Search the Community

Showing results for 'accutron' in topics.

-

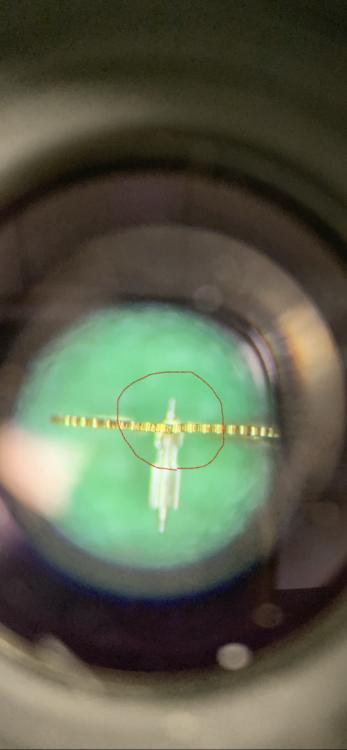

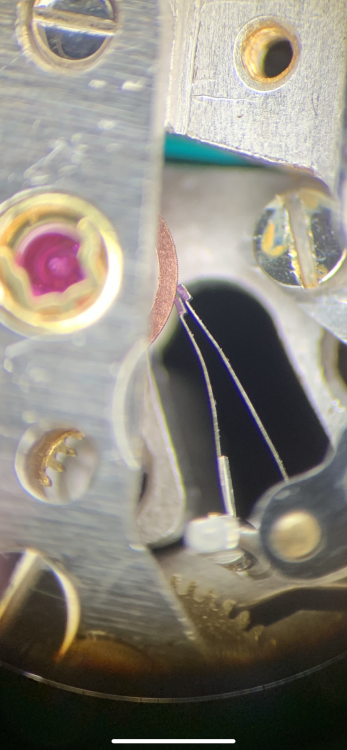

Hello everyone, I hope this finds you all well! So a friend of mine picked up a non running Accutron 214 and asked me to have a look at it for him. I’ve worked on a few in the past but this one is giving me some trouble. The watch hums nicely but when I look at the indexing mechanisms something seems a little off. I’ve been going through Henry Frystak’s tutorials about indexing and also have compared it to some of my personal Accutrons and something doesn’t look right. The jewels are extremely close to each other compared to watches I have and videos I’ve watched. Also, the springs, if possible seem long? In Frystak’s videos he mentions that both springs should have a slight bend in them when not in contact with the index wheel, but be flat when in contact with it. If these springs would be flat they would be really high on the wheel. From what you see in the picture, is this something that can still be adjusted or is something else going on here? Any and all help would be greatly appreciated!

