Leaderboard

Popular Content

Showing content with the highest reputation on 01/08/24 in all areas

-

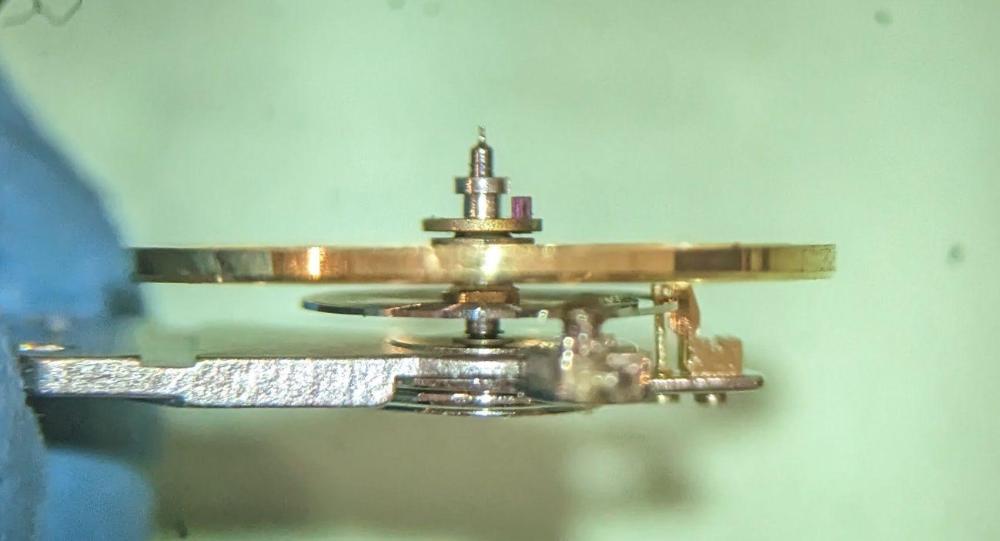

1973 Bulova Sea King HH. Before and after pictures. The bracelet was not original but a Hong Kong special with lots of wear and DNA. Could use a new crystal but the old one cleaned up okay and I plan to work on it more. Added a blue leather rally band. The dial is almost perfect as are the hands except for a loss of some lume. This would be a good case and crystal to practice polishing on as well. The case was difficult to open but the gasket did it job and the movement is clean. definately needs a service with the low amplitude.5 points

-

Just made a program to download all issues I could find of the AWCI Horological Times to my OneDrive. I hope I didn't do anything illegal, but I'd be happy to remove the files in case I did. Enjoy! https://1drv.ms/f/s!AnVrKJ9agkNWkfFk72cqE5ISkNJ78A?e=mYbidJ3 points

