Leaderboard

Popular Content

Showing content with the highest reputation since 05/01/24 in all areas

-

I should have done this a long time ago. I would like to say a big thank you to all my followers new and old. If I can help in any way just message me and I will do my very best for you.10 points

-

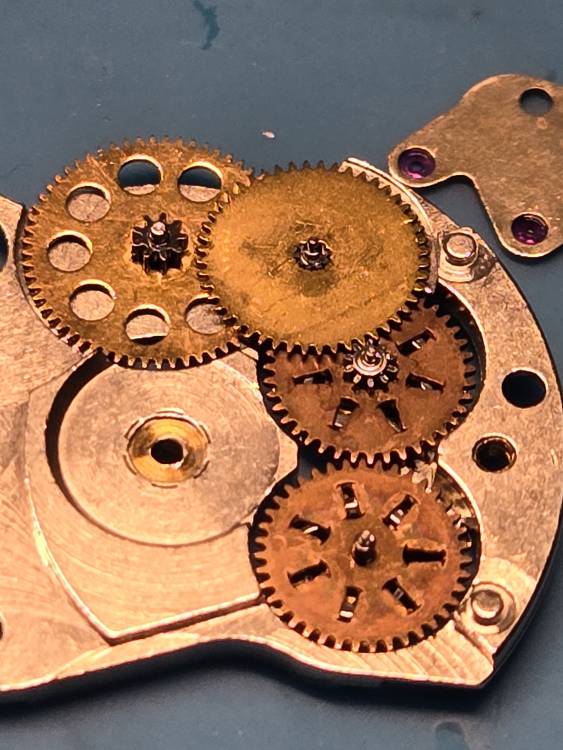

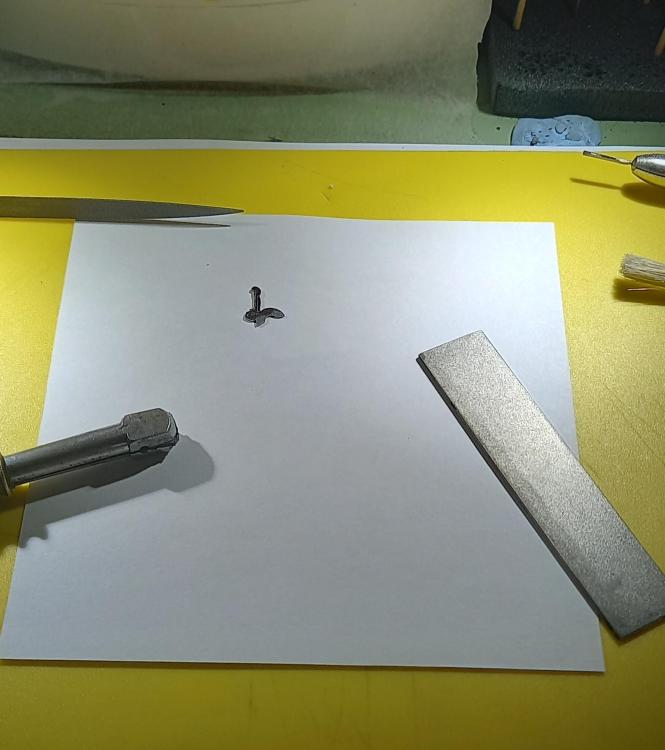

Tah-dah. A mini blow torch to harden it, then quench it and just a lighter held under a brass mainspring barrel that the part sits in to temper, Its important to wipe off any grease from fingerprints with ipa, you might be able to see i missed a bit at the top of the arm. Its a very satisfying process. I now just need to deal with the more difficult repairs, anybody any good at replacing rubbed in jewels ?6 points

-

Finally figured out why my hands are so god damn steady. My mum 87 years old , 4 weeks after her stroke and has a macular hole in both eyes, she wiped the floor with me and my lad at a kids stacking chairs toy game. Here she in rehab placing the last chair into position, bloody ' Supergreatgreatgran' i hope I'm half as fit at her age5 points

