All Activity

- Today

-

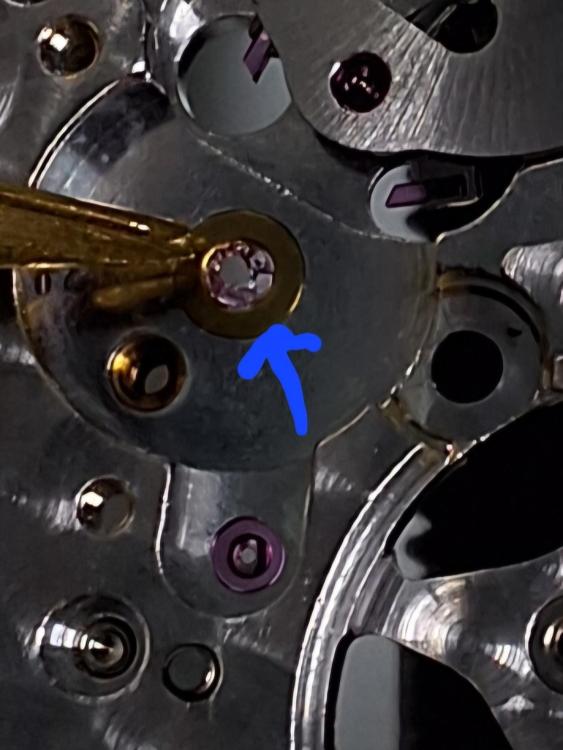

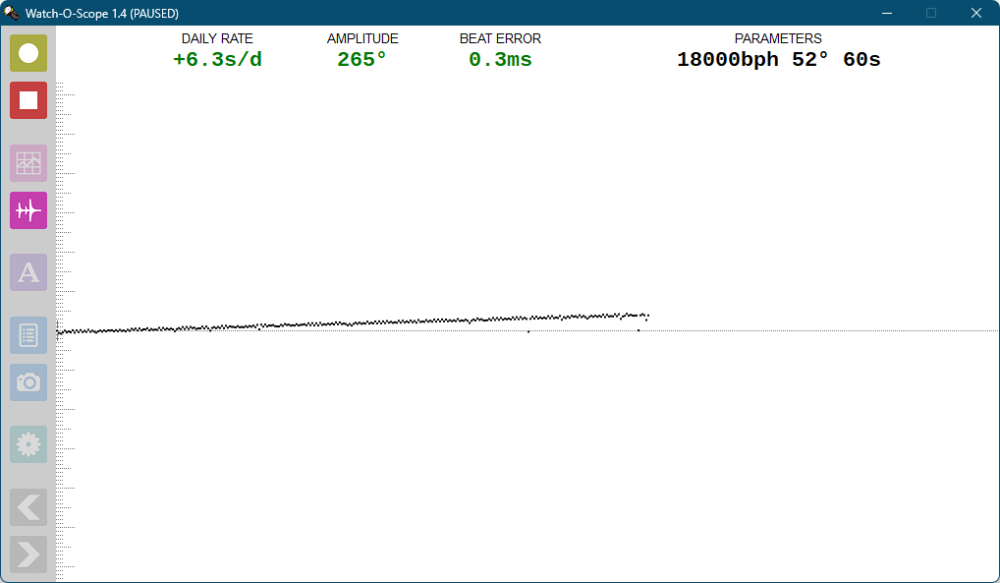

I overhauled a ladies Rolex and noticed erratic performance so I stripped in down again and did fault finding. This is what I saw. I cannot understand how the watch was running erratically in the first place, as the lower jewel (the one in the plate) is cracked and the hole is too big. After stripping it down I did re-clean the main-plate (and parts) by hand with a fine natural fiber brush. I somehow missed the fault the first time and cannot understand how it was still running. Perhaps re-cleaning it dislodged some pieces of the jewel widening the hole? I don't know. Now I need to replace the jewel but don't have a Seitz tool. The Rolex part is 2130-0913 and the top and bottom come complete in brass setting with KIF elastor spring and cap jewel--I have never replaced a jewel. I do have good vintage stacking set. Can I replace using a stacking set? Any suggestions would be greatly appreciated.

-

GuyMontag started following Seiko 6601 Tech Sheet?

