Leaderboard

Popular Content

Showing content with the highest reputation on 01/07/24 in all areas

-

Just made a program to download all issues I could find of the AWCI Horological Times to my OneDrive. I hope I didn't do anything illegal, but I'd be happy to remove the files in case I did. Enjoy! https://1drv.ms/f/s!AnVrKJ9agkNWkfFk72cqE5ISkNJ78A?e=mYbidJ9 points

-

3 points

-

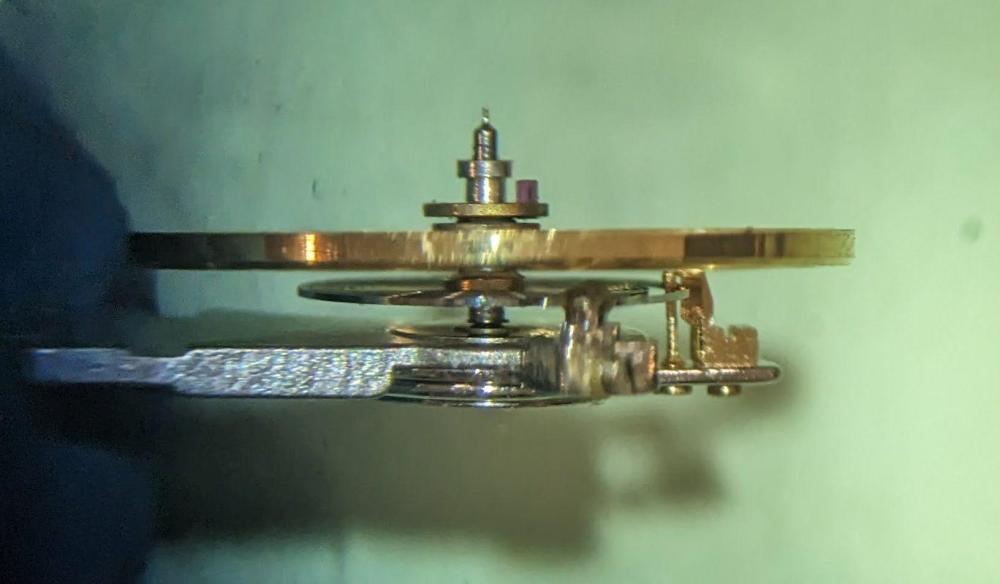

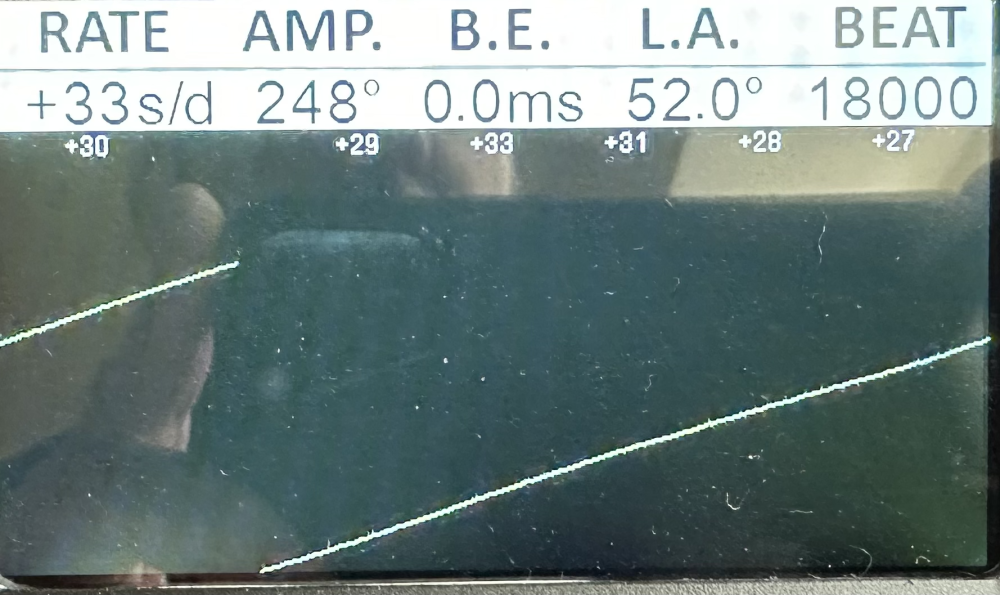

A picture of the top of the balance cock and regulator may help here. The reason being that you have both coarse and fine regulation options available. The fine tuning is done using the eccentric (looks like a screw) with the graduations around it, the coarse adjustment using the regulator arm its self. I would normally set the fine adjustment to the middle of its range, get the rate as close as possible to 0s/d with the coarse adjustment, and then go back to the fine tuning to get it spot on. You may already be at the limit on the coarse adjustment which would be an issue, but if not then you should still have some range left to take out that 30s/d. A pic would help to determine where you are.3 points