-

4 points

-

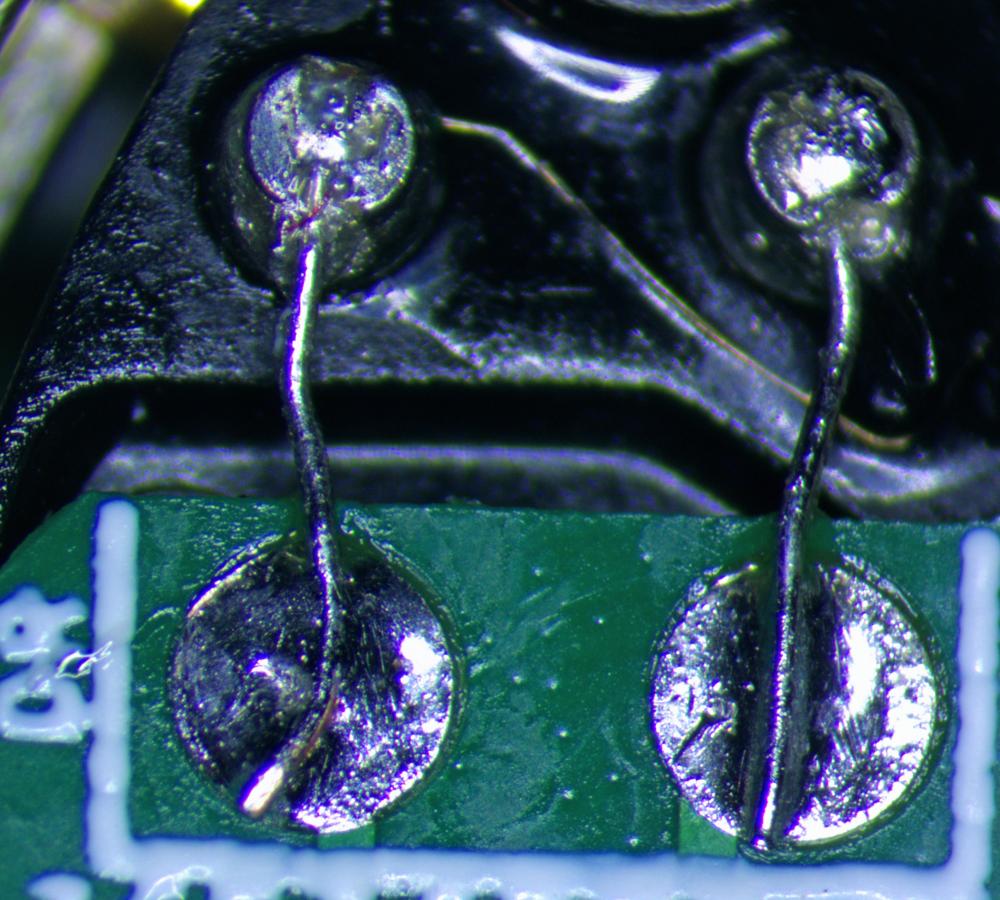

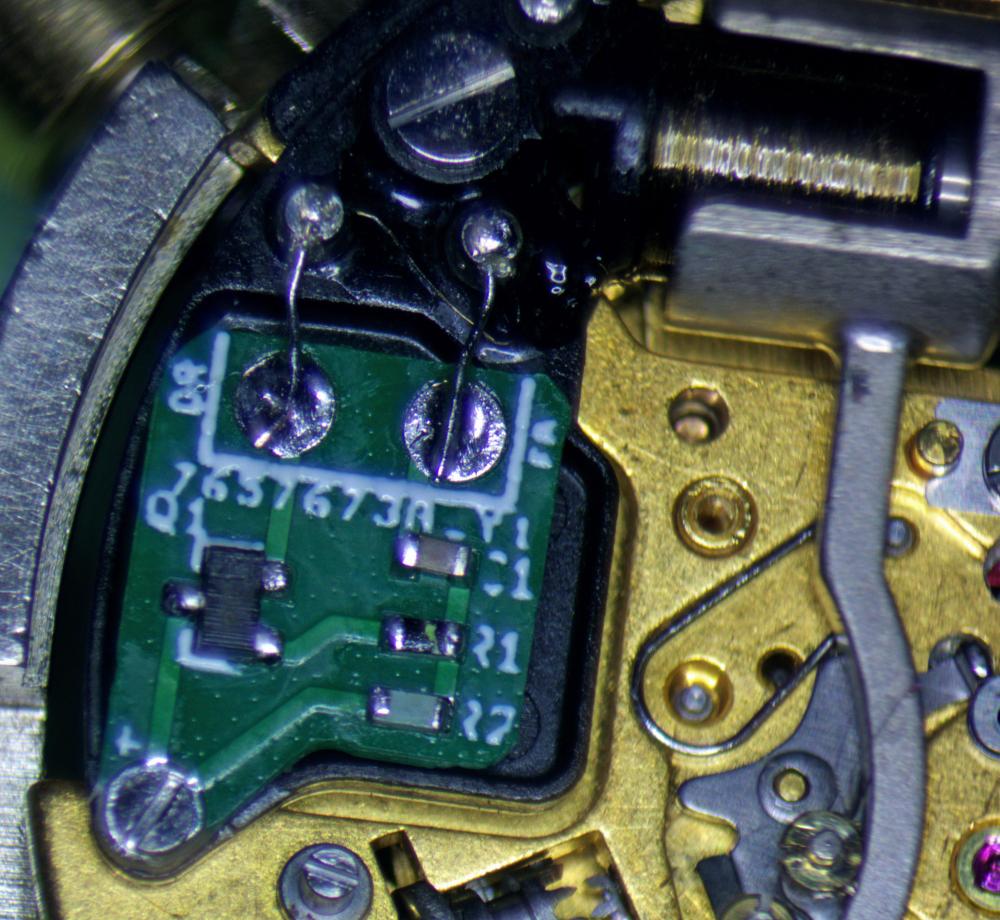

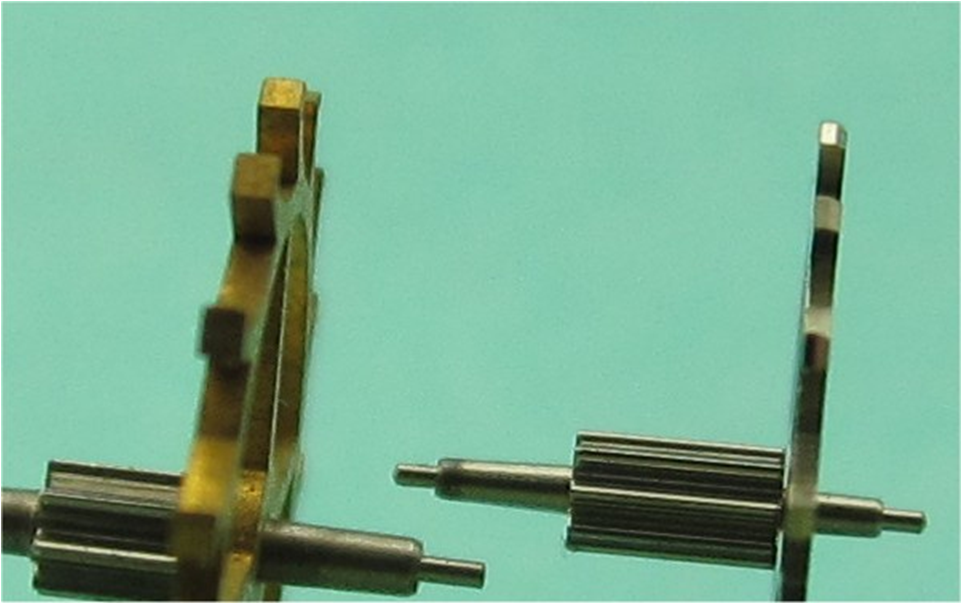

Here are the pics of the bridge. Looks correct, but as soon as I screw on the rotor, the watch stops. Video here: https://1drv.ms/v/s!ArG5E62RGctxjokY5ws85BzuJLVakA Pics. Might have figured it out. I have been working on this watch for a while and since I got it as a non runner in a terrible shape, there was no guarantee that parts were proper. I think the main screw that was used on the rotor was too long, so it was stopping the main train. As soon as I fished out a much shorter and larger headed screw, things were good again. Please celebrate with me.4 points

