Search the Community

Showing results for 'lighter fluid' in topics.

-

I read couple of threads about cleaning in water+degreser, IPA, gasoline (lighter fluid I believe) and people used to say that lighter fluid is highly contaminated by many things as its main focus is to evaporate and burn, not clean things, hence I decided to stick with water and degreser? I don't know, I guess time will tell.

-

Changes on timegrapher...

kd8tzc replied to kd8tzc's topic in New to watch repair ** Safe Zone For Learner Watch Repairers **

Well let me ask this... maybe I am testing this wrong. If I heat it and melt it to something metal (say just the pallet warmer), and then let it cool completely. If I take something like my tweezers, should the shellac crack and flake apart when I poke it with the tweezers? I just tested that just on the pallet warmer without anything else. I made sure the pallet warmer was clean, and I heated it up a bit first to allow anything that might be on it after being in lighter fluid and then IPA for a bit (it was dry of both chemicals). When I melted two small pieces of shellac on the warmer, allowed them to cool for a good 15 minutes, then poked them, the shellac broke apart and flaked. See the attached image. The two arrows on the left show the one blob of shellac that I melted and the piece that flaked off. The arrow on the right shows another that flaked, but it doesn't show the piece that broke off (just the small crater). Maybe what I am seeing is normal... I know shellac can crackle depending on the kind, so maybe I just have the wrong type. It is blonde (dewaxed supposedly). I'm not 100% certain on the dewaxed part or if this is what would happen with wax in it. I do have more shellac coming (two different kinds... one is flakes... garnet this time, and another is the rectangular stick). -

Cleaning Fluids

Nucejoe replied to djmcd's topic in Watch Cleaning Machines / Ultrasonic Cleaners / Case Refinishing

Are lighter fuel and lighter fluid the same? Avgas( aviation gas )and lighter fluid in ultrasonic leaves pallets shellacless in matter of seconds, which goes to show both fluids at least soften shellac. that I have tried and know as a fact. Some say naphta is lighter fluid. Regs -

Replacing a broken glass crystal

LittleWatchShop replied to Walt's topic in Watch Glasses/Crystals and Glass Gaskets

Lighter fluid will not work -

Replacing a broken glass crystal

Walt replied to Walt's topic in Watch Glasses/Crystals and Glass Gaskets

Thanks, I'll try acetone; I used lighter fluid but that didn't work. I don't know if you can make out the glass fragments it the upper right of the photo. -

BBQ lighter fuel is basically de-odorised kerosine (paraffin). It is less volatile than lighter fuel, but 'oilier', and will have far more impurities which can lead to more unwanted deposits. No doubt it could be used as a cleaner but not recommended for watches! White spirit is a different animal again! If not the bulk purer petroleum ether, then a good brand lighter fuel (not the cheap ones as they can leave deposits due to low quality). The old mirror test is best for assessment. Plus good ventilation is needed for extended use. For interest for my hobbyist cleaning process, I use premium brand lighter fuel in two small containers, 1st and 2nd clean. The 2nd clean I use filter paper and re-use as the 1st clean. The 1st clean I again use filter paper to recycle for more 1st cleaning. I discard after each watch. 2nd clean is always fresh fluid. I use a soft craft paint brush (1 for each pot) for most parts and run the parts in the pot through US cleaner. The parts then air-dry on an absorbent non- fibrous base mat.

-

Way back in 2018, I picked up the Newmark shown in the post above. I've been keeping an eye out for a suitable "404 club" style donor with a balance for it. One recently showed up on ebay, so persistence paid off, eventually. That of course is where the problems started. The donor arrived and I harvested the balance, and it sort of ran, slightly. So I stripped down the donor, cleaned it all and fitted the balance. It ran a little better, but the donor had no sub-seconds wheel, so I then stripped down the original movement and cleaned it too. It still didn't run well. The issue was traced to a loose shaft on the balance fork, so the balance fork was also harvested from the donor. It ran a lot better, but the hairspring was now causing problems, as it was sticky. I eventually resorted to degreasing it with acetone, as my usual trick of dipping these crude balances in lighter fluid didn't work. Now it runs pretty well, if somewhat fast, so I'm going to leave it going to see if it makes it through the next 24hrs without any issues. If so, I'll regulate it and see if I can correct the beat error at the same time without wrecking the hairspring. I'm also tempted to swap in the plate from the other movement as rather oddly it has something resembling Geneva stripes on it, Croydon stripes perhaps. I'm now a bit of an expert on these somewhat agricultural movements. I can't say I'm impressed with the build quality, but they are quite easy to strip down and re-assemble. The balance is a little bit finicky to fit, and the hairspring is somewhat delicate. The least little disturbance tends to pull it out of alignment. A new crystal was fitted, and a new navy blue Nato band is on its way for it, and then it can finally join the 404 club after an almost five year wait.

