Leaderboard

Popular Content

Showing content with the highest reputation on 05/28/23 in Posts

-

I've just had the wood stove door seal replaced. I was hoping not to need to do that again for a few years. In the name of science I can't say I'm not tempted. I mean how dangerous can it be? Says the man who encouraged his friend the plumber to use phosphoric acid to dislodge the solidified sodium hydroxide that had blocked the bath U bend. We did take that outside first though, and yes, adding concentrated phosphoric acid to sodium hydroxide crystals and drain sludge is as bad an idea as it sounds.. so we did it several times, laughing like delinquent school boys until the explosions of brown goop stopped. The operation was a success, but sadly the patient died (or rather, melted), and we had to replace the U bend anyway. Children, please don't try this at home.2 points

-

I forgot to mention it in my post, but when looking for tools I have learned that it can be profitable to note the names of tools in both English, French and German. Neither eBay nor chatGTP usually manages to translate tool names correctly and therefore it is easy to miss many listings which can be costly. My Jacot tool purchase is a good example of that. I intend to compile a list of tool names in English, French, and German as I go, but it would probably be beneficial to include multiple languages such as Italian, Dutch, and Spanish too, but right now it just consists of the following: English Jacot Tool French Tour à Pivoter German Zapfenrollierstuhl2 points

-

The Swiss lever escapement is a surprisingly robust construction. Even with the ghastly results seen in the link you provided, I'd bet it is still a (somewhat) decent timekeeper. Well, decent enough that it would be useful to a wearer who winds it consistently once per day and doesn't mind setting the time once a week, or so.2 points

-

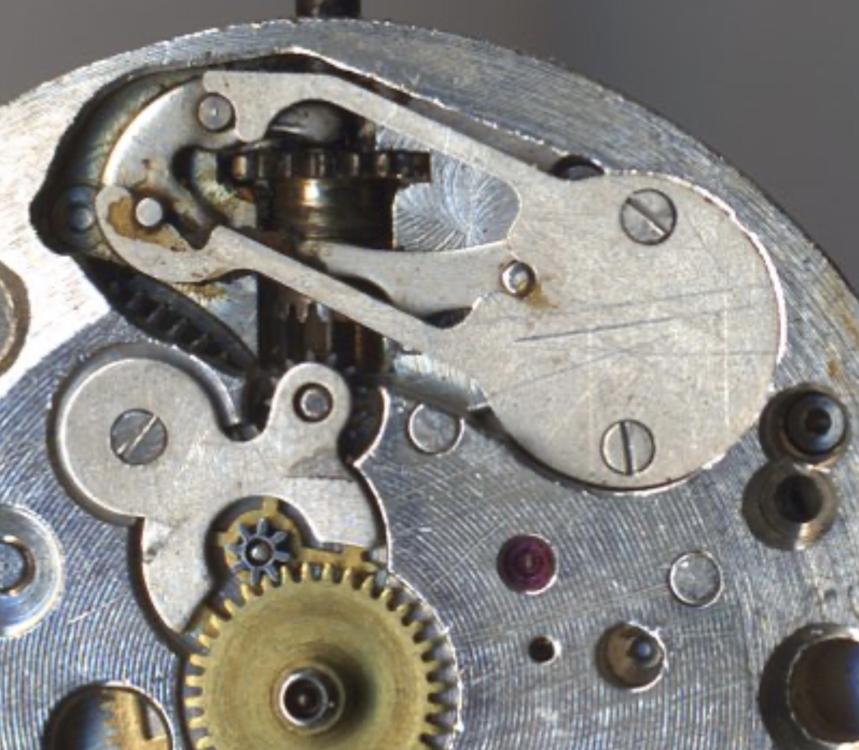

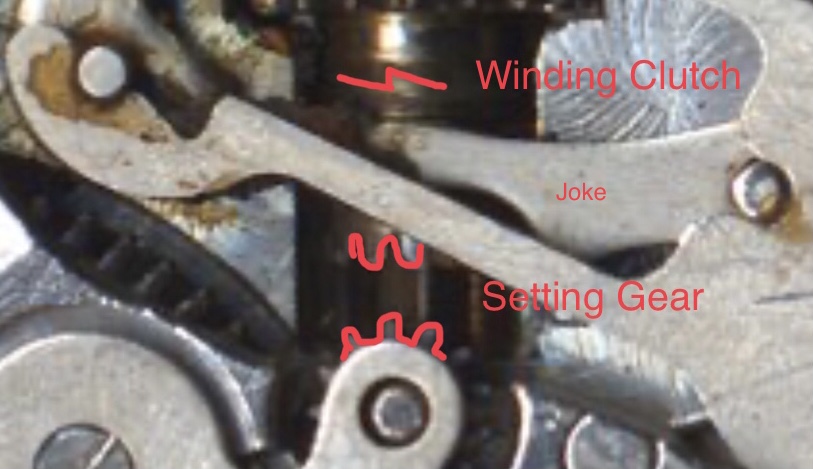

I would be happy to do it if he lived in the states. Once, someone on this forum sent me a 2824 that had the well known keyless works issue and I fixed it for him for free. I think he paid me for shipping...but maybe not. Currently, all of my work is for free...which is why I suddenly have so many new friends.2 points