-

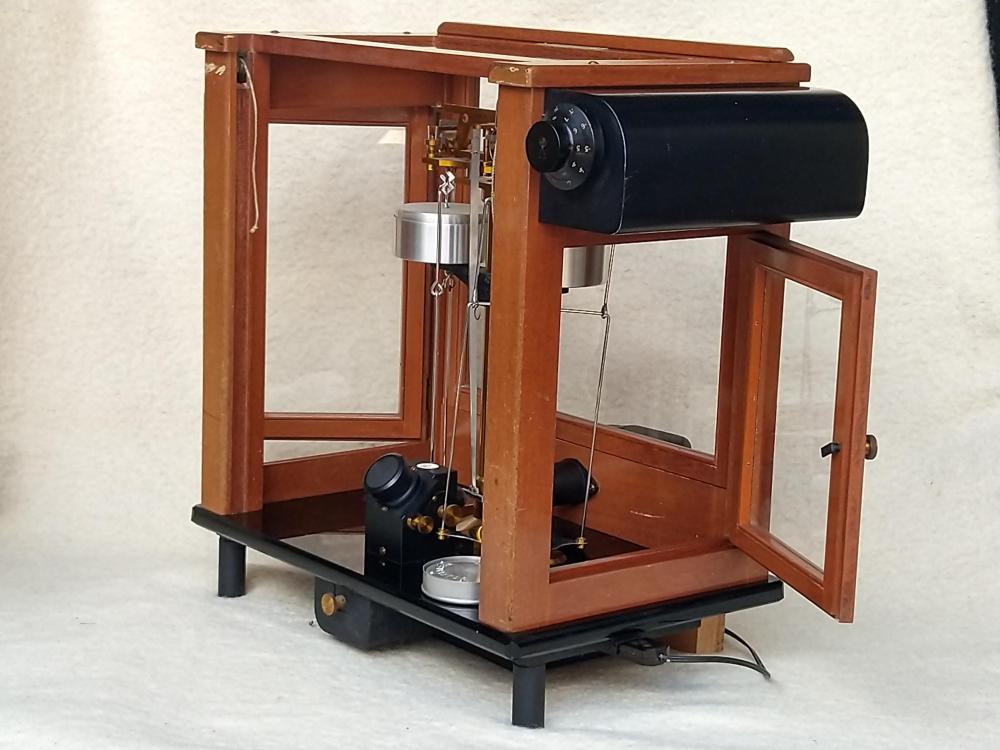

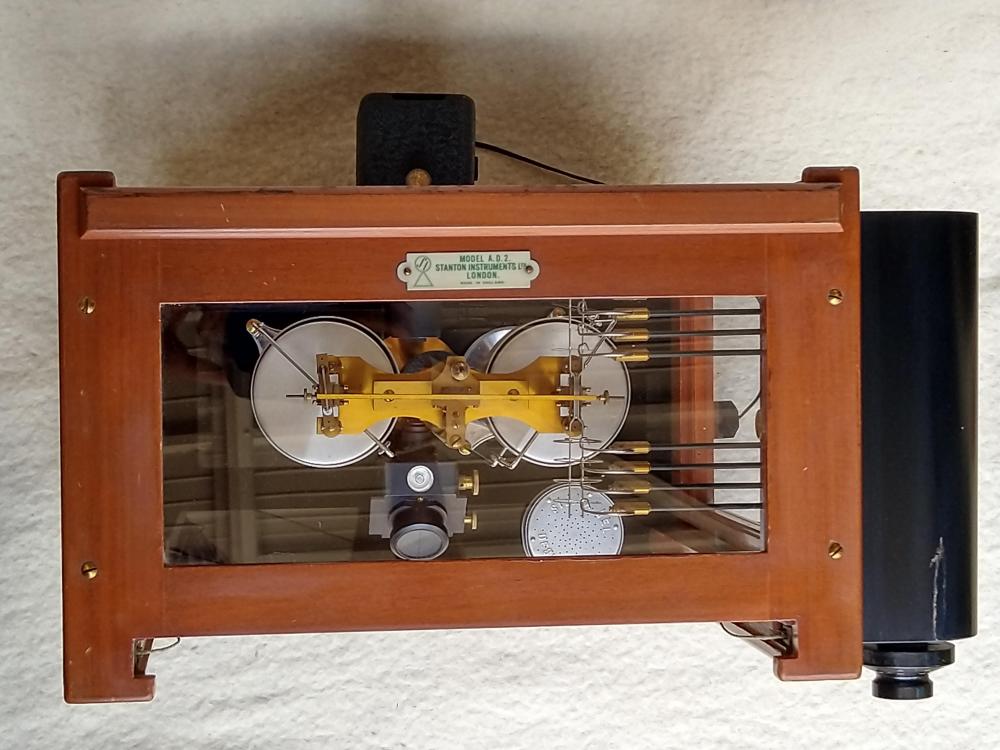

Moved in. Now working out the best place to have things so moving around the room makes sense. The wooden movement testing rig may end up being suspended from the roof with some pulleys and ropes that I salvaged from some alfresco blinds that we replaced. I always seem to salvage things from things we scrap thinking, "I have an idea what I can use these for." I hope I'm not the only one that does that. My wife hates me for it. "What are you going to do with all this crap?" Anyway, here you go. If anyone has suggestions for workflow around a room, speak up. All Ideas are appreciated. The bench on wheels will carry either a laptop or my Samsung table for using with the little camera that is on the tripod for photos while dismantling etc. The small bar fridge in the corners going to have water etc in it and I might move the coffee maker from the kitchen out there as I am the only one that uses it. I want to get an ultrasonic cleaner so I may set up some sort of cleaning rig in front of the glass of the sliding door. Where the grandmother clock is currently standing. I'm hoping that I will be able to transition my working area, which is the table that the stool is sitting in front of, fairly easily between clocks and watches. I'll be doing my best to make sure that tools for each are separatedwhen stored. Logistics. I'll have a bit of wall space for being able to hang clocks if I find some that I wish to keep or hopefully at some time to be able to hang customer clocks for monitoring after servicing/repairs. The clock on the left in the blue pillow slip and the grandmother clock are earmarked for Jarryd and his wife, Sara. He helped me move the benches in today. And then went on to tell me that ticking clocks drive him nuts. Who doesn't like the rhythmic ticking of a clock? I have a green pad for adding to the bench for a working surface. It is not a cutting mat or one of the Bergeon mats. It is actually a green desk writing mat. Was really cheap and will do exactly what I want, I think. I also have to get the sparkies back that put our new stove in to put some power points on the walls behind the benches. Hopefully this is all going to go well. I'm excited about it. It'll beat having to live out in the garage doing it. The other thing I have to do is cut a circle or square of plastic to go over the bouncing watch or clock part black hole in the middle of the floor. I would pretty much guarantee that anything that sproings off the bench would end up going straight down that drain. I think I have been on this forum about 4 years and still yet to really strike a blow. That's a bit sad isn't it. Signed up to Mark's watch course and have yet to buy the movement for working on. Have most of the tools I think I will need so now all just a matter of will. I have to make a crank handle for my Joe Collins spring winder as well and some spring retaining tubes as I can't find where I can buy them. I will be salvaging (here I go again) the aluminium tubing from my old hang glider which I have to scrap as I can't fly anymore and it is too old to sell. All the aluminium tubing is aircraft grade so I am hoping it will be suitable for the winder. I have also been making a bushing tool and I have just worked out that it will work well with my Dremel stand. So another thing that I can turn into a working tool. Don't know if you guys have ever seen the ad about the guy that buys himself a new 4WD and the son says "We're going to need a bigger boat." So Liz is looking at all the stuff we have to get rid of and says "We're going to need a bigger bin." Really difficult to work out how big a Dempster bin we need. Sigh.4 points