-

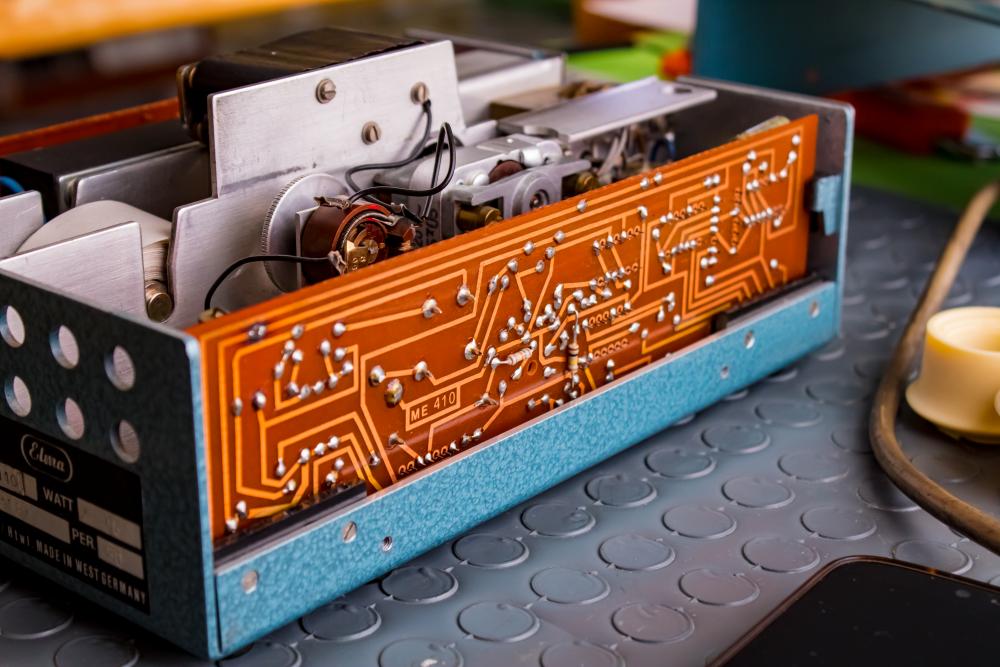

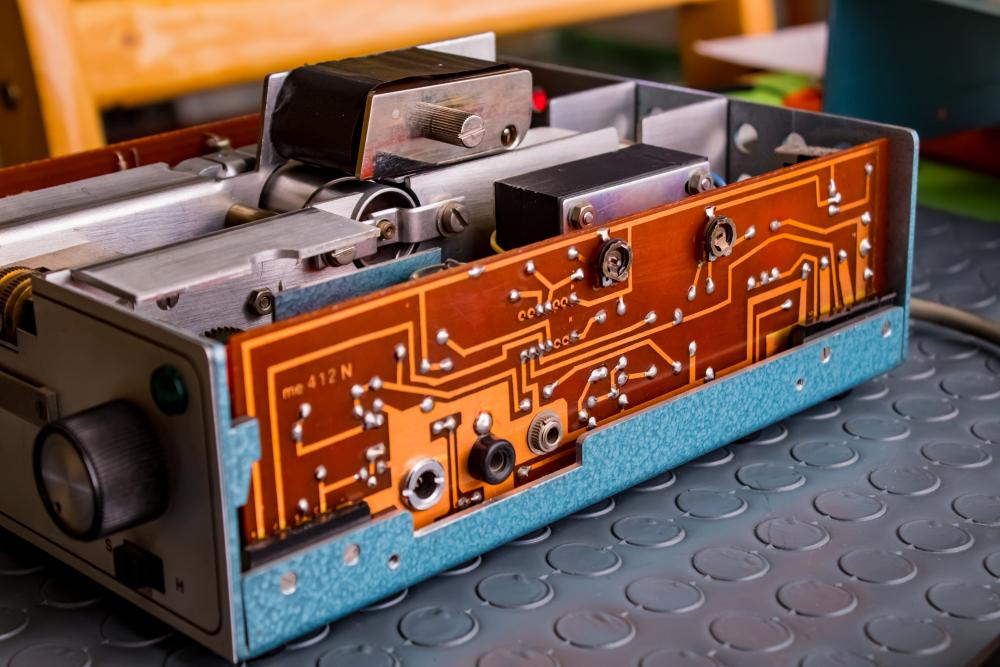

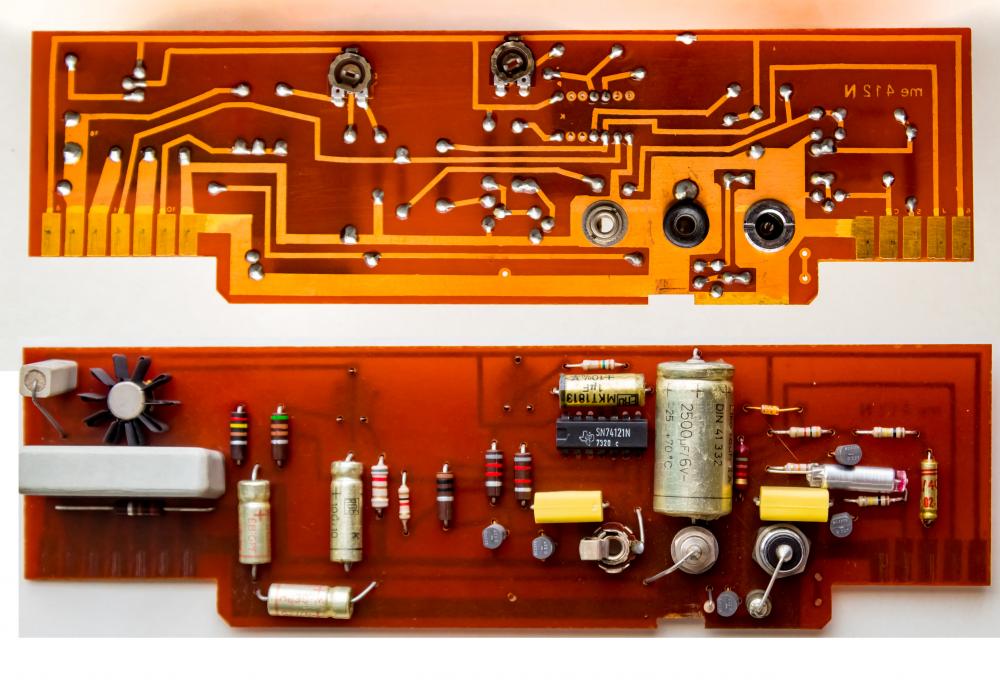

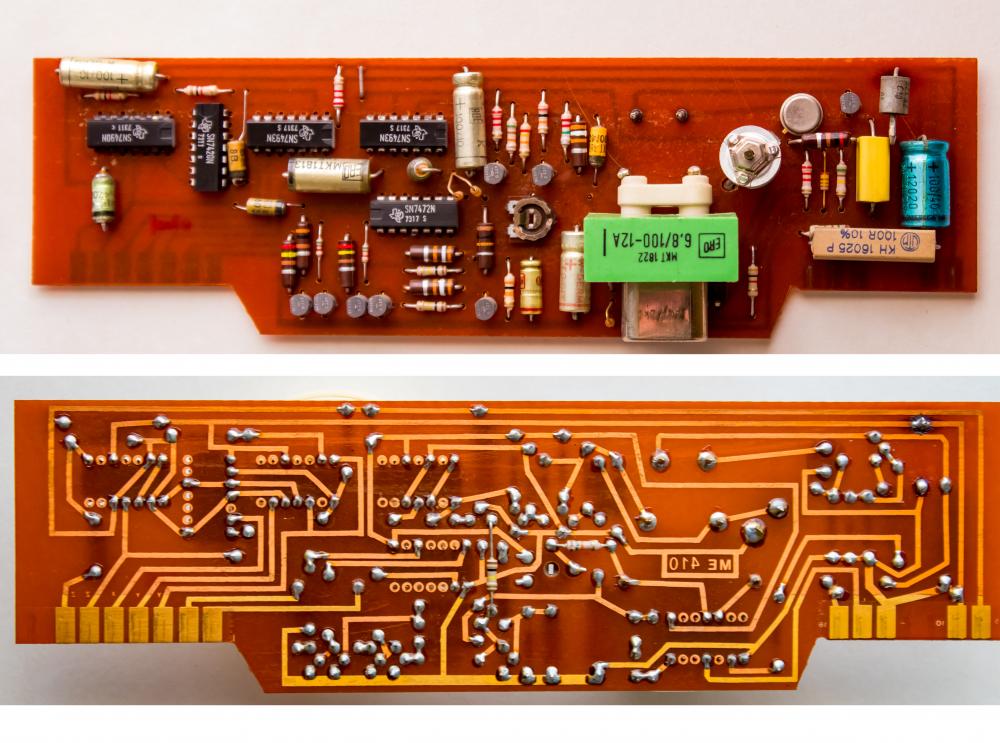

Good afternoon everyone. I have a great project, however my skills and knowledge on the subject are limited. Let's say that I inherited from a relative of mine, my father's brother, a watchmaker, this beautiful machine from about 1974. Although it is very well cared for, it does not work. I have inspected and I think the problem is with a zener diode (BZY92C10). Or a pair of transistors that activate the solenoid that hits the cylinder with