-

You were catering for everyone. I can go along with that some dont want to ask for fear of embarrassment, something that clearly doesnt bother me. You may notice i dont ask about much, if i see something i dont understand it gives me the opportunity to dive into a book. Its usually when i have an idea and want feedback if it could work. I'll certainly take on board your advice and include more popular names and terms. I think we are of the same ilk ( I'll let you google that one yourself ) and like to be asked questions, I've employed quite a few apprentices over the years and enjoyed explaining and teaching them.2 points

-

because the circuitry is all more or less identical the crystals are basically almost all identical. Other than perhaps packaging. Except when we get to newer watches the quartz crystal is not going to be oscillating at the exact frequency we perceive it's going to be adjusted off a little bit I believe it's running fast. Because when you get a much newer quartz watches there's no trimmer capacitor and they use a logic regulation circuit. Simplistically they miss place a little bit of the frequency. Unfortunately that means you cannot adjust the trimmer frequency of the watch at all at one time you could reprogram that if you have the right witschi machine and if you knew which program the watch had. Notice the word if in other words the circuit didn't say which program they were using and that was basically just short-lived. The reality look quartz watch run so close to frequency it doesn't really need much regulation normally.2 points

-

Nothing is standardized in watchmaking. So each combination of movement and dial requires its own case in terms of dimensions. You have to be more than lucky to find a matching case for your movement and dial.2 points