-

I think thats the problem with napha, depending where its processed we dont know exactly what we are getting. Its composition isn’t consistent enough from plant to plant to be a reliable enough cleaner. Lighter fluid was my cleaner when i started, it was ok but quickly discovered its drawbacks, too much variation from brand to brand and it does contain extra ingredients besides naptha. I still occasionally drop back to using it experimentally, the mirror test is a good indication of residual leftovers. Try IPA that can leave a white outer ring after evaporation. The mirror needs to spotlessly clean before testing. Actually Mike, I'm wondering if any oil based cleaner such as naptha is going to cause problems. Oil can be a bugger to shift in any situation. You know when you've cleaned paintbrushes with white spirit how much fairy you then need to remove that and how greasy your hands are. I'm thinking not to introduce any oil composition into cleaning and stick with alcohol. That oil residue is going to spread from rinse to rinse adding to what is already coming off the old oil lubrication of the parts.

-

You are replying ok Tadas. This looks ok as far as lighter fluid goes if your translation is correct. Distillates petroleum, so naptha. Light and low boiling point will mean a light naptha this would evaporate more quickly than a heavy naptha which is an advantage from a parts drying aspect. If using in jars in an ultrasonic just ba aware of the low boiling and flash point, so do not use a heater if it has one. Ultra sonics can heat up without a heater so also keep an eye on the temperature of the water in the tank. Yes ipa can dissolve shellac also any other jewel adhesive will. So if you are going to rinse after the lighter fluid clean, do so quickly with the balance assembly and pallet fork and dry them quickly on watchpaper and with a puffer. I would advise doing them separately in a shallow jar so you can get them in rinsed and out and dried quickly and efficiently then there is less risk to the shellac. If the amount of shellac adhesive used is small and less aged then obviously the risk is higher The other watchparts will be ok in the ipa for any reasonable length of time.

-

Hello @dadistic, Well that sucks. I doubt highly that I can send you what I'm getting over here considering the restrictions on mailing flammable substances. Maybe what we can do is hit on a common testing protocol to see if the two different formulations perform the same way and give the desired results? I promise it won't cost too much or take too long, and might be useful for people around the world wondering if their lighter fluid is leaving any unwanted residue on their beloved micro-machine parts. Here's what I plan to use for my experiment: 1 x Bell or Flying Saucer-shaped Cover 3 x 40x25 glass containers (with lid) 5 x Watch Paper 1 x RONSONOL Lighter Fluid (133ml) 1 x Mobile Phone w/ Magnifier & Microscope Plus application (FREE version) 3 x Sheet of White Paper 1 x Time Measurement Device 1 x Light Source (2nd mobile phone) with White Screen application (FREE) Here's my experimental protocol: A) Clean 3 x 40x25 glass containers with water B) Wipe 3 x 40x25 glass containers dry with watch paper C) Drip enough RONSONOL into bottom of 3 containers to cover 33% to 50% of the bottom surface D) Cover 3 containers with cover, leaving the apparatus in a sufficiently ventilated area flammable liquids management! E) Wait long enough for the RONSONOL to fully evaporate (12 hours? 24 hours?) F) Stack 3 x Sheets of White Paper to provide sufficient contrast (assumption is residue is not white) G) Place 3 x containers on White Paper Stack H) Take photographs at 100% using Magnifier & Microscope I) Take photographs at 200% using Magnifier & Microscope J) Take photographs at 400% using Magnifier & Microscope K) Using 2nd mobile phone, launch White Screen application L) Place 3 x containers on Mobile Screen M) Take photographs at 100% using Magnifier & Microscope N) Take photographs at 200% using Magnifier & Microscope O) Take photographs at 400% using Magnifier & Microscope P) Clean apparatus and put all materials away Q) Circulate results indicating feedstock RONSONOL size, labeling and ingredients along with photographic results What say you? If you are missing any of the equipment listed I'd be happy to send it to you. (I am assuming you have access to 2 x mobile phones and a time measurement device.) g. -----

-

What's the best way to repin the hairspring on a Timex?

