Leaderboard

Popular Content

Showing content with the highest reputation since 04/26/24 in all areas

-

Hi All, I started this forum over 10 years ago and never intended for it to me a 'for profit' concern. Since then, I launched an online course and I draw funds from that business in order to fund this website. There is also a little bit of funding from Google ads but I don't rely on it because they keep changing the goalposts. The forum costs a few hundred pounds per month to run and Im comfortably managing it. Why a few hundred pounds? I am OCD about backups and not relying on a single company to host those backups, I use amazon S3 to backup hourly and daily, I also use Digital Ocean. I use a separate mail service to handle the serious amounts of emails sent from the site, I am on here most days admin'ing and updating the site or servers/applying security patches and the like - its not a big deal, I enjoy it. In short - you might not see me a lot posting (for my sanity as it's addictive (same on all my social media)) but I certainly do a lot behind the scenes. I can't control my mortality and so there's always that - but other than that, I'm damn committed to this site as I am committed to my commercial site watchfix.com which supports this site. I have no interest in shutting down, selling or otherwise changing this sites format. Having said that, if anyone wants to consider taking on moderation tasks to help (in particular, making sure people post in the correct place and moderating new members posts) that would be very helpful. (Only members who have been active for more than a year please). Finally, thanks very much for your support and kind words - I truly appreciate that. This forum has to be one of the friendliest I am part of - a massive refreshment after reading some of the Facebook groups I'm part of - except mine FB group - that's also great with great people13 points

-

I should have done this a long time ago. I would like to say a big thank you to all my followers new and old. If I can help in any way just message me and I will do my very best for you.10 points

-

9 points

-

Alright, the job is done. I first filed down the stubs flat. I then used a Proxxon hand drill first with a 0.5mm bit to score a point to work from, then a 1mm drill bit to properly drill out some lug holes. I just went slowly, checking the depth as I went. I drilled the inside of the lugs, leaving the outsides unblemished. I was worried that drilling at an angle might be a problem, but it turned out fine. Lug holes don't need to be very accurate, so it was actually easy to create holes to easily accommodate a spring bar. The result is a 'good enough' outcome that worked for me. Thanks for your help everyone, loving the hobby so far. I learn so much with each project.7 points

-

Why is it when that little voice says, "This is a bad idea," we always want to talk ourselves out of it? I had the low blood sugar jitters earlier, but insisted to myself that I'd be able to oil an especially tiny cap jewel on my friend's Omega 1001. With lots of concentration, I nailed it. But when I put the hole jewel on top, it was too much oil and it squoze out everywhere. It didn't spread on the cap jewel much thanks to the epliame I'd applied, so it was more than it looked like from the top. Back in the cleaner, dried, re-epilamed, dried. Time for a second try, but now I was more shaky even than the first time. "This is a bad idea," my brain told me. "Take a hike, brain," I said as I watched the oiler jiggle into my microscope's frame. And just like that, the jewel was a tiddlywink and flew out of sight in the blink of an eye. With a strong UV flashlight and the waste of a lot of time I did find it on my desk, but that's some stress I didn't need in my day. So friends, listen to your body, and listen to your brain when it tells you now's not the time for precision work.6 points

-

You are so true on a lot of what you have said. The main reason for changing the mainspring even if the old one is in good order is because it will take out your thinking that the mainspring is contributing to poor power output or fluctuations in amplitude. If a new spring is fitted that box can be crossed off as a potential source of a problem. Most customers are happy to pay the extra £20 for a new mainspring if they are already parting with a couple of hundred pounds for a service. A new spring is an investment for good running for the future.6 points

