Leaderboard

Popular Content

Showing content with the highest reputation on 01/25/24 in all areas

-

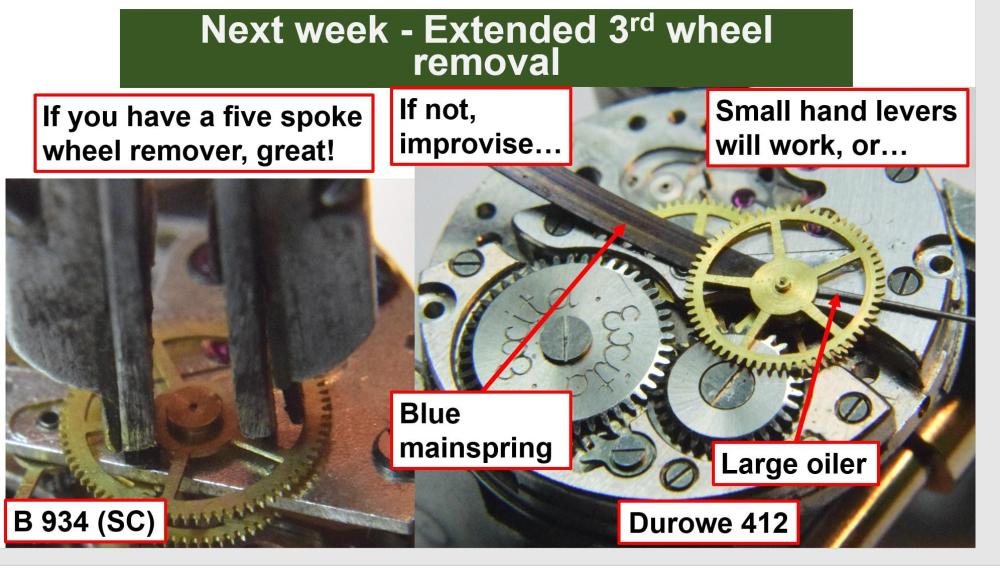

Waggy. Decided against the tools. Actually made a pair of extend levers as shown. Bent wheels twice. Will stick with my peg wood. Chronoglide system works perfectly. Place two pieces of cut pegwood through leaves and to base of hub. Rotate both back and forth in fingers slowly. Believe it or not, the gentle pressure lifts the wheel. Takes a few minutes, but always works. As the wheels were pressure fit, this is the reverse. No damage to wheels at all.5 points

-

I originally put the barrel cap in a step chuck and enlarged the hole to receive the bush. So the hole should have been centered to the barrel cap. But the barrel wobbled terribly when it put it back in the movement. So, I cut out the bush I put in last night and put in another one. But this time I fitted the cap back into the barrel, then I trued it up in my 4 jaw chuck and finished the hole receive the arbor. It runs true now. I checked my step chuck just now and I think that it was the problem. For some reason, the step chuck doesn't run true. Looks like I've got to chuck the chuck.3 points

-

2 points

-

2 points

-

Don't you just love the people on this forum. Just made a tool for closing a cannon pinon that is loose. I had tried to close a cannon pinion by using my Staking set, but applied to much 'hammer'. Actually pierced the pinion Saw this DIY on this forum, made by a member. I have now converted a nail clipper. Taken out the plunger. Inserted a bolt, made it solid with a filed down nut and then put another on the top. I now have the facility to do what he did. Using the flat edge as a gauge I can apply pressure to about 1/1000" depth. Need to file the cutting edge a little. But it looks ok.2 points

-

2 points

-

Sorry, I didn't see this untill now. Well, I use this tool for removing the roller. If You look at the video, in the beginning, the roller is removed for 2 seconds, by the same tool... The other thing I use the tool is for removing the wheels that stay on the 3th wheel pivot and drive the seconds center pinion, and in chronographs on the 4th wheel pivot and drive the chrono Oops, now that i checked, I have put wrong video, my mistake... The correct one is here https://www.youtube.com/watch?v=PzdtN7F_YVc2 points

-

Often (usually?) step chucks are soft enough to turn. They have a through-hole of a given diameter, chuck on a piece of bar there, then you can retouch the step/s. Make sure there aren't any bumps or burrs on the cylindrical and tapered portion that fit in the lathe first! If the bushing needs to be flush on the inside, I like to cut a small step (can be very small, like 0.2mm deep and bigger on diameter), and make the bushing with a corresponding lip, so when all pressed together it's almost impossible for the bushing to accidentally push out.2 points

-

Each wheel in the train has less torque than the previous. You notice when under power if you hold each wheel back the escape wheel has the least pull. The lever has less, plus the escapement takes a big chunk of energy on the draw. Add to that some waning amplitude and whats left is some pretty pathetic torque. I would assume any oiling to the lever pivots is more robbing energy than lubricating. If it were to be lubricated you would expect it needed to be so thin that it runs everywhere and have to rely on a retaining application to keep it in place. Maybe the torque is so low that the only lubrication it needs is air friction ?2 points

-

G'day all, with about 3 years to go to retirement and intending to downsize to a smaller house my current woodworking interests are unlikely to fit into the new digs. I needed a new hobby and as I've always had an appreciation for watches it was a pretty easy call to switch to watchmaking. I am starting out with Marks course and with the sale of my woodworking gear I am looking forward to the purchase of some new toys....errr...tools I am primarily interested in older mechanical/automatic movements and and odd quirky watches such as those from the soviet era. I also hope to pick up the odd project at op shops etc.1 point