Ashket replied to Ashket's topic in Watch Repairs Help & Advice

Hey JerseyMo what fluid would you recommend using, I have to admit to using ronsonol lighter fluid, then two rinses in 99% isopropyl alcohol as I understand there isn't any shellac in the movements. What should I change the lighter fluid to? -

This maybe a dumb question but what is lighter fluid . Is it like Zippo fluid you use for a gasburner . I have seen it lots of times here an in other forums in english .

-

That is want I wanted to see. That is the original platform. Poor time keeping will be down to a dirty hairspring or as I said before it could be magnetized. Clean the hairspring in Ronsonol lighter fluid and dry it with your bench blower. Make sure the tools you are using are not magnetized, now use tweezers or an oilier gently push the coils so they touch one another and see if they stick if they do then the hairspring is magnetized and you will need to demagnetize it. I would also put the pallets and escape wheel through. I would also clean all the platform and you will need a Pocket watch oil for the platform.

-

@Zero You're right, of course. MY APOLOGIES to @12052 for hijacking their thread. I got too excited about my own interests. Sorry. Back to the subject at hand: In one of the books I am reading (de Carle) mention is made of the convenience of immersing entire movements in ultrasonic cleaning machines in order to evaluate them in situ post-cleaning. What is not mentioned in that passage is the nature of the cleaning fluid in the ultrasonic cleaner. The other day while visiting one of the several "Watch Streets" in Hong Kong - a place called Ap Liu Gai - I saw a streetside Watchmaker apply RONSONOL directly to a Seiko movement that was still in its case and then shake it to see if he could get some action out of it. I am pretty sure that's NOT the way to go - but that's what he did. I saw it. Obviously, I am not advocating such an action on your part, because I do not know what the consequences might be for you - but I did see it happen, so it is clearly one of your options if you know what you are doing. The question, as with most things, seems to be more like when you can safely do this rather than if you can safely do this. In its current formulation, ZIPPO and RONSONOL (Liquid Lghter fluid) are composed of 70% white/clear petroleum distillates and 30% naphtha. That's what the Material Data Sheet (MDS) says. Both components are highly volatile petrochemicals that, if they can reach them physically, will certainly "dissolve" whatever oil-based contaminants that might be gumming things up. But be careful - they will also perform a dissolving action on any other other oil-based "things" in the movement, which may include things you didn't want dissolved. To answer your question directly, it depends. If the movement is sufficiently disassembled (i.e. the dial has been removed) and the movement has no sensitive parts and the movement has ample replacement parts if you end up dissolving something important and, and, and.... This is why best practice with all machines is pretty much the same: Disassemble, segregate parts by cleaning modality, clean parts using the modality that is appropriate to their nature and usage context, reassemble, lubricate, test. That's the protocol that I am striving towards with the micro-machines we call clocks, pocket watches and wrist watches. So the question then transforms from when and if to should. I don't think, normally, you should soak an entire movement in lighter fluid. I think you should take them apart "properly", clean them "properly", assemble them "properly" and lubricate them "properly" as they were designed to be engaged with by the people who developed them. Watch movements are not designed to be engaged with in any other way, and this truth is deeply embedded in the social pattern we recognize as Watchmaking and its attendant practices. Hope that helps.... g. ---- Disclosure: My own experience with Watchmaking so far, this thread and other comments I have come into contact with on this Forum have motivated me to start writing a paper entitled "How (and Why) We Clean Things" that I will be circulating to potential publishers for peer review later on this year. I am encouraged to produce written work as a Tutor and Lecturer at PolyU, so I seek out puzzling and paradoxical things in everyday life and write about them. The work is still very much under development, but when I am finished I will (naturally) make it available to this group once it has finished peer review, probably some time next year. Academic publishing wheels turn very, very slowly.

-

Yes a better cleaning procedure I think is in order. Did you know you can actually order or at least it's listed Amazon will let you buy cleaning fluids from them with free shipping. As of you don't want to do business with the material houses in this country you can buy it from there. Then yes I know a gallon will last you well almost forever the cleaning fluid will probably go bad before you use it all up at least that's what happened to my first gallon. But the rinse will last basically forever. Then they actually do make as someone else pointed out above special cleaner for hairsprings. It's a horrible smelling substance but it does seem do a really nice job of removing sticky things from watch parts. So I use it for spot cleaning stuff and the hairspring then for detecting magnetic fields you can use the compass method but I'm not a big fan. Then there have been apps for your phone don't actually know how well they work they will pick up magnetic fields I just haven't tried them yet with the watch. Then the current recommendations from the Swiss can be found at the image below. Basically the recommending a tool it would detect if the watch has been magnetized and only then is it demagnetized and that I guess it verifies that it actually successfully did the job. But my real guess is that you have something sticky on the hairspring and lighter fluid really isn't's a good cleaning product for watches despite the fact that everyone on this group thinks it S getting something more appropriate would be better.