-

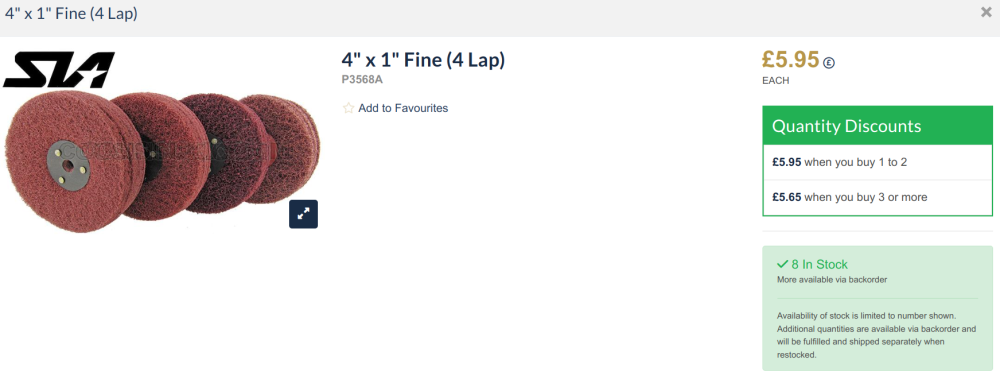

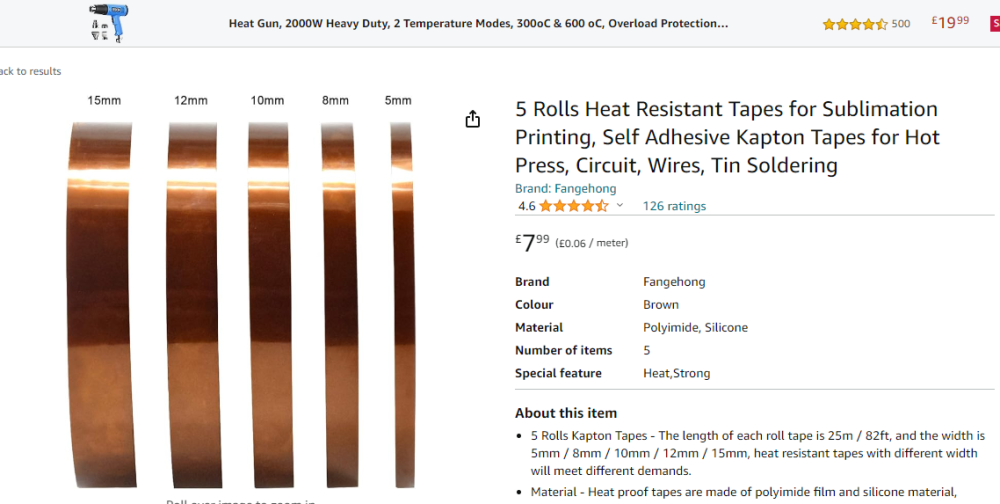

I used these lap wheels which feel like those green scotchbrite pads you scrub your dishes with from our friends at CousinsUK: I have a few of them, the fine gives a frosted effect where its less obvious the direction of brushing, the medium (I think I used in this case) shows the direction, and the course I use when the brushing is a very visible feature You should only use these lapping discs after you have buffed and polished the rest of the case - I mask off the areas I don't want brushed with heat tape, helps to use a fresh razor blade to trim the heat tape. Here is an example of the finish from the fine disk:3 points

-

3 points

-

Due to my location (and I'm a cheapskate) it takes around 2-3 weeks to get a new crystal, hence I have had to develop my acrylic crystal refurbishment skills to revive the original crystals that come with vintage watches and I thought I would share how I do this as I now have pretty good results, assuming the crystal has only scratches and no cracks or chunks missing here is my process: Use 320 grit wet-dry paper over the entire surface of the crystal evenly to remove the deepest scratches - hold your nerve, this will look terrible after this step Use 600 grit wet-dry paper over the entire surface of the crystal evenly to smooth out the results of the step above Use 5000 grit wet-dry paper over the entire surface of the crystal evenly to further smooth out the results of the step above Use Autosol metal polish (see below) in small circular motions over the entire surface of the crystal evenly with a cloth until the paste disappears, may need to repeat this step 2 or 3 times, this will get you 95% of the way there Use Autosol acrylic polish (see below) in small circular motions over the entire surface of the crystal evenly with a cloth until the paste disappears, rarely have to do more than one application, this will finish the job Side note: I have tried the Autosol acrylic polish side by side with Polywatch and there is no difference in the performance or how it looks/feels - I even got my son to decant some of each into containers in a double blind test and the results were indistinguishable. Hence, in my experience, the only difference is that gram-for-gram the autosol acrylic costs 3.7% the price of the polywatch. Here is a quick example of before and after using the above process:2 points

-

That's right, polish entire case to high shine, then after this just brush finish the bits that need it.2 points