the helical track that prints the succession of points. PCB1. The side tracks is rotate to match PCB 2 Is rotate o mirror to match The motor turns and the paper strip advances. But the characteristic sound of the impression tapping is not heard. In fact I was able with the help of a tip to check current of 12-24 volts, I could see that at the output to the printer / solenoid, a pulse corresponding to the beat of the clock is generated. But it seems that the current is not enough to drive the solenoid coil. The solenoid coil works if I activate it with a 9 volt battery. In other words, you can hear the “click”. If any of you wish to join me in this project, I would greatly appreciate his help. Thanks

-

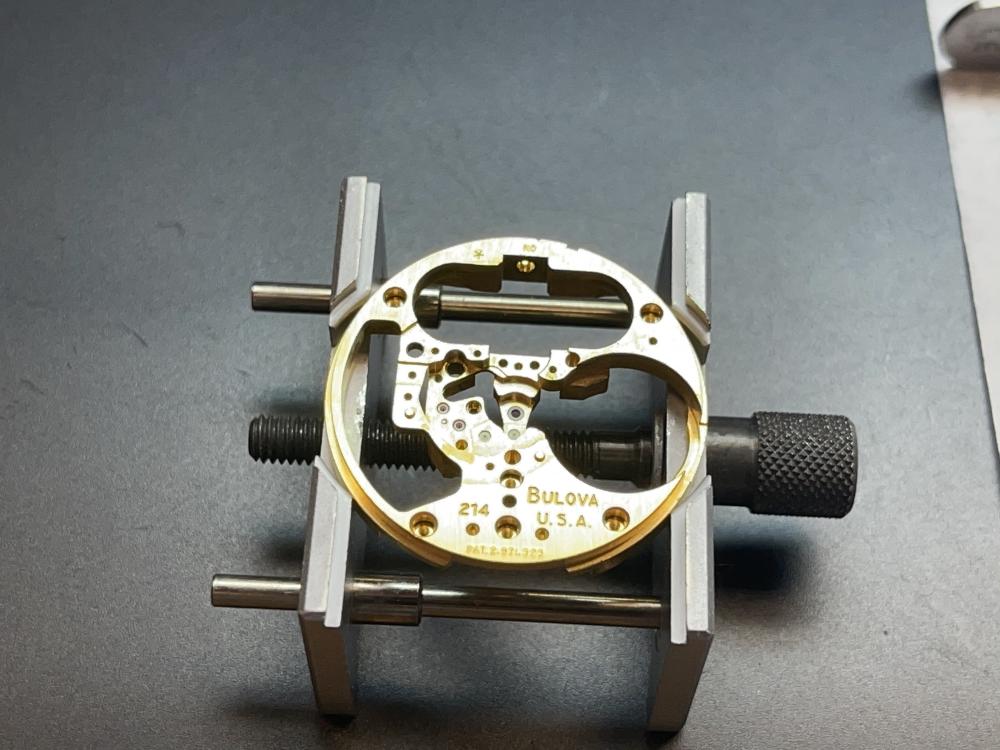

Hello everyone! So I've picked up a Accutron 214 non runner and decided to have a go at servicing it to see if I can bring it back to life. I own a few accutrons but have never gone this far into one before. So after cleaning and inspection I have found the 4th wheel has some damage. Doing a little research, it looks as though the 214 and 218 4th wheels have the same part number. Before ordering one for a 218, I was just wondering if anyone can confirm that they are the same?