-

1 point

-

Yes Ross, the people on this forum are brilliant. Could you use a wing nut instead of the ordinary nut or would there be too little torque? Ps , you could add washers to limit the closure.1 point

-

nevenbekriev, please except my apologies, I didn't realize it was the same type of clock. I have removed it.1 point

-

Good tip Ross. Easing the tapered tip of a sharpened pegwood under the hub with some rotation can work really well. Another is Alex from about time uses 2 brass rods with a step cut out. The idea that the pegwood can be compressed without damaging the wheel.1 point

-

You have no idea. I’m recruiting my aspiring film maker nephew to produce the music video- gone viral by this time next week. If you have a headbanger in your collection- you’re welcome1 point

-

Welcome to the forum! Sounds like a fun retirement I started out with a soviet watch. It's possible but not necessarily the easiest. Just make sure you start with a watch that already runs. You could also buy two identical watches (or a spare movement) right away to have spare parts ready to go -- an additional movement won't break the bank and probably save you some frustration when the first shock spring disappears into the "kosmos". Cheers and good luck1 point

-

1 point

-

Hear Ye! Hear Ye! Let it be known thru ought the land every Bobble Head Mickey or Minnie Mouse shall henceforth be recognized as HEADBANGER Mickey and HEADBANGER Minnie! So sayeth ZANDR and WIFE OF ZANDR!!!! One of theseand one of these1 point

-

My mistake. It should be (R_outside² - R_inside²)*pi*21 point

-

Got there in the end, with some lessons learnt : 1. Copper plating is a great base layer to fill defects. It requires a lower temperature than nickel, and is easy to do (but you must use the proper PDO copper anodes). 2. Don't be too vigorous with polishing the nickel ! I put on about 20 microns, but still managed to go through on an edge when trying to polish out a defect. I ended up re-plating the nickel which I wasn't sure would stick, but if you activate it with acid correctly, there's no problem. I'm happy with the results. To the naked eye it looks good, with defects only really visible under magnification. I'm still getting a few micro holes, I'm not sure why. Before After (it's really hard to take pics of curved shiny surfaces) Now to fix a VERY embarrassing and expensive error I made when servicing my Breitling Aerospace1 point

-

1 point

-

It does adjust the beat error however they are co-dependant. If you move the orientation of the stud then the regulator will be in a different position. The converse can happen too if there is friction between the stud mechanism and the regulator mechanism, I have done a few where I have had to figure out a way to keep the stud mechanism in the same place to adjust the regulator. Tom1 point

-

one of the basic things when servicing a watch is separating the balance from the watch. But all of these watches seem to have the balance bridge still attached weird? if this was a newer watch with the etachron system I could see why you keep it attached but to remove it from the bridge is so simple and no you don't need a microscope.1 point

-

You can do it Ross. You understand learning technique i know you do. Yes that was the worst i ever managed to bring back to some form, i have a picture somewhere as it was coming to a finished state. It wasn't perfect by all means and easy to see that it had had some distress, i think there was one slight shallow verical bend that i just couldn't remove but that watch ran quite well with it. Been doing them almost from week one out of necessity and insanity, wierdly i enjoy it which really helps. I use a pair of no 7 tweezers, thats the curved tipped ones and a bent acupuncture needle set into a piece of pegwood or a narrow fitting pinvice ( i call that a pick , the one in the picture i use to twist the hairspring to raise or lower out of flat springs ) mostly. I hold the tweezers very differently to standard practice to get the correct working angle. The bent tweezers help with coming in on top the hairspring to straighten the out of round bends ( these are the bends that make the coils touch together when looking down on the hairspring) Stability is key here, you will noticed massively hand and finger shake without very good grounding of the wrists or palms of the hands. To further the angle of the tweezers and pick they are slid between my ring fingers and index fingers this helps to keep your hands stabilised while manipulating. Start from the inside of the hairspring and work out . With out of round bends find the largest gap ( coil running outwards ) or smallest gap ( coil running inwards ) and work back 90° into the hairspring, this is where the bend begins, this the manipulating point. I always remove the inward bends first otherwise the hairspring coils will come in on themselves and get tangled up. The out of flat bends and twists are another game altogether, these are the ones that raise the hairspring up or down when looking at it from the side. The twists are quite easy but the bends along the height profile of the hairspring are a real pain to fix. But i wouldn't worry about the out of flat for now, there may not even be any. Some of the correcting you might be able to do with it is on the balance and maybe even with it in the watch. A really common issue of the hairspring bunching up can be just one little correction at the stud. Do some research and make a start see where you get with them i have faith in you Ross, learning to fix them can save you a fortune in replacement balances.1 point

-

Ross, taking balance out of the bridge and putting it back is something simple. Why microscope? Just a small screwdriver needed to open the regulator and untighten the screw of stud carrier. Then the balance gets out, piece of cake.1 point

-

Hi Waggy. Send it to Nucejoe for a dose of the coke treatment, sit back and wait for the return. It does work but this one may be too much,1 point

-

Thank you for this thread... I have a bobble head (or as we called it, 'headbanger') Minnie to get running for my wife. As a newbie, I would have been lost as I started taking this thing apart.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)