-

4 points

-

4 points

-

[SBGA405] Grand Seiko “Godzilla” Spring DriveI always enjoy coming back at the end of the week to my first Spring Drive watch which is a combined automatic mechanical watch and a high quality quartz — a Spring Drive.Impressive accuracy (10 seconds per month) and wears remarkably comfortable at 44.5 mm in diameter and 95 gm.Love the power reserve indicator, and the colour of the dial amd the watch band.One of my “perfect” watches!!4 points

-

4 points

-

Hi, guys I got there in the end after several attempts using a screwdriver and Rodico, I couldn't wait for the tool to arrive and was getting pretty confident handling the stud screw without it flying away. At first, I was using far too much Rodico, and then realized you only need the smallest amount inside the screw slot. Putting the cock back onto the movement also helped as it gave me more to hold onto while my shaky hand tried to align the screw wobbling away at the end of the screwdriver Anyway, job done and I can move on. Thanks again for all the advice it's really appreciated for a beginner.3 points

-

My newest 404 candidate, a late '60's / early '70's Waltham with a UTC 33 / Seiko 6601 17 jewel automatic movement. It needed a new crystal and I put on a strap from my Strap Graveyard. The timegrapher was a snow storm before servicing but it cleaned up nicely. I really like the funky font used for the hour markers.3 points

-

3 points

-

My second iteration. Cleaning to be underneath the towel rails. That makes sense. Moved the fridge and the maching/printing table around to the right. Changed the lathe to be used over the end of the bench. Not much room in front of the 3D printer, but you don't have to stand there while it is doing its thing. I may swap the fridge and the machining/printing bench yet. Not sure. And the 'doing' area. The power that was brought in for tha spa was 30A I think, so there will be more power than I need. I will have to check how level the benches are as well as find a spot for the movement testing rig to go. The tiles do have a fall toward the drain so I will have to work something out to be able to level the rig easily no matter where I put it. I'm also going to cut some slots in the bottom for pendulum clearance and some squares in the top section to be able to better see the movement. I'm getting more excited now.3 points

-

Tbh thats how i would do it. Being a joiner and setting up a few workshops in my time. I would have full worktops all the way around instead of seperate benches, but still a station for each process. Dedicated disassembly/assembly (clean area ) cleaning, repair , polishing and lathework.3 points

-

That can be tricky. Sometimes I hold the movement from the edges in left hand and with right hand I push the release with tweezers and simultaneously pull the stem out with right hand pinky or something.3 points

-

Hope you mum keeps on mending. I was adamant that I was going to get myself going after my stroke. I was only 52. I still have a lot of life left to live. Some people give up. Some people don't let it beat them. Your mum sounds like one of the winners.3 points

-

So leave off the seconds. Stand the movement on its edge, its the dial edge that rests on the pad ( either rubber or cork , something that wont slip ). Use a finger of your left hand to hold the movement upright, right hand presses the release and flicks out the stem. I do it this way so i can see what I'm under a microscope. But you could hold the movement between two fingers of your left hand, its the right that has to manipulate the stem out by pushing the release and flicking out the stem with right ring finger nail. Sounds more complicated than it actually is. I guess you could fix a push pin to something solid, then all you need to do is push the release against the pin, leaving your right hand completely free to pull the stem out.3 points

-

I think what peter means oh is once he has fitted the hands and checked for alignment if them and that they dont foul, how does he then hold the movement to remove the stem in order to case up. The dial cannot be laid on a cushion or in a movement holder as the hands will get damaged. This can be quite tricky for a beginner, what i do is to stand the movement on edge on a rubber pad so it doesn't slip. Hold the top edge with one finger then my dominant hand uses 3 fingers to press the stem release and flick out the stem. See below peter, leave off the second hand as this is the longest and gets caught the most, then fit it once the stem is out. Alternatively place the movement in one of the cup style holders, i imagine this is what they are designed for. They only touch the very edge of the dial.3 points

