Leaderboard

Popular Content

Showing content with the highest reputation on 11/27/23 in all areas

-

Hi. 7 weeks in hospital kicked the crap out of me, and at nearly 80. Was a bit severe bur I survived although not able to get back to the watches, hands a little unsteady I shall in time. I have a cylinder in the workshop ready tp go. But I remain on here to help where I can. After 60 years doing watches and clocks I can’t let go yet. Cheers to all4 points

-

Watchweasol. Looking back on my posts, you were the third person to reply to me when I started in November 2021. You've given me a plethora of advice, information and direction. Way to go! I'm still a novice, but you can see how far I have progressed. We, other novices like me, are in your debt. I don't regret it. As you can see by my posts. I relish my time learning. Regards Ross3 points

-

3 points

-

22mm will be the size to order, from your photo it does look like it’s double flanged. If you can measure the diameter in the middle of the broken spring bar and order parts the same. When I get a broken spring bar like this I usually change both as they are likely to be similarly worn and the other could break soon, not a big deal if you’re in bed but it hitting a concrete floor or the like can be a problem. Tom3 points

-

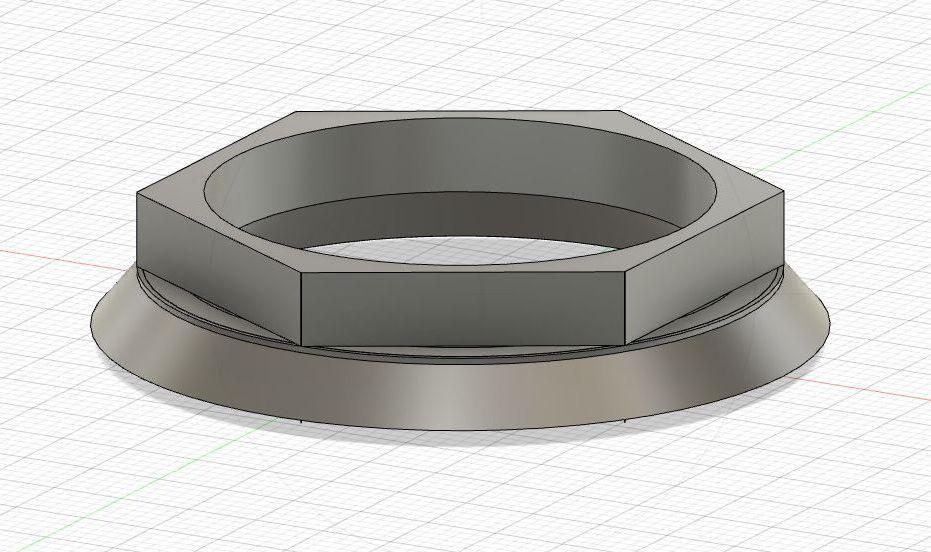

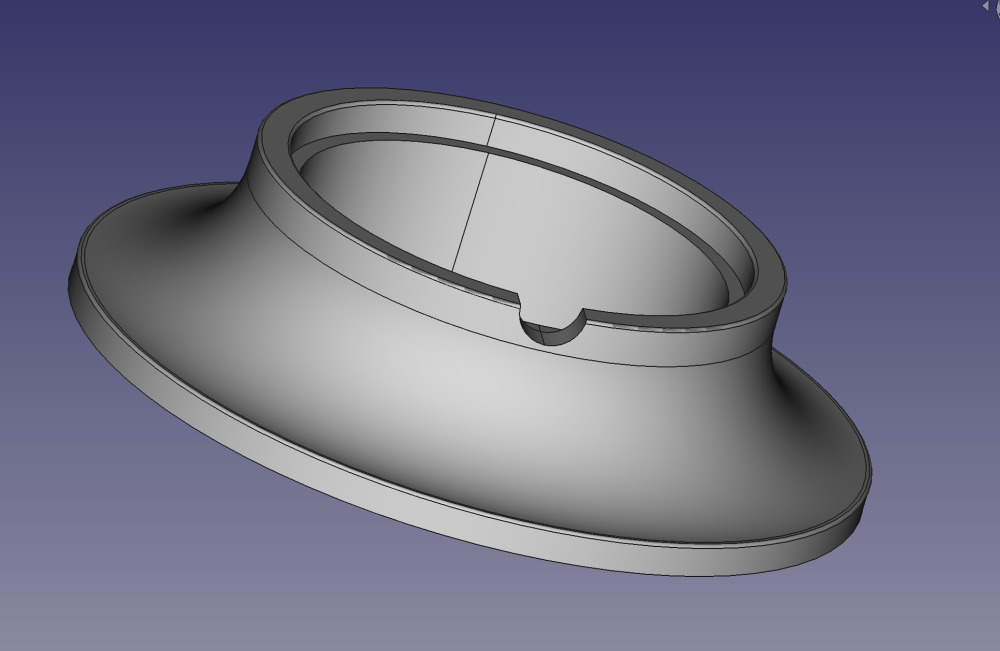

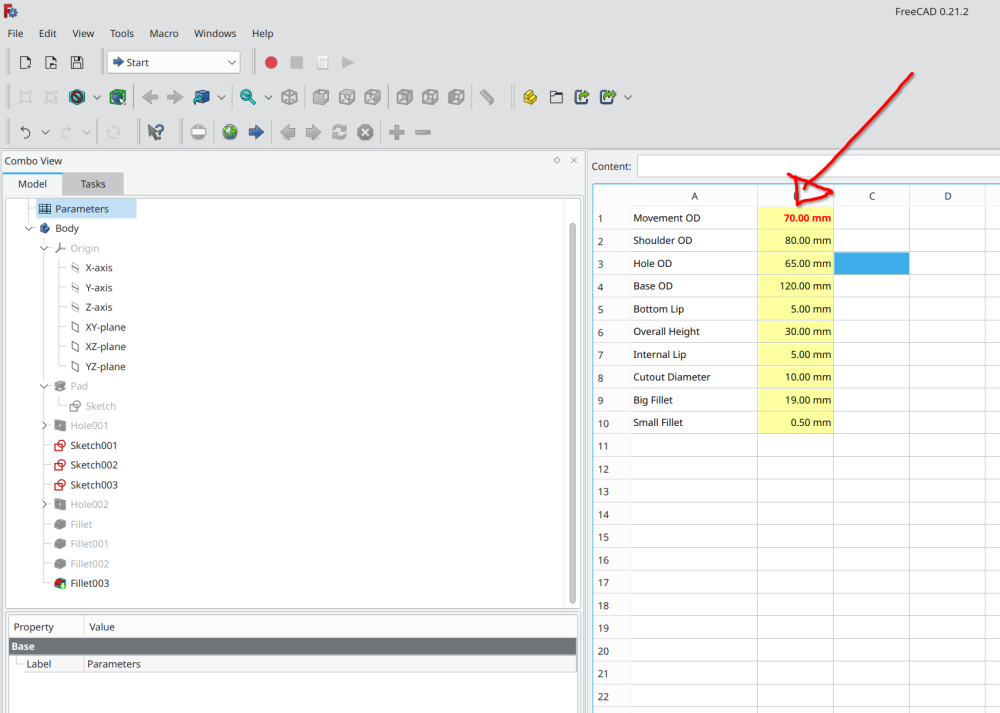

