Leaderboard

Popular Content

Showing content with the highest reputation on 03/08/24 in all areas

-

I have spent over a week tweaking my Longines 30L, to see how accurately I could get it running. I had to change the balance staff, so the balance is very slightly out crown left. I decided it was good enough. I may tweak it the next service. Fully wound Amp +/- DD 296 5 DU 290 3 CD 248 -7 CU 250 15 CL 246 -33 I wind it each morning and I've been wearing it through the days since Monday - when it was set exactly to the correct time GMT. At 8am this morning (Friday) it was within 1 second. Throughout the day it loses slightly, As now, at 5pm, it is -4s. But through trial and error, I have found that setting it to +4s/day DU at full wind (the trace is rock steady), sat on the desk overnight, by morning it is back to within a second of the correct time. I guess this shows that it is accurate, but not precise ! (Though it has never been more than 5s out) What it has taught me is that the setting on the timegrapher is only the starting point - you need at least a week of wearing and tweaking to get real accuracy, and it will be different for every person depending on their lifestyle and what they do.4 points

-

4 points

-

@Qutadah, see, You first need to have the watch in You hands, or at least to have good pictures of the movement. What the seller says is useless, as if He understands enough of watchmaking, He would repair the watch. We need to see this hairspring, as it may be really bad, but it may be quite easily repairable too. And it concerns not only the hairspring, but all the other parts... The main problem that I see is that You intend to repair this small and fragile calibre without having any experience. Such attempts usually end up with ruined hairspring and/or broken pivots. Actually, the hairsprings end up ruined never by themselves, but only because someone did'nt handle them properly.3 points

-

@VWatchie “if it works, it doesn’t have enough features “ Tom3 points

-

So we are getting somewhere, we need to fettle the train and escapement to achieve precision then proceed to regulate to achieve accuracy. Summed up by many folks as “you can’t regulate a watch until it is working perfectly “ Tom3 points

-

3 points

-

2 points

-

My point is that there's no point taking SD's of amplitude. The difference between amplitude horiz to vertical is a consequence of the design of the watch. It's always going to be there. But SD's of error in all positions is the right thing to do. I wrote a spreadsheet for dynamic balancing where I work them all out (That crown left value is bugging me though. It's a watch where I can easily get the balance out when it's cased. I might have go tomorrow shaving a touch of a balance screw).2 points

-

I’m older than you Rich but the meaning is the same, gently manipulating until the desired outcome is achieved Tom2 points

-

If it works perfect it can get regulated accurate and adjusted precise. Think high grade watch with split second precision. thats close to perfect. its both accurate and precise, stable period of oscilation is perfect.2 points

-

Percision is only togetherness of tics in small groups. which can be way off target. its where we seek consistancy of periods of ticking. Accuracy is an average of all tics . Regulation is getting this avg as close to the target as we can. Rgds2 points

-

Most NH3X movements we will see are manufactured/assembled in seiko’s Malaysia factory and are usually marked as such., though not always. I wouldn’t be surprised if some components are made in china. Having worked for a global manufacturer with a lot of sites and people in china it is not uncommon for western QA rejected items to be sold out of the back door as they work fine as far as they are concerned. Tom2 points

-

@Neverenoughwatches Rich, you are absolutely right, I have a collection of plastic boxes that far exceeds my meagre watch collection Tom2 points

-

Honestly, once I started with the multi-lens setup, I never looked back.2 points

-

I remember my grandfather asking me if I were stranded on a desert island and could only have one tool what would it be. The answer is a file. With a file you can make all the other tools.2 points

-

I am sorry. My pen is sometimes more sharp than neded, and this is due my temper. The idea that someone might think the plates may be made not of brass, but of still, made me wonder how and why is this possible. But Rich is right, i don't see any difference in the meaning of the both phrases. See, the main problem of no jewels Timex watches is the wear of the balance staff tips. They wear for 2-3-4 years of constant use and the watch may still work, but with lo amplitude and bad timekeepinng. The way to restore the movement is to sharpen the tips and if they have been sharpened allready 2-3-times, then the cup bearings must be restored too. Just forget the other bearings, no significant inprovement will happen from there.2 points

