Leaderboard

Popular Content

Showing content with the highest reputation on 02/24/24 in all areas

-

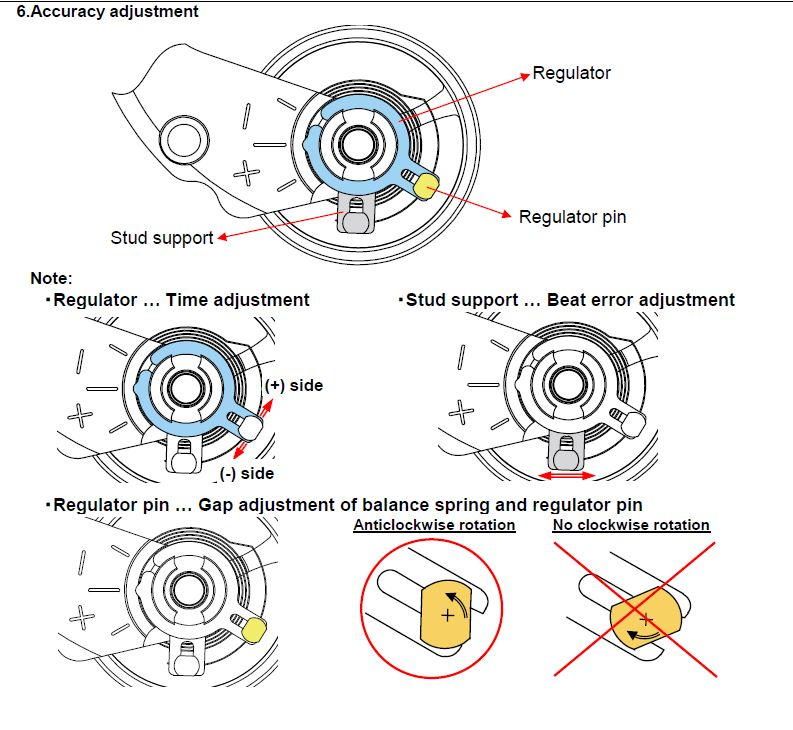

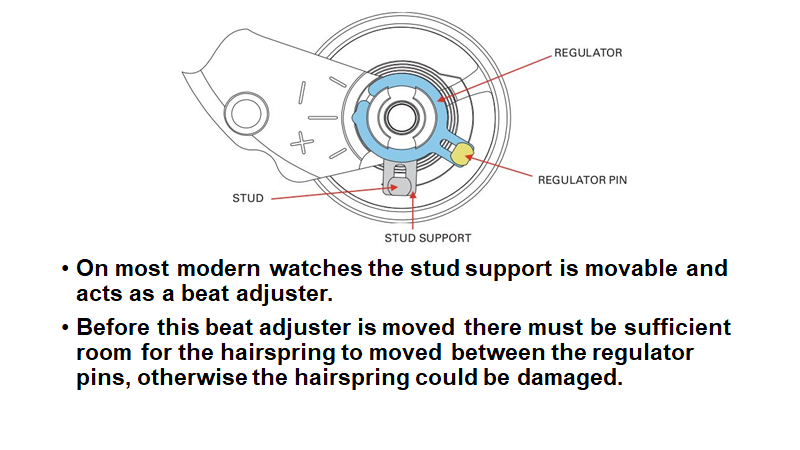

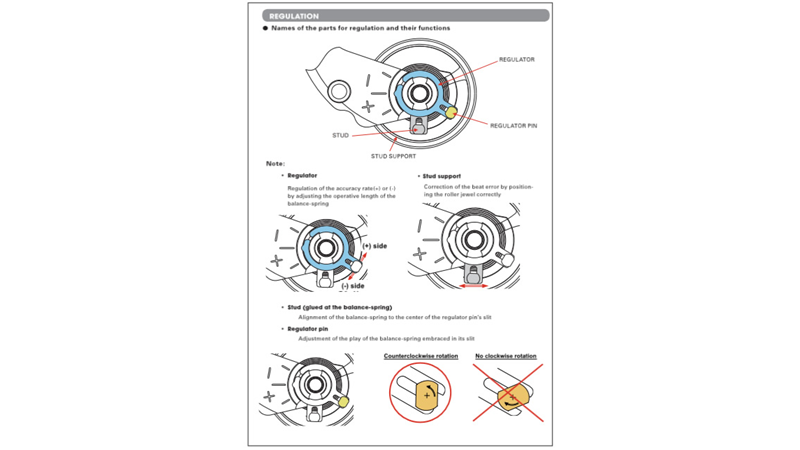

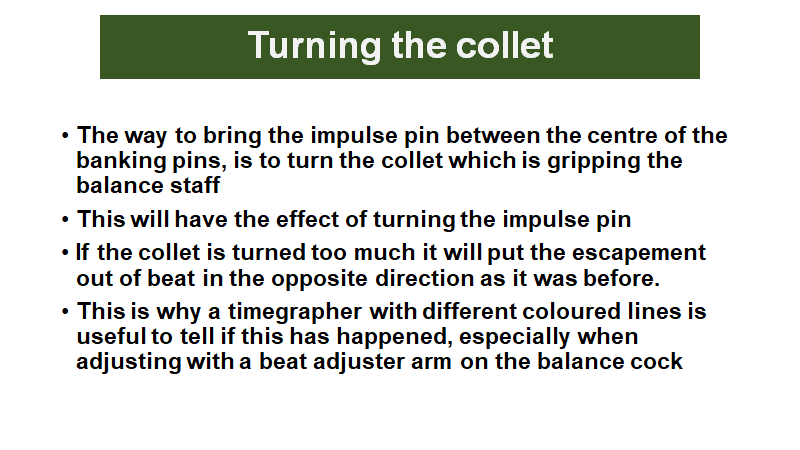

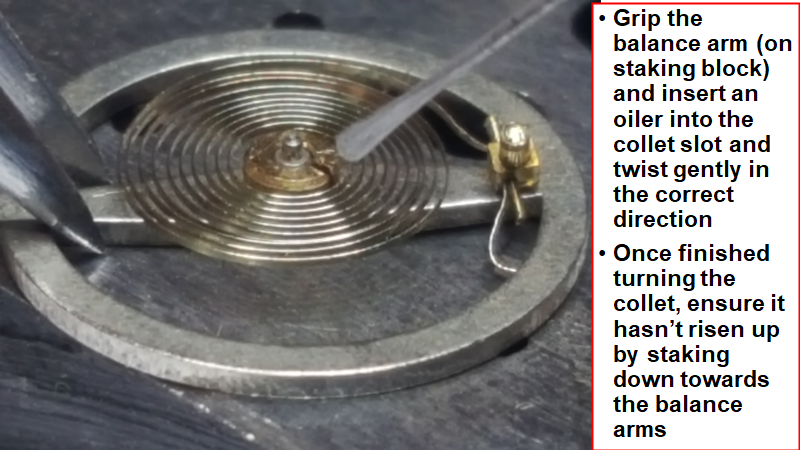

Thanks for this excellent tutorial and very fine illustrations @Jon! Really first class! I noticed that your image was a bit too small to read with ease, so here's a larger copy of it. I summarized @nickelsilver's method for adjusting beat errors to the following, but you can find all the info in the thread I linked to: “For everyday work, from the smallest ladies’ movements to marine chronometer, I set the balance with the cock on a bench block so the roller table is in a hole, balance on the block. Lift up the cock and move it over- not flipping it, just moving laterally, until I can see the slot in the hairspring collet, get in there and adjust (for tiny watches this is usually with an oiler, larger, a small screwdriver). Go back in the watch and check on the machine. I hold a balance arm of the rim with tweezers while moving the collet.”4 points

-

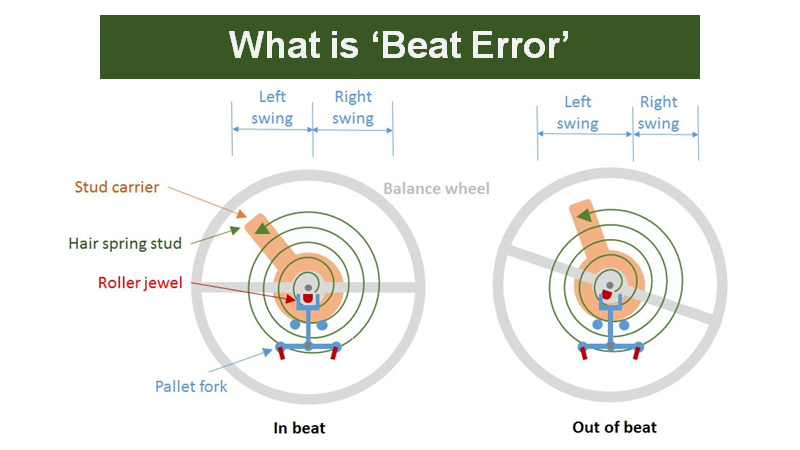

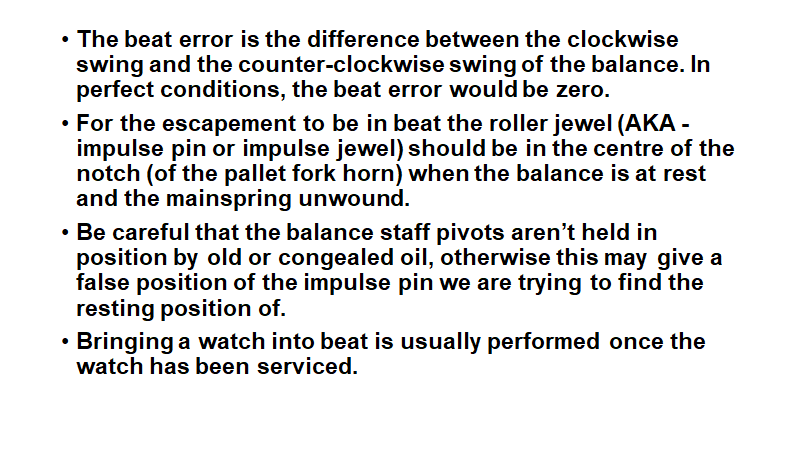

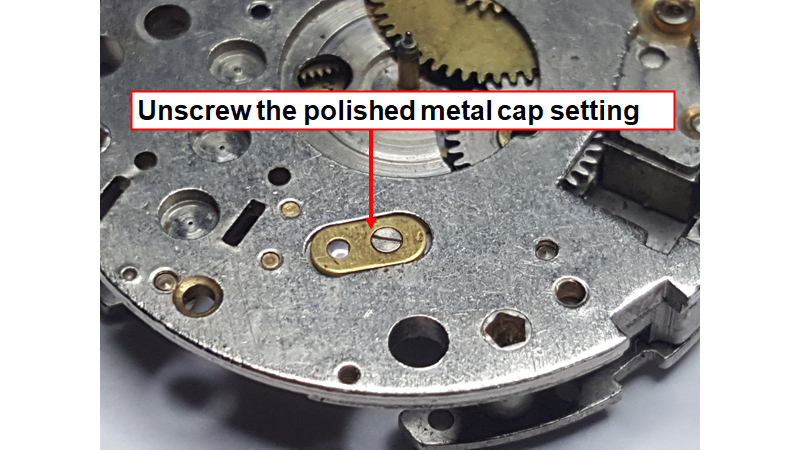

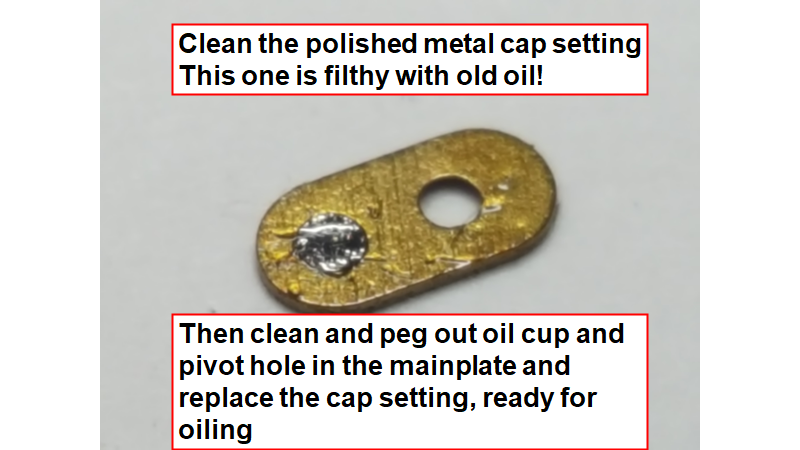

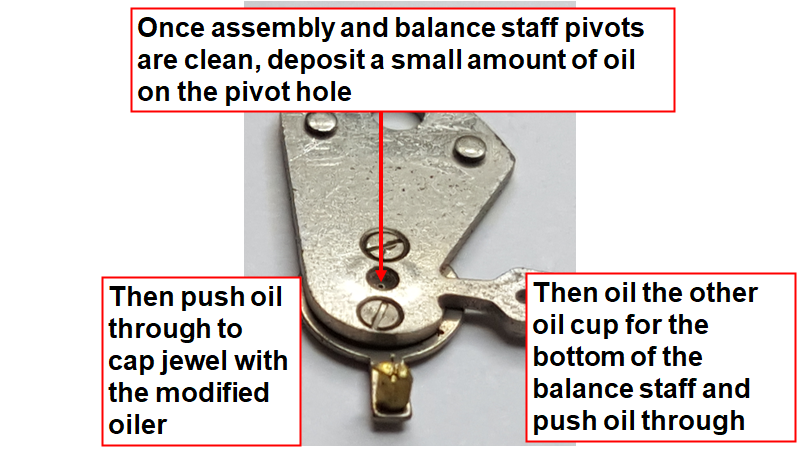

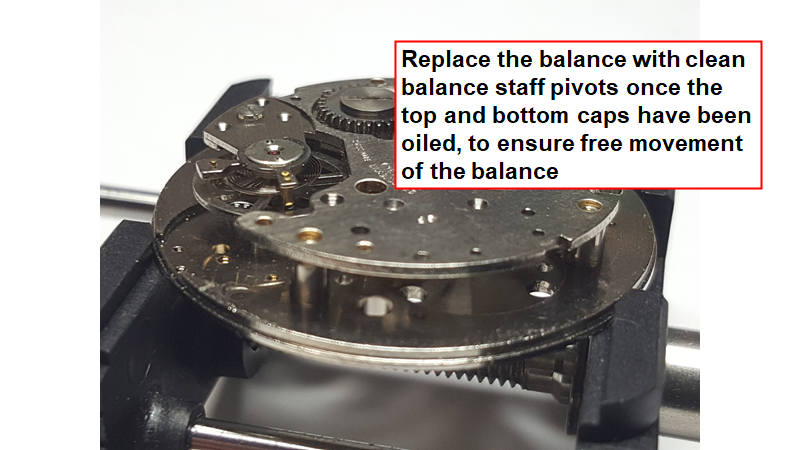

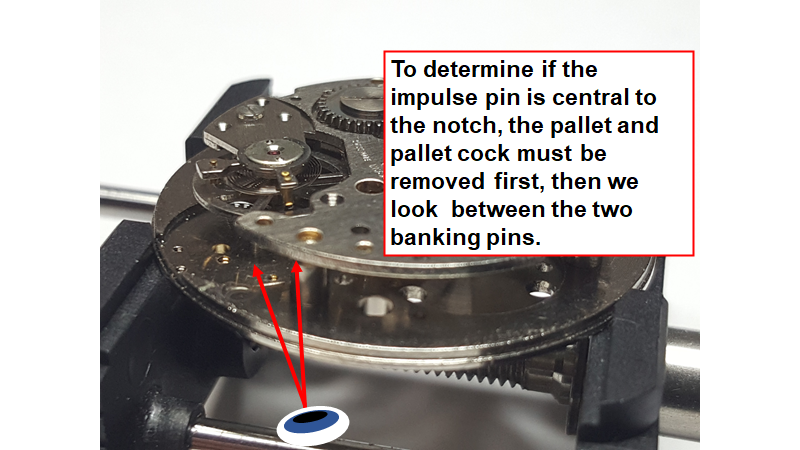

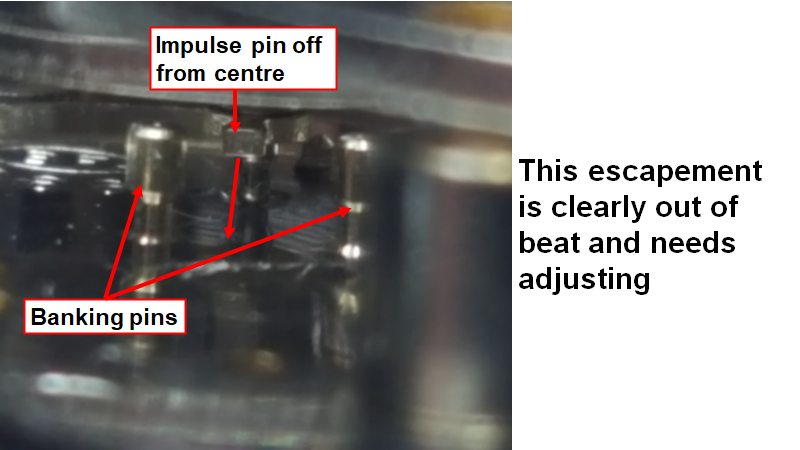

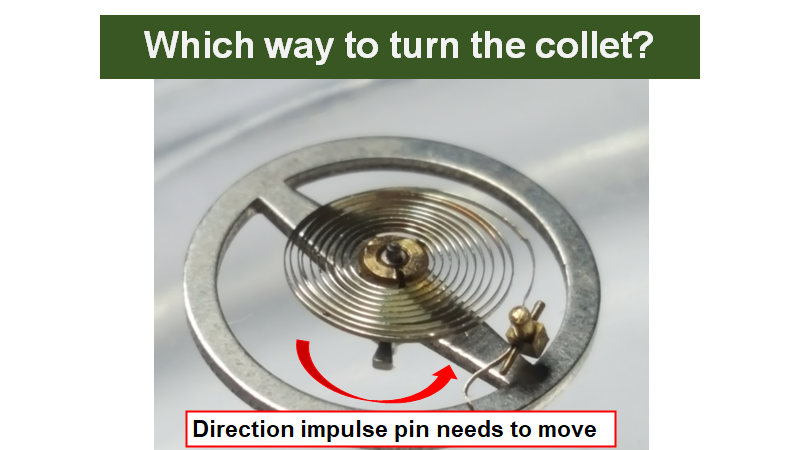

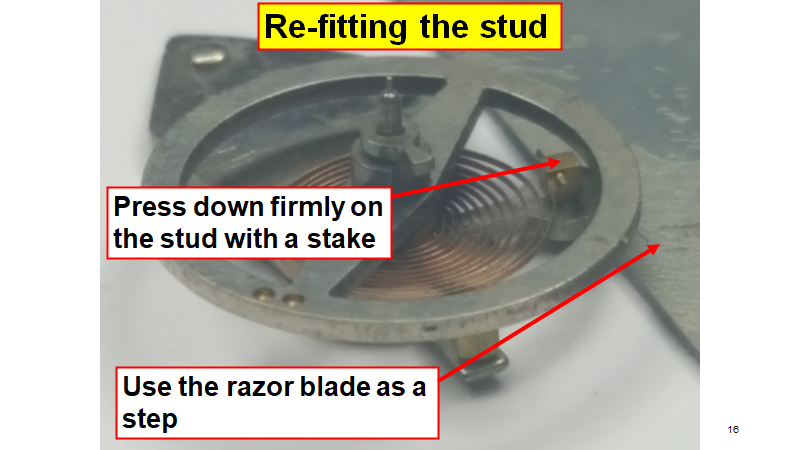

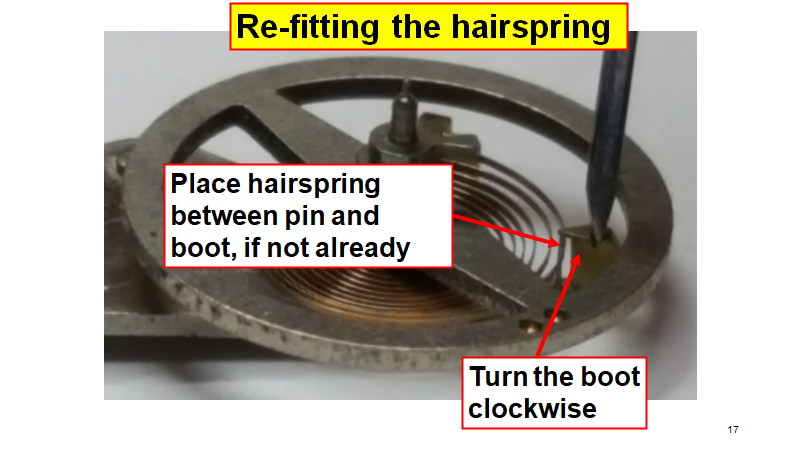

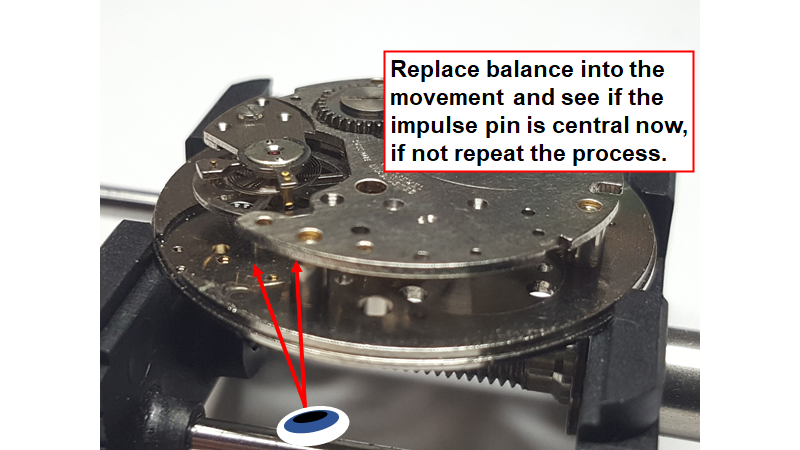

Hi, This is the third instalment on the Baumgartner BFG 866. I wanted to show how to bring the watch into beat On a previous walk-through of the BFG 866, I have described in detail how to remove the balance and hairspring to be able to oil the cap jewels As you look between the banking pins, the impulse pin is off to the left side slightly, putting the watch out of beat. The collet is turned in the opposite direction to the direction the impulse pin needs to move. So if in this case the impulse pin needs to move anti-clockwise to get it perfectly between the two banking pins, then the collet needs to be twisted in a clockwise direction You can attempt to turn the collet whilst fixed to the balance cock, but there is a much greater risk of damaging components, especially the hairspring. This is the way I teach my students, as it gives them the skills and confidence to remove the hairspring and balance from the balance cock and while removed they can oil the cap jewels as I've shown in this other walk-through on the BFG 866. I've got two more walk-through's on the BFG 866 that I'll post on the subject of adjusting the friction fitted minute wheel that is on the barrel and removing/re-fitting the centre seconds wheel and oiling the movement...3 points

-

For some inexplicable reason, I felt inclined to take my CycloTest apart That thought would never even have entered my mind before I started tinkering with watches. So, how to go about it? Well, there are a lot of screws in the front and since I have now, after six years of practice, learned to handle screwdrivers reasonably well I thought "How hard can it be". So I removed a couple of screws and heard a metallic sound as something detached on the inside. Shaking the thing I heard a loud rattling noise. "It was at this moment he knew he f-cked up". Oh well, having come this far I thought I might as well remove all the screws and then scrap the thing. After all, I wouldn't be losing a fortune. Anyway, these years of tinkering with watches have obviously and somewhat to my surprise taught me a few things. Patience, patience, patience, and even more patience. To my astonishment, after an hour or so I had put it back together. I gave myself a standing ovation! The trick, as I found out, is to open the thing from the back, not the front! Just thought I'd let you know should you for some inexplicable reason, feel inclined to take your CycloTest apart2 points

-

Unfortunately if you have used mild steel you will have little hope of hardening and tempering it, it simply doesn't contain enough carbon. You need to use a steel with a higher carbon content like tool steel or spring steel. One good source for this is engineers feeler gauges which can be picked up relatively inexpensively and provide a range of thicknesses of material. this will then harden and temper in pretty much the way you have described.2 points

-

If you live in the UK then you can take the exams at Upton Hall at BHI head quarters in Nottinghamshire UK. Since I live in the US, I found an invigilator in my town, approved by the BHI exams supervisor, to manage my exams here locally. My invigilator will receive the exam material and provide it to me at the appropriate day for the designated amount of time I have to perform the test. In the higher level courses there are some that you must take at Upton Hall in person (D9, D11, D16, D18 and D20). You can find more information here https://bhi.co.uk/training-education/examinations/ I still have to decide what level I want to achieve, but know my understanding of horology has greatly improved by the material I have covered thus far in this course.2 points

-

OK. So, high school AP level. Not exactly straight up CS, but something with substance. A raspberry pi timegrapher... wait for it!... that provides diagnoses. A Raspberry Pi should have all the computing power necessary, I'd imagine. The usual piezo transducer pickup. The usual timegrapher interface, like you do. But, and here's the kicker that puts it into money territory, diagnostics. You can show timegrapher outputs to the old timers here, and they can tell you "pallet depth is off", "bent wheel", whatever. This stuff is all in multiple textbooks somewhere, I'm sure. The other half of the money territory is the cost factor. By building it on a Pi, you can chase the low cost angle. Build a kit with the transducer, an adapter board, a touch screen, a case, and the memory card, you should be able to get the cost of this thing in the neighborhood of the Weishi jobs, but WAY better. People will fall all over themselves to buy these. So the easy part to get into the project and wrap his mind around it is obviously the basic timegrapher piece. The novel/challenging part is to give the machine the intelligence to interpret the output. The fun part is printing money. And I'd bet there's bonus points if he finishes early enough to sell a few on here, and can go to his teacher and say something like, "and I've sold X units so far across Y countries."2 points

-

Hi Fernando. Try this copy . TZIllustratedGlossary.pdf This is the original copy I picked up some time ago.1 point

-

Thanks Marc, clearly I have a lot to learn about metallurgy. I’d expect the cutting of tool or spring steel to be a lot harder to cut into a precise shape- I expect I’d have to anneal it first?1 point