-

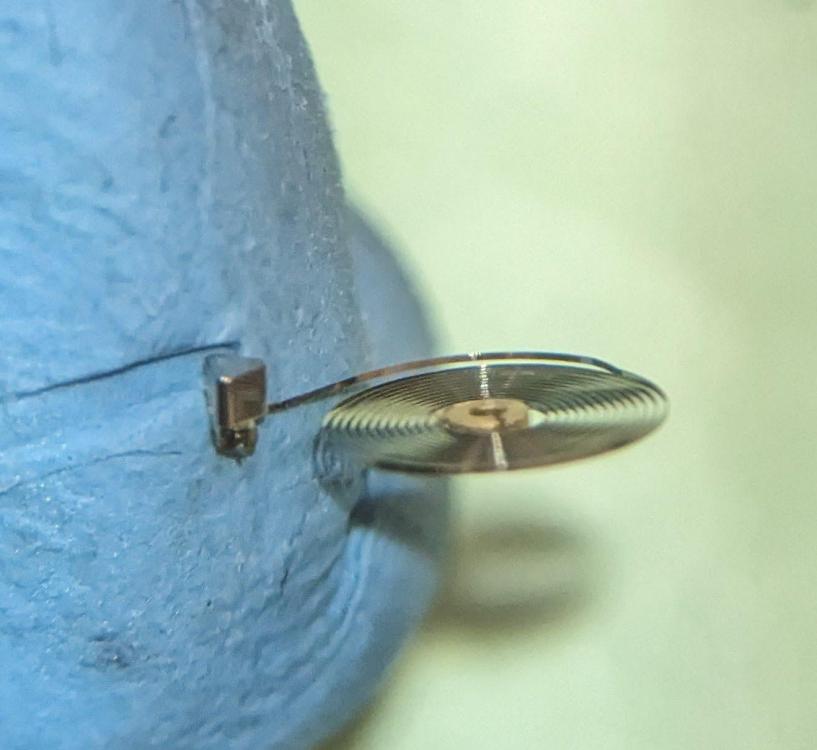

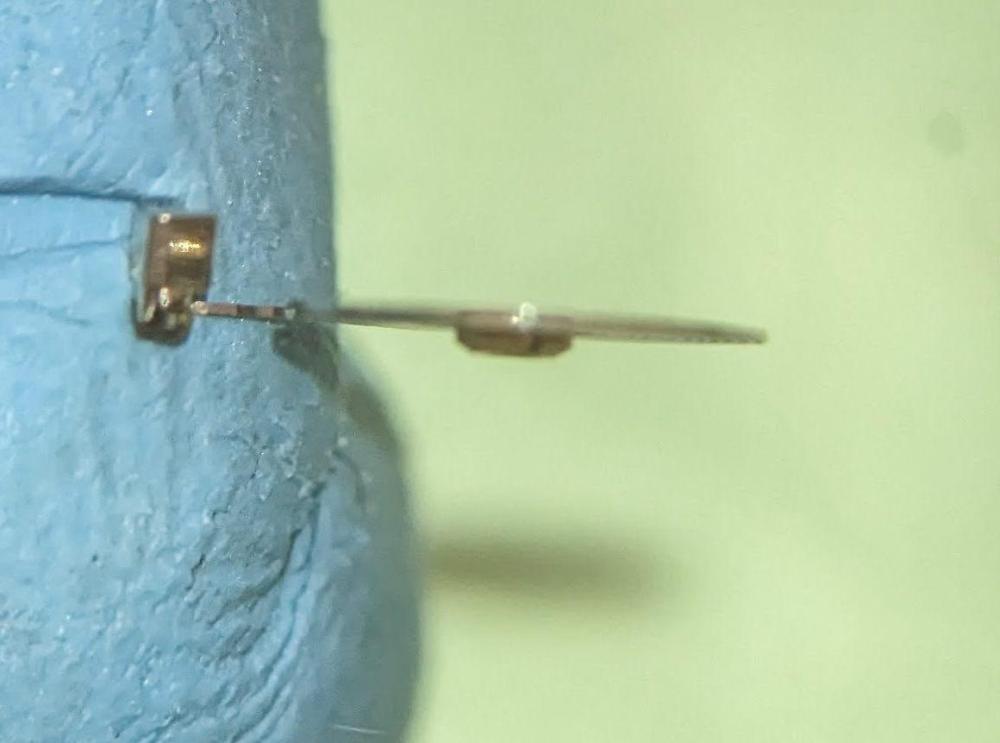

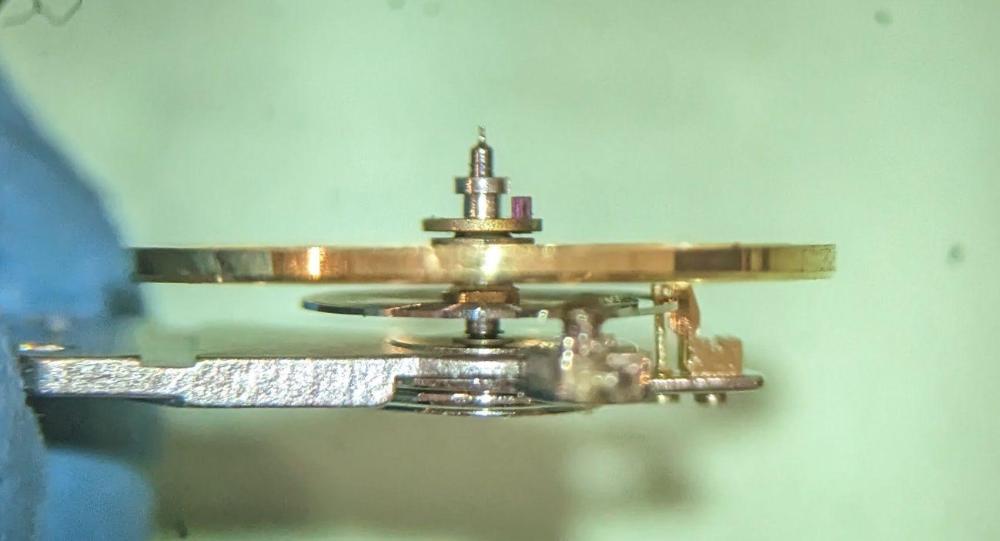

Wow, thank you very much, all of you, you are great helpers! My skills and toolset are very limited, as I am really a beginner, but after working hard on it for like 4-5 hours, I could reform the hairspring finally to look somewhat better. It is very far from ideal shape, and this was my really very first time manipulating hairspring so I'm proud that I haven't completely destroyed it. I really don't want to make a watch of +/- 5 sec a day out of this one, as it was bought as damaged/for parts, I only wanted to try out how far I can go servicing it, to be able to run at all. After agitating the hairspring about 50 times, and put together the balance like 10 times, installed it like another 10-15 times, but finally, it started working! I only gave a very few winds via the rotor bearing, and it looks like the amplitude is very low, so I can check it with timegrapher to see the horrofying numbers later, but for now, it was a long day with a lot of ups and downs, and a final result I dare to say success. Thank you all for your kind help and wish you all a nice relaxing weekend!2 points

-

I'd like to thank all of you for your advice and help in getting it up and running! Full story here: https://wordpress.com/post/jeremylaurenson.wordpress.com/2182 I do have one final question - it's running about 30s fast per day and I have the adjustment screw all the way... I assume fixing this thing is a case of trying to manually lengthen the hairspring which is not something I think i want to mess with (I did demagnetize the movement)1 point

-

Hello to all from a new member. Am relatively new to watch repair/modding, with modest experience and skill level. I hope to learn from other's experiences in watch restoration and repair, and perhaps make some useful contributions to the community along the way. Will be posting some pics soon of a 1976 Timex Viscount project that I have started.1 point