-

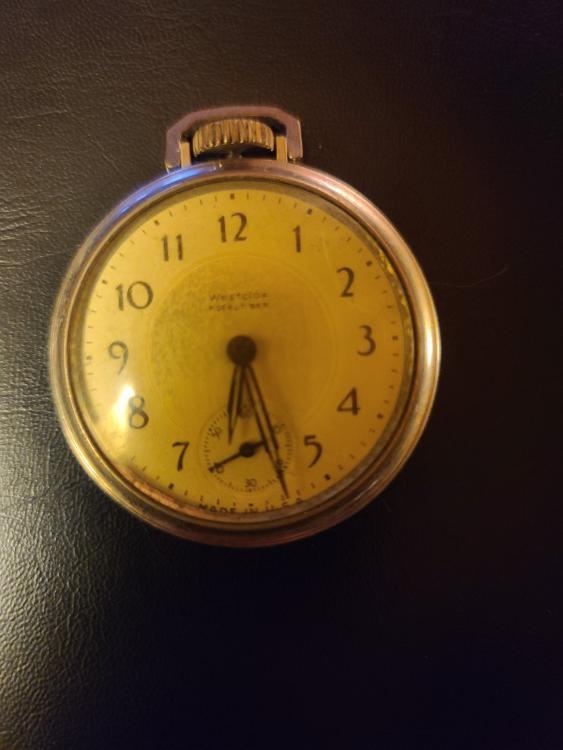

These are the watches I acquired from a local thrift shop, I am trying to figure out what exactly they are. I will try and give as much detail as I can. There is a Seikomatic-p, a Bulova accutron, a eternomatic, a Parker, 4 different Hamilton's, a westclox pocket watch, and a Virtus twin pocket watch. Any help is appreciated,

-

Ok. Working on a 214 tuning fork astronaut! I am getting dizzy trying to fix this one. I lack the experience on tuning fork watches. So my big question is what is affecting the gears from rotating on the dial side. After I install hands? The cannon piñion rotates well on its own, the minute wheel will rotate if added, then after I put the minute bridge on it will stop, but this isn’t happening with a different bridge(without hack) a lot shorter bridge just covers minute and setting wheels. So that’s how I have it on now, saw rotation of gears, got excited so I dialed up and installed hands, watch buzzes the second hands spins, but the hour and minute hands don’t move... so my quiestions are as follows. specific to astronaut model only 1. Does it matter if I use regular 214 minute bridge? 2. What causes the rotation of dial side to seize, when the stem hasn’t even been installed? If the hack is missing ( watch can’t be hacked) correct? if stem is out of the casing, it can’t be the stem! Right? I am sure I am overthinking. Your help is appreciated. TIA Ps. I did replace the centre second pinion jewel with new shatton.

-

Accutron Astronaut 214 repair help

watchweasol replied to Watchit06's topic in Watch Repairs Help & Advice

Hi you might find the attached accutron service manual of some use. cheers accutron_service_manual_series_214.pdf -

My name is Jaime and I am a watchmaker certified by WOSTEP. Work out of New Mexico. However it’s my first time doing a astronaut watch, I had fixed a couple 214s 7 years ago. Now I am wondering why I took it in for repair. I was referred to this place by a wise watchmaker. I am working on an accutron 214 astronaut watch. For my misfortune or fortune I can’t seem to get it running. The index and Paul are just how they should be, there isn’t any blockage to the gear trains or motion train until I put the hands on. Also not hacking, there is a good hum, but minute and hour hands won’t move. Only second hand moves but won’t hack.

-

Hello, I am working on an Accutron Astronaut and after putting it back together, (cased up) I notice it hums, (doesn’t hack) and the minute and hour hands don’t move... everything was looking good during the overhaul. Paul and index line up how they should, the tuning fork vibrates the coils are good. Can anyone with more experience on these help me out? Please and thanks.

-

Hi, my name is Mike. I have been a collector for over 20 years. I was in the process of teaching myself watchmaking when neuropathy in my hands kind of put a stop to it for the most part. I still try to tinker with my Timex watches as they are not quite as expensive if I goof. (Though that seems to be changing!). I still have a pretty big collection. I like Soviet era watches, and Accutron watches too. I have a running Soviet Slava Transistor (a virtual copy of the Accutron 214) that is one of my prized watches. I find it difficult to type so I wont be posting a bunch. I be happy to answer any questions if I can. Thanks all.