-

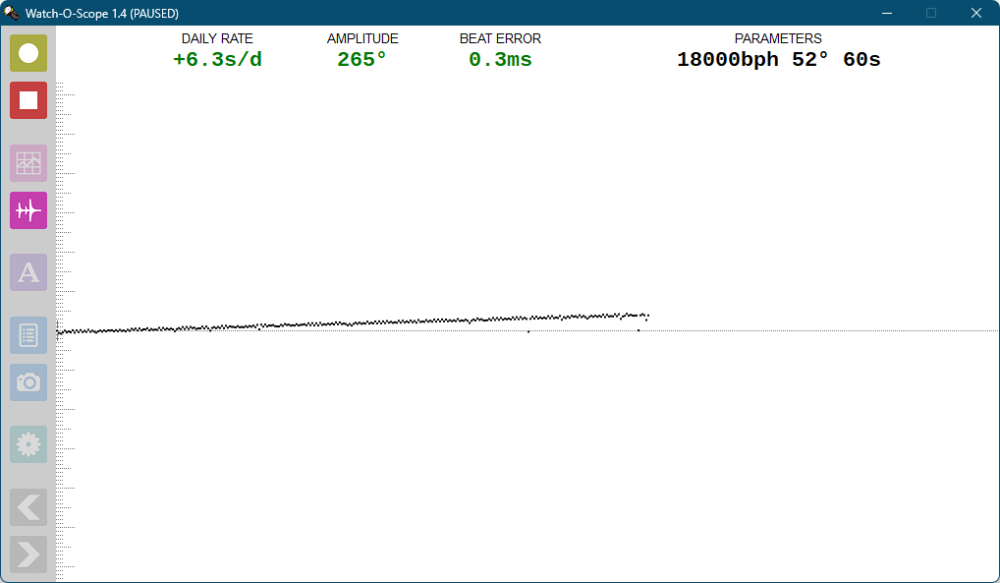

Yeah you need more amplitude, and if this is full wind a new mainspring isn't going to get you there- there are other issues. Good news is if that's your max delta at this miserable amplitude it will probably run great when you get it up to something normal!6 points

-

The K&D (Levin made the same style too, probably others as well) are a clever design and work well when you get used to them. The only issue is if you wind the spring so that the tongue goes in, there's a really good chance it slips futher and then comes out the next slot, usually breaking off. Best to size it so you can fit it in the barrel with the tongue sticking out.6 points

-

Tah-dah. A mini blow torch to harden it, then quench it and just a lighter held under a brass mainspring barrel that the part sits in to temper, Its important to wipe off any grease from fingerprints with ipa, you might be able to see i missed a bit at the top of the arm. Its a very satisfying process. I now just need to deal with the more difficult repairs, anybody any good at replacing rubbed in jewels ?6 points

-

6 points

-

I put this quick vid together today when I was replacing the tropic crystal on this Rolex Oyster Perpetual. It wasn't the greatest filming, but hey!5 points

