All Activity

- Past hour

-

BT666 joined the community

-

Watch with a leaky battery won't work

Kalanag replied to CNG's topic in Quartz and Tuning Fork Battery Operated Watches

- Today

-

VanDan joined the community

-

mthomas828 joined the community

-

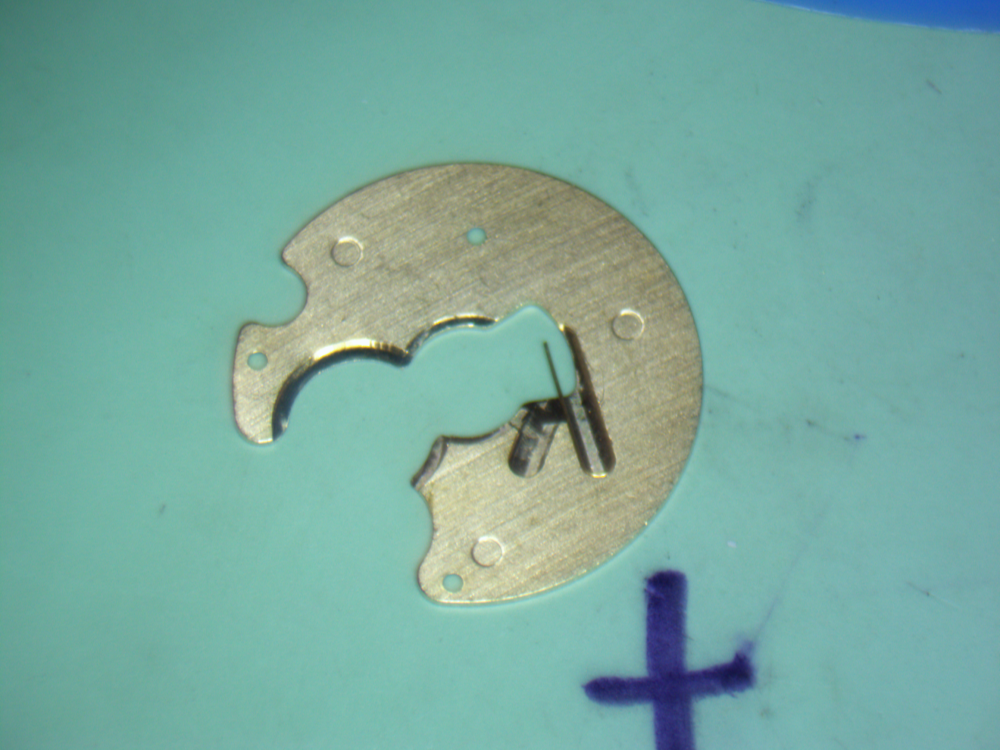

Thanks! I saw it. In fact, it's what reminded me that I had the tool. Mine is more complete and, at his request, I have sent the photo in this post to J. D. Richard. My main question is whether I have the complete tool, or is it missing any parts. My tool is more complete than J. D.s. I talked with my former watch instrutor, who also has one, and he says mine is complete. Still, I'd be interested in a demo of its use.