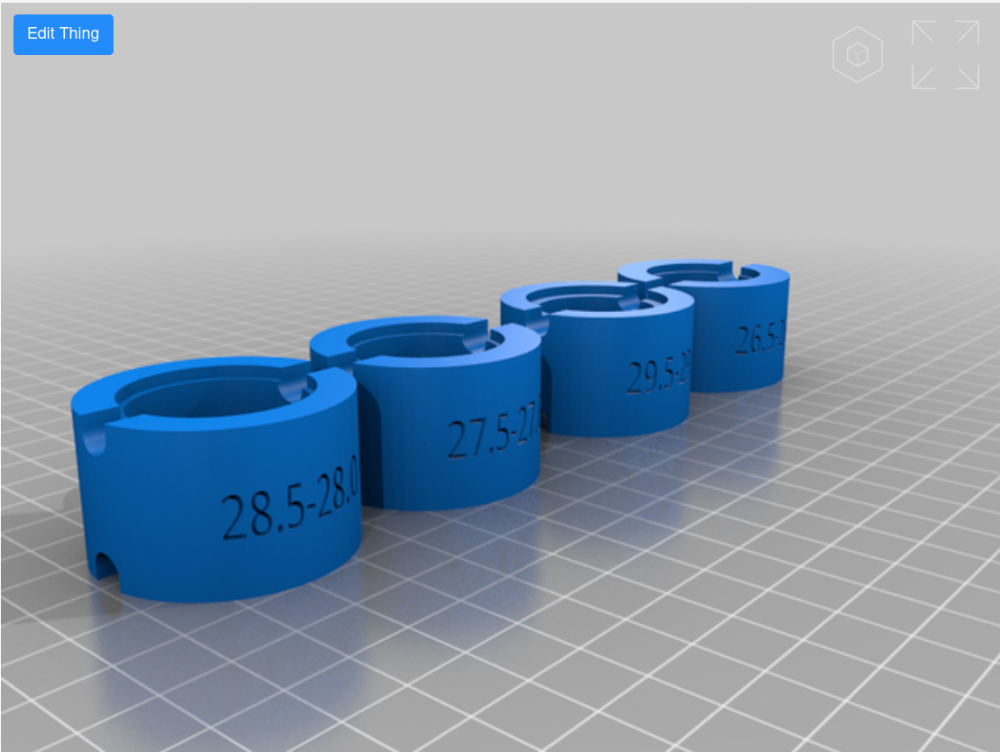

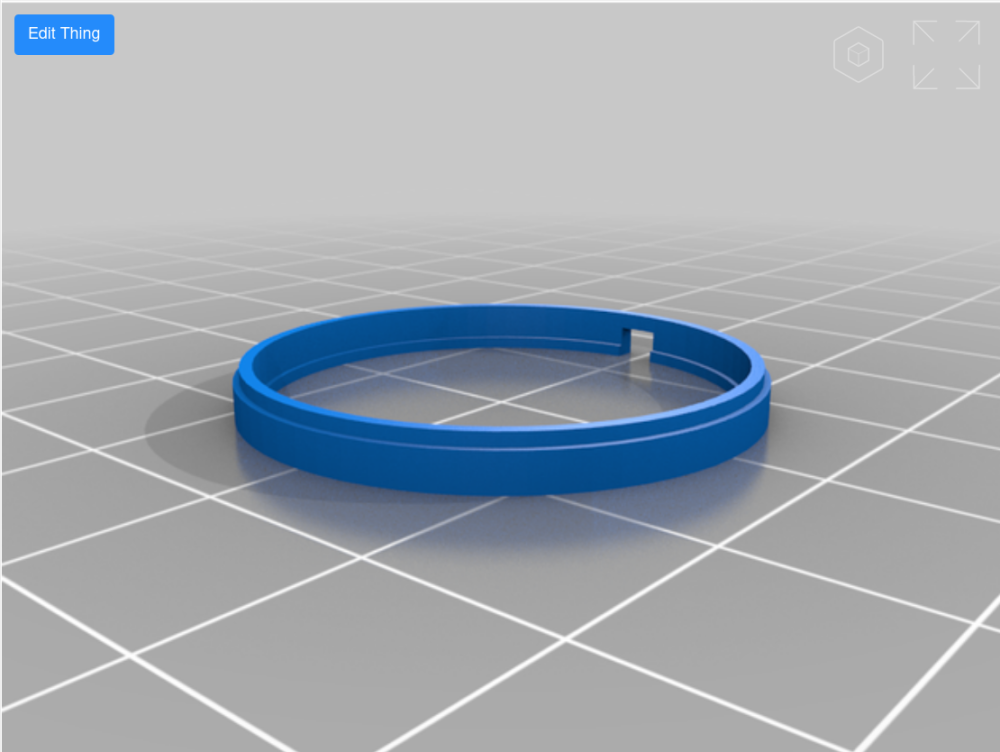

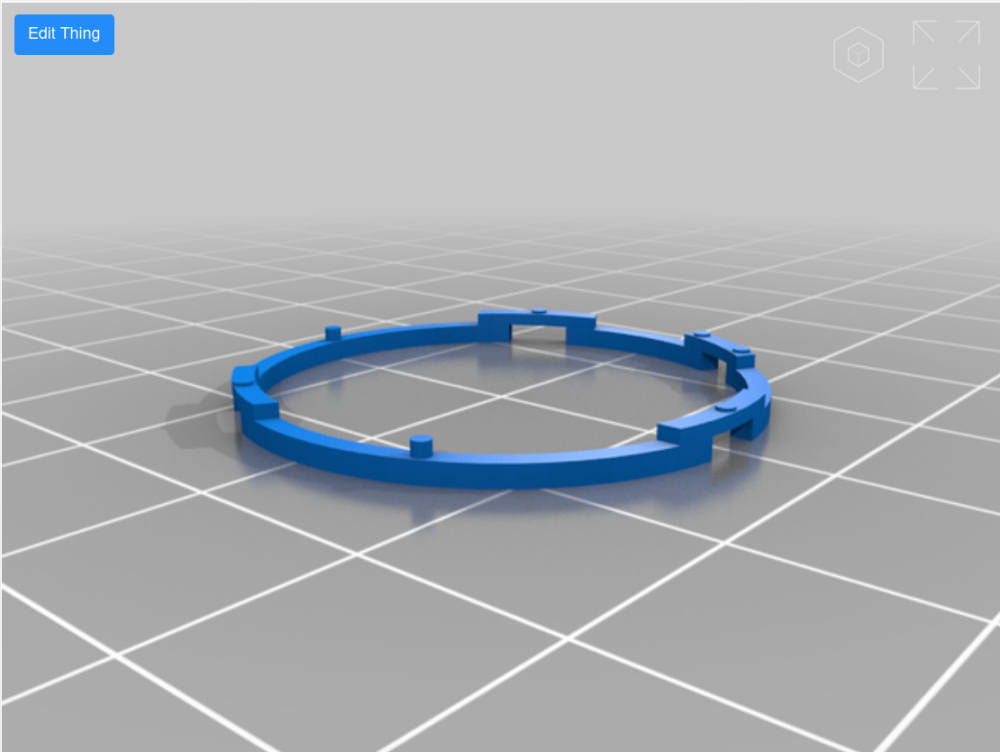

Think I did it..... Below is my parametric movement holder (size 30mm movement) Below is size 10 mm movement (minimum size before model breaks): Below is size 70 mm movement (maximum size before model breaks): And here is the Parameters table - only need to change the red text cell at the top: PM me if you want the link to download This is in FreeCAD not sure if it will play nice if exporting in other formats, but I'll give it a go if you let me know what you need. I think I managed to create a link you can download the freeCAD file: LINK HERE Thingiverse link: LINK HERE3 points