-

5 points

-

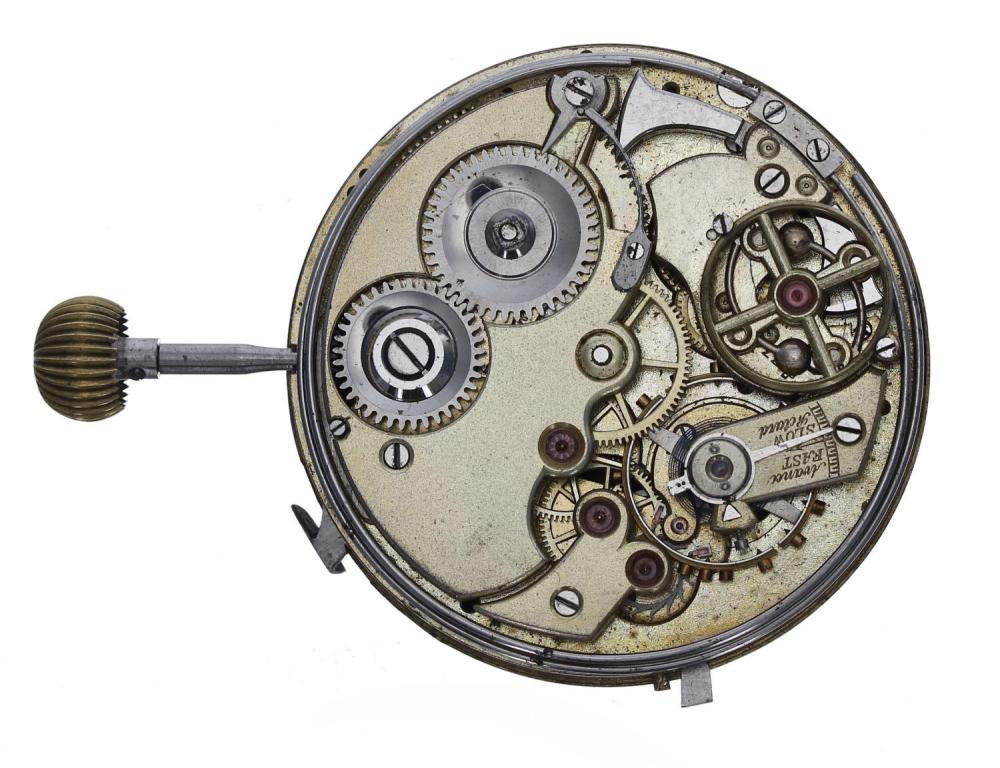

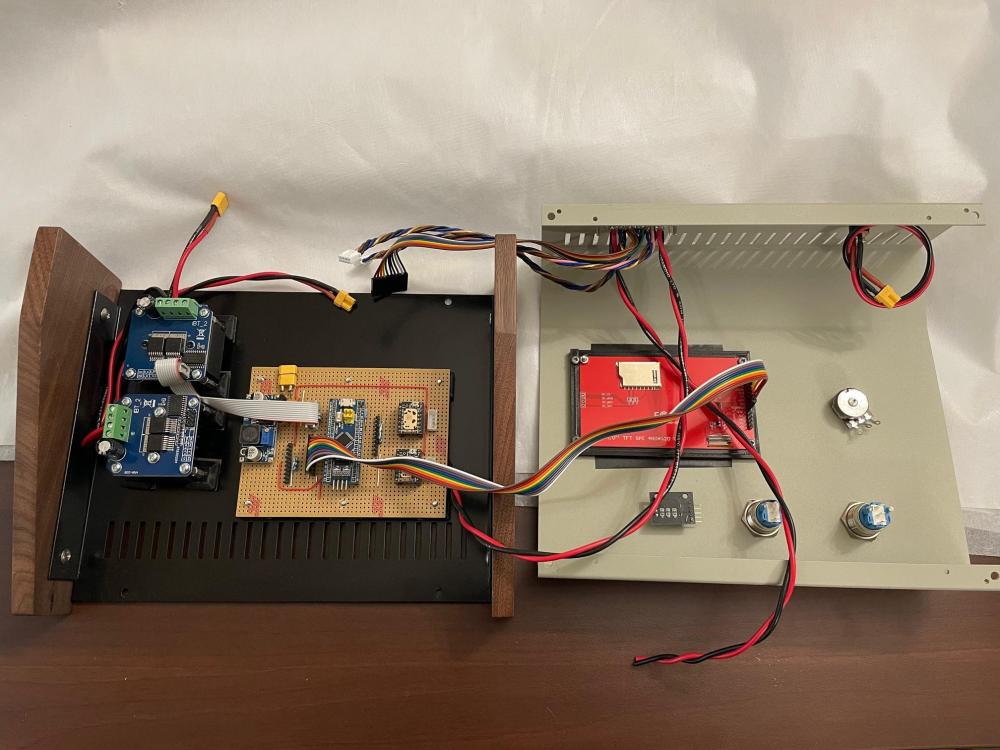

The cleaner smells of ammonia, but it's not too bad; just keep it covered as far as practical. I use an ultrasonic machine on a kitchen worktop. The rinse does not smell strongly, it's vaguely like paraffin. I did check the safety data sheets before buying it & it's said to be safe in normal use. My dedicated watch cleaning machine is still a work-in-progress; four position linear, based on 1L kilner jars for station spacing, to have a heated dryer in position 4. It uses standard, readily available parts as far as possible to make it easy to reproduce, plus 3D printed bits for the custom parts. (The horizontal drive motor is out at the moment while working on the stepper drive software)5 points