-

Hi please keep in mind that English is not the first language of many folk here. Words and phrases can have slightly different meanings to different people. Consider Nev's words again as the question it was meant to be. # what makes you think there are steel plates in Timex movements # what makes you think ? = why do you think ? This is a change of just two words only, yet the perception of the attitude of the questioner can be very different . To Nev they probably are exactly the same and perceived the same. Nev's first language is not English and is still learning to understand it's idiosyncrasies better.2 points

-

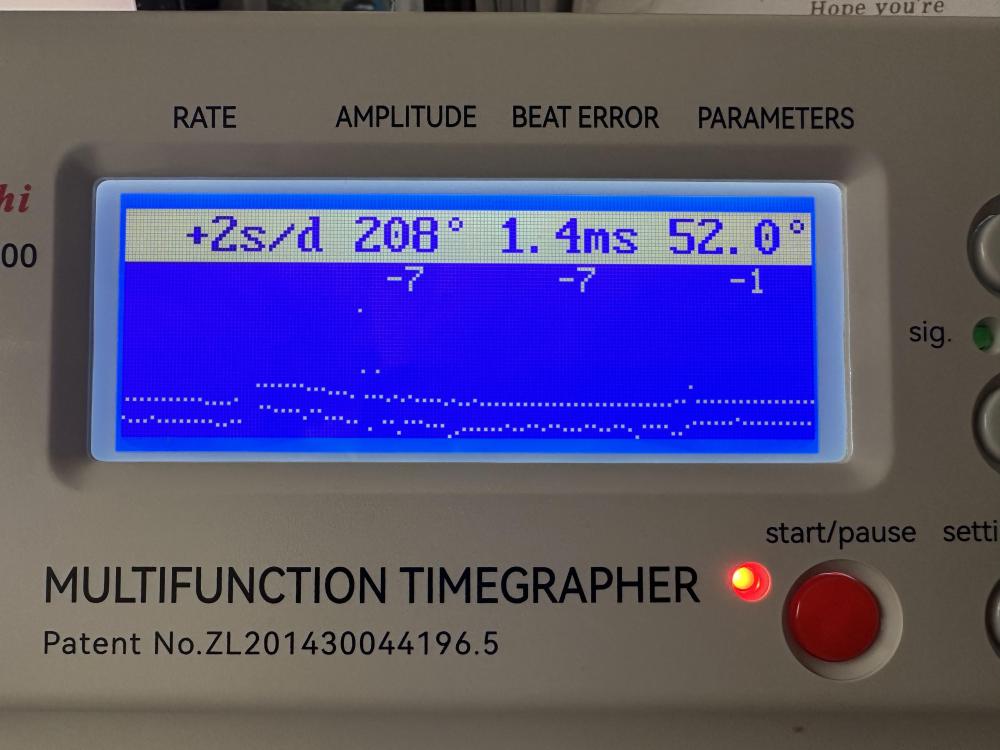

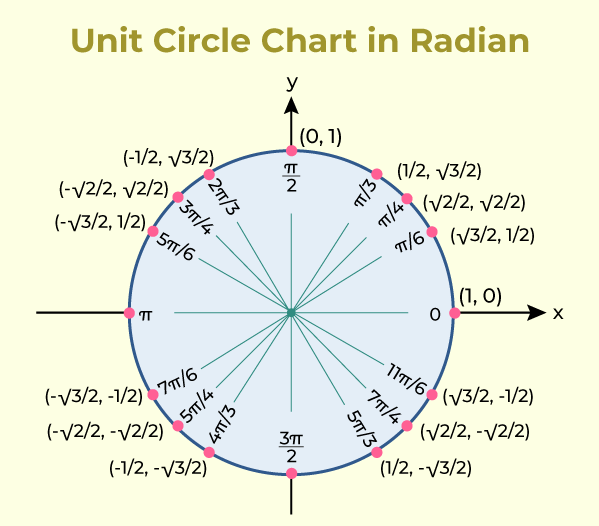

Hi mike, This is the watch that I gathered you didn't poise after restaffing, each rate tells how close to center of circle did your watch land the dots, IN DD position it runs precise DU position runs precise. CL not precise. a fautt in escapement. If we were to presume the fault is in the oscilator , then you can even predict where the heay spot is located. refer to the image of trigonometric circle. Heavy spot is in half circle from 180 deg to 360 degs, iin other ward 3rd and 4th quarter , when the heavy spot is traveling upward against gravity.1 point