- Yesterday

-

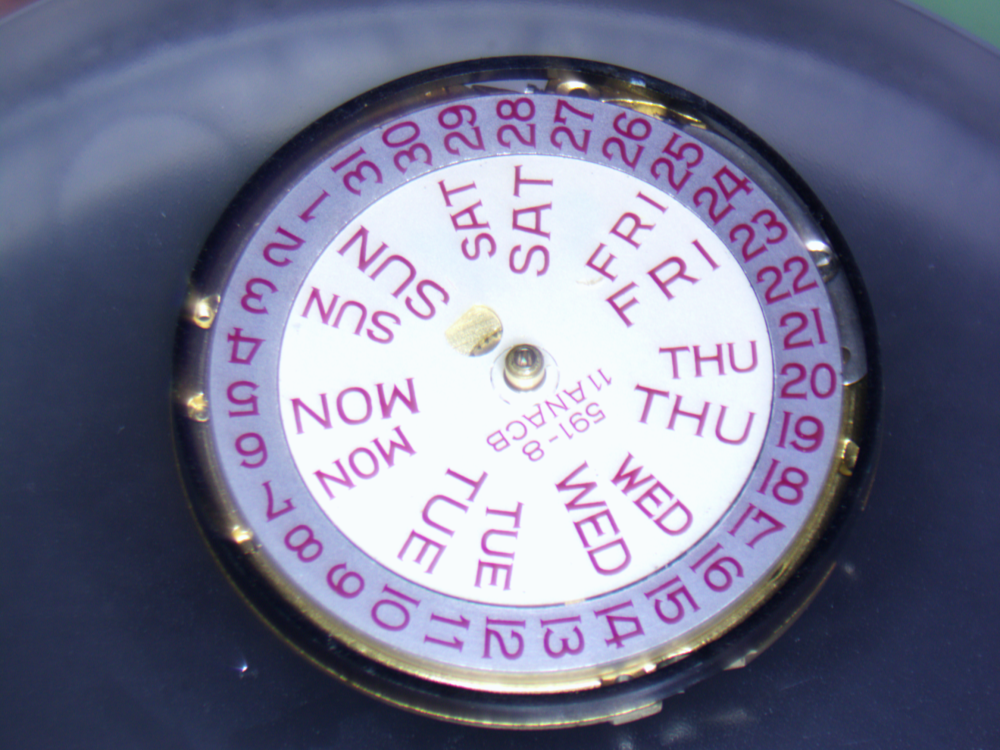

ManSkirtBrew started following 1972 Bulova President "E" Sea King 11ACACB movement