-

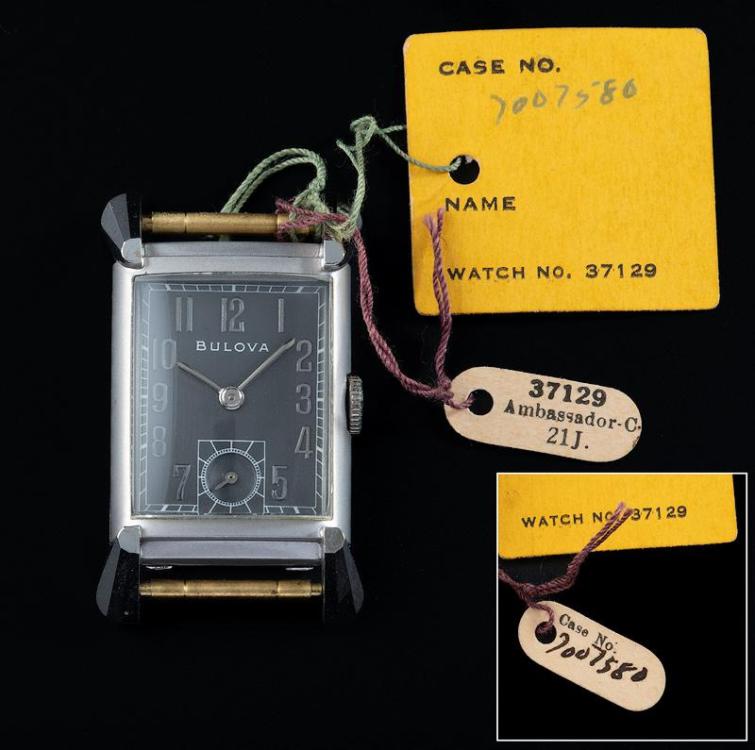

Just picked this up earlier today. This find just about epitomizes vintage watch collecting for me and what really keeps me going. Hit 2 antique malls today and saw a couple of pieces at the first one but just nothing that I needed. At the second one saw a Accutron 218 but it was 20 minutes behind the actual time. These "malls" have numerous booths of a variety of sellers who likely go in once or twice a week. Considering that that watch should be within a couple of seconds a month, I figured it hadn't been phased so passed on that for now knowing it would need work to run correctly and the price tag. Then I found this Excelle in a display case. I never heard of the brand, but in was an auto and had a little heft. It turned out to be 40mm lug to lug, 35.3mm case width, and 12.3 mm thick. On the spiedel once size fits most flex band. At $10.80US with tax I immediately pulled the trigger with nothing to lose. Before pictures: I spent a nice 30 minutes taking it out of the case and running that through the ultra sonic replacing the crystal and gasket and recasing, but spent five minutes first getting it running close on the timegrapher. Had a new crystal already in stock. I probably could have sanbed and polished the old one, but for $3 there is nothing like a new acrylic that makes a watch pop, in my opinion. The caseback gasket was hardened and just glad it wasn't tar. Changed that as well. Here is the after Pic on a temp black strap while I decide on a leather or steel bracelet. An added bonus was doing some research and finding out the Elgin connection and the movement is a PUW 1563T which is German I am pretty sure and probably why it doesn't say Swiss made on the dial. This movement is supposed to have a hack feature and quickset date by pushing the crown. But neither of those complications seem to be working. Not sure if the stem is cut too short because there is no gap for the crown to move. Either way at some point will need to be serviced and check the keyless works to find out what is going on with the quickset and hack of the sweep second hand.5 points

-

Is magnetism such a major problem that we (as home hobbyists) need to spend $$$ on a fancy demagnetiser? I use one of the cheap blue Chinese demagnetisers (£10 from ebay). It works, and has never failed to demagnetise a movement, or my screwdrivers. Magnetometer - who needs one? Take a very small screw. If it sticks to the clean part, it is magnetised5 points

-

5 points

-

A big thank you Mark for clearing all this up. We all appreciate you and the work you put into the running of this forum. If I can be of anymore help to you and this forum just ask. I love it on here as well.5 points

-

I existed before the term mechatronics engineer existed. I had to combine electricity, electronics, pneumatics, hydraulics and computing just to keep my own equipment working. I have never sub contracted any of my own repairs to the suppliers because I know I could do a better job. For a long time, dental suppliers in my country would bring their dead equipment to me that their own engineers cannot handle. I have accidentally embarrassed a couple of hospital heads of engineering by demonstrating their inadequacy. I think mechatronics is the most under-appreciated, under valued of all the engineering sciences. I had a part-time dental assistant about 25 years ago, who was studying mechatronics in the polytechnic. She was absolutely clueless about the job prospects for a mechatronics engineer. I asked her about her aspirations and she replied that she really wanted to work in the games industry. In our dental profession, equipment have evolved from simple mechanical to electro-mechanical to logic-driven electro-mechanical and currently to computer driven machines. The medical equipment suppliers who employ mechanical engineers and/or mechanical engineers cannot cope with the repairs of the newer equipment. And many times end up changing whole modules and whole machines just because they cannot repair them. But I think HR is afraid to employ a mechatronics engineer just because they don't know what a mechatronics engineer does. Mechatronics is much more fun. It combines almost all of the engineering sciences and produces an all-rounded engineer. But until HR changes their mindset, not all door will be open.5 points

-

5 points

-

My newest 404 candidate, a late '60's / early '70's Waltham with a UTC 33 / Seiko 6601 17 jewel automatic movement. It needed a new crystal and I put on a strap from my Strap Graveyard. The timegrapher was a snow storm before servicing but it cleaned up nicely. I really like the funky font used for the hour markers.5 points