-

Are you rinsing it after cleaning in lighter fluid? If not there may be residue. Try rinsing with 99% Isopropyl alcohol, and dry it with gentle heat, with the parts in a basket you can use a hairdryer. A puffer works, too, if you have one. Fluid can get trapped between the coils and take forever to evaporate, but I'm not seeing that in your picture.

-

The Harris MK1 clock mainspring winder is underway, photos to follow. So far £0 but I may have to go mad and spend £20 to finish it. Hehe. What's the best way of cleaning the bottom/ dial side plate? Terminology? I usually use lighter fluid followed by IPA, it would cost a fortune, could I use petrol, followed by IPA?

-

Adding another oil into servicing.

JohnR725 replied to Neverenoughwatches's topic in Lubrication Tools and Products

If you think this is confusing what about this lubrication at the link below Let me highlight the important things from the link below. It comes in a larger bottle such much cheaper than the normal oil we use. The viscosity is 110 is makes it more fluid than 9010. So this is a extremely light oil but look at its description it's good for "Synthetic oil especially developed for alarm clocks & pendulum clocks. Can also be used for watch escapements" So apparently oil Lighter than 9010 is ideal for clocks or watch escapement's? Then while you're there you can get the spec sheet.So the definition of synthetic is neat's foot oil which is not synthetic that I'm aware of. I believe that would be an organic components. Then the rest of it is paraffin oil which I suppose could be synthetic. I'm also attaching the lubrication chart test specifications.. Specifications and you'll notice all the lubricants are superthin and the chart really doesn't make a lot of sense at all. Which is the typical problem with descriptions of horological lubrication's of basically descriptions in the technical specs suck. Normally were stuck with the viscosity but even here the viscosities are way too light and yet the light oils can be used for clocks so viscosity apparently flies out the window for making decisions. On the other hand the oil below is a lot cheaper. So it isn't entirely sympathetic like it says on the website. https://www.cousinsuk.com/product/novostar-type-r Oh and then 9021 of my watchmaking friends said 9020 was obsolete. Because of you look at a lot of modern tech sheets it's no longer shown as a lubricant. It's basically 9010 and HP oils. Oh and there was something bothering me about 9024? Notice at the link below if you go to the top of the page it's in the category of lubrication for Synthetic Oils for Polymers? Then those pesky words again because look at the description that cousins hasWhere the oil is good for high temperatures we don't really care about that.But it's back to the reference of is used for plastics? So it looks nice on the spec sheet where it doesn't really bring up the plastics aspect. Okay I got oh improve my reading skills if you go to the PDF for 9024 and read the wonderful words it says at the end of the paragraph is says for plastics. But the technical features in addition to the word plastics they do have the word metal. https://www.cousinsuk.com/product/moebius-9024-syntaviscolube?code=O1073 So if you want to go insane read all the technical descriptions on the cousins website of everything related the horological oil and see if you can figure out what would be a suitable one to use for anything? Oh maybe a book would be helpful? Yes it's a little out of date synthetics didn't exist but still it's of interest. https://archive.org/details/frictionlubricat00lewi -

Which Watch Have You Got Coming In The Mail ? Show Us !!!

AndyHull replied to SCOTTY's topic in Your Watch Collection

The 99p Kienzle lives. Here it is next to my Citizen Quartz mechanical alarm from around 1989. When it arrived, it had an ominous stink of WD40 when I opened the packaging, so a bath in lighter fluid was needed to clean all the gunk out of it. Once stripped, cleaned and lubricated, it run nicely. Sadly the same cannot be said for a second slightly older one I picked up recently. Someone has completely mangled both the palette fork and the hairspring in that one. Oh well, you don't win them all. I may try to "unfankle" the fork and hairspring on the other one, but I think they may a lost cause. -

I don't have a cleaning machine so I clean all the parts by hand with the use of little brushes. It is a very tedious job but I currently don't have any other solution. First I clean all the parts with lighter fluid, and after that, I rinse everything with rubbing alcohol (except the pallet fork and balance wheel). It is the old way of cleaning watch parts and I have had excellent results.

