Leaderboard

Popular Content

Showing content with the highest reputation on 10/04/16 in Posts

-

In simple terms the lower the mass of the balance the faster it will beat. The hairspring also has to be matched to the balance mass to get the correct beats per minute.4 points

-

3 points

-

curiously enough I have just serviced one of these in a Rapport pocket watch for someone. It wasn't too bad quality wise but the general fit and tolerances were not as you would expect on something Swiss and this did reflect in the performance of the watch. As far as multiple train bridges are concerned this is a fairly common arrangement, particularly with train layouts that are a little less conventional. Again, just off the bench I have a Sekonda from the 70's powered by a Slava 2428. Now there's an unconventional set up of ever there was one; 2 main springs, funny side ways pallet, date quick change arrangement built into the movement ring... and 2 separate bridges for the train. I shall have to put it together as a walk through when I get the time.2 points

-

Just a wee reminder to everyone. Please do not make any posts that either directly or indirectly constitute a sales advert, as it contravenes the long established forum rules and it will be removed. Thank you.1 point

-

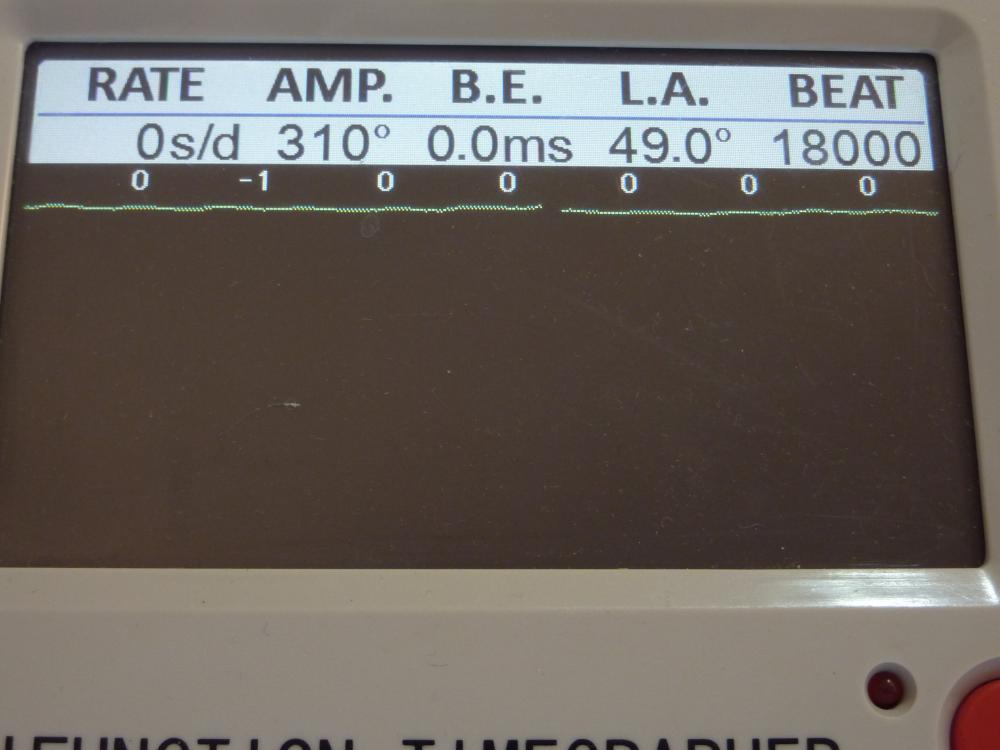

I haven't done one of these for a while and as this is my 1000th post I thought I would do something a little less ordinary. As the title says it's one of those crazy Russians, a USSR Sekonda from the 70's sporting a Slava 2428 in all its quirky glory. This one came to me as a non-runner and a preliminary investigation turned up a broken balance pivot so it went into the "to do" box until I could source a replacement, which it turned out I had all along from another watch previously scavenged for parts a while ago, as I discovered during a recent tidy up. So here goes...... Looking a bit sad, a grubby face and a bit of corrosion on the hands, and as already mentioned, not running. Also the date corrector pusher which is above the crown is jammed in. It's obviously seen a bit of wear in its time as the plating to the rear of the case has started to go through. Inside doesn't look too bad. Dirty and dry for sure but I've seen worse. The stem however suggests that things may not be so good further in. Uncased and the dial doesn't look so bad. The hands may need a bit of a spruce up. Oh dear... with the dial off the hint that the stem was giving earlier becomes a grim reality and the reason behind the frozen date corrector is clear. Heavy rust around parts of the date quick set mechanics has seized everything solid. With the day and date wheels out of the way and safely bagged the full extent of the problem can be seen, and maybe it's not quite so bad after all so long as none of the screws shear off as I try to undo them. Success.... all the screws out and nothing stripped. The rusty parts have been carefully rubbed down and are now enjoying a strong cup of tea.....to stabilise the remaining rust deposits. And here is the first quirky bit, all of the date quick set mechanics are mounted on the movement ring, not the movement itself. Strange but true! The movement now flipped, balance cock and barrel bridged removed, and the second and third deviations from the everyday run of the mill design philosophy become apparent; that curiously asymmetric pallet fork, and those tandem main spring barrels. The first of the going train bridges removed .... ... and with the second train bridge and wheels removed, the replacement balance is installed without jewels ready for a spin in the Elma. And here we have all the bits nice and shiny out of the cleaner, with as much of the rust issue dealt with as possible. Is it me or are there a hell of a lot of wheels in this little baby? Both main springs are in good shape so they are greased and rewound into their respective barrels. I don't know if it was strictly necessary but I did take the precaution of keeping the barrels, lids, and arbors together as sets during the cleaning process so that the same bits went back together as came apart. Balance jewels inspected, lubricated, and reinstalled. The hair spring is pleasingly flat, parallel to the balance, and concentric, and once set in motion the balance doesn't seem to want to stop. A good sign... In goes the first set of train wheels along with the idler that couples the twin barrels together. With the first train bridge in place the escape wheel and centre seconds