-

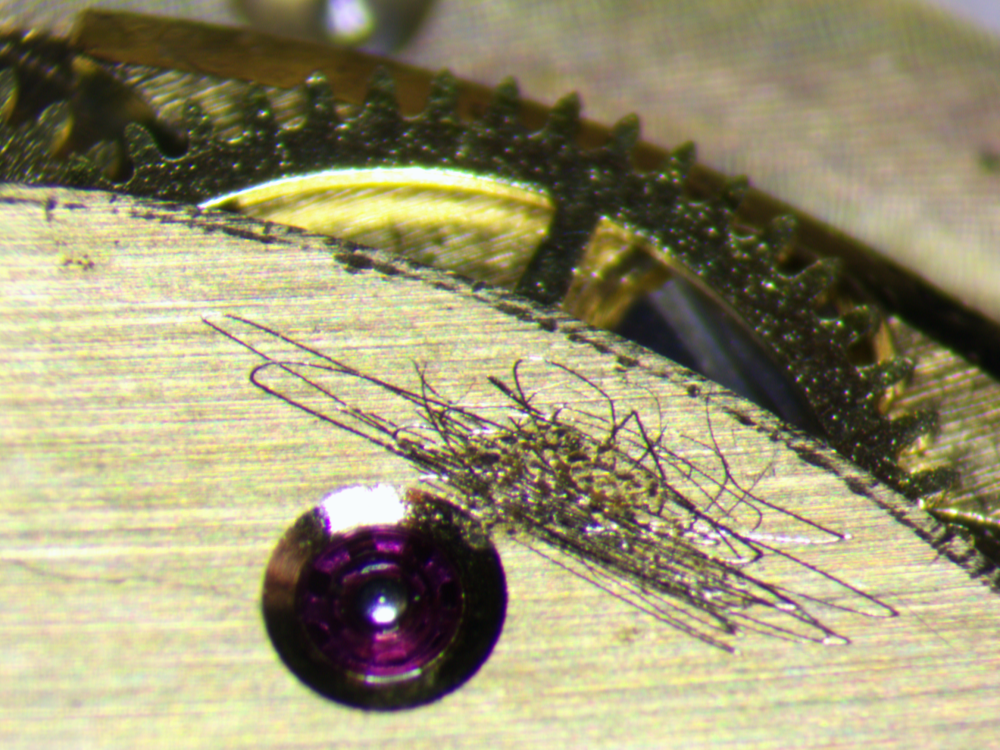

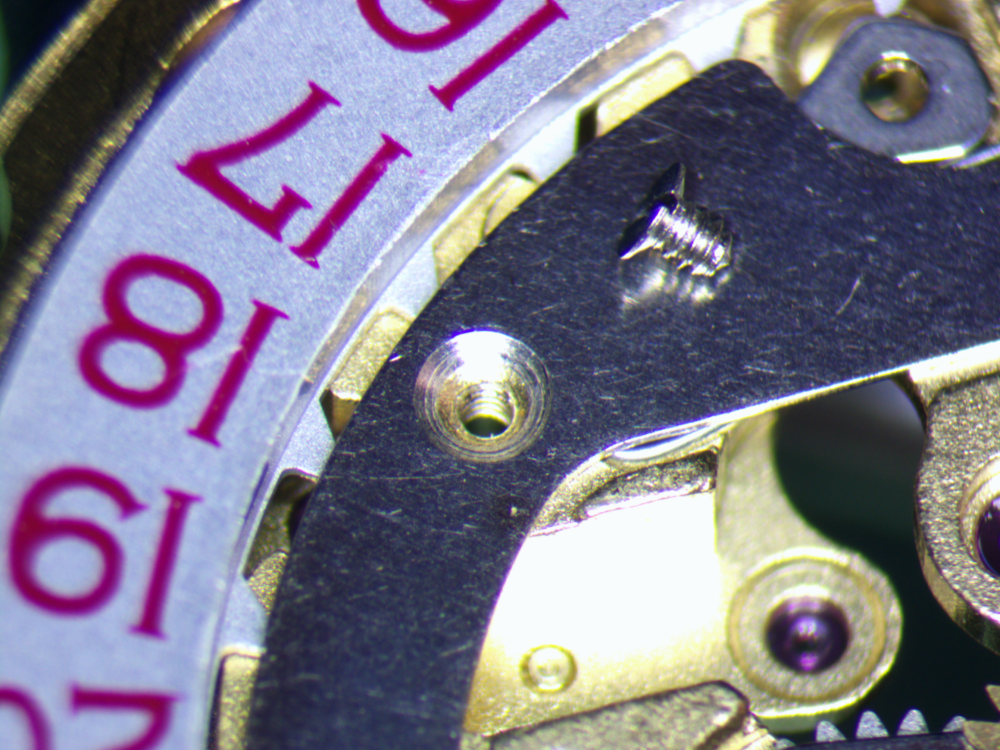

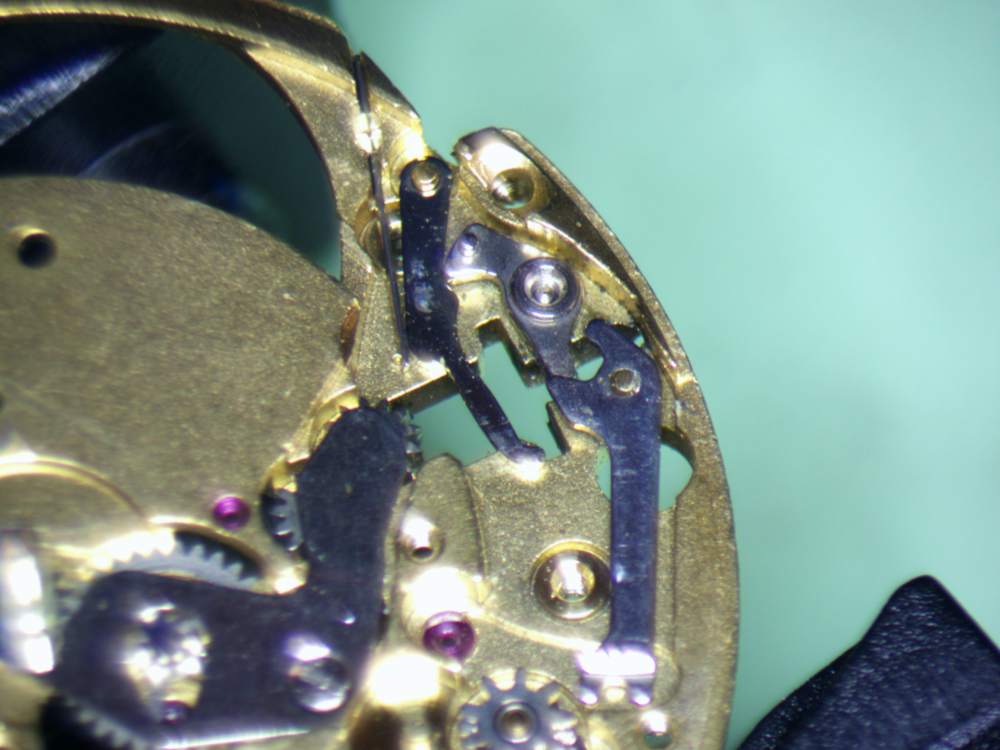

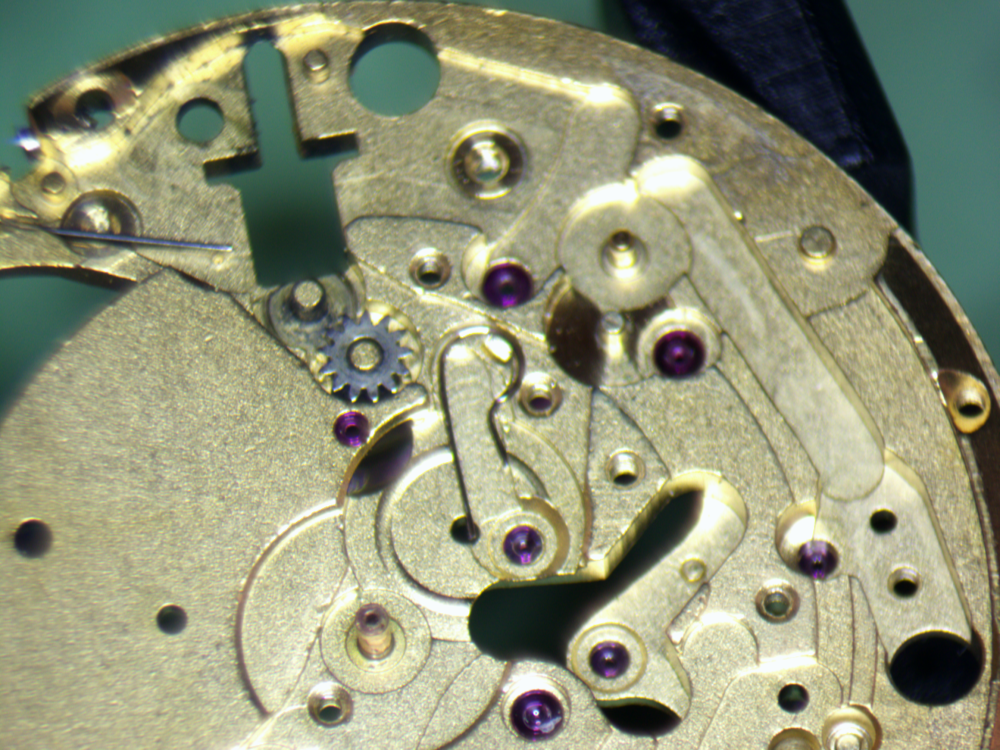

Recently picked this guy up, and took it apart for cleaning tonight. Looks super clean inside as far as wear and tear goes, but there are puddles of oil everywhere! Hopefully a good cleaning will bring the amplitude back up. I did learn that the automatic bridge is spring loaded, which you can see below in the yard sale of wheels and gears all over the place. Sorry in advance for all the pictures and if some aren't in perfect focus. I take a lot of progress pictures through my microscope, and I figure if someone is here looking for help, they might be useful to them. And this is where I stopped, since I got into the wine.