-

@mikepilk, I don't know if 50⁰ is high but the standard deviation is high, my point wasn't to show any errors in your watch but to use your data to show that precision and accuracy aren't the same thing. Your watch isn't precise but is accurate. Many apologies, I feel that texting lacks nuance and sometimes can be misconstrued.1 point

-

1 point

-

Thanks Tom. Just to be clear: I should put a very small amount of glue around the circumference of the small dial, being careful not to have it 'bleed' through & be visible on the front of the main dial ? The small seconds dial already fits in the hole but not as snugly as it did before the ultrasound-ing....1 point

-

1 point

-

Weigh the watch and product a counter balance.1 point

-

I can find barrels complete but not the actual spring. You can remove the spring and measure it.1 point

-

Agreed, however the engineer in me just won’t let it go Tom1 point

-

If you're like me, you have more than one (scrap) watch which you can simply attach opposite of the one you're testing. It may not be the most elegant solution, but it works reasonably well and requires minimal fuss.1 point

-

I think the variable that should be equally considered is frequency and the size of the data set. For example a watch regulated to a 0° BE and loses 30 seconds/day is not accurate but precise. A watch with a positional BE delta of 2° but keeps time +/- 2 seconds a day is accurate but not precise. But this is only at the time of measurement. Now what if we had a watch that ran 20 seconds fast when fully wound, but 20 seconds slow after 24 hours and the owner wound it once per day? The watch would be accurate if the owner only looked at the time when he wound it.1 point

-

On your wrist , point might have certain distribution, and different distribution on my wrist, but both can avg out to accurate. Precision is limitting distribution of points in a dense group. In watches, we seek to avg to accurate , whilst torque supply deminishes, so in case of manual winds, better to wind every twelve hours or six for a relatively consistant torque supply. Selfwinders do consistant winding for us.1 point

-

Adding back to this thread, I knocked together a stand for this and am testing it now. I want to make a few refinements as it does wiggle left and right with the weight of a watch on it, I did expect that just not figured out what I want to do about it but looking at a temp solution of using a couple of 2020 brackets to trap it for now (I’m sure we all know how permanent temp fixes become ). Not settled on sorted the cable yet either. I used two pieces of 20100 aluminium extrusion 350mm long, easily could be just 300mm. Tom1 point

-

Check accurate but not precise, image. It can be consistantly imprecise but accurate.1 point

-

I hope Nickelsilver tells how manufacturers regulate, shows tools/ equipments etc. I guess some manufactures disallow showing their proprietroy tool to the public.1 point

-

I think it really brings in the context of testing in positions. If DU only 3 minutes could be considered precise as it is consistent. However if it varies to say 1 minute per day DD then the Watch could not be considered precise or accurate. Precision is essentially consistency and accuracy hitting the intended target. Hope this makes sense, great topic for discussion @Nucejoe, I am very interested in this very subject as I am trying to put together a testing/ standard process to look at my service and regulation quality. Tom1 point

-

If a watch loses 3 minutes a day consistently then its precise but not accurate?1 point

-

As a former competitive shooter and coach I can relate to the illustrations Joe. In watchmaking, specifically timekeeping would accuracy equate to s/d and precision the positional delta? Tom1 point

-

1 point

-

My Dear Nev, I do apologise for my knee-jerk reaction to your original reply: I responded without thinking, as Neverenough reminds me, that English is not everyone's first language & instead assumed that I was on the end of another of those aggressive posts that are all too common on Social Media more generally. In the circumstances I am particularly grateful for your considered response above.1 point