-

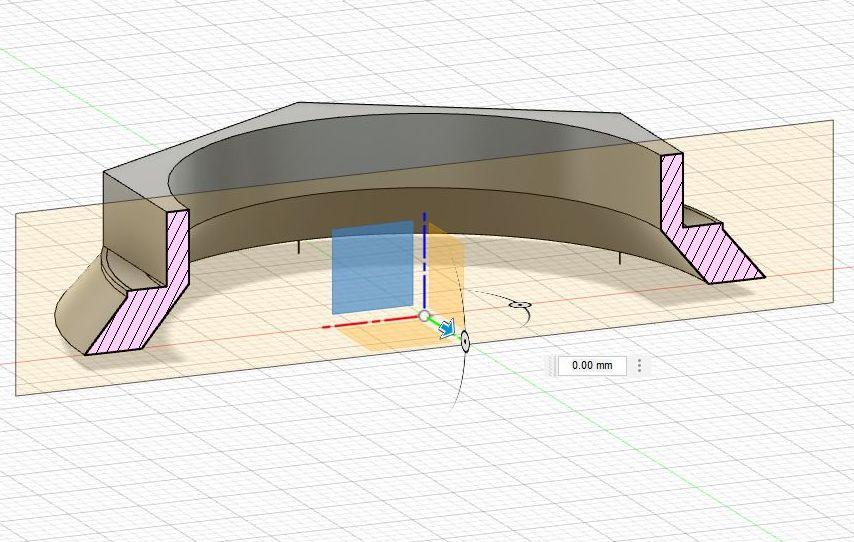

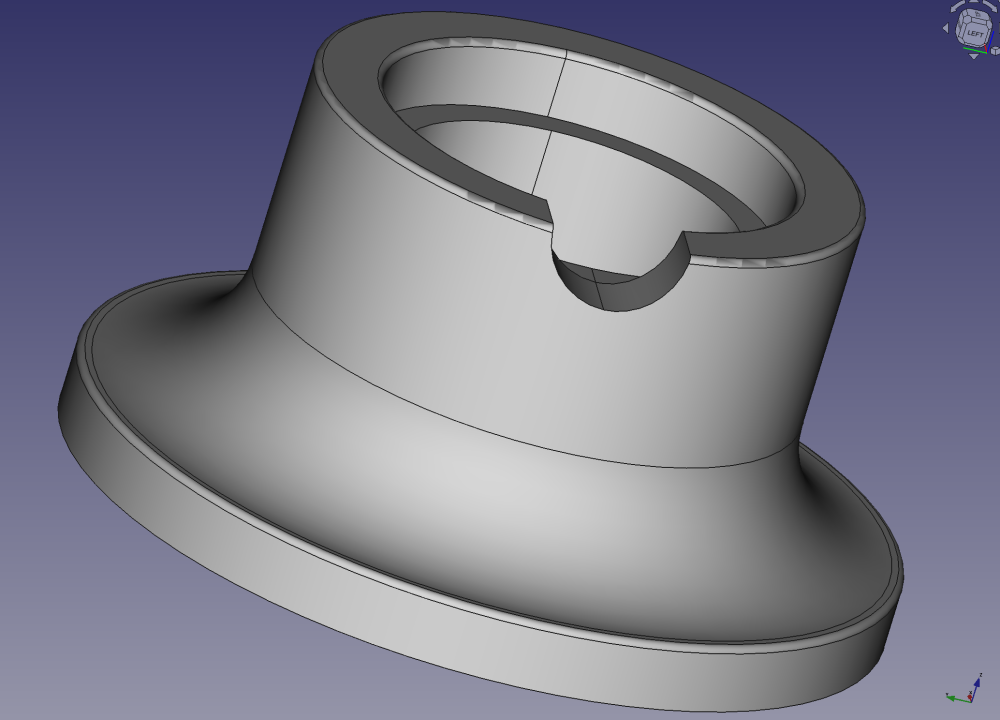

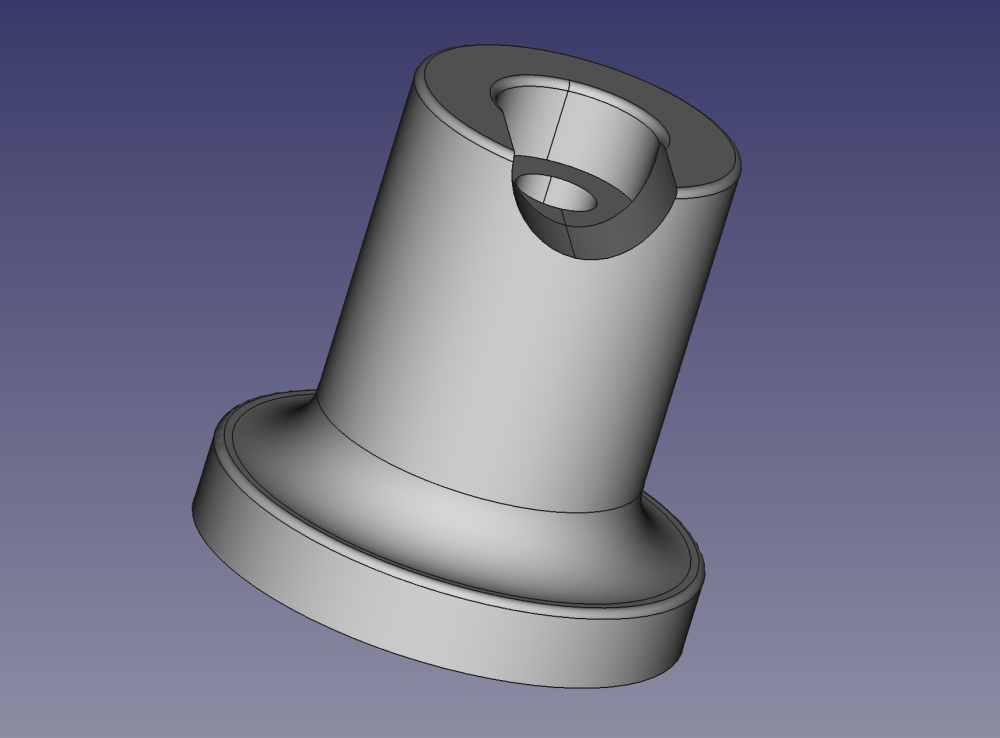

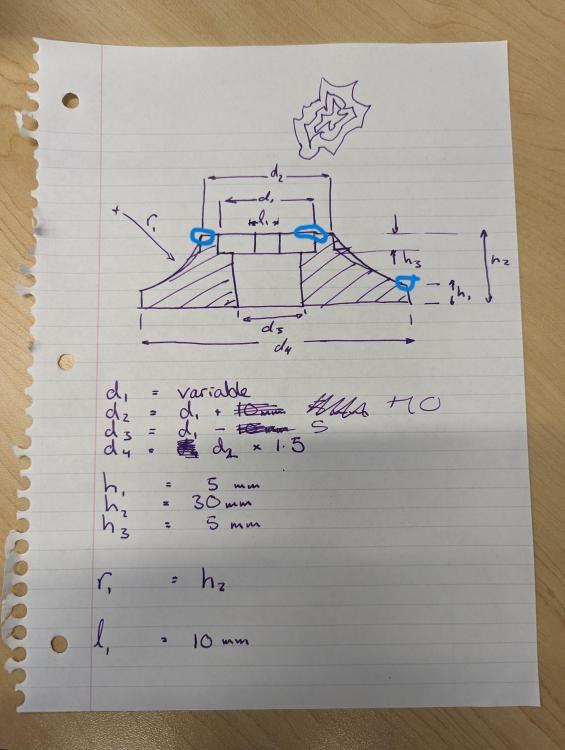

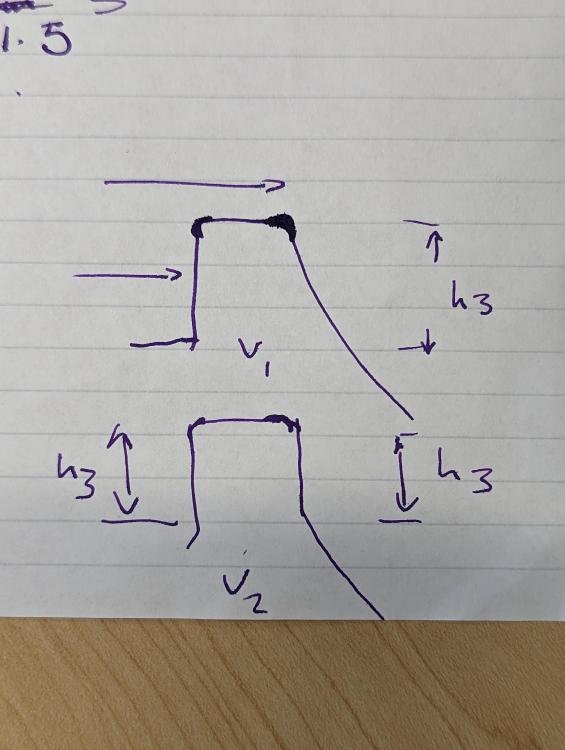

Wow, great minds think alike, I use freeCAD and also have a 3D printer being delivered by Santa , I currently have to bribe my son to use his. I was was thinking on Friday afternoon that it may be cool to try some parametric modelling in freeCAD and sketched out a parametric movement holder. My idea was to measure the movement outer diameter and then let freeCAD spit out the complete design. Here is what I sketched in my lunch hour (including a doodle I did whilst on a very boring conference call) on Friday: I also plan to put a fillet (0.25?) on some of the outer 'corners' mainly for aesthetics, and one on the entry to the seat to make it easier to get the movement in, but didn't get time to add them to my sketch, blue circles above. Also l1 is the cutout for the stem/crown, was thinking of making it U shaped rather than square, but would model it as a square and simply fillet the corners to make it a U shape. Just in case you can't make out my handwriting: d1 = variable (the movement holder OD and the only input you need to make) d2 = d1 + 10 mm d3 = d1 - 5 mm d4 = d2 x 1.5 r1 = h2 l1 = 10mm (with 2mm filets{?} to make it a U shape) h1 = 5mm h2 = 30mm h3 = 5mm (will only need this outer dimension also to be h3 if I decide to keep the 'shoulders' at the top of the model, thinking I may just skip the outer shoulders and have the top and bottom linked by an ark without the shoulders... I will need to think about this....any ideas??? My initial thinking is that the shoulders may flex a little as you push the movement in and grip the movement better, but not sure how realistic this idea is?) - see version 1 and version 2 below. Once I get to grips with it, I'll post the freeCAD design on thingiverse and you can also PM me for it from here Version 1 and version 2 of the top of the movement holder3 points

-

I just uploaded these movement holders to thingyverse as well as two types of movement rings for Seikos, all free to use, modify and distribute. Just doing my bit to help fellow enthusiasts.: https://www.thingiverse.com/thing:5866401 https://www.thingiverse.com/thing:5866398 https://www.thingiverse.com/thing:58663883 points

-

Just enrolled in Mark's course. Was running out of time for the discount. I haven't told Liz. I'm in the poo. Sleeping outside tonight, I imagine. Or if anyone has a spare room that I could rent?2 points

-

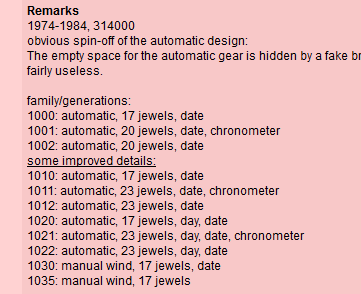

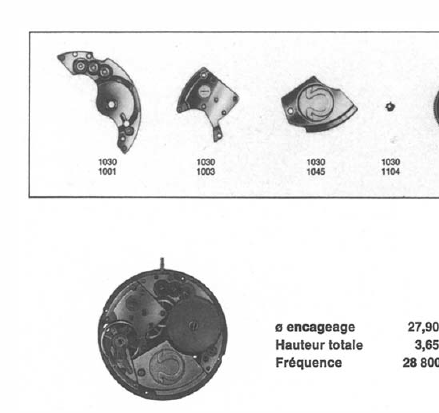

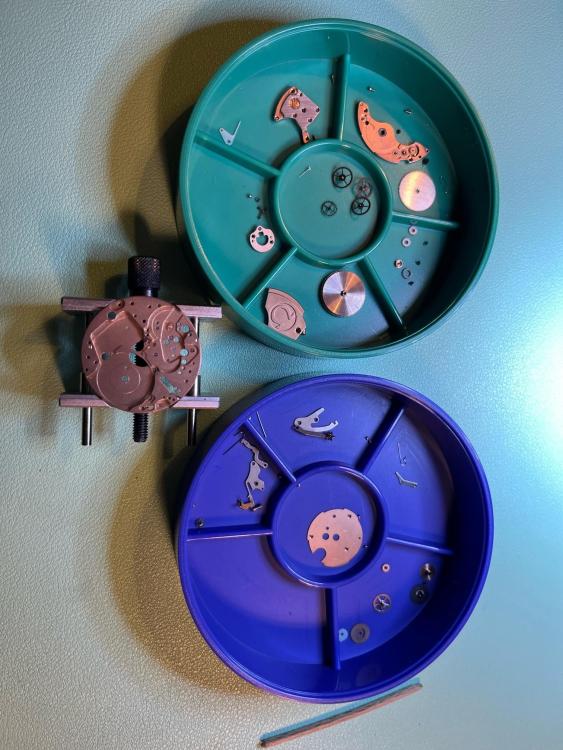

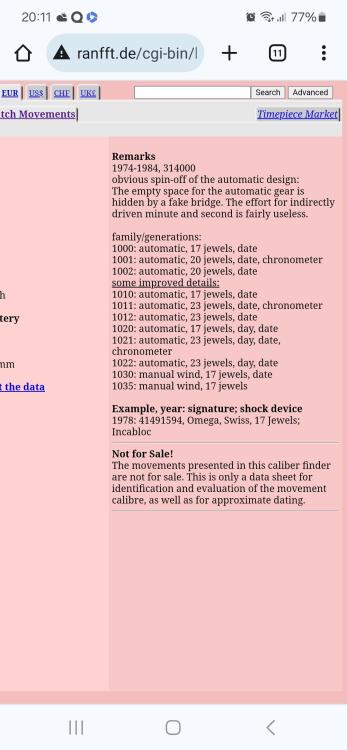

Looks like I need to improve my reading skills normally I think of a base caliber is a manual wind and in the automatic comes but it looks like Omega did the opposite the manual wind is at the bottom of the list and it does match the 1030 So basically what they did is take the automatic movement remove the automatic and put a plate the cover up where the automatic watch it. Which still seems a little strange but it's what they did Oh and we do get an answer for something parts list attached where have I seen apart with a big omega symbol like that before? http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_1030 Omega 1030 424_1030_1_2250.pdf2 points

-

Hi Ross. Kind of you to say so, help is what we do, and helping each other along with encouragement. The horological journey is a long one and can be lonely sometimes but a kind word and a helping hand is all you need. I have watched your progress Ross and I am impressed. Long may it continue.2 points

-

2 points

-

Just wanted to post to thank everyone for their help. I got there in the end. Key thing was finding the correct end stones, I think. I found someone selling end stones on eBay just labelled as "2836 end stones" and they were the right size. I noticed after getting the correct end stones that one of the chatons was damaged, so in the end I replaced the whole balance wheel/cock and used my one good chaton on the other side. Amplitude is now somewhere between 270 and 360 (not sure exactly), so I'm carrying on. Automatic /self-winding is done and working. Just finishing the face side of the watch. Keyless works is done. So hopefully no more major problems and just a few hours to go! Thanks again, Lee2 points

-

Hi Ross. I toyed with an idea such as yours a while back but never got it done,, maybe when I get a little more mobility I shall resurrect the idea, one for the list.2 points

-

2 points

-

Hi Ross the answer is does it work as intended, if so it’s neither amateur or anything else it’s a working tool adapted to overcome some short comings. Well done you.2 points

-

I am in the same boat - just boxes of sparks as far as I can make out2 points

-

Hi Ithink Bergeron do very well with their emasculation devices. The price alone is enough to make your b**ls squeak.2 points

-

1 point

-

1 point

-

Hi Richard what’s the make/ calibre might be lucky, the Seiko charts seem quite informative as do the eta, I think a combination of the two would sufficient they cover most bases.1 point

-

We've a couple of spare rooms but it would be a bit of a journey. Hehe.1 point

-

1 point

-

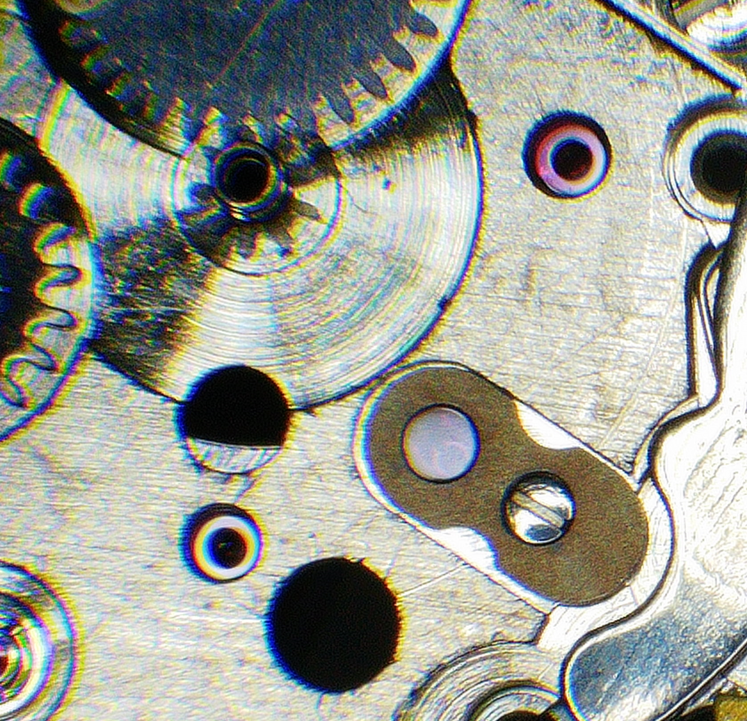

Nothing You can see above where the barrel sits that it's just an empty space. On the auto movement it's where the automatic works sits. One screw holds holds it in place.1 point

-

1 point

-

Don't think I've ever seen such a large omega symbol but that would be to tell you it's an Omega watch. Then this reminds me of a watch in the discussion somewhere else in the universe except it seems to missing the automatic perhaps? As I thought it was this watch http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_1020 It doesn't match the early version but I'm giving you this because where have we seen that big omega symbol before http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_1000 Probably this which is really similar to attend 20 anyway http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_1010 Not a very good pictures in the service bulletin of the weird arrangement for the gears has to do with the automatic winding which seems to be missing from your watch on eBay. That's obviously why there's a recess in the middle of it that's were some of the automatic would've gone. At least that's my guess. As it wouldn't be any need to the peculiar wheel arrangement for a non-automatic watch. 214_Omega1010,1011,1012,1020,1021,1022.pdf1 point

-

1 point

-

You're an absolute bloody legend to stay with us WW, i know we all look forward to many more years of your help and appreciate all the years that you've put in.1 point