-

New type of balance

LittleWatchShop replied to AshF's topic in Chat About Watches & The Industry Here

Having spent the last 45 years as a technologist, seeing novel innovations like this is exciting. However, technology for the sake of itself may be little more than titillating. So...what have they done with this new innovation? Well, they merged two established arts: mechanical movements, with MEMs ((microelectromechanical systems) technology. MEMs stands on the shoulders of 60 years of silicon (not silicone, btw) fabrication technology. All of you have MEMs in your life already. It is in every one of your phones. Some of you (on another thread) are playing with MEMs microphones for watch timers. If it sounds like I am dumping on these guys, I am not. This is clever innovation. One market served by this innovation is the one where people desire a sweep second hand in a thin, low-power watch. This is the niche where they will thrive IMO. Accutron was the early sweep solution, but there were problems. Accutron now has a high-frequency watch with a sweep second, but I think it is power hungry and thick (correct me if I am wrong...going from memory). Is there another sweep-second solution out there? I have a friend who wears a Rolex. Probably worth 15 grand. Sends it in once a year for service at $600 a pop. There is much I do not understand about this business!! -

Hello everyone! I hope this message finds you all healthy and well! So I was having a look at some watches I recently acquired, both Bulova’s with date codes of M6 (1966). The 2 I was comparing were a Surf King and an Accutron. So both watches have luminous hands and dials, but I noticed the Surf King had “T” markings indicating tritium but the Accutron does not have any markings indicating lime material. Now with both watches being from 1966 I would assume the Accutron is tritium as well. I doing some more research, I find the Accutron is made in the USA and the Surf King has “SWISS” between the T’s. So I’m just curious, would the US and Swiss have different requirements as to the markings of their dials? Any thoughts would be appreciated!

-

Hello, I have been collecting watches for a few years now, and have interests across the spectrum. I am most interested in vintage watches, but do still have a number of modern pieces as well. My collection consists primarily of Seiko and Timex, but I also have some Accutron, Vostok, Rolex, Omega and Zenith as well (amongst a few others). I have done some of the basic cosmetic watchmaking tasks of crystal replacement, gasket replacement, and case cleaning/polishing previously with success. I am an engineer by occupation, so my desire to learn watchmaking is primarily at the hobbiest level right now. I would eventually like to be able to pick up 'rough' vintage pieces and perform restoration work on them, but also learn to maintain my collection to a certain degree. I have purchased a pretty wide range of tools at this point, mostly cheap ones, but a few of the nicer Swiss made products as well. My intention is to start on some of the Timex and Seiko pieces that I have picked up as parts of larger lots. Most of these pieces are of little value, and have pretty simple moments, so there is minimal penalty to the mistakes inherent with the learning process. I look forward to the wealth of information on the forum and am excited for the benefits it can provide in my horological journey. Thanks in advance for the assistance and acceptance from its members!

-

Update on my earlier comments about Accutron test gear. I found this picture of my Dad's watch bench (after he sold his business and was working from home). I believe that black unit is the Accutron test meter. I forgot about him having it and I do not know what happened to it--he probably sold it. Incidentally, that is the watch bench and equipment I inherited (sans the meter).

-

Wonderful to see this. My dad was really proud of the accutron work. He started doing them near the end of his career. I wish I had paid more attention at the time, but I was busy building my own career.

-

I would say current consumption is somewhat important if you don't want to be changing the battery every few months. The gear train of a quartz watch is so delicate that testing it by turning the wheels is not a good idea. And with a stepper motor at the other end, you can't get the wheels to spin freely. Without a current test, you'll never know if there is a problem with the circuitry or resistance in the gear train. That's the reason why some watches stop working soon after battery replacement. I test the current consumption of my quartz movements with the Bulova Accutron meter. It might not be as accurate as a Witschi but it'll do the job.