-

2 points

-

2 points

-

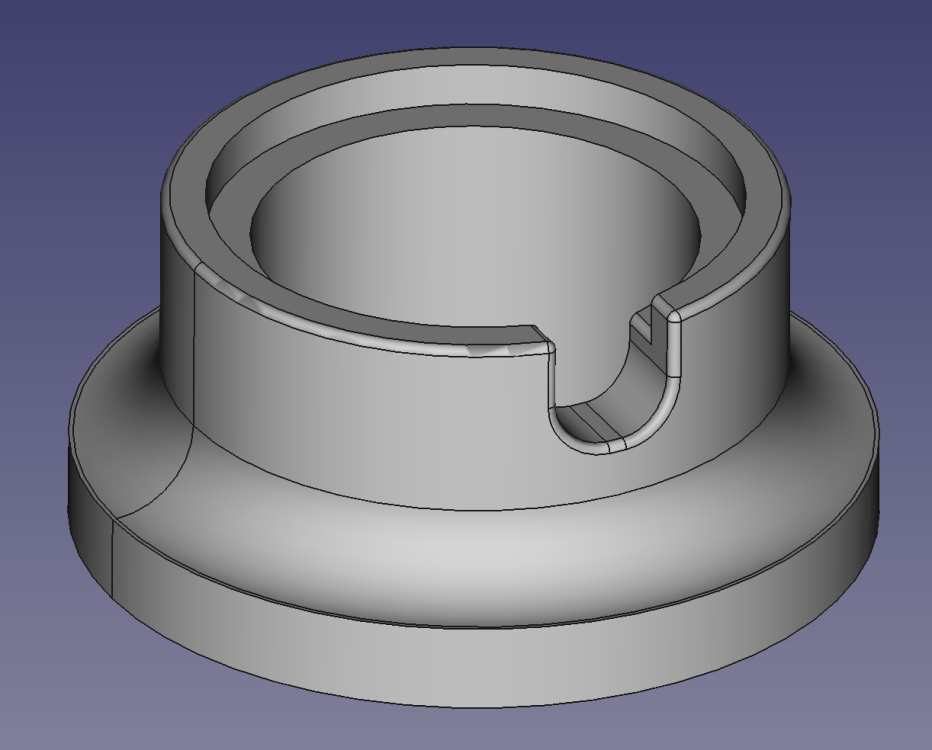

New version of parametric movement holder, link HERE, updated based on feedback from other WRT members and removed a few bugs. I have printed in PLA+ and PETG and prints well, rendering below: I uploaded FreeCAD, step and .stl versions to printables web site as this seems to have replaced thingiverse as the go-to place for 3D models - opinions? Note, parametric functionality only works in the FreeCAD file version All you need to do is measure your movement outer diameter (OD) and then put this value into the model spreadsheet and it will generate a bespoke model of the holder to fit your movement that will look something like the one above. Depending on your settings the print time will be around 1 hour. How do you upload the FCStd and stl files here? Whenever I try I get a warning box saying that the file format is not allowed.2 points

-

Hi Roxy. There are companies on the net and eBay who will cut the glass to size, a bit more expensive the an off the shelf though. Could try A.G.Thomas Bradford or Gleave and co. Meadows and Passmore were. Good source but I think they only supply the trade now, might be worth looking though.2 points

-

2 points

-

1 point

-

1 point

-

There are a lot of 72A junk movements available, mostly without a balance, even in my own country. So replacing the whole train at not too much more cost is feasible. I wouldn't take a chance on ordering a 4th wheel alone, in case it's mislabeled. After that I would have a nicely hot rodded old Waltham with a perfect dial and higher bps.1 point

-

It wasn't just hard times, keyless works replaced key wound, so the cases were scrapped, swiss level replaced English lever etc and the cases were scrapped.1 point

-

I'll test this later. I'm am pretty confident if it can read it, it will be bang on 240 min fast. The movement is running perfectly +2s, 0.0, 280deg, albeit in an alternate world where one minute is only 50 seconds long. I use the open source tg timing software rather than a Weishi, and it is pretty flexible in what it's willing to calculate and display. I did count the teeth on my spare P72 escape & 4th wheels. They're 15 & 60 respectively, same as on my too fast movement. So I won't be swapping in train parts I happen to have on hand. It will need to be a different balance if I do pursue this.1 point

-

I have a smiths bezel including glass I will measure it tomorrow if it’s correct size you can have it for postage cost. Dell1 point

-

Hastily typed, and missing the "A". The listing was P62A/P72A. Apologies for the confusion.1 point

-

You're an absolute gem watchie, my favourite person of the month1 point

-

The total size of the compressed zip is about 2.9GB. There is a treasure trove of information from Perkins, Fried, etc.1 point

-

I don't know how I did it!! It was a long time ago. Maybe they changed the file type available. Here's an idea. Change the extension to ".jpg" and inform the reader to change it back to ".fcstd"1 point