wheel are installed. Second train bridge goes back on followed by the tandem barrels Barrel bridge with all of those amazing coupling wheels to keep everything turning the right way all the way back to the crown wheel and its clearly marked lefty screw. At this point all of the pivots have been oiled and a quick test of the free running of the train is done. A couple of clicks on the ratchet wheel and the escape wheel spins nicely down and then back with just a little recoil. After that the pallet fork goes back in and the pallet stones are lubricated. Typical of many Russian watch movements, the balance cock has a shim. Whether or not these were available in different thicknesses so that end shake could be adjusted I have no idea. I've never had a problem swapping them between watches though which suggests that they are all the same thickness. Balance back in and that lovely moment when it starts to beat again. And then back into its big metal spacer ring come date quick set extension. Time to rebuild the dial side. It's a bit cleaner now. Keyless works back in place. Motion works reinstalled. Incidentally, as can be seen here 5 of the 26 jewels are vertical rollers for the date wheel and 4 are set into the main plate for the date wheel to ride over. Cynical marketing ploy anyone?? The date corrector mechanics are reinstated into the movement ring, all now free running. Most of the rust damage cleaned up reasonably well but there is significant pitting at one end of the spring. If I ever find a donor I will replace the worst affected parts but for now they work and the rust has been stopped. Calender wheels back in place. Date wheel back in place and the day wheel jumper and spring installed. Day wheel drops into place. Dial and hand back on following a clean up and a little fresh black paint in the hands where it was beginning to crack. This is the date corrector pusher and is I suspect the origin for the water ingress that caused the rust damage. It has a little neoprene seal on its back face so that the spring tension should seal it against the inside of the case. It was bone dry and all it would have taken is a little dirt stopping the pusher from closing properly and its an open invite for any contamination that comes along. Now cleaned and re-lubricated with silicon grease it will hopefully keep the water out. Re-cased and ticking away nicely. With the exception of the date corrector pusher issue these are well designed cases. Although they make no claim to water resistance they do use a design similar to that used in the Vostok Amphibia cases, with a thick gasket, a steel back that drops into place, and a threaded clamping ring to hold it all together. Looking a lot happier than when this all started. You can now see the date corrector pusher protruding from the side of the case above the crown so it is definitely sealing against the inside of the case. A new crystal allows the cleaned up dial and hands to look their best. And there is something about the dial layout and hands that just seems so Russian to me. I really like it. And of course the proof of the pudding.... This is dial down. DU was almost the same, only difference was amplitude which fell to 298. The vertical positions showed a tiny bit of beat error, up to 0.4ms, amplitude down to around 275, and slight rate errors, coming in at -5 s/d at one extreme and +3 s/d at the other, quite a respectable result. Maybe those crazy Russians aren't quite so crazy as they first appear. The little design quirks here all add up to a nice piece of engineering. The train wheel layout, and the asymmetrical pallet fork allow for a comparatively large balance wheel for this size movement (thinking about it without the date quick set and the extension ring). The use of 2 main springs running in tandem allows for a more even torque delivery as the springs wind down which should help to reduce isochronism errors, while also making good use of the available space. It all actually makes quite good sense in a kind of lateral thinking sort of a way. If you should be tempted to go for one of these then I would suggest that the earlier USSR ones are the better ones to go for. The later "Made In Russia" versions at some point were updated to a 21600 train, but weren't so well finished, and that date corrector/spacer ring became plastic with the mechanics riveted on, presumably to reduce costs. Bit of a shame if you ask me. If you made it this far then I guess I haven't bored you to sleep. Thanks for reading.1 point