-

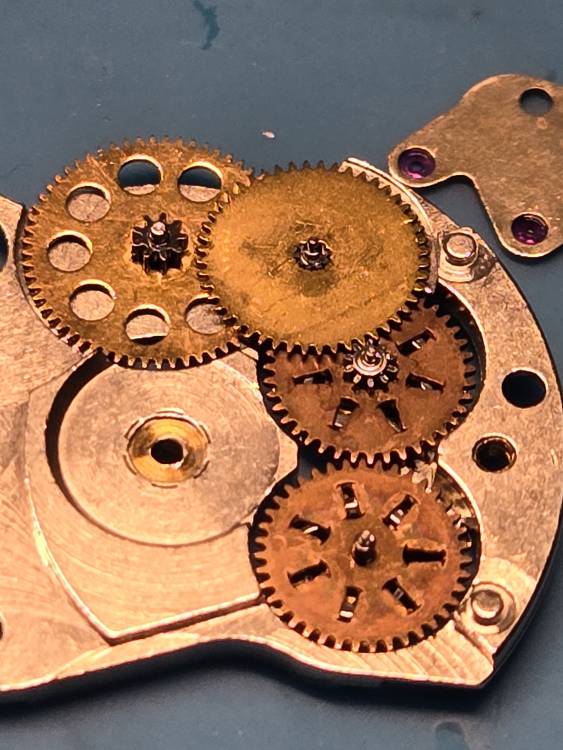

Here are the pics of the bridge. Looks correct, but as soon as I screw on the rotor, the watch stops. Video here: https://1drv.ms/v/s!ArG5E62RGctxjokY5ws85BzuJLVakA Pics. Might have figured it out. I have been working on this watch for a while and since I got it as a non runner in a terrible shape, there was no guarantee that parts were proper. I think the main screw that was used on the rotor was too long, so it was stopping the main train. As soon as I fished out a much shorter and larger headed screw, things were good again. Please celebrate with me.5 points

-

Finally figured out why my hands are so god damn steady. My mum 87 years old , 4 weeks after her stroke and has a macular hole in both eyes, she wiped the floor with me and my lad at a kids stacking chairs toy game. Here she in rehab placing the last chair into position, bloody ' Supergreatgreatgran' i hope I'm half as fit at her age5 points

-

5 points

-

I've never touched my life without alcohol . I'm your complete opposite Ross4 points

-

Never touched alcohol in my life. I don't need alcohol to be stupid. Just comes naturally.4 points

-

If the hood will not slide off there might be a catch on the left side as you look at it. open the door and feel up inside to the left. Hoods normally slide of or lift off. Due to age it can be a very tight fit so a little force is needed but be careful not to pull the whole case with movement in side over, you don't want it to come crashing down. The lines are fraying and need replacing it isn't even on the pulley.4 points

-

4 points

-

4 points

-

Did you notice in your technical documentation of 1970 it mentions this newfangled epilam stuff? One of the unfortunate problems of technical documentation is it does not magically update itself to the newest version and if it did it would disappear because it's restricted to Swatch group people only. Then there is the other problem of supplemental documentation. For instance in the late 50s in their lubrication guide they talk about epilam and practically everything in the watch. Then in the ever-changing thoughts of the day go to orally epilam adding the escapement components. But in the newest generation of stuff because epilam is less volatile solvents is more stable at room temperature they've gone back to epilam ing of the entire watch. It's actually in the last jar the cleaning machine with only a couple of things come out. Then we're back to a Problem of time again. Yes the reverser can come apart but ideally not to destroy it you would need the special tool which you do not have. A very long time ago I worked in a shop that was Omega authorized that I was looking forward to even seeing the special tool and he didn't have it. But yes it can come apart and you really don't want to do it. I'm attaching a working instruction which came from cousins hence notice on the corners we see where it came from. If you look on page 19 they cover lubrication of the reverser wheels. Even if and I can't remember which one one of the technical documents I have actually shows the tools explains it can be disassembled and then basically says just dip it in the whatever and be done with it and don't disassembled. 8645_WI_40_rules for lubrication cousins.pdf4 points

-

Too true! I particularly enjoyed fixing the end shake issue with my brand new Chinese horia clone. I have now used that to improve 3 non runners - would have paid for itself already if I ever got round to selling the projects I have worked on!4 points

-

4 points

-

I don't wear or own a watch. I have 12 clocks in my home but I only wind one per week, each week it is a different one. I'm funny that way.4 points

-

These are some from a couple of job lot ebay batches totalling 40+ watches I got a few weeks ago, ~£2 or less each. I'd only looked at a couple of specifically interested ones so far, as I already had others of interest to look at I've just gone through some of the smallest ladies ones. I was expecting them to be mostly cheap quartz, but only one of them was - the others are all look like good quality mechanical ones! There are also a good selection of other types, including a couple of nice looking old Casios - and some blingy things..4 points

-

My Omega Seamaster aqua terra. It's just me, very understated but classy ( not that I'm classy). I don't like dive watches, the bezel puts me off or any kind of bling. I prefer indices to numbers. I don't have any other luxuries, not into clothes, seldom go for expensive meals etc. So it's my little treat to myself. Not my watch but exactly the same, just got home and taken it off.4 points

-

No, only about 1000f. But i took pleasure in roasting these annoyingly magnetized parts4 points