-

rehajm changed their profile photo

- Yesterday

-

This happened to me several years ago when I first got my barrel closing tool. In my eagerness to try out my new tool, I closed the cap without the arbor. I don't quite remember how I opened it. I might have used compressed air to pop the cap off. I sometimes use compressed air to open those "sealed" Seiko barrels.

-

MiG29 changed their profile photo

-

MiG29 joined the community

-

LittleWatchShop started following Bulova 11BLC

-

Bulova 11BLC

nevenbekriev replied to Boggie46's topic in Service, Repair & Adjustment Techniques (Not Timing or Regulation)

Put the arbor in the barrel in the correct direction and look at the hook of the arbor. It will show You the direction of the spring. -

I do believe in one of the manuals I saw for the 2892 DD module, you could unscrew it from the 2892, and submerge the whole thing in your cleaning machine as a single unit. I havent tried that yet, but when I was having issues with my Omega 1140, I got lucky and found a brand new one in Poland, and ordered that. So, if someone needs parts from an 1140 Omega/2892, I have the chronograph module in my parts bin, although its disassembled.

-

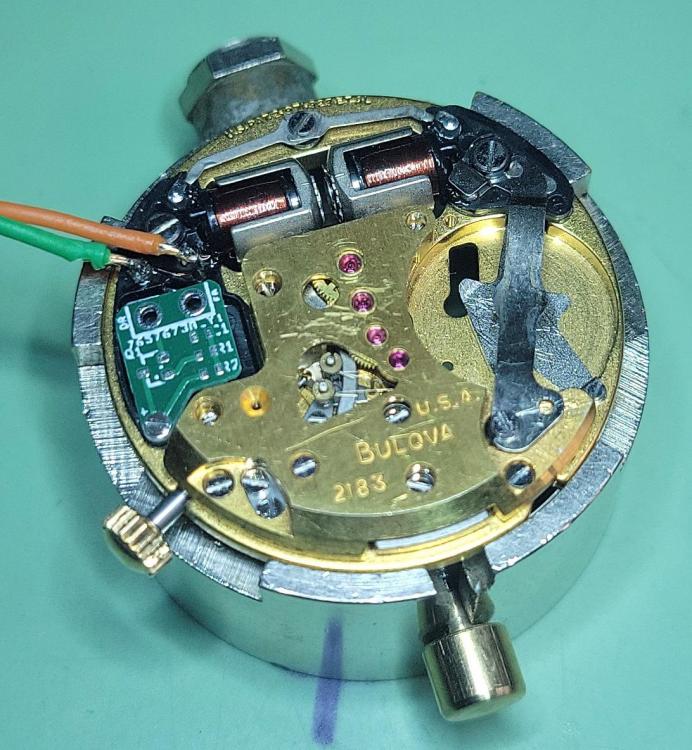

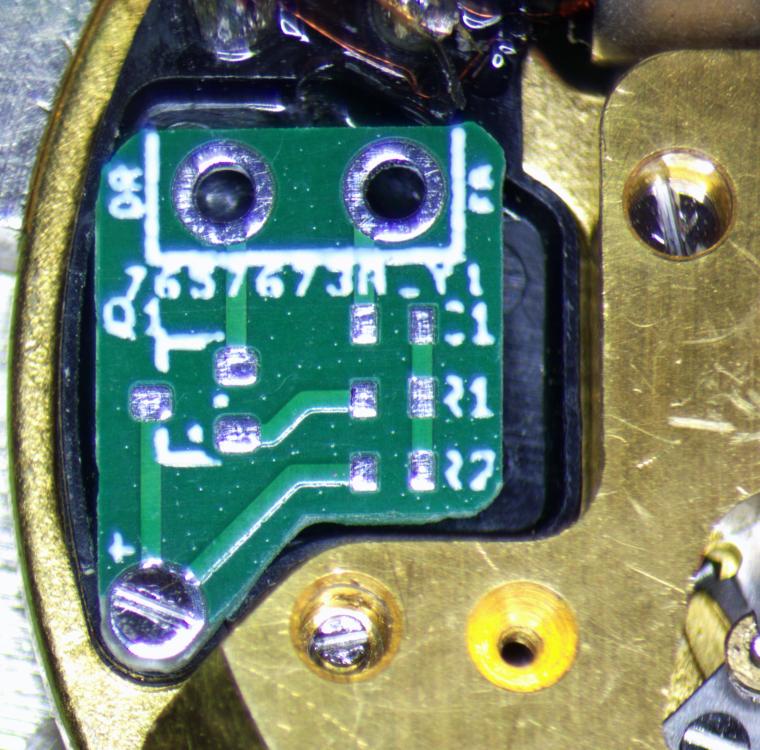

Accutron 218 transistors

ManSkirtBrew replied to ManSkirtBrew's topic in Quartz and Tuning Fork Battery Operated Watches