-

Hello, I'm just getting underway with watch disassembly as my new hobby. The plan is to also put them back together but I don't want to get ahead of myself. I'm a physician/anesthesiologist living in Canada. I'm busy gathering my tools to get started. Magnification, light, movement holder, cushion. Decided to go for new screwdrivers, still in the post. Today my bid won an assortment of Dumont tweezers on eBay, including several #5s (sorry if others were going for this!). I'm almost there. I have several non running and running Swiss movements from the 1950s (?) from eBay that I will experiment on before risking any complex or valuable pieces. It's all new and I think the information available here will be invaluable. Yesterday I was reading about how to get the tiny amounts of lubrication into a cup for usage without spilling vast amounts. That's gold! Looking forward to lurking and learning!1 point

-

@VWatchie I agree it’s not easy. So from my trying to figure it out really 3 levels work fine. Though if you need to do a get rid of deep scratches stage the you do need to do the pre-polish stage, however if you can (the scratches aren’t too deep) go straight to pre-polish and then onto polish. Just be gentle and don’t get too carried away. Tom1 point

-

Looking at Gerts picture it is likely a 775 dc motor. Cheap to get and brackets, controllers etc. are all easy to come by. Tom1 point

-

Thats brilliant watchie, i think you'll get the most liked post in history with this one1 point

-

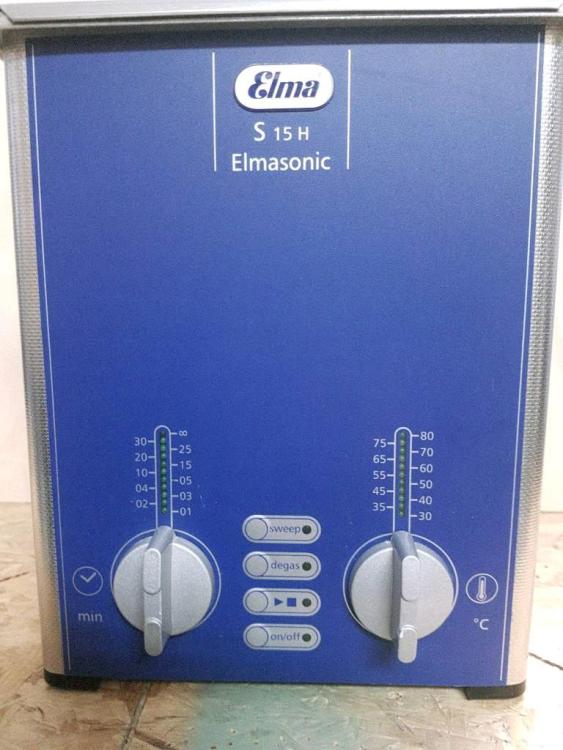

@Neverenoughwatches Hi. Thanks for the link. I'm for Zurich. I am planning to build something similar to what Gert had. I was wondering about the parts he used. The device from the link would probably do its job pretty well, but I'm interested in the different agitation levels and so on. And if I do it myself I would not have to explain to my wife, why I invested thousands in to a cleaning machine, that doesn't actually do much of cleaning. )))))1 point