-

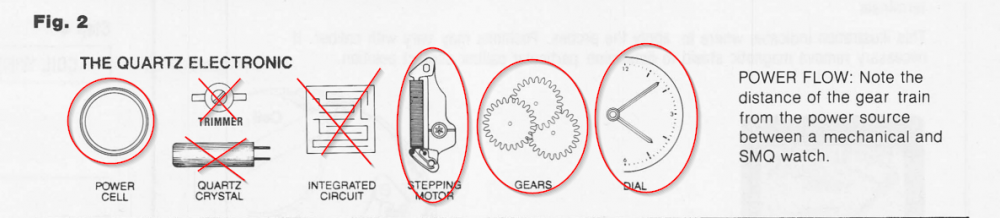

Re Tuning Fork watches: I have never worked on one. However, my father was trained to work on them--I have his certificate of training above the watch bench where I work. I have lots of Accutron coil assemblies that he labeled as "bad." I frankly do not know if they are bad and I wonder if he knew. He did not use any exotic equipment to test and repair Accutrons other than a Bulova monocular microscope. He used a Radio Shack analog volt-ohm meter and only used it for checking batteries (it is good for that). So I refer to the diagram in the SMQ service manual which I have attached with annotations. Those items encircled CAN be repaired. The X-marked items cannot (maybe the crystal for the fearless). So the only testing that needs to be done is that which points you to those items that can be repaired (as I alluded to in an earlier post). Back to the Accutron modules. There is a transistor, resistor and a capacitor as I recall. All three of those can be replaced if you have a fine soldering iron and sufficient skill. The equipment to test the transistor is, at worst, a curve tracer ($$$), and at best, a multimeter that has a transistor tester built in (cheap). But to test it you would need to remove it and extend the leads to fit in the transistor test socket (there are other ways...but). Can you find the transistor to replace a bad one??? I really do not know. I doubt it is a conventionally marked 2Nxxxx device. Resistors and capacitors are trivial to find. Measuring current to troubleshoot the gear train is a good idea, but why not do it the same way you do for mechanical watches?

-

This Accutron has a similar vibe (well, not literally) and I think the same fake crocodile pattern on the strap.

-

Omega Constellation Chronometer 1976 1250 wont run

JohnR725 replied to Bradlandry's topic in Watch Repairs Help & Advice

typically they're not supposed to run fast if they run fast somebody didn't phase the watch correctly. Or they didn't phase the watch taking into account that there now using a silver cell with a higher voltage. perhaps today this is true because were all familiar with quartz watches. At the time in the tuning fork watch came out Bulova discovered the watchmakers were having issues. So they had a several day training program. Unlike the training programs or stuff the other watch companies were doing where you got a certificate just to be there this was different. Two days of intense training with a written and practical exam. Only those people that passed got the certificate and could call themselves a Certified Accutron Technician. as this is an electric watch the same test equipment you have for quartz watches will work fine. Variable voltage power supply with the ability to measure microamps. Unlike quartz watch repair a microscope is necessary to do the phasing. The index wheel and the jewels associated are really tiny and a microscope would be rather nice here. to get you started I have some light reading. The 214 service manual is really where it all get started so it explains about how it works phasing etc. Then there's a fact book that explains similar stuff. then the Omega tuning fork in this discussion wasn't really made by Omega. The Swiss needing their own tuning fork watch designed a new tuning fork watch and it was sold by a whole bunch a Swiss companies. I have the manual for that and this is interesting watch as it implemented all sorts of improvements to make it much easier to work on. then an interesting link. Notice they have a reference to how to phase the tuning fork watch to run at a higher voltage. These watches were designed specifically to run with Mercury batteries and were never meant to run on silver cells with the higher voltage. This requires a slightly different procedure for phasing which is why you require a variable voltage power supply. http://members.iinet.net.au/~fotoplot/acc.htm Accutron 214 ServiceManual.pdf Accutron Facts Booklet.pdf ESA 9162 Repair Manual Omega 1250.pdf -