-

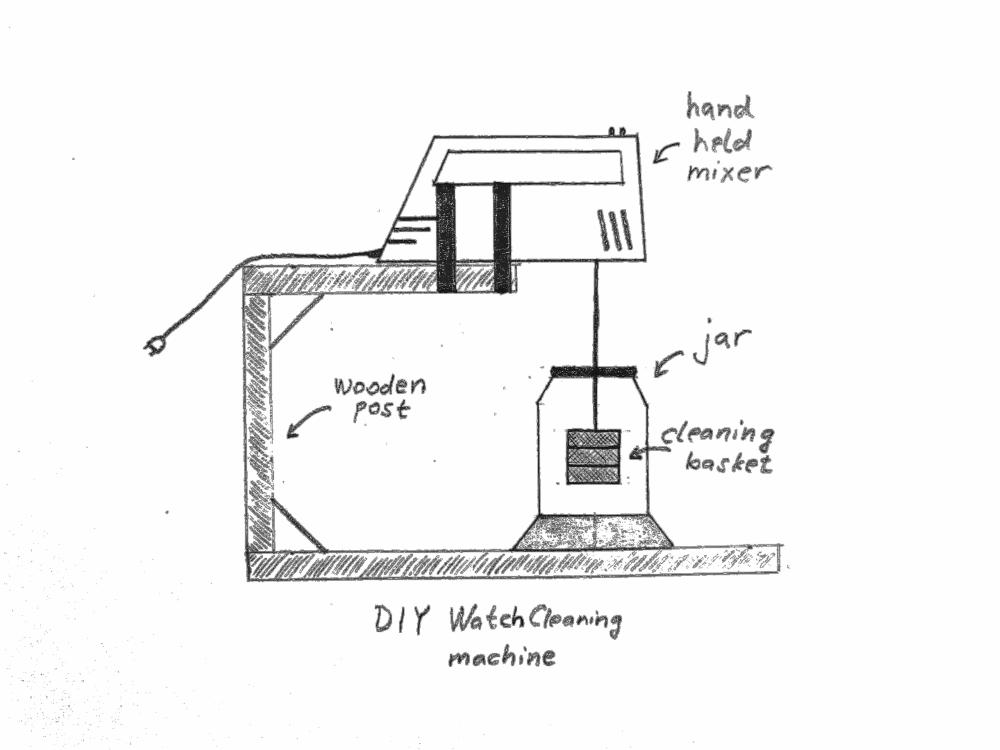

Wow, your 3D-printed watch cleaning machine looks great. Used cleaning machines are impossible to find where I live, and new ones from Elma cost more than I make in a year. That puts hobbyists like me at a real disadvantage, so I have to clean everything with little brushes and lighter fluid I will also try to make my own cleaning machine in the near future. I have no technical knowledge nor a 3D printer so I will have to improvise. Lo and behold my preliminary plan for a DIY watch cleaning machine P.S. It was not drawn by a kid

-

OIl and OIlers should be here today or tomorrow. I did use a little lighter fluid around the movement, but that didn't seem to help. A few days ago, it was running, and then just stopped. I might just do a full clean on the watch and then re-oil once all that gets here. The one thing I am trying to figure out is how to oil the balance wheel. I think I found a video that may help here though. The thing doesn't run now, so it really can't get any worse (well it can, but ...)

-

Depends on what is the cause of the dirt. Generally if it is just from years of grubby fingerprints, I would start with some light solvent, like lighter fluid or perhaps hand sanitizer. Test the surface first to ensure you are not about to lift the lacquer and the lettering, or destroy the surface of for example acrylic panels. Try to avoid anything abrasive, unless absolutely necessary. The clear plastic panels on that cassette deck, and the metalwork on the lid got a good polishing with T-Cut, which is of course mildly abrasive. It works on watch crystals, and it worked fine on the acrylic panels and the paint work. For black plastic, and black metallic cases you could also try some of the car dashboard products, but be careful as they often contain some kind of blackening agent, which may not be what you want on the front panel of an amp. Looking at pictures on line of your amp, the front panel looks like black painted or anodised, brushed aluminium, maybe start with kitchen cleaning wipes, and if necessary some lighter fluid. Clean in good light, and wear rubber gloves so you don't have to remove all of your fingerprints at the end of the process. Switch off and unplug obviously before you start.