-

You still have a good pin in the lug ( of the other side ), measure it.1 point

-

1 point

-

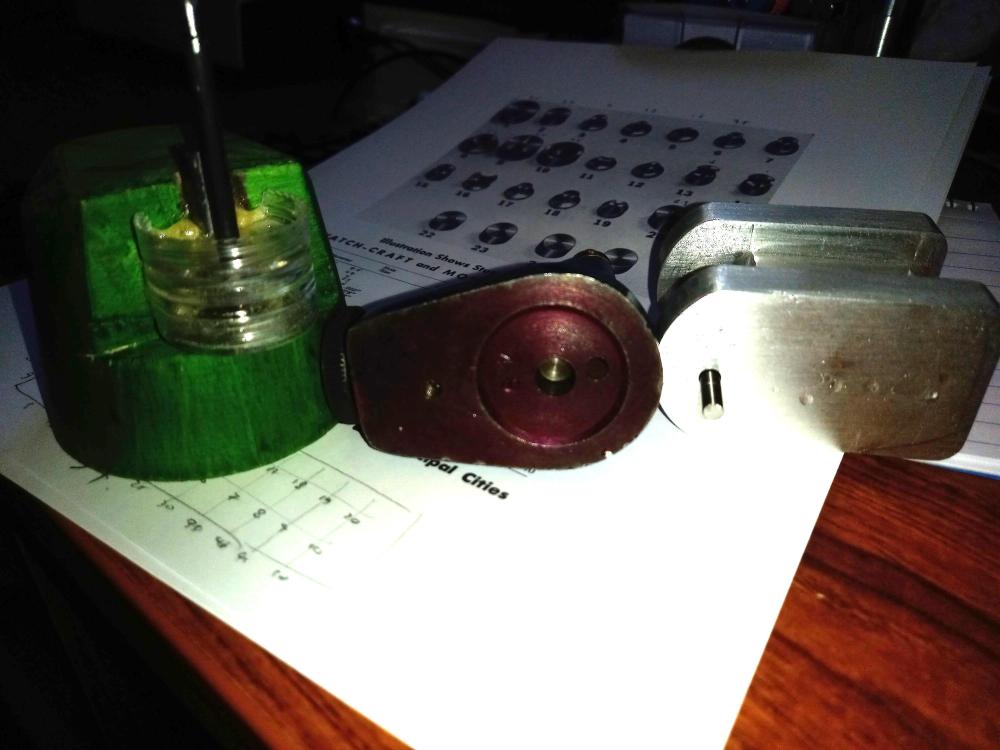

Update on base. I did not realise that the 'shed' man had drilled the base incorrectly with the stump hole to the opposite off centre. Thus, the base was incorrectly aligned to the top. I have gone back to my own wooden base. To made things more sturdy I have place a spigot that holds the base to the inset of the holder. Also, I have added an extra support to the stump making it more secure. Now it performs the same as the professional made sets. Pictures attached. I know it looks amateurish, but it does the job as good as the named ones.1 point

-

1 point

-

1 point

-

No she is still alive and kicking and will outlive me . I cant help it, my disposition has me labelled as "clincally chuffed"1 point

-

Hi NEW. It might have grabbed the body but not the mind. Getting better each day.1 point

-

I’m not sure of laughing at this joke is the correct response? Or this question either? Or that one? I’d better stop now I think.1 point

-

A few of the stumps in my Star set are made of brass , mild steel mostly has more impact resilience than brass. Any wear or deformation that you experience with your hand made stumps Ross you should be able to address with periodic maintenance.1 point

-

I did a FHF 96-4 a few months ago (with date complication). I think there is one cap jewel that is a screw down type. Leaving that out would make the escape drop down and not engage properly with the rest of the train. Just something to check. I made that mistake a while ago with a different movement.1 point

-

My copy of 'The Watch Repairer's Manual by Fried, Henry B', has arrived. Purloined by my bride and I will receive it on Christmas day. Can't wait!!! I've looked a the .pdf of the 'Electric watch repair manual' and envy the members who understand it. Goobledegook to me. Ah well. Just pleased that I am a 'mechanical' man.1 point

-

1 point

-

1 point

-

1 point

-

Hi in addition to Joes input I should check all the gear work again for some blockage ie, dirt or a bent tooth on the train and or the keyless work.1 point

-

Nah mate, it wasn't stupid at all, if you dont know you dont know and if you dont ask you might never know.1 point

-

1 point

-

The 7736 has 12h recorder, which works with a pinion that rides on the barrel arbor (extended barrel arbor) and lifts up and down; up is disengaged, down is engaged, with splines machined into the face of the bottom of the barrel. So no, not interchangeable. You can make out the difference in this tech sheet; it also specifies that it is a different barrel.1 point

-

You just take it easy WW, plenty of rest mate to get better. We need you around at least until we are all professional enough to have our own businesses .1 point

-

1 point

-

Typically on a street quartz watch with no complications reset is not required. Then hopefully M not reading that the way I am which is shorting the positive the minus which is shorting the battery out which is not recommended on watch batteries as they just don't have enough power to withstand. The problem with brand-new watches are there brand-new to you but how long has it been sitting in the store the warehouse the factory etc. if the battery is dead well it's been several years and it also depends upon temperatures like it was a jewelry store under bright lights getting nice and toasty warm for several years that would be a bad thing for the battery and lubrication Sounds like no warranty issue except you already opened up the watch. Companies usually get nervous about warranty issues if others have been playing with the watch. Interesting wording of somewhat serviced? That is a standard Seiko service guide implies that it can be serviced. But it's still a brand-new watch covered by some sort of warranty I would go that route first. Then maybe don't want to service the watch may be the just replace the movement https://www.esslinger.com/genuine-seiko-2-hand-quartz-watch-movement-6g28-small-second-at-6-00-overall-height-5-0mm/1 point

-

1 point

-

Great check list. I am still not sure how to properly check the condition of pivot or staff tips (how the condition should be). Another point is the prohibitive indication to not put back the mainspring manually. Does it always require the winding tool? I mean those tools use to be way expensive, above a lot of good watches.1 point