Citizen HISONIC movement (3711A date only model)

watchweasol replied to khang's topic in Watch Repairs Help & Advice

Well thats a bit unfortunate, from the enclosed blurb they are based on or exact copies of the bulova accutron made under licence, hope the attached will be of some use in determining the model you have and give you a lead as to the exchange unit if it can be found. One would suppose they are interchange able. I have also attached the sheet for the 214 which will be pretty close to the 218. Also have a look at Ranfft for the Bulova 218 for more tech details. Bulova Accutron 214.pdf Citizen - Electric Watches.html- 3 replies

-

- 1

-

-

- citizen hisonic

- caliber 3711a

-

(and 1 more)

Tagged with:

-

Citizen HISONIC movement (3711A date only model)

khang posted a topic in Watch Repairs Help & Advice

Dear all, I always wanted an Accutron but you know they are quite expensive (converted ones a little cheaper). So I purchased a Citizen HISONIC for a reasonable price from Yahoo Auctions and learned my lesson :). You get what you pay for. The case had and the crystal had a lot of scratches, which is not a biggy but the movement is dead. When I looked with a loupe, I saw that index jewel is missing, pawl jewel bent badly, one of the coils smashed and more issues. So trying to replace these parts, especially the jewels is beyond my skill and it will be a challenge to find each and most probably will cost me almost an Accutron I assume. What would you do? Try to replace those parts or find a new movement? Where is the best place to source a new movement or parts? Watch shops here in Japan are asking crazy expensive prices. ¥40.000 - ¥60.000 (around $400 - $600) to fix it and I cannot afford even if I could, I'd buy myself a nice Accutron instead. I was so happy until I unscrewed the back cover, auctions are not my thing I guess :). Thank you in advance. Cheers.- 3 replies

-

- citizen hisonic

- caliber 3711a

-

(and 1 more)

Tagged with:

-

Hi and thanks to all, f300 are (IMHO) the "easiest" to fiddle among the tuning fork watches, they are built into two different modules one for the fork itself with the index wheel and the other for the watch itself, but any case really tricky even with a good microscope and firm hands (no my case) I dared to touch some, incredibly easy to break or unset the fingers and very delicate to adjust, but never tried even to touch any accutron (the original and first diapason watch)) I hope to learn a lot from your awesome knowledge and ideas, and share some of my projects, usually very simple ones, as my hands and eyesight aren't what they used to be. Again thank you all for your warm welcome. Ricardo

-

Hi, and thanks for the greetings, I have some accutrons as well, I discovered through the expensive path that you could destroy a tuning fork watch if you dare to more than watching it, although I was able to revive some thanks to old stock bought years ago, but quite expensive in today's market. I promise that I will never touch an accutron further than hands, dial or keyless, but was able to repair and adjust some ESA and Omegas. those movements are far easier than bulovas, even with my hands and a microscope. Not dealing with tasks as I only dream with better tools, but keen to learn and share if I can help in any way. Again thanks for the welcome post. Ricardo

-

Hi everyone, My name is Gordon Chow, and I have always been interested in timepieces. I used to replace the movement entirely, but have been interested in learning to repair the movements themselves as ETA movements are no longer available. My first watch was a Bulova, and my favorite watch is a Bulova Accutron 63c105 (their last watch to use ETA 7750 movement) that I received for finishing university and starting my first ‘grown up’ job. I wanted to join this knowledgeable group to learn more about repairing movements and join the class.

-

The Voumard Accutron Hallmark and Hunter are all running. The Hamilton pocket watch runs when I give the barrel a little pressure with my thumb nail. I'll have to look for a stem to give it a wind.

-

Welcome to the forum. I have 2 Bulova Accutrons. 1 working fine and the other a parts donor. After reading the service manual and watching a few YouTube videos on Accutrons, I don't think I have the guts to disassemble one. There is supposed to be an index wheel in there with teeth so fine and delicate that if the second hand is not fitted spot on without any rotational movement, the teeth could get damaged. There aren't many watchmakers out there who can service an Accutron. If you search the web, there is only a handful. Good luck in your seach.

.thumb.jpg.4c8af3ef6b0ebd38fcf9dd76f0dc2292.jpg)