-

Funnily enough, when heating iron or what watchmakers use for making tools which is 'tool steel', or what is also known as 'high carbon steel', as it has a carbon content between about 0.06 to 1.6% carbon content, (but don't quote me on those percentages!) and can be hardened and tempered, when the steel reaches a cherry red, around about 1450 to 1500 degrees Fahrenheit it becomes non-magnetic, so if you placed a magnetic close to or on it there would be no effect at all. I believe it is the steel/iron turning to austenite from martensite, if I remember what I read in an old metallurgy book I picked up in a car boot sale; It's a bit of an esoteric read! In years gone by, cattle bone was used to encase the small piece of steel to be hardened and tempered, so the carbon from the bone was soaked up by the steel when heated for several hours at a particular temperature, in effect 'case-hardening' the steel. It's amazing what we came up with many years ago. We humans are very inventive, yet very destructive.4 points

-

4 points

-

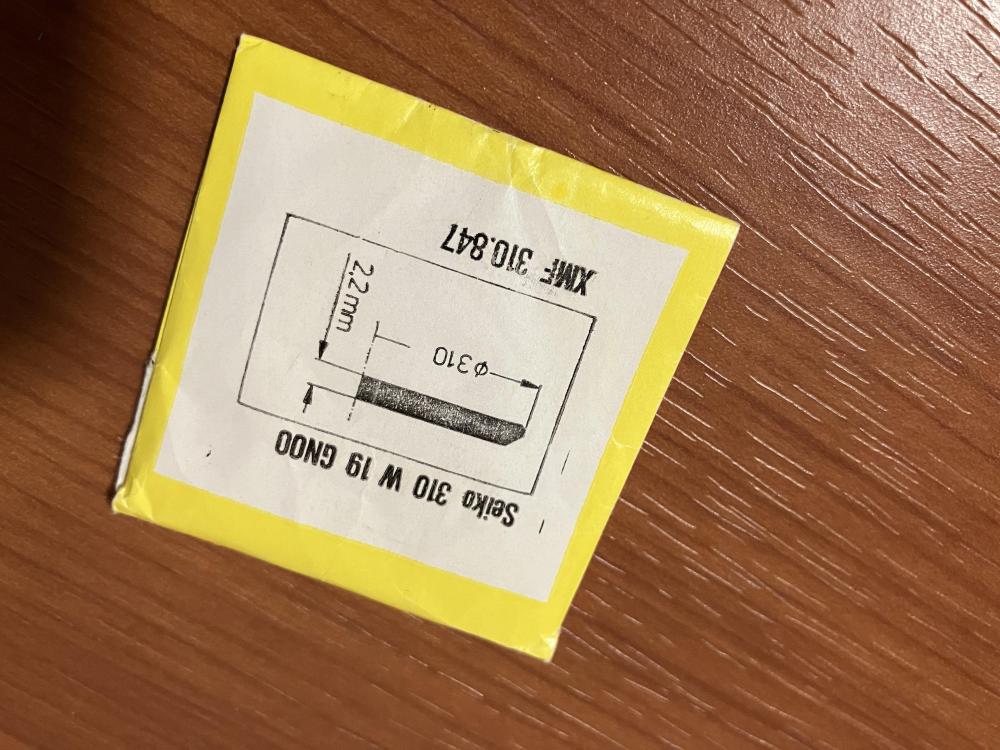

@steve1811uk close but no cigar I don't smoke anyway. I checked in my stock of parts and that's the closest I got to your dimensions. Good luck in your search. @RichardHarris123 I have an accumulation of all sorts of odds and ends that I acquired as a result of buying up the tail ends of old watchmakers estates. Usually after all of the great stuff has been stripped out, which means that the sweepings off of the workshop floor can be had for peanuts, but if you have the patience, can often be found to contain gold (both literally and figuratively ). These came to me through on of those purchases. I doubt that I will personally be able to make use of even 10% of my accumulated stock, but having it, and knowing what I have, means that I can at least pass bits on to those who can use it whenever possible.4 points