-

the marvels of modern cinema? Unless they're actually doing a live stream they get to practice. I know someone who does a YouTube channel and for the limited time of the video you see they did a whole bunch of background filming. Then of course because they don't want to have a disappointing video not going to show, oh dear the roller jewels on the wrong side of the fork never to see that.2 points

-

I don't usually fancy the yellow crystals but it seems to work with that dial... ...and you can't set fire to it unless you share video. I speak for all of us...1 point

-

For the last couple of evenings, I've been working on an Amida 15 Jewel based on the Amida 500 movement from sometime around 1950. This is a slightly odd mechanism, as it has the initial appearance of a jewelled lever arrangement, but is in fact a pin lever. The movement is well made, and pretty easy to work on. After a little swithering, I did change the crystal. It looked original, and I would probably have left it alone, but it had yellowed somewhat, but the thing that sealed its fate was the crazing that became evident if the light struck it from just the right direction. As you can see, it made a marked difference to its appearance, although some might argue that the yellowing gave it a warmer look. I'm in two minds also regarding the hands. I suspect they might polish nicely, but the nagging voice in my head is saying, they might also end up looking uneven. It does run reasonably well all things considered. It doesn't quite qualify for the 404 club, as it came in at a rather too hefty price tag of £4.99 GBP. but since I've made a few other exceptions to the rules recently, it may just get an honorary membership. There are a couple of other issue I need to address. The first is the fixed pins and rather small lug width, which measures at a rather odd 15.3mm. I'll either need to source a strap, or perhaps use this an opportunity to make a custom sized strap for it. The second issue is.. do I dare set fire to the old crystal, just to see if it is made of nitrocellulose? If you hear a loud bang and detect the smell of singed eyebrows, then you will know the answer.1 point

-

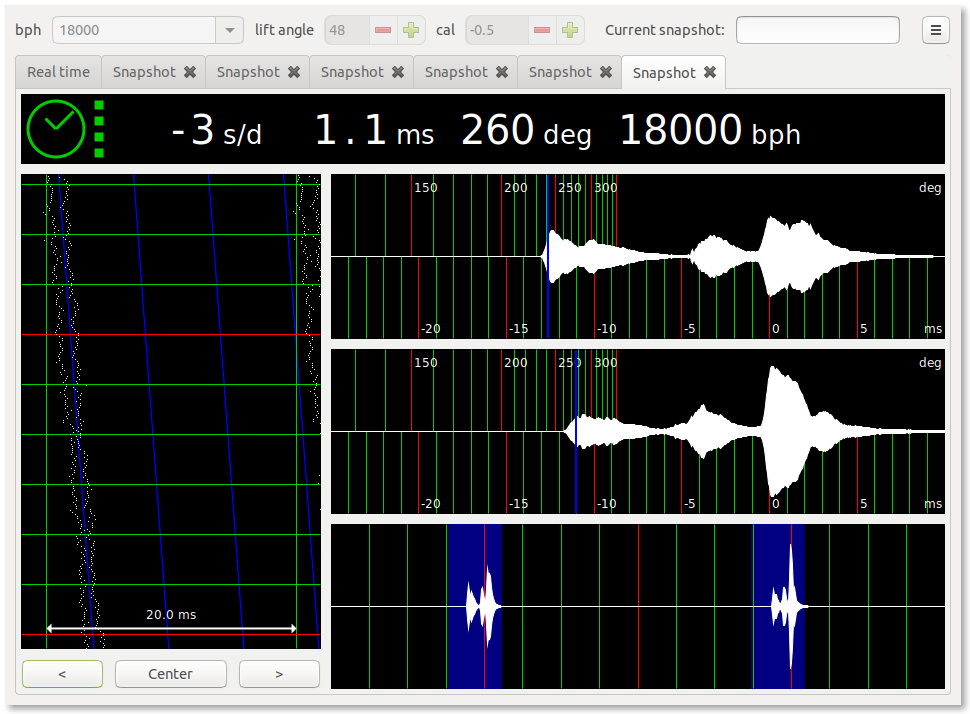

I see that that's a rather interesting chronograph in a big heavy case. As you have the lift angle I don't suppose you have the technical document that explains from the factory how you should be timing the watