Leaderboard

Popular Content

Showing content with the highest reputation on 02/23/24 in all areas

-

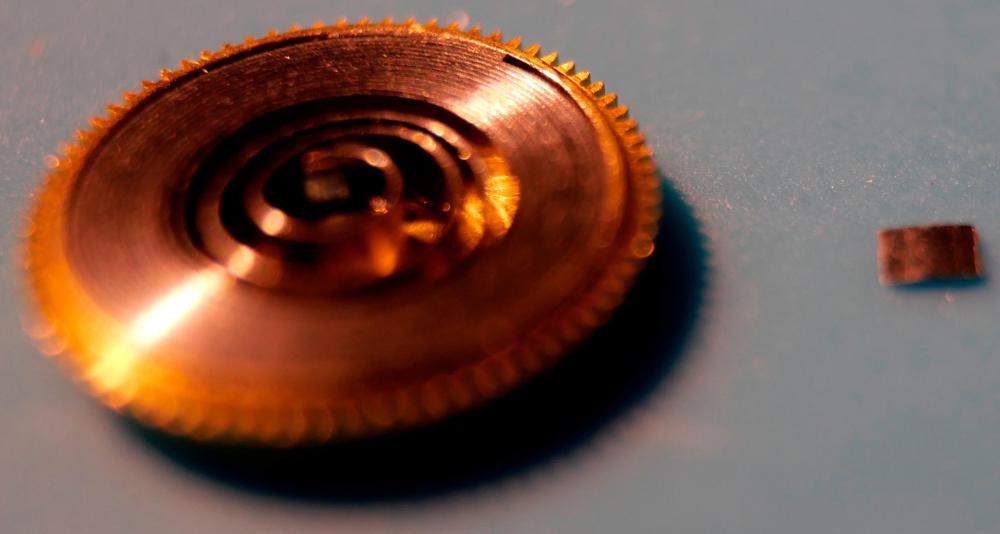

I spent some of my spare time, this last weeks, to set up a logbook system that fits me, helps me to follow my progress and my stocks and more. I also started a "Tableau de casse", a word game in french like hall of fame/shame, literally a table of broken One diafix on a Seiko Lord Matic : I spent time with this diafix to remove the jewel, and when it was time to put it back, the diafix was blocked. I tried to move it forward without success. Backwards, sideways, then I forced it a little (too much)... I found some spare in china. Extracting a scratched glass on a Seiko Lord Matic Deluxe (buying the right dies will help): First sprint put back in its barrel (almost, except one part...): From this broken one. The first time it's difficult to hold the winder and push the end through lunge... I hope I'll do better the next time! And you, how do you manage your evolution ?2 points

-

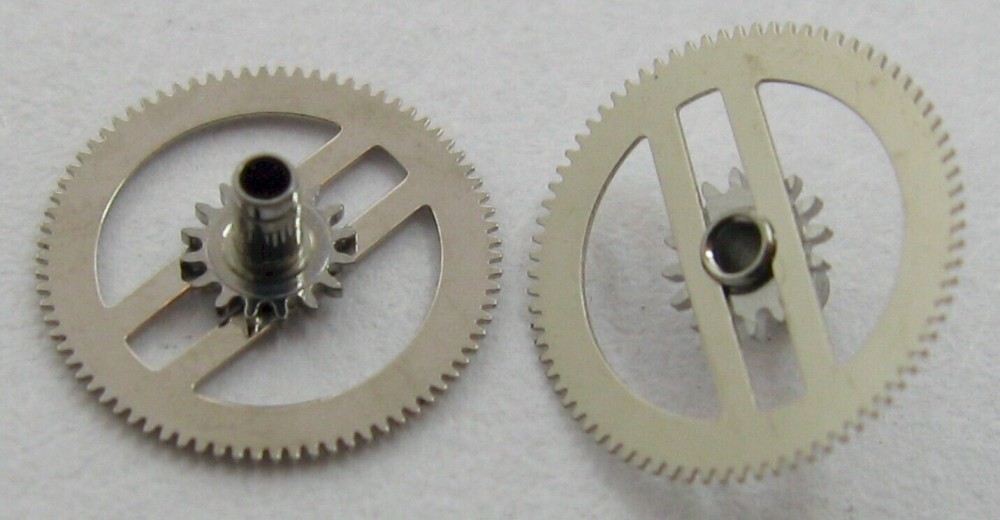

Just to be clear, when the watch is assembled and the setting position is stiff, the hands still move, correct? By removing the pallet fork you allow the train to run freely, so when you put the keyless works in the setting position, the cannon pinion won't slide and you are turning both the motion works and the train. The 2970 uses a cannon pinion wheel setup like this Make sure you've lubricated the contact points between the wheel and pinion.2 points