-

As far as i know Seiko are fully in house and have been for a long time, so its probable that these are seconds sold by Seiko to various outlets, passing any comeback onto them. If they can sell thier mistakes instead of binning them then hats off to Seiko.1 point

-

They look like the real thing to me, maybe the shop that makes them send 100 out the front door to Seiko and then send 100 out the back door to these guys? They look so similar, the only issue would be if they use sub-standard materials, but as the rest seems 100% spot on so I would be surprised if they messed up on this step after getting everything else right. based on your pictures, my gut is telling me that you have the genuine item for a great price!1 point

-

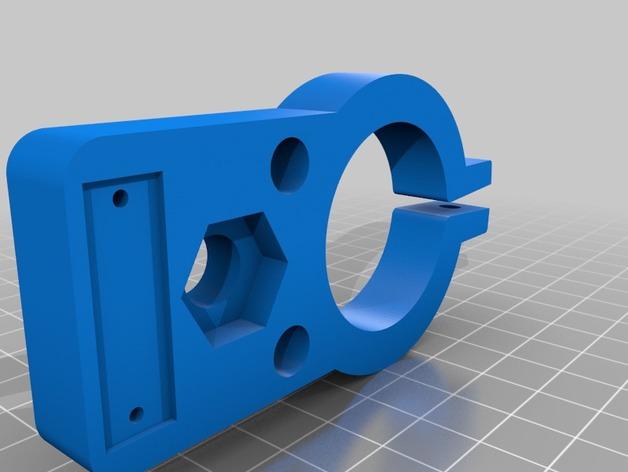

I use a similar setup using a Adonstar microscope from Amazon (similar to your link) removed from it's table mount. I attached it to a microphone boom arm with a 3D printed bracket. It stays above the bench and when I need it to take photos, I pull it down. It makes it easy to document a disassembly. The nice thing about the microphone boom is that it stays where you place it. I also added a light source.1 point

-

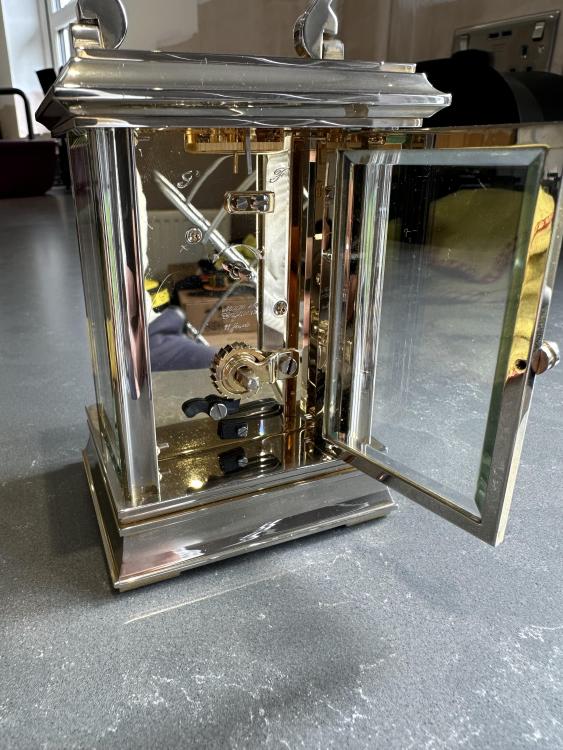

Needs a new balance staff. The hairsprings needs sorting out as well. Are you able to make one? You could look on ebay. You could get i touch with this person. Specialists in Elliott Clocks 14 Langdale Court Witney OX28 6FG1 point

-

1 point

-

Yep you're well on your way to being a tool junkie Ross. I think we spend nearly as much money on plastic cases. I have to admit I'm the same, I'm not pulled by the expensive brands at all and certainly nothing new or modern. If someone gave a Rolex i would sell it . I'm in my happy place using all the gadets and gizmos to fix the unfixable. Yoda1 point

