yes with a cylinder but why would you want to do such a thing and don't forget you will need to re harden the cylinder, if not it will be open to wear out quick.1 point

-

Out of curiosity when was the watch last serviced? Then what sort of timekeeping are you hoping for? So to understand what clockboy saying about regulating and timekeeping of your watch I have a link to a PDF that explains a lot of the terminology. Then for proper timekeeping you need to time over 24 hours especially if the watch has a calendar mechanism that can affect timekeeping. Then other things that affect timekeeping like where was the watch when you are timing it? In other words were you wearing it in which case the automatic should've been able to keep the thing wound up. With a constant amplitude it should keep reasonably even time. If the watch was wound up and slowly unwinding the rate will change. If the watch hasn't been serviced in a while the rate of change will be more dramatic depending upon the condition of the lubricants and the cleanliness of the watch. http://www.witschi.com/assets/files/sheets/Calculation of the values X-D-DVH-Di-Im-N.pdf1 point

-

Different positions effect the balance Pip, the balance wheel will not be in perfect poise, thus giving the positional errors in most cases, (other factors do come into it), happens in all watches, we all strive to get the best possible balance to bring our error number (delta) to an acceptable level.1 point

-

Watches run/perform at different rates depending on its position. That is why when regulating a watch it is adjusted in various positions (Dial up/dial down etc.) to get a good mean average. I suspect this is the reason you are getting differences.. Also as the mainspring winds down it will gradually loose power & hence slow down. However if it is an auto then in theory this should not happen.1 point

-

1 point

-

Thanks for the warm welcome folks. I wish I still had that Timex...1 point

-

1 point

-

1 point

-

Welcome to the forum Anil. Your first watch was made across the road from where I used to work in Dundee. I too wore a Timex back in the early days!1 point

-

Hell Anil. Lots of info on here for you so enjoy yourself.1 point

-

Welcome Anil. You just got to the right spot to talk and share experiences about everything watchmaking! Enjoy the site and yes, tell us more about your equipment and progress so far! Cheers, Bob1 point

-

Hi Anil. Welcome to the forum. Have you started acquiring some tools yet? You'll find lots of information around here and people with big experience and tons of knowledge. Have fun.1 point

-

Thanks Brian. That's very nice of you. I will take time off work at the end of next month and I intend on firing away on my first watch repair project. I will definitely keep posting as I make my way into horology. Meanwhile I'll keep on reading and acquiring a little knowledge from you guys. Cheers.1 point

-

1 point

-

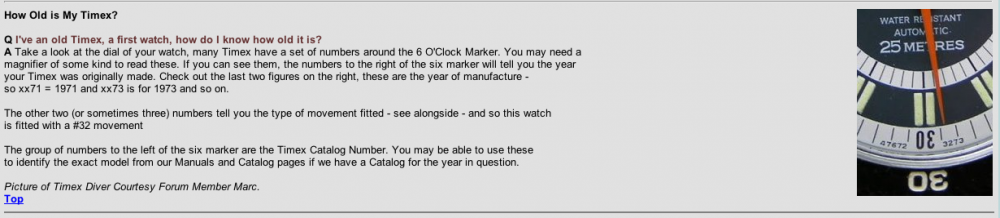

From the number at the bottom of the dial it has Cal.24 movement and was made in 1969. This is the 4 digit number to the right of the 6 index. I believe the number to the left is a catalogue number.1 point

-

It just warms my heart to see these, I have a Timex (the small boy type case) which I received as a Christmas present as well. Every so often, I give it a few turns just to see the magic again. Thanks for posting this.1 point