-

1971 Bulova Accutron Spaceview 214

ManSkirtBrew replied to ManSkirtBrew's topic in Your Current Projects and Achievements

I EXTREMELY carefully pressed the seconds hand firmly back on, so fingers crossed. While I had it apart, I took the opportunity to press the Spaceview crystal back in, and I have a vintage Caravelle rally strap on its way to me. I do not get tired of how beautiful this watch is. -

JohnR725 started following Watch with a leaky battery won't work

-

Watch with a leaky battery won't work

JohnR725 replied to CNG's topic in Quartz and Tuning Fork Battery Operated Watches

Quartz watches like mechanical watches need to be serviced from time to time. If they been exposed to foreign substances like leaking batteries getting into their gear train then they definitely have to be serviced. But servicing a cheap quartz watch does not make economical sense it's cheaper just to replace the entire movement. -

watchweasol started following Watch with a leaky battery won't work and SEIKO 8B53-0AF0 how to remove the crown

-

Watch with a leaky battery won't work

watchweasol replied to CNG's topic in Quartz and Tuning Fork Battery Operated Watches

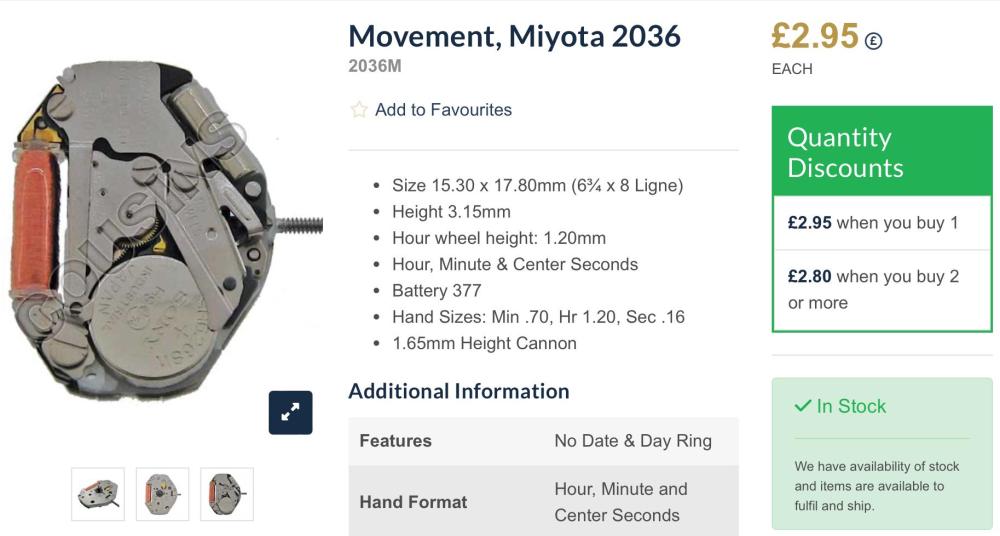

Hi you could clean the contacts with a fibre glass pen brush and try again, or remove the battery and spin it up on a line release too just to free the train and hands then refit the battery with the clean contacts. Or a Richard suggested just change the movement, looks like a miyota 2030 or 2035. Cheap to replace fron cousins or HSWalsh. -

Setting Up A Klik Radio Controlled Watch.

rjenkinsgb replied to Minuteman3's topic in Chat About Watches & The Industry Here

Try pressing all four buttons at the same time - every segment on the screen should show for a second or two, plus it beep. That's a "hard reset" which should get it going, if the battery is making proper contact and there is no fault. I've just tried it with an old Klik of mine, with a new battery. If that works, it may take anything from a few minutes to a few hours to lock on to the time signal and set itself. Keep it away from computers & wifi devices etc. to minimise interference until it sets. Edit - mine set itself while I was typing that! Not bad seeing it's not been used for years. -

RichardHarris123 started following SEIKO 8B53-0AF0 how to remove the crown and Watch with a leaky battery won't work

-

To be honest I had not read the fine print. But I went back and read the fine print and let me snipped out an image. So it appears to be I should have read the fine print. But there's also my confusing email I sent the image of the watch the somebody who I figured would know any did. So this is the answer I got back Now we have a problem or I have a problem of not paying attention to users names in the discussion group. You'll notice in my quoted email to persons name is Jeff who happens to be the exact same Jeff in the discussion. So it's not my fault if the exact same Jeff gives us two separate answers for the exact same watch. So apparently one of the Pierce chronographs has rubber and the other one does not.