-

I appreciate being part of this group. I started with this hobby two years ago , and is an amazing journey, learning something new every single day! Thanks!1 point

-

1 point

-

1 point

-

I use the felt or stitched cotton with cutting compound, then clean the part so as not to cross contaminate my mops, then polish with the soft cotton and rouge, so it is 100% shiny finish. Then mask off the shiny parts you dont want brushed and then brush the exposed (untaped) bits. If you try and polish after you brush the polish will flatten out the brushing you just did1 point

-

That's a lot of reading, downloaded 1st half and in the process of downloading the second half now, thanks for sharing.1 point

-

Same issue another interesting series started called: Common Sense Escapement Checking1 point

-

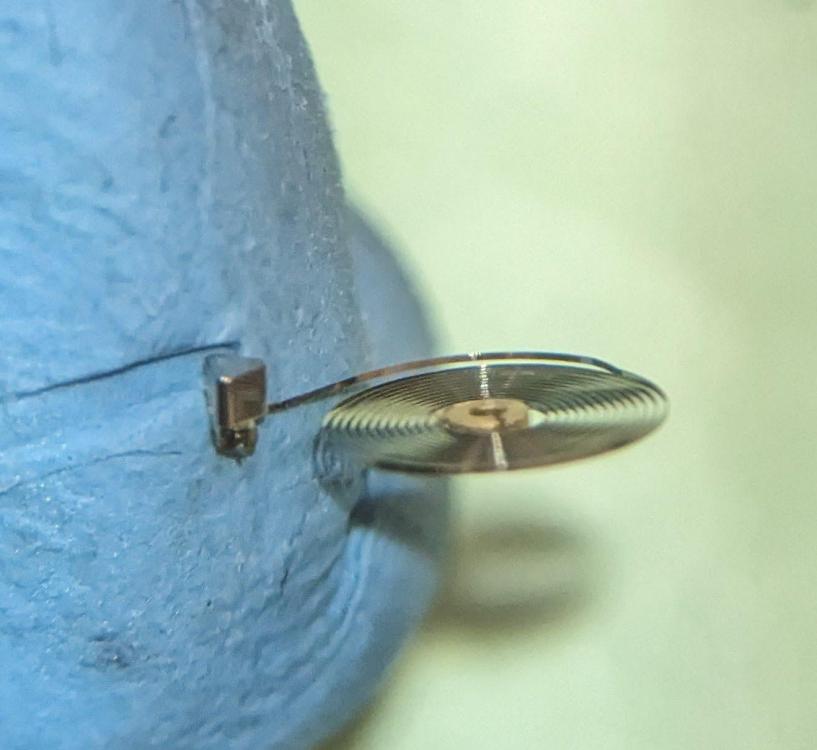

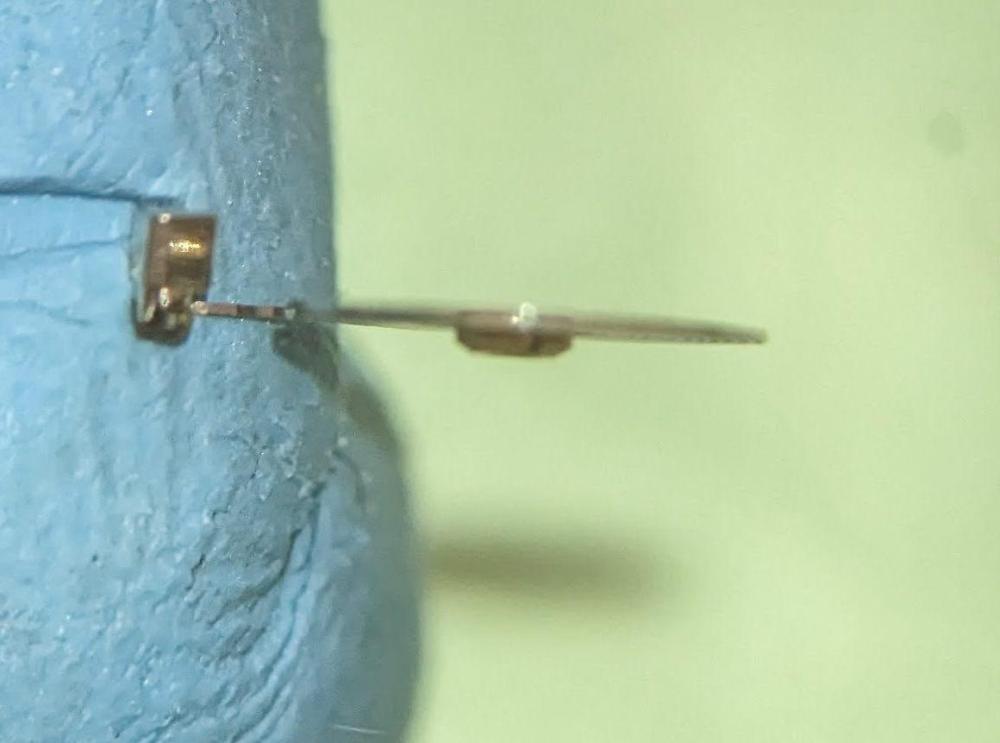

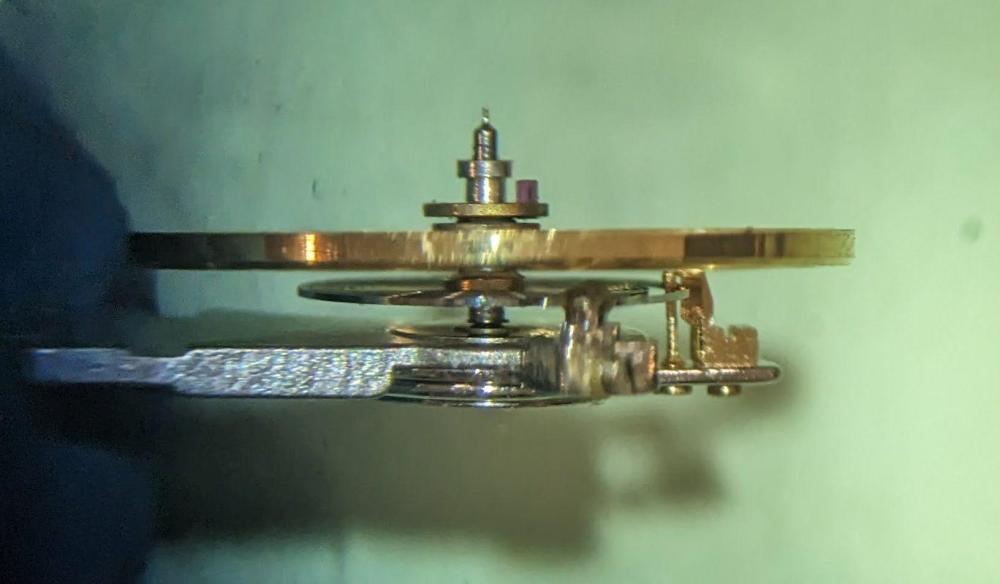

Very well for the first time! It is important to understand what You did wrong and how to avoid it later, and what are the principles of hairspring adjustment. @ Nickelsilver gave You the best advices, but I will try to explain a little bit more. There are two hairspring adjustments – one about the collet and one about the stud. The collet, as You learned, has to be in the middle of the spring and in the plain of the spring. As You don’t supposed to have balance calipers or smoothing broaches, then a regular sewing needle that is with proper diam. for the collet can be used. By turning the needle, one can see if the hairspring is ‘in plane’ and ‘centered’. To see the ‘flat’, hold the needle horizontally, as the mass of the stud will change spring position other vice. To see the ‘centering’, hold the needle vertically. Imagine that the spring is a vinyl record. When a vinyl record is well centered on the platter, the arm moves gradually from periphery to the center. When not centered, it moves in-out with every revolution too. The same is with the hairspring – observe the internal coils when rotating the needle – they must move not in-out, but only in or only out. The stud must hold the hairspring in the plain of the bridge/balance and in a manner that the collet will stay exactly above the jewel of the bridge, when the stud is in the carrier (hairspring is out of the balance). The outer coil must be exact arch that goes thru pins of regulator and moving of the regulator must not change the position of the spring, the spring must be not pressed to some of the pins. Now, I must say that all needed could be done in the beginning without taking the hairspring from the balance and even with the stud in place in the carrier. Just some skills and experience are needed to know where and how to manipulate the spring that must be gathered… One must know that even bent out of flat, not concentric and so on hairspring, no mater, still may work with perfect amplitude, the only condition is no coil not to touch or rub anywhere. What we say here about the ‘flat’ and ‘concentric’ only is that the above condition is this way easier fulfilled… and looks better! And, the hairspring position adjustment has certain impact on the position errors and isochronism, but this is for another topic…1 point