-

New Great wheel arrived, rebuilt the watch and managed not to break anything. Had a minor issue with a screw I'd found to use to secure the date corrector wheel - it was fouling the escape wheel. Changed for a shorter one and it seems all good. Running pretty well I think - not yet adjusted it, will let it run for 24 hours first.3 points

-

Yep, that's exactly how it should fit. The reamer shank is tapered and the socket in the spindle is also tapered so that the one centers in the other and is gripped tightly. If there is any wobble when the reamer is seated as far it will go then there is a problem. The cross hole in the spindle is to allow you the push the reamer back out again. If the reamer seated much deeper then it would limit the access for pushing it back out again. Here is one of mine for comparison.3 points

-

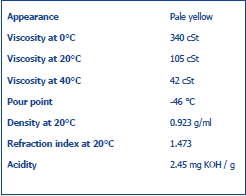

This is the 3th attempt for this specific pinion. Othervice I have made many for pocket watches, but they are much bigger. This is really small. The pictures does'n t show things correctly, there are blinks that my phone camera can't manage well3 points

-

Not a family member, and yes, it no way near as good, as some information got lost from original site and some information got incorrectly copied. The original site is available as iOS app here: https://apps.apple.com/fi/app/ranfft-watch-movements-archive/id65020089393 points

-

Even the amount picked up by the smallest oiler can be too much. I made my own oiler with a 0.2mm wire. And I use the amount picked up by the smallest black oiler and use that to transfer an appropriate size droplet to the tip of my homemade oiler. The final amount of 9415 used is so small that it seems ridiculous.3 points

-

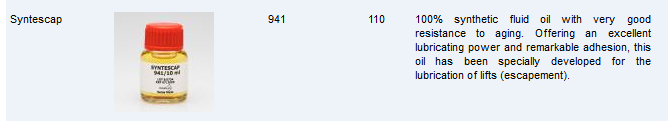

I assume you're using 9415? the concerned with 9415 and I'm attaching a PDF from Omega is too much can cause a decrease in amplitude. This is why you look at what they do they go to extreme lengths to put extremely tiny quantities. so as you've discovered proper lubrication of the escapement increases the amplitude. We've seen it on this group where people are having typically newbies issues and I will ask if they lubricated the escapement the usual answer is no they had not because and once they did they saw spectacular improvement. one of the amusements with lubrication tends to be so many variations. For instance I was in a classroom once and the students all came from for the most part accredited schools in watch repair. So the instructor asked how did we lubricate our escapement's and I don't remember the actual quantity but it's really quite amazing how many people can interpret slightly different ways of doing the same ask. Of course the instructors method was the approved one. This was the place a drop of oil on the impulse face of the exit stone. Allow one third of the teeth to go by and place another drop then another third and your escapement should be lubricated. But sometimes and yes it will show up in the timing machine you'll see in your regular line because if the oil didn't transfer all the way around to the other stone that does cause a issue with the timing machine. Oh but when I was in school we were using 9010 as 9415 did not exist yet although 941 did which is an oil recommended for escapement's. it has to be dissolved in a proper solvent with the right amount of concentration as you want a microscopic layer on whatever your treating. My understanding is the vapor process is the very best but the vapors are not good for human consumption. The reason why the vapor process is nice is that it puts a very very thin coating on versus dipping in a solvent which can vary depending upon the concentration. 8645_WI_40_rules for lubrication cousins.pdf3 points

-

Sometimes you can see a burn mark on the dial from hands that have stayed in one place for decades, which is a clincher, but I don't really see that here. An inexpensive detector could let you know for sure, but considering the dial/hand style and the darkened condition of the dots on the dial in the absence of any clear water damage, I'd give 90% likelihood that there is radium there. Tritium is usually marked out on the dial, and although it moves to yellow and tan as it ages, it doesn't get as "toasty" as those dial spots based on what I've seen.2 points

-

Thanks, that's useful to know. Will save some expense. "school in the 1900s" ! I didn't know you were so ancient @nickelsilver2 points

-

I'm confused, I can see the click in the usual position next to the ratchet wheel. Surely the click spring is there?2 points

-

That looks like normal behavior to me. That movement only winds in one direction, not both, so when the rotor turns anti-clockwise it winds the main spring and so is fighting against the mainspring tension. As a result it will turn under its own weight but it won't free spin. When it turns clockwise though it has no resistance and so can spin freely.2 points

-

Removed a couple of mm of grout from every tile joint on the floor and regrouted it this morning. Final clean up tomorrow and then I am going to start moving things in from where I have them in the garage. Just have to work out the layout of the room once I start moving things in. Garage just didn't work out. So if you are setting something up, don't consider your garage. Not really a viable option.2 points

-

2 points

-

The part is roughed out with a speed run diamond disk. Finish both the ends first that way the spring doesn't get any stress and then go ahead and bring the jumper down to size last. Slowly cutting my time down. This one will be 3 hours when its finished, two hours is very doable with some practice from start to finish inc. a little polishing up on the main contact points.2 points