-

Nothing is lost at this stage. But You first have to take out the clutch part from the pinion. Then next is to fix the wheel table to the pinion. If it can not be riveted, then must be soldered. Then trueing, and clutch part reattaching. It is possible to make a bush that will stay press fitted between the table and the clutch and will hold tight the table in place instead soldering.

-

watchweasol started following Casio AQ-321G Battery

-

Casio AQ-321G Battery

watchweasol replied to Waggy's topic in Quartz and Tuning Fork Battery Operated Watches

Hi. Thing to do is measure the battery space. Diameter. X depth .. I have seen it listed as sr626sw. 377 measure to check then check the dimensions of the 377. -

pii joined the community

-

@JohnR725 that's very helpful. I appreciate the time you took to give those instructions and post the pictures. below is a picture of my staff, which looks identical to the ones you posted. The approx measurements I got are: .772 on the left part of the staff; .715 on the right side of the hub; the hub is 1.107; and the overall length (minus the broken pivot) is 5.248; which seem to line up with the measurements you posted. I didn't think to measure the pivot, which I'll do if there's enough of one left on the staff. Thanks again.

-

DDean changed their profile photo

-

Thank you to both of you! I've been somewhat derailed by this quandary for a couple of days now. I am guessing that the point of the wider tweezers is to support the whole spring at the same time in an effort to prevent it going under tension... I have already discovered the Zen of a clutter free space, and trying to keep my work well away from the edge, however the most terrifying of the flights wasn't so short, I had my work in the middle of the table and nothing else around. That particular launch was towards me. I distinctly recall feeling the spring hit my left hand as it escaped. I only found it by dumb luck, on the floor, between the legs of my chair. I need to order a pack of replacements just in case. I think I recall a thread discussing where to find them, and the differences between the clones and the authentic ETA ones, pointing out that they're not interchangeable (the clones being longer IIRC). Now I just have to find that thread again. What I haven't mastered is the zen of the search function here. I'm sure I"ll get that down eventually. So this is similar to, but different from one of the posts I had found in my original searches (or maybe I'm just hallucinating, I can't find the post I thought I remember). The bits about the corner filled in a gap in what I'd read before. At least I have a more clear picture in my head about what needs to happen now. Yes, I've learned about how touchy these springs are. What I'm not sure I have a good grasp on is the understanding of what causes the spring to flex, other than to say "the slightest little touch" I think I'm going to try a small bit of Rodico to position the spring next time.

-

DDean started following re-seating an incabloc spring

-

Casio AQ-321G Battery

HectorLooi replied to Waggy's topic in Quartz and Tuning Fork Battery Operated Watches

I think it's stamped on the inside cover. 309 I think. -

One of my customers have given me a watch from his father's collection to fix up, first it looked like a easy repair. I just had to fix the bracelet.and then Change the battery but the battery had been their for too long and the watch want work.the movement is miyota a movement and there are frosted stains on it I changed battery but to no avail do you guys have any ideas?

-

CNG joined the community

-

Hi all, needing a little help. I have an old Casio AQ-321G, but have no idea what battery it takes. I've looked around online, but cannot see anything... I see a 309 stamped on the case back, could this be it....? Can you please help, below are some pictures:

-

The radial teeth are for hte seconds register, and the other (which is simple and doesn' take away significant torque from the train) for the minutes register.

-

The original 6139A manual is very clear in how to disassemble and how to assemble ...... step-by-step. However I haven't seen the 3169B manual, even in the Japanese version around, which clearly highlights the difference in center-wheel. 6139A Seiko Technical Guide.pdf 6139_A.pdf 6139A.pdf 6139b.pdf 6139B repair guide jp.pdf