-

1 point

-

...and I downloaded to my computer...lots of reading ahead!!1 point

-

That's what I do too. Still, I think most people won't for fear of making a fool out of themselves. It takes a lot of confidence to stick your chin out, especially when you know the question may be wrong or irrelevant. I have worked as a teacher for many years and one of the biggest challenges is to get people to stop me talking whenever they have a question. As long as the question grinds in their heads, they don't hear a word of what I say. This is also why I am adamant about announcing and keeping time for breaks even if I have to stop in the middle of a sentence. If, for example, you need to make an important call or just need to go to the toilet, you are guaranteed to think about when you will have a break instead of focusing on the teaching. Tell me all about it! When I say to the class three times in a row "This is crucially important, without the following information you won't pass the examination and you will possibly be terminated from the program" at least one student out of 25 or so will somehow miss it. Communication is the most crucial activity to reach any kind of success in life and it's also one of the most difficult. One sacred principle to stick to as a teacher is "Don't answer a question that was never asked". Still, I often find it difficult to adhere to this principle. I guess it's the teacher in me who just has a hard time keeping my mouth shut, so I guess that's why I couldn't help myself with the lever/pallet fork comment.1 point

-

Thanks watchie, i did read that explanation from Jon an accurate way to determine if the set up is correct. Mine was from an experience 6 months ago of a missing endpiece plate, the top pivot didn't reach the top jewel. I had a big selection of endpieces and just needed to reposition the cap in the plate. The threads might have shown some brass surface where the nickle was scrubbed out from the screw.1 point

-

I just assume that if someone didn't know what was being said that they ask about it. Thats what i would do, in some way i think if you ask you are more inclined to remember than if you were told. Goes back to the same principle that you can tell someone something until you are blue in face, it generally wont sink in. Only when they say it themselves out loud do they realise and accept it. A lot of folk have the inherent idea that they dont like to be told anything, a good way to win an argument when someone is at fault is to draw them into having them say the issue out loud.1 point

-

Haven't read all posts on this topic in detail, but anyway, if the goal is to determine if a cap jewel is missing I would start having a look at the shape of the pivot as I'm under the impression that it would always(?) be conical for a jewel with a cap as illustrated and explained by @Jon.1 point

-

Nevermind, found the tiny hidden lever. I'm sure I'll be back:)1 point

-

Hi, yes I have the left one. The picture doesn’t really show it but the left one is flat and the right one has an oil sink. The threaded hole on the right doesn’t seem to have ever been used so I suppose it’s always been this way. I noticed a couple of coils on the balance spring were stuck together (probably me oiling the pallet stones poorly) so I re cleaned everything and it is now working!! Thank to you all I am now aware that even if there is a machining detail and threaded hole it doesn’t mean something was ever fitted!1 point

-

1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

No need, thank you. I got it figured out - spacer goes between the hole jewel and cap jewel. My problem was bent pallet fork horns, not sure how that happened because it was running before the old hairspring got damaged. I had another pallet fork from a parts movement that was also bent downward and not contacting the roller, so I went back to the first fork and pretty much just said YOLO and wedged tweezers into the horns. Guess what - it runs perfectly after that. The watch has no sentimental and little monetary value but it was mostly a matter of sunk cost to get it ticking.1 point

-

Thanks! The back issues are excellent. Archie Perkins wrote a 17 part series called "The staking tool and how to use it" from HT issue 1/84 to 5/85. I am sure there are many other useful series. I wonder how much space is needed for them all!1 point

-

I used to have the physical magazines! Gave them to a student when I moved to Switzerland early 2000s. The 70s and 80s, also 90s, had some amazing long term series articles, stuff you don't find in books. I don't know I'd awci would be upset you shared this, but I've tried several times to re-up my membership to no avail (which gives access to the old publications), so heck with it. Thank you! Only up to 2009 though (but the good stuff is older)1 point

-

Lol...2.5 years ago. I probably have pictures of the assembly at home. If I remember tomorrow I will take a look1 point

-

with the case number and the luck we get a link with case parts. You click on each the items and find out what other watches use the same item as your watch. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK+CS%237009-5110&submit=Search1 point