-

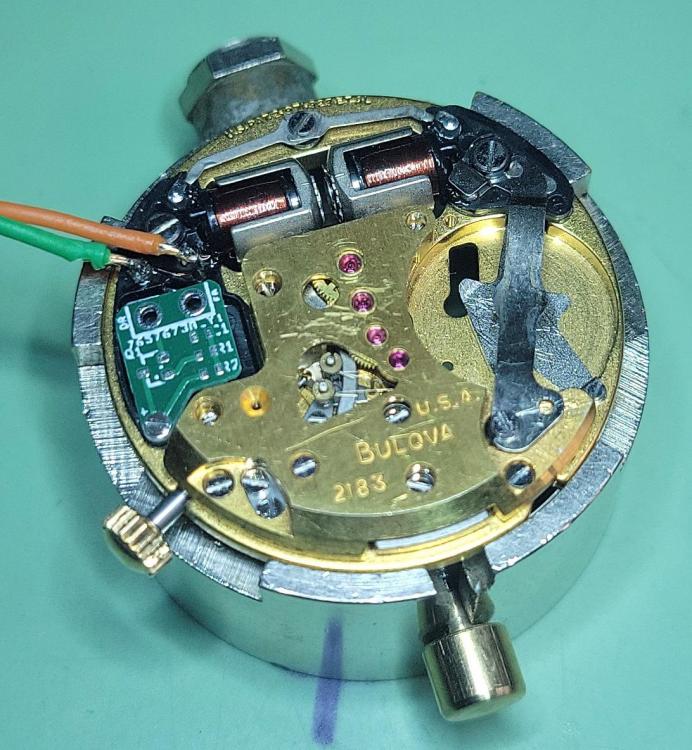

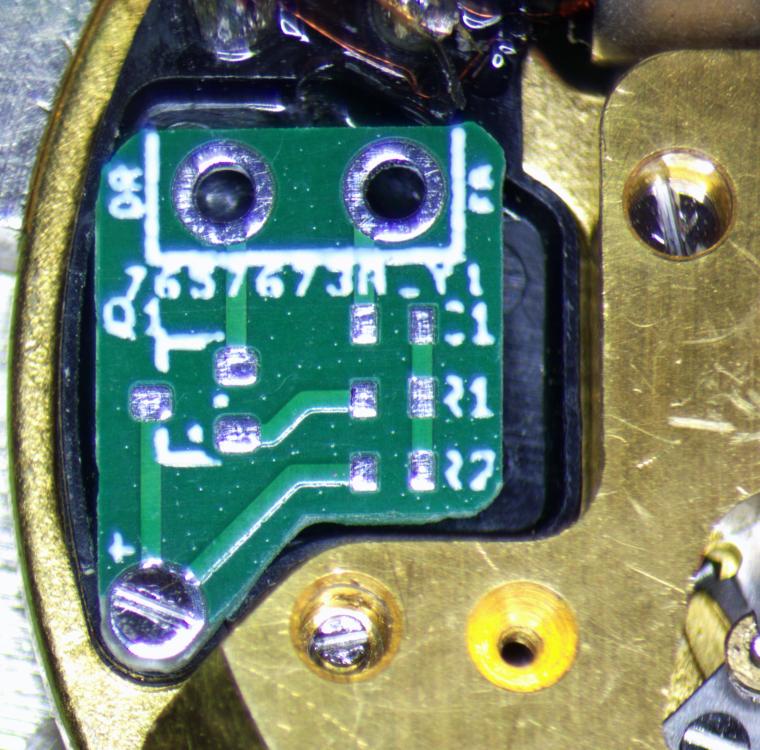

Hi All, I'm Geoff and I've been working on/with watches and clocks since I was thirteen. My dad was a watchmaker and while he did not want me in the field as a profession, I've always maintained a pretty good working knowledge. In the '70's I kinda got pulled back into things because Quartz revolution began and he only had limited electronic knowledge. So we combined skills. He the watchmaker and me the electronics tech. Being here in NY helped because we got to know the folks from Bulova, Seiko, Citizen, and WOSIC. H.B. Freid was my Dad's teacher and I was fortunate enough to get to know him too. I still maintain a bench here at home and occasionally work on watches for friends although the hands aren't what they used to be. Not going to be working on any FHF59 or AS1012's any time soon. Oddly enough though my years working with the field taught me how to work on almost anything else mechanical and mostly electronic. Since I was the one in the family who maintained Dad's cleaning and timing machines. those experiences carried over quite nicely into the worlds of recording and audio as well as others. I look forward to the discussions and maybe still learning a trick or two. Cheers to all and nice to be here.4 points

-

I use on of these Eclipse demagnetisers. https://www.eclipsemagnetics.com/products/workholding-systems/table-top-demagnetiser/ I got fed up with those Mickey Mouse blue things and went industrial You can pick them up on eBay from between £70 to £100. They will demagnetise anything. I mean, anything, from a hairspring to a hammer head. The table is about 5 x 6 inches. You are not going to find anything close to being this good! It will demagnetise the biggest and chunkiest of cases with the movement inside. You'll never wonder again if your demagnetiser did the job.4 points

-

I can remember in the army, doing a tactical night march and the officer leading the march had the bright ide of taping his compass (with tritium tipped hands) to the end of the barrel of his rifle so he could get a better bearing in the dark. We ran around in circles for hours until he realized that the compass was reacting to the steel of the rifle barrel. To say he was unpopular was a bit of an understatement.4 points