-

So it runs and keeps good time even with that train wheel. You are lucky I would point out to the owner about the wheel, just in case at some point they take it to a different clock maker.

-

Hi New. More of a get you out of a hole than a bodge. There is no substitute for a new coil.

-

Hello and welcome to the forum. Enjoy

-

watchweasol started following Spinning link screws and Benarus worldiver gmt movement

-

Benarus worldiver gmt movement

watchweasol replied to Blackminou29's topic in Quartz and Tuning Fork Battery Operated Watches

Hi Zannuto.it on the net have one got €16 . 40. From Italy ithink -

Hi and welcome to the forum.. I take it you have held the opposite end tight and the business end is just turning , yes. If so sounds much like stripped threads, the screws might need cutting out and a new bar and screw fitting . But as clockboy said pictures please it makes life just that bit easier.

-

Hello and welcome to the forum. Attached a little reading TZIllustratedGlossary.pdf

-

Benarus worldiver gmt movement

mikepilk replied to Blackminou29's topic in Quartz and Tuning Fork Battery Operated Watches

Cousins don't stock it any more, but this is from their site Then put the size and features in to their search function https://www.cousinsuk.com/category/filter/watch-movement-search-match-by-ligne-size you may be able to find a matching movement -

RichardHarris123 started following L&R Varimatic Needs Adjustment and Intro

-

Hello and welcome from Leeds, England.

-

Blackminou29 changed their profile photo

-

hello everyone, I am a new enthusiast of fine mechanics and I come to your community to learn more. I completed the complete watchrepairchanel course, which I greatly appreciated. I'm starting a small collection of divers, new and old (benarus worldiver, yema superman, seiko skx, hamilton frogman...) and I also bought some old movements and equipment, in order to start operating with an open heart. please excuse my somewhat limited English but I'm French and it's a bit cultural for us... Thank you for your welcome and see you soon

-

Blackminou29 joined the community

-

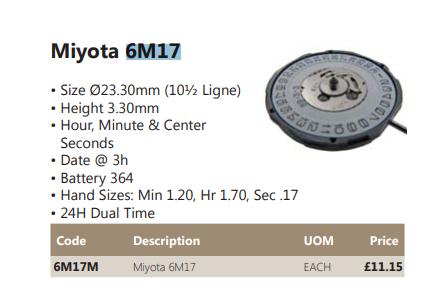

Hello everyone, I have a little problem with my watch which has a Miyota 6m17 gmt movement. I wanted to know, apart from dismantling it and replacing it, if there is a mechanical movement of the same size that would be compatible (same diameter of the movement and hands)? thank you in advance for your help.

-

L&R Varimatic Needs Adjustment

RichardHarris123 replied to storminwestie's topic in Your Current Projects and Achievements

Hello and welcome from Leeds, England. -

Kalanag started following nevenbekriev

-

StephPrime joined the community

-

L&R Varimatic Needs Adjustment

clockboy replied to storminwestie's topic in Your Current Projects and Achievements

Welcome to the forum, enjoy. I have a varimatic that went out of sequence because it’s hydronic oil ran very low. Must admit it’s still in my garage just know time to fix it. Purchased a cheap Indian Junta/ sonic Pearl as a stop gap a few years ago and it still performs perfectly so no incentive to fix the Varimatic. -

The plate is OK, thanks. It seems the answer to my question is that this is a 'hack' & for me another reminder that in general, one won't be the first person to be tinkering with an old timepiece!. As you day, I've been fortunate to have gotten some good advice and, just as important, encouragement. I've been lucky then not to have the balance spring break as a result of my novice 'ministrations' - but I did remember to 'stroke' rather than bend per se. The clock is of sentimental value to the owner so I'm relieved to have now got it running to time with the support & encourage of forum members like yourself.