-

I can't remember the last time I followed through, probably when i did a really strong curry a few months ago . Its just control watchie and its not the slightest bit difficult. I keep pressure on the stake between my index finger and thumb and both are pressed tight on top of the guide. The stake isn't going anywhere i dont want it to, a couple of sharp taps and the staff is free, i watch close with a x10 loupe, very easy. Better than a punch on it's own but I'd still rather learn to cut out the staff, will only carbide cut, ive read about a way to anneal the staff.1 point

-

I am certain that the bearing has sized to the upper housing. Try wiggling the post back and forth while pulling. Also try the heating idea1 point

-

Not long ago there was a discussion about a tool for grinding the bottom part of the staff togrther with the hub This is on the same principle as @Delgetti uses with His method. This tool is usefull specially for those who don't have or use lathe. I have seen similar self made tools in the russian forum and will try to give link here if manage to find the thread. Here is link with images of one http://forum.watch.ru/showpost.php?p=2410366&postcount=101 point

-

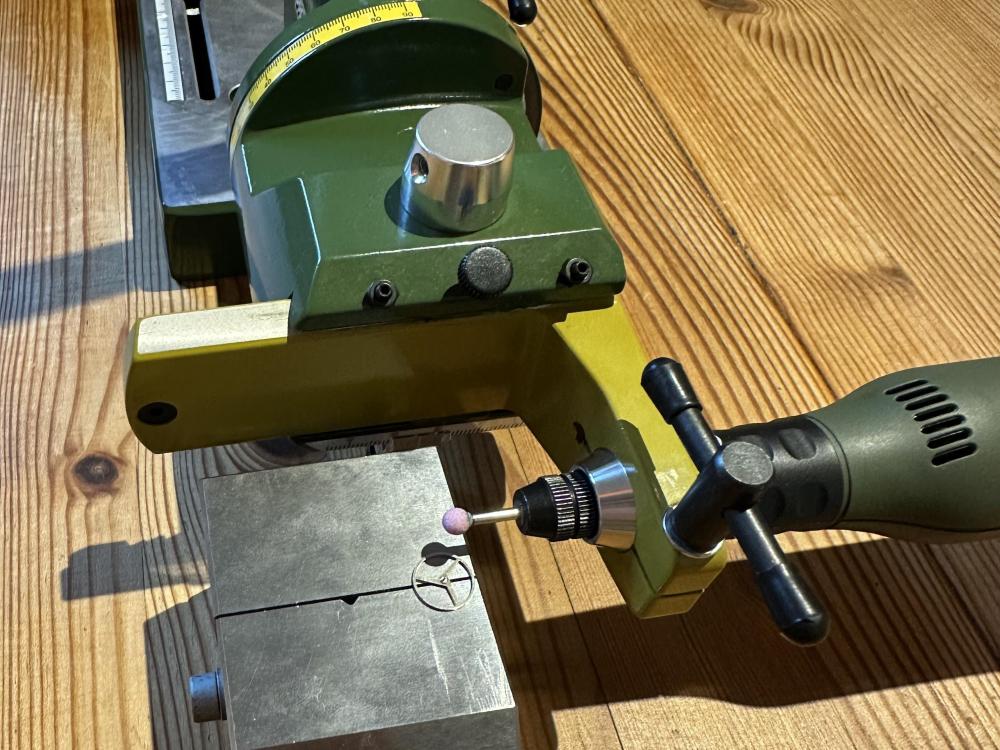

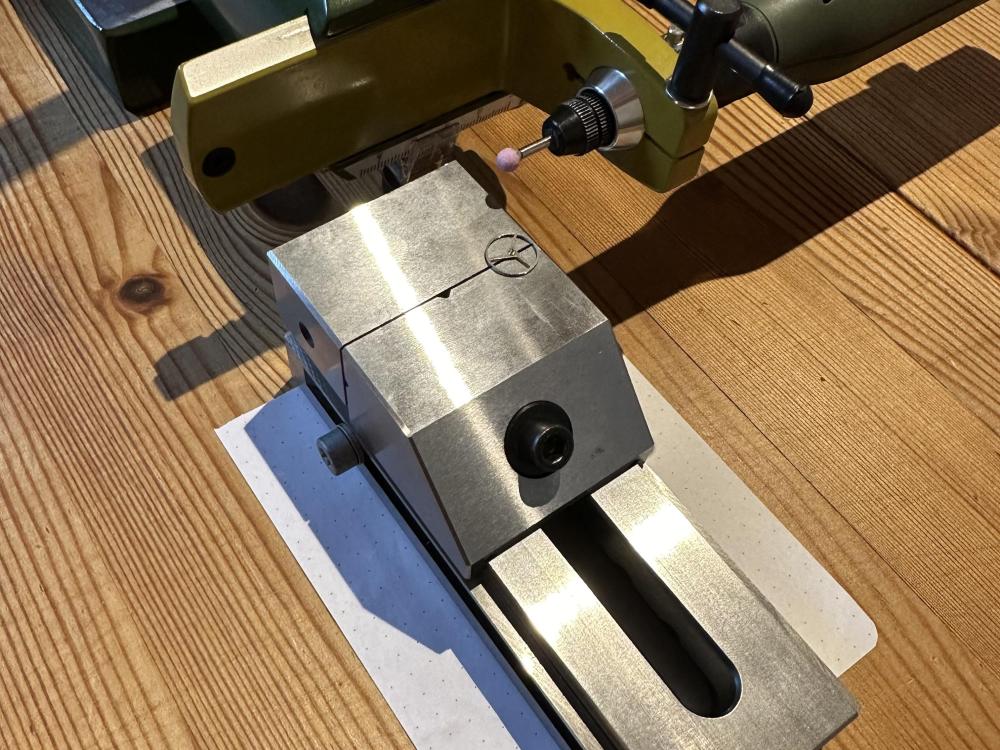

I don‘t have to do this task (replace balance staff) often, maybe one time in a year. As I ruined a Valjoux 72 balance wheel by pushing the staff out without any work on the staff before, I became a fan of the „grind the hub away“ method. So here is a description of my amateur without lathe setup. I put the balance in a vice, hub side up. I use my micromot with a ball grinding attachment. Then I grind the staff away freehand until the rest of the hub is maybe 0.5 mm. Then I put the micromot in a stand and adjust the height roughly. Now I grind away the hub step by step by putting sheets of paper (0.05 mm thickness) under the vice. Stand and vice have to be placed on a very flat table of course. When the hub is grinded down to about 0.05 - 0.1 mm you can punch it out in the staking set (correct support from the downside!), the thin rest of the hub will just break off, no damage to the hole, as many others already mentioned. As always you should first try this with a balance from the scrap box.1 point