-

2 points

-

2 points

-

Oops, had only bridge shape/ layout without image of the keyless. I only make few hundered mistakes aday.2 points

-

Regardless of what the cause of the problem may be, as long as the option is open to return it to the seller, I would say return the watch to the seller and let the seller sort it out. As soon as you open the watch, that option is out of the window and it becomes your problem / responsibility; could be simple & cheap or costly ........ ? AND; a good Rolex shouldn't have any of those problems ...2 points

-

1 point

-

1 point

-

OK. So, high school AP level. Not exactly straight up CS, but something with substance. A raspberry pi timegrapher... wait for it!... that provides diagnoses. A Raspberry Pi should have all the computing power necessary, I'd imagine. The usual piezo transducer pickup. The usual timegrapher interface, like you do. But, and here's the kicker that puts it into money territory, diagnostics. You can show timegrapher outputs to the old timers here, and they can tell you "pallet depth is off", "bent wheel", whatever. This stuff is all in multiple textbooks somewhere, I'm sure. The other half of the money territory is the cost factor. By building it on a Pi, you can chase the low cost angle. Build a kit with the transducer, an adapter board, a touch screen, a case, and the memory card, you should be able to get the cost of this thing in the neighborhood of the Weishi jobs, but WAY better. People will fall all over themselves to buy these. So the easy part to get into the project and wrap his mind around it is obviously the basic timegrapher piece. The novel/challenging part is to give the machine the intelligence to interpret the output. The fun part is printing money. And I'd bet there's bonus points if he finishes early enough to sell a few on here, and can go to his teacher and say something like, "and I've sold X units so far across Y countries."1 point

-

Buying an existing stem/crown combination always carries the risk that it isn't quite long enough. Best to get a new stem and fit it to your crown/case combination. Cousins will be able to supply a suitable generic crown.1 point

-

if it's a serial number it's not a very unique serial number. It is probably more likely and what it looks like is a casing number. then searching for that we do get better pictures at the link below. https://www.ebay.co.uk/itm/2244100665811 point

-

I haven't been keeping a written log or hall of shame, but I can tell you that my early attempts to unwind mainsprings have resulted in two barrel arbors entering the ionosphere. Still MIA. I've launched but subsequently found incabloc and trior springs, a few yoke springs, and a third barrel arbor, but those first two remain elusive. (and one was from a ST36... not a small piece of metal, really)1 point

-

I see all the suggestions above as what we would like, not what would be innovative and impressive for the young man to achieve in the current IT world. my suggestion would be to look at a machine learning application to diagnose mechanical Watch issues from an input form. something a bit different and also challenging whilst being very relevant in today’s IT world. Tom1 point

-

I believe the discussion use the word Rolex and that means it's pretty darn hard to get a document for all the various Rolexes. There is a seller in Italy though you could purchase one they are but as far as PDFs go there's not a lot of them out there. Plus they all look really really bad typically which is interesting is the newest manuals are really beautiful in color at least they were up until they went purely online and when none of us will ever see those. the amplitude would be fine as long as you're in the right position the image you showed way up above look like it was dial down that is not the right position this is a interesting remark? In other words your friend is buying a defective watch and hoping you will fix it? So why exactly is the watch being sold in what condition is it being advertised in? One of the problems with Rolex and other high-end watches is people often times past their problems on to unsuspecting buyers. There is a series a Rolex watches where the base caliber runs at one frequency but the others run at different frequencies and often times we get these watches with awed timing stuff because someone did a mixing and matching of components to make a watch and then pass it off as it has a minor issue. So where is buying this should get some sort a guarantee that the watch is actually an perfect running condition which it's not if you're looking at it as somebody may be just passing problems on to the next person which is why you're having a problem1 point

-

looks good on the timing machine fully wound up but what does it look like on the timing machine 24 hours later? then if we look at the three items what is the difference we see? Fully wound up on the timing machine with limited motion. Sitting calm and relaxed overnight with no movement then I assume on the wrist the watch moves around? We don't get a picture the dial side how closer the secondhand for instance to the crystal? You're asking for gases there is a guess not a good guess but sometimes the hands to rub I would be much more interested in seeing what it looks like on the timing machine after eight hours on the wrist is still have the right amplitude how does timekeeping look.1 point

-

Since 2017 I've been working, On & Off, on this 1975 Mark II. The story in between would be the size of a novel Some worn parts replaced with NOS, adjustment of the pallet-jewels, old hands restored etc etc etc ....... My next wish is to restore the case, but for that I need to learn new skills and search for additional tools / equipment ..... story to be continued Anyhow, here the current Before and After; Before (2017): Currently (2024); With this speed I hopefully will get old enough to finish it off1 point