-

Thanks, ManSkirtBrew. I started looking for a setup like yours and ran across this. It was about half the price of the JKA Feintaster (depending on what auction you were in), and it's a Bergeon. I bought it because I thought the price was fair (eBay - Buy it now), and I'm a sucker for vintage tools. It also has a table, so it should be easy to use for measuring jewels. I wonder if the the contact points can be changed out. Bergeon seems to manufacture new tables and accessories for the contemporary dial version. What do you guys think of it? I'm sorry this post seems to have taken a detour. I'm new here so let me know if I should start a new topic.2 points

-

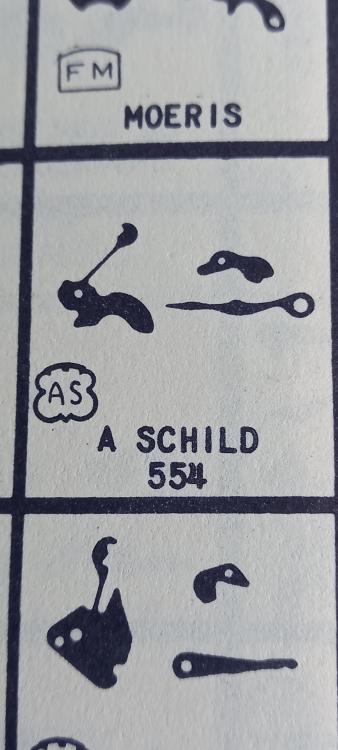

Next one up an AS 554, looks like a bit more to this one. First job is to check thickness, most springs are somewhere between .3 and .4, this one measures .35, that matches in with the .4 spring steel i ordered. So for marking up a permanent marker comes in handy to colour up the steel to be marked later with a scriber once its dry. Bestfit provide the extra bit of info for the jumper spring that is missing.2 points

-

2 points

-

2 points

-

Just installed it on my iPhone (my only iOS device) and it appears to be intact and functional. I may have to go out and buy myself an ipad just for this app.2 points

-

The original database is available on iOS devices here: https://apps.apple.com/fi/app/ranfft-watch-movements-archive/id65020089392 points