-

I have done a few of these...one very recently. Please show pictures of the bottom. The set screw holds the stator and has no role in holding the two halves together, but it is ok to remove it. There is a bearing race that mounts at the top. Usually it separates from the housing, but not always. I have never tried this, but you might heat the top and see if it releases. I cannot recall if the two halves have freedom to rotate a full 360 degrees. Probably not. Could be a hard stop based on design. I feel confident that you need to break the bearing race loose. Be careful. If you decide to do some tapping with a hammer, use a rubber mallet or jewelers leather mallet.1 point

-

Now brace yourself for when you realize it has uses beyond watchmaking! Recently in another sphere of lunacy, I've been digging into leathers from different species to try to figure out how to tell the difference (specifically between horse and cow leathers). Also very useful for making/repairing electronics. Also, I modified a watch oiler (the biggest one in the set that never seemed to get any use) to fix skips in vinyl records. Also, I found micrometeorites in the driveway with my daughter (lots more coming on that front no doubt). Like you, I was very much on the fence about buying a microscope, and I have ended up using it for so many things beyond what I thought I would.1 point

-

I agree & would have appreciated such a request as "are you sure they are steel rather than electroplated brass?". More to the point, however, I am really grateful for your comprehensive post.1 point

-

My wife took these pictures today. Not sure if there is a message that I am supposed to get The first bench is the one from my Dad. The second is the one I bought from Maine. The third I bought from someone in Wyoming. The last watch bench came from Dallas. The other bench is just a converted office desk. The last picture captures a portion of the room. This was not staged...and I am a little embarrassed about how it looks. That's me and Cromwell.1 point