-

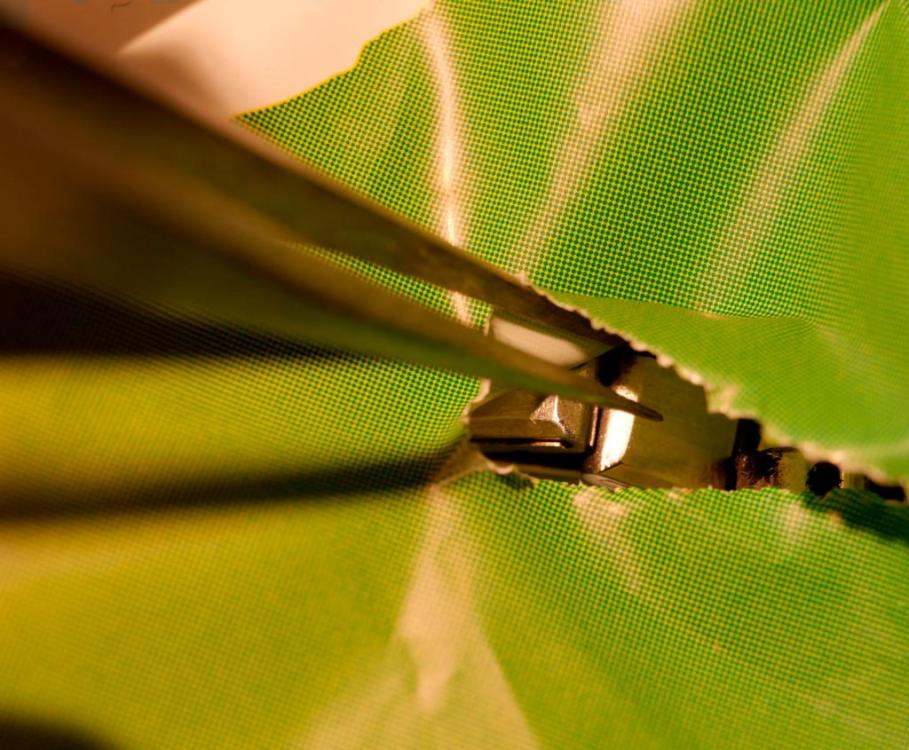

I'll don't take in account the 3 or 4 little springs that flew away and the same amount of hours I spent to find them Now I work under a bag in which I cut a slit when I have bad feelings with springs and I work like a surgeon . As I'm not sure the translation is correct, so to illustrate my current approach I took this picture. Of course I use a little transparent bag1 point

-

Hi Hiaz, I see you didn't get this link usually given to new members by oldhippy, here , useful stuff. 704789946_TZIllustratedGlossary(2).pdf 4.2 MB1 point

-

Yes. I understand (now). I regret to say that I am servicing watches without fulling understanding the cannon pinion function in relation with setting the time (and many other theory aspects of the orology!!!). If is too tight the hands won't move and on the contrary. If the pallet fork is not installed the train of wheels will spin freely and if the remontoir is on the setting position the motion wheels will also move. I will use HP 1300 for the cannon pinion setting. I am happy and grateful and of course I will report back as soon as I can. Thanks1 point

-

1 point

-

I haven't been keeping a written log or hall of shame, but I can tell you that my early attempts to unwind mainsprings have resulted in two barrel arbors entering the ionosphere. Still MIA. I've launched but subsequently found incabloc and trior springs, a few yoke springs, and a third barrel arbor, but those first two remain elusive. (and one was from a ST36... not a small piece of metal, really)1 point

-

good machine, glad you have the basket included.....I see jars and such every now and then on eBay for these....1 point

-

@Knebo, there is difference in behavior when the crown O-ring is tight and the cannon pinion is tight: if the resistance is from the cannon pinion, the free play in the gears when crown rotates forward/reverse fills like no resistance for some angle of rotation of the crown. If the crown is tight and the cannon is loose, then no such free play will exist. Another thing: If the movements work correctly but the hands stay in place, then the second hand must work correctly too and if observed frequentlyand compared to some quartz watch, this may help to understand what happens. It is possible if the rotor bearing is worn, the rotor to touch the balance wheel in some position of the movement, thus stopping the movement for a while1 point

-

Nickelsilver Showed this tool, must be nice to have, helps adjusting hairspring to a near zero beat error. Without the tool , I put the balance less hairapring back on the watch, Impulse pin inside the fork horn. Rotate the balance clockwise while keeping an eye on the fork which moves when impulse pin hits it. Rotate the balance counter clockwise , the fork move when impulse pin hits the other horn of the fork. You see an interval within which impulse pin hits either horn, at the midpoint of this interval your balance would be in beat. On the rim of the balance wheel ink mark the point thats right in front of the stud holder arm, where the stud is fiited. Remove the balance and instal hairspring with the stud right on the point you ink marked. Your in beat, not sure if the balance complete be in beat as well. lol I don't understand why this guy is laughing. . what so funny? Rgds1 point

-

I have cheap ebay tweezers from my first set. I do two things often. Demagnetise and keep them 'dressed', sharpened. The demagnetiser cost me £10. A honing stone cost me £3. that's it. Press the red button on the magnetiser, Demagnetise the tweezers by lifting them off the base ad going up. Release the red button. Repeat twice. Dressing. Using my magnifying glasses to confirm what I think I see. Shape and form the points. Dress all four edges and then gently removes burs. Job done. I use a pair of curved brass tweezers when working on an expensive watch that might show scratches. These were a massive £3 also. And, I do keep them dressed. Would I like high end tools. Of course, but to what end would it make my work better and this stage of my learning curve I ask myself? My standards are getting better by practice, not by high end tools. This is a great hobby1 point