-

2 points

-

2 points

-

2 points

-

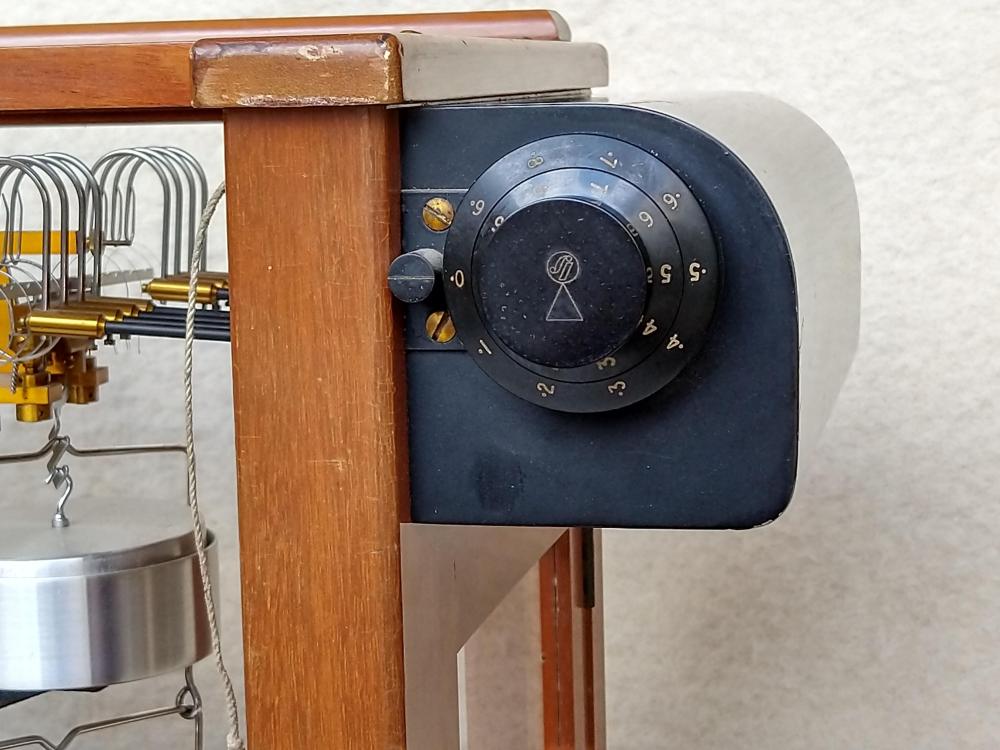

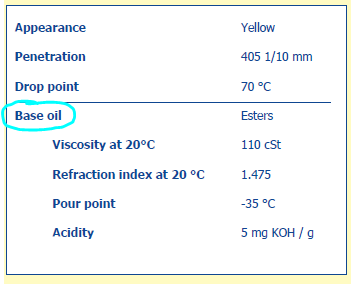

I wonder if 9415 is based on a base oil of 941? it's interesting what questions bring and the tech sheet answers it's the viscosity of the base oil. Then the impact? There is something we're missing here for that which would have a big influence on all of the house image above is 9514 image below is 941.then always interesting when specifications do not exactly agree? They ledge above for 941 indicates 110 viscosity but the image off the spec sheet is slightly less but I guess close enough my understanding of the concern of too much 9415 is as we know the loss of amplitude. But why do we have a loss of amplitude? So impact it's basically oil should be very slippery. But what about non-impact? Like the edges of the escape wheel? Another thing that comes to play here is the shape of the escape wheel itself. Notice on the last a more vintage escape wheel with just a flat surface whereas the modern escape wheels usually made out of steel versus grass much much thinner their contact areas greatly been reduced and sometimes I think there even slightly curved. So is it conceivable at everything that isn't a flat surface on impact is going to be sticky? So this is where the shape of the escape wheel will have a big impact literally on how slippery things are. Oh and for all of you obsessed with worrying about too much 9415 I never worry about it because typically I'm doing pocket watches and it doesn't seem to be an issue at all. on the other hand I'm much more concerned about a watch that keeps time for 24 hours as opposed to the concern of the group of keeping amplitude for 24 hours. Then yes some pocket watches have steel escape wheels and do look like the escape wheel on the right.2 points

-

2 points

-

Just realised my previous reply could be misunderstood. I epilame treat the pallet stones (not the entire fork) but I do not let it run dry before applying the Moebius 9415. George Daniels is likely turning in his grave over the use of epilame, oiling, and the use of the Swiss lever escapement.2 points

-

I'd like one of those for my staking set. I bought a cheap roller remover, thinking I could just file the jaws down so that it worked well. It didn't, so I ended up buying the Bergeon version, which does work well. Though, as @Neverenoughwatches points out, you do have to be careful not to damage the roller of staff. Rollers are very soft and easily bent whilst trying to remove or refit.2 points

-

I recently helped my mentor to service 7 Seikos and he told me not to lubricate the pallets. His reason was from his experience from the advanced classes that he conducted, his students all ended up with worse amplitudes after oiling the pallets. I have to admit that I had the same problem when I oiled the exit jewel, like so many videos on YouTube show. I actually ended up with worse amplitude. But now I oil the escapement by oiling the teeth of the escape wheel. I think Rolex used to train their technicians this way. I find that I get about 20° -40° increase in amplitude oiling the escapement this way. I've only started playing with epilame recently. I got a bottle from a Chinese seller on AliExpress. It's supposed to be Episurf Neo but everything on the bottle is in Chinese. When the bottle arrived, half of it had evaporated or leaked. And when I brushed on a thin layer on a mirror, it dries rather slowly and even feels a bit tacky. When I did the oil spread test, like my experience with stearic acid, the treated and untreated surface of the mirror yielded similar results. The contact angle of the oil drop looked about the same for both the treated and untreated surface. When I epilamed an actual pallet fork, the escapement was so sluggish that I couldn't even get 180° amplitude. I dunno if I got conned by the seller but the results are just not convincing.2 points

-

I usually just use 2 pair of pliers to remove the roller ( just kidding ) I want one,I have an adjustable free standing one. But i really like the little bradux tool that nips under the roller with two tapered jaws that lift it off. You can get under a scope with it to see in detail how the job is going. There is some technique involved to stop you chopping the staff, doesn't particularly matter if the staff is already broken but it naffs up the tool's jaws if you crunch the staff, and the jaws need to be in good shape to prevent damaging the roller. But well worth a try if you've never used one and you can find one that hasn't been misused or buy a one new. The trick is to keep one of your fingers between the two arms to soften the squeeze, with a little practice its a handy little to. I will now prepare myself for an onslaught of negative feedback on it2 points

-

2 points

-

Used with the correct fitting staking punch it will remove the roller.2 points

-

Knocked out another 404 last night...when you are in the zone! This watch was a non-runner which I picked up as part of a lot of 8 watches, so works out to be $3.12 per watch. Before: And the finished watch, new crown and stem and the crystal was cracked so was replaced. I also replaced the mainspring as the original was the old steel type spiral and very 'set' - all else is original: The Movement was a AS 1686, but in reading around a little the ACCRO watch company were sued for their use of the five point crown on their Jacques Pere range as it resembled Rolex, see below: ACCRO then reverted to just ACCRO on their watches - I have done some sniffing around the internet and haven't seen another example of ACCRO and the crown together on a dial so maybe I have something unusual, or maybe I was looking in the wrong places .2 points

.thumb.jpg.6f205289b9d3240d01dc76aceacb7b37.jpg)