-

Do you use them? I have several pairs but never used them for watch repair work. The problem is the spring tension is already too high and may cause a "ping" when you release to grip the object. A conventional tweezer gives better tactile feedback. I use the fine grindstone on my bench grinder, then polish with a nylon fibre wheel to get a satin finish. I grind off about an 1 inch zone to distribute the stress to prevent metal fatigue from the repeated flexing. Take a close look at our College tweezers. Most of them have a thinner section just after the joint to give them flex.4 points

-

For those of you who are looking for a Seitz jewel gauge, I just want to make you aware that there may be a good opportunity right now at Tradera.com (Swedish eBay). The site has significantly fewer visitors than eBay and I have made several fantastic deals there. 1500 SEK corresponds to approx. £110/€128/$137 https://www.tradera.com/item/1922/631487681/seitz-urmakarverktyg-matare Just to make sure, I'm not associated with this listing in any way!4 points

-

I think we all get a lot out of this group, and it has been pivotal in my development by the sharing of knowledge, experience and learning from more seasoned experts such as @JohnR725 and others (you know who you are!) as well as fellow novices. I think that having a backup communication plan in reserve so that if there is a future problem just makes good sense. I don't think anyone is trying to undermine the forum, but if something unthinkable happens, like the Ranfft website for example, then it would be good if those who are willing can still keep in contact. Speaking personally, and I know I risk a charge of heresy, it would be good if Mark could be a little more visible in this forum, and maybe give any insight from time to time on the future/progress of forum and instructional videos etc. even if its just to confirm the status quo. I appreciate he is a busy man with a full time job, but so are most of the rest of us and to post a few lines every now and then shouldn't be too much to ask to reassure the restless villagers. Best outcome for me would be a message saying something along the lines of: "Hi guys, all good, no planned changes... enjoy the forum, will message again next month!" Just my two cents.4 points

-

Knocked out another 404 last night...when you are in the zone! This watch was a non-runner which I picked up as part of a lot of 8 watches, so works out to be $3.12 per watch. Before: And the finished watch, new crown and stem and the crystal was cracked so was replaced. I also replaced the mainspring as the original was the old steel type spiral and very 'set' - all else is original: The Movement was a AS 1686, but in reading around a little the ACCRO watch company were sued for their use of the five point crown on their Jacques Pere range as it resembled Rolex, see below: ACCRO then reverted to just ACCRO on their watches - I have done some sniffing around the internet and haven't seen another example of ACCRO and the crown together on a dial so maybe I have something unusual, or maybe I was looking in the wrong places .4 points

-

4 points

-

According to these guys "Coating watch parts with a thin, even monolayer of epilame provides an effective oleophobic barrier that halts oil spread in its tracks." Which is exactly the same process that causes water beading on a waxed car. An oleophilic treatment would actually cause the oil to spread out to as thin a layer as possible as every oil molecule would try and come into contact with the oleophilic surface. The reason an oleophobic surface prevents spreading is because the oil behaves in such a way as to have as little contact with the treated surface as possible.4 points

-

Picking up this side-tracked post again as I just removed a balance staff of a 1920's Omega (35,5L-T1) I was impressed by the way @Delgetti had his setup when he had to change out a balance-staff (https://www.watchrepairtalk.com/topic/28854-new-balance-staff-not-riveting-to-balance/page/2/#comment-244054 Not only that, but also the idea of removing the seat first before punching the staff out from the seat-side, avoiding the whole discussion of the rivet yes/no enlarging the hole. I didn't have the fancy clamps & tools Delgetti has, so I used my screw-head polishing tool. Initially I used #1500 grit diamond paste on the steel wheel, which kinda worked, but very slow. I changed to #800 grit diamond paste, which worked better, but still slow. Then I glued #240 sanding paper to the steel disk; That worked and the disk was hand-driven. Once close to the balance wheel, I took the sanding paper off and continued with #800 diamond paste. One can only do this when the balance wheel sits true on the staff and has no "wobble". I went on grinding until I saw some diamond paste on the rim of the balance wheel. This was as far as I could grind and it seemed that at that point there wasn't much left of the seat. Carefully, with my staking set, I knocked the staff from the seat-side out. Turns out that the thickness of the seat left, now a small ring, was only 0.1mm. The balance wheel hole is in perfect shape and no damage done to the wheel at all. Of course, if the wheel has a "wobble" or isn't seated true on the balance staff, you can't get as close and there will be more left of the seat. In my case, it worked perfect I'm very happy how this method worked out !4 points

-

4 points

-

4 points