-

1 point

-

Good news, you can probably get most, if not all, of these out. I posted somewhere on this forum about the method I use on acrylic crystals to refurbish them - not promoting myself as an expert, but it may be useful to you.1 point

-

The way to do the job is to turn the wheel upside down. And, before replying that this is silly and will not work, just try and will see that it works, and may be will understand how and why it works.1 point

-

1 point

-

1 point

-

Ah, I was wondering about that, if there were more recent issues of the magazine. I had a couple of URLs and saw the simple pattern so I just made a nested loop to update the year and month for each download the app did. If anyone has a URL to a later issue than December 2009 please share and I'll see what I can find. Well, if they don't want them shared which could very well be the case, I'll remove them, or a moderator can remove this thread. So, if you want personal copies should that happen, simply press [Ctrl]+[A] in the OneDrive window to select all 396 issues (make sure to scroll through the entire page first) and then click the "Download" button.1 point

-

Wow, thank you very much, all of you, you are great helpers! My skills and toolset are very limited, as I am really a beginner, but after working hard on it for like 4-5 hours, I could reform the hairspring finally to look somewhat better. It is very far from ideal shape, and this was my really very first time manipulating hairspring so I'm proud that I haven't completely destroyed it. I really don't want to make a watch of +/- 5 sec a day out of this one, as it was bought as damaged/for parts, I only wanted to try out how far I can go servicing it, to be able to run at all. After agitating the hairspring about 50 times, and put together the balance like 10 times, installed it like another 10-15 times, but finally, it started working! I only gave a very few winds via the rotor bearing, and it looks like the amplitude is very low, so I can check it with timegrapher to see the horrofying numbers later, but for now, it was a long day with a lot of ups and downs, and a final result I dare to say success. Thank you all for your kind help and wish you all a nice relaxing weekend!1 point