-

1 point

-

Thanks watchie, sorry i prefer to use the traditional terms. I think of the pallets as the end that holds the jewels that engage the escape teeth and the fork as the end that engages the roller and impulse jewel. Lever sometimes called the anchor I just think of it as a good idea to learn all the variations of names, they vary from country to country and generation to generation. I sometimes bracket the name with a common variation used. The habit comes from my joinery background, i was taught by old school joiners that apprenticed in the 30s and 40s1 point

-

1 point

-

AKA "pallet fork" (if anyone should be feeling confused). https://www.awci.com/wp-content/uploads/ht/1995/1995-09-web.pdf https://www.awci.com/wp-content/uploads/ht/1995/1995-10-web.pdf1 point

-

Looks like you are dealing with rubbed-in jewels or rubbed-into bushes and pressed in. Someone like JohnR725 or old hippy could answer your question. To be honest if you are looking for that buzz of a movement coming to life, you are choosing the wrong kind of watches. Too old , too broken and lack of replacements. These are difficult to work with murks, they are guys here with 5+ years experience that wouldn't attempt this kind of repair. I applaud your bravery indeed, i tried something equally as difficult last week. I wasn't expecting a good outcome and it wasn't but i wanted to test myelf and i did learn from the experience, so i do get where you are coming from if thats your reasoning to try this repair.1 point

-

Correction: power reserve is 48.5h. So barely over nominal. I guess that excludes the worry of the mainspring slipping too late. I've not observed/heard any knocking. And timekeeping on the wrist is exquisite - so no signs of knocking. I'll just be happy with the high amplitude..1 point

-

Questions are not always picked up first time murks, just keep posting till someone answers. But pictures are nearly always needed unless its just a general enquirly. One reason is your question might need someone advanced or watch specific to answer and they may not be available. As an example i never answer anything clock related as i have next to no knowledge in that area, also very rarely seiko questions or pocket watch questions. My knowledge lays mostly with vintage mechanical wristwatch era 30s -70s , Brand history, tool related , making tools, general all watch related issues and a little quartz knowledge. This is what interests me at this time, but sometimes you just need to be patient for the right person to answer.1 point

-

1 point

-

Well done Michael some times thats all they need gets rid of a bit of grit or a gummy bearing, although they are plastic i sone times put a very tiny drop of quartz oil on the bearings. never had one come back yet.1 point

-

Amazon sell a lot of products and regardless how happy the majority of the costumers are with that product, there are always some "one"-stars. One can look at the happy crowd and make up you mind, or you can purely focus on the "one"-stars. It doesn't matter what Cousins incentives are, the fact that they stand up and are willing to spend all that time & money to fight the Swatch-group is in my opinion highly praiseworthy. I'm concentrating on the good, which, IMHO, outweighs the "one"-stars by miles.1 point

-

This little beauty arrived today! An Omega "tank" from thr 1930s. Cal 12.6 (or T12.6). I love it and its blued hands. It'll be a birthday present for my mother after I service it. It was supposed to cost 200 EUR - already a great price for such a piece, I find. But the seller admitted that it was running 30-40min fast per day. So we agreed on 160 EUR. Since I wanted to service it anyway, I was happy. Well, when winding it, I immediately felt that the mainspring must be broken. The obvious click-slip sound after every 2-3 turns of the crown. Well, I had already ordered a new mainspring anyway Then on the timegrapher... complete snowstorm. So I demagnetized it. And yes! that created some clear lines and at least some output on the Weishi. But running super slow now. When I looked at the regulator, I saw it positioned all the way to R/slow. The seller must have tried to compensate for the magnetism (making it run super fast). Sliding it back to a more neutral position, I was able to get some more horizontal lines. But still wavy. I will report back after the full service1 point

-

I could not resist this one and hope that it really looks as nice as in the pictures of the seller. I'm salivating over those blued hands. An Omega ref 730.17 from 1939 with the calibre T17 that was record breaking at the time for it's 60h power reserve. In fact, Omega took until 2006 (call 8500) to surpass this number. It has a nice 22mm (without crown) by 39mm (with lugs) size.1 point

-

Do not use any oil on this wheel. The wheel has to slide completely free. Oil keeps the wheel sticking on the plates.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)