-

I think the Chinese movements are getting better in build and quality compared to a few years ago.1 point

-

1 point

-

1 point

-

No I did a bit of research and I am convinced its a chinese reproduction there are quite a few about at the moment. I also checked on ebay and this seller had sold it before for £680.00 under a different user name but same location and pictures that always put's me off when users have multiple seller accounts, why did the sale fall through ?. It may be a good clock regardless but it is clearly not what the seller stated and at £344.00 I was happy to pass on it.1 point

-

Hello watch enthusiasts! I have often wondered what makes some watches tick at 21,600 bph and others at 28,800 and so on. Does it have to do with how many teeth the escapement has? Or does it have to do with a specific layout of the movement? This is something that really fascinates me and I would love to know how this works.1 point

-

Did you tried the red rose in bloom present on the dinner table. And candles...and maybe order some Chinese or Italian food if you can't cook...just make the table pretty and have a bottle of some spirit she likes, handy....Not to confuse with white spirit. That is only for cleaning watches!1 point

-

Maybe a strange reflection of the background make it looking like a bent one.1 point

-

1 point

-

I agree with Szbalogh. All of the printing is already lost so there is nothing to lose by refinishing. The applied indices and logos all have tiny posts on the back of them which fit into holes in the dial. Carefully push them out from the back of the dial so as not to damage them or the dial. Then you can refinish the dial surface and reinstall the indices. To be honest though this is a Constellation dial and as such it may be worth getting it professionally restored. As a redial it will never have the value of an unrestored original in good condition, but it will at least have the printing, which unless you are set up to do this properly, a DIY cleaning job will lack.1 point

-

There is a set on ebay at a cloud cukoo £600 pounds I think it would be of interest only to Omega collectors but a more realistic price I would think £200-£300 but do you really want it and are you going to use it? because you could source similar tools cheaper to do the same job.1 point

-

Agree with above answers, length of the hairspring, I used a hairspring vibrating tool like this to vibrate my hairsprings at school, they were oversized and once you found the vibrating point you needed you cut the hairspring, then the fun part of introducing bends, pinning to the collet etc.........1 point

-

Geo is correct the physical characteristics of the balance hairspring combination determine its rate of oscillation. Then the gear train ratio determines the rate at which the hands revolve.1 point

-

Sounds like a happy ending . A similar situation occurred with one of my watches recently . After cleaning and refitting , the balance seemed to be dragging . It turned out to be junk in the bottom pivot hole . Re-cleaned the jewels and swabbed out the pivot hole with my smallest oiler and it ran fine after that .1 point

-

You could go to a place that sells rubber mats? That you have in the industry . V-ribbed rubber mats? Just as an example? http://www.guldstrom.se/sv/utrustning-fran-usa/rubber-matting-v-ribbed-black Available in different sizes and shapes . Round ribbed.1 point

-

Im more pottery and cameras than bronze i still cant believe I did a degree in studio pottery and ended up becoming a draughtsman where did I go wrong oh I remember now it paid more1 point

-

The Chinese characters read "Made in Switzerland by Swatch" so they must be expensive!1 point

-

I use this Bergeon set, the Bergeon 30081-S: but have been incorporating other models from the same brand as well as others from other brands, mainly AF and Horotec. I'd say, if you go the Bergeon way, don't get the ones with the round top. They will roll and fall from the bench as soon as you forgot you left them laying on it. The AF and Horotec are nice. Some people prefer the Horotec to the Bergeon...I like them both about the same...Horotec has a nicer, more accommodating top that should be good for certain hands while Bergeon will accommodate others. AF is a compromise between them. They all get the same tips...which I use from Bergeon, both steel and non marking (soft material). If you go the Indian or Chinese way, some may accommodate good quality tips...I did experiment that way but they were not exactly centered or had a fitting problem, so you have to be careful about which you choose being the quality so variable. In fact, I went the Bergeon way after my first cheapo set and have never looked back...OK, maybe sideways since, as I mentioned, I got some other brands too. I hope this helps. Cheers, Bob1 point

-

I bought an AF set from cousins for just under 50 quid, AF are supposed to be ok and are a happy medium i think. (don't quote me on this) i'm just a beginner.1 point

-

1 point

-

1 point

-

1 point

-

1 point