-

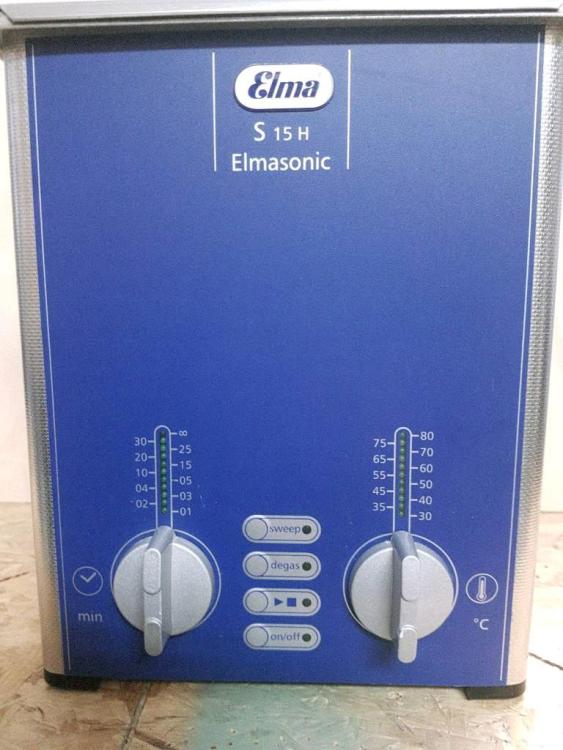

Hi guys, I joined this forum a few years ago now and have enjoyed reading the posts and offering help where I can, as well as learning things I didn't know. Although I am a professional watchmaker and watchmaking tutor: https://www.jonthewatch.co.uk/ I still learn a lot from you guys on subjects and watch movements I haven't come across before. I especially enjoyed a post this week by @eccentric59with his walkthrough of an ETA movement that had a plastic fork and escape wheel, which I haven't worked on before. All watchmakers, including professional watchmakers, are always learning something new. It would be incredibly arrogant to say 'I know it all'. Even WOSTEP-trained watchmakers with many years under their belts are always learning something new, even from those relatively new to the art of horology. I trained a watchmaker from Christopher Ward Watches recently and hopefully will be writing them a service manual this year for their in-house movement, the SH21 because they want the expertise I have to be able to train their guys how to service it, which I feel quite honoured about, as I am not WOSTEP-trained. I know I'm rambling a bit, but the point I'm trying to make is that we can all learn from each other no matter where we are on our horological journey, be it professionals, seasoned enthusiasts, or the weekend fettler. I would like to share something with you which is a word of warning, that some of you may not be aware of. This isn't a character assassination or a resentment I have, it's just a fact that might help some of you. Cousins UK: https://www.cousinsuk.com/ ONLY sell to what they call 'Trade Buyers' it is stated in their Terms & Conditions; that means that you need to be a professional watchmaker in the trade to have any real binding contract with them. They are happy to take your money as many are not in the trade, but if what you buy is defective, damaged, missing, or you want to return it to Cousins for whatever reason, you don't have a legal leg to stand on and you may not see your money again. So if you are planning to buy an item that is quite pricey keep this fact in mind if that item is not working properly or stops working a few weeks or months later, then you won't get any redress. Companies such as HS Walsh and Gleave and Co. sell a lot of what Cousins sells for a very similar price and sometimes cheaper, but at least you will have a chance to contact them and make a claim. I buy from Cousins from time to time, but wouldn't buy an expensive tool or item for this reason. Mainly watch crystals, gaskets, batteries, and the odd mainspring. I mainly buy from Gleave and Co in Clerkenwell, London, as they have the expertise to be able to help you on the phone and they are also a small family-run material house that I have trust in and would prefer to put my money their way. Gleave and Co. have integrity. Their website is getting better and sometimes what they have isn't listed on the website, but a phone call (8.30 am to 10.30 am) or WhatsApp message (anytime) will sort that out. Expensive equipment, such as Elma watch cleaning machines, or Bergeon case back removal tools 5700, etc. can be bought from HS Walsh or even cheaper from a German Company called Beco Technic: https://www.beco-technic.com/en/ You have to set up an account with them, but even with shipping and VAT thrown in, it will end up cheaper than buying from a British company. You get a 10 to 15% discount on their prices once you register with them. I was a consultant for watchmakers in Essex who saved about £25000 buying through Bec Technic. I can only tell you my experience and some may have had a good experience with Cousins getting a refund. It took me once over six months to get a refund for a £40 quartz movement that was delivered to the wrong address in an order that was several hundred pounds and after spending about £5000 with them, as I was the buyer of a watchmaking college. Only when I threatened to buy from elsewhere that they refunded me/the college for the missing movement. I hope this helps some of you in some way, as there are more material houses out there other than Cousins.1 point

-

1 point

-

Almost the same method waggy. I start a little higher with the emery grade first 600 and then come down if any deep scratches are very slow to remove. I have a few more inbetween grades 800, 1000,1500 then 2000, using water as a float, not sure if spit is better. Then finish with just the original autosol. Under low magnification there are still very fine scratches, the eye can possibly detect them as an overall view, but i kind of like that ' has had some life look ' .1 point

-

1 point

-

What frequency is your timing machine saying you are running at? I believe the balance are interchangeable, in the sense they will tick in either movement. But if you have a 21,600 balance in a watch that needs 18,000, you are getting an extra tick each second. 12 seconds extra per minute. You observed the minute hand making a turn in 56 seconds, so the math doesn't seem to work-except, often the higher beat watch will have 20 or so teeth in the escape wheel, and the other gearing has changed. On that note, for a "family" of calibers, often the center distances didn't change even though there were gearing changes to allow raising the frequency. In some cases the gearing can get mixed up- so maybe you have a 4th wheel meant for an 18,000 beat watch but a 21,600 balance, or something similar; it can get a bit complicated.1 point

-

I consider myself ISO9001 compliant as I continually improve! (at least I think I do)1 point