-

1 point

-

See, there ia another, more correct way to do this job. I will describe it and will use word 'chain', as in the most cases it really is one. 1. The movement is assembled without the chain and the lever (or the verge, if it is a verge escapement), the train is oiled and the wheels turn free. 2. Attach the chain to the barrel and rotate the barrel to the direction to wind entire cain on the barrel. Then attach the other end of the chain to the fusee and force the barrel to strain the chain and to bring the train to motion untill no more motion is possible, and the chain is pulled to the end, at this point it will be perpendicular to the fusee wheel. 3. Holding the barrel as to strain the chain, put the ratchet wheel, wind the spring a little (about 1/2 turn) and engage the click. This is the procedure to put the chain in place. Next is the first winding and the check and adjustment of the torque on the fusee. Block the train and start to wind the spring (by turning the fusee arbour) Observe how the spring goes in the channel of fusee and if needed, help it to go in the channel correcty, do not let it go out of the channel. This is only when first winding, next times the chain should go where needed by itself. Observe if the end of winding is limited by the limiting device correctly. Then release the train and let the spring unwind by train turning. The torque on the fusee wheel must be equal all the time (this is the aim of the fusee), this can be evaluated by the 'speed' of the train spinning. If near the end of reserve speed reduces, then the initial tension of the spring must be increased ( by the ratchet wheel position) and wice versa. As You have replaced the spring, have in mind that the fusee has been calculated and made to equalize the original spring torque, so it is not obligatory to be able to fully equalize the torque of the new spring. Also, if increasing the initial tension to much, it is possible to reach a momment when winding the spring to the end wil get limited by the spring end, but not by the limiting device, which is not acceptable.1 point

-

When the day disc is in place, it kicks it up anyway. So, the actual issue was that the Unlocking yoke maintaining plate was not installed right and was not holding down the date indicator driving wheel. Its back together and working, but now my winding stem no work right, so ill be "practicing" some more1 point

-

1 point

-

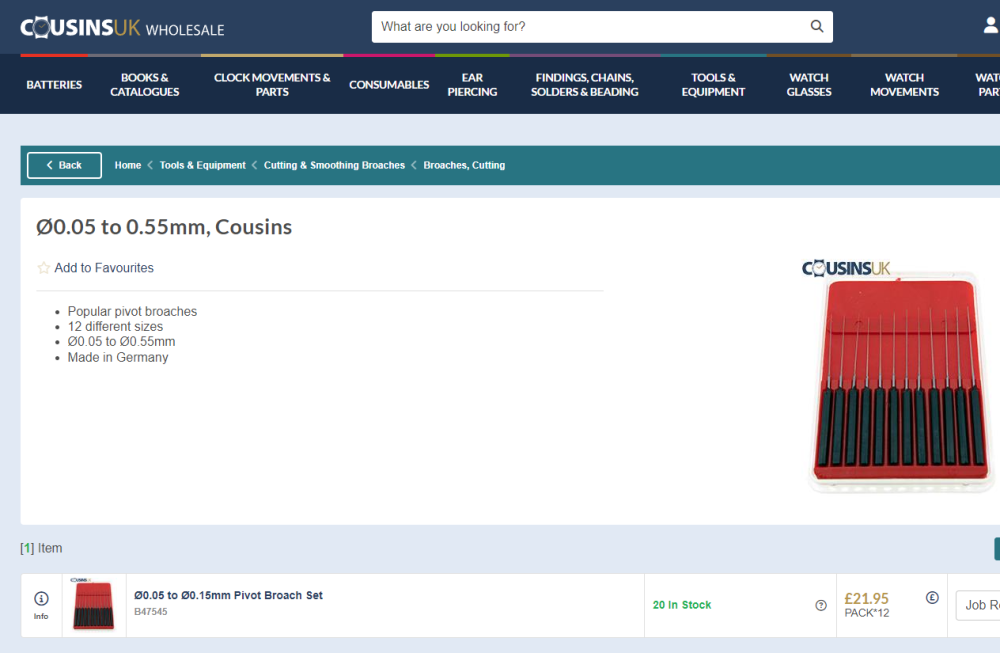

Some seconds hands can be tricky, the tube on the hand can be misshapen or sometimes have a little paint in them from the paint used to colour the hand, this reduction in internal diameter can make them a very tight fit. You did the right thing in walking away, trying to force it may damage the hand or worst case the pivot onto which the hand fits, then you have a much larger issue. If you suspect what I am saying is correct you have 2 options: Use a different seconds hand Use a broach (like the ones below) to open it up slightly (in baby steps!) Let us know how you get on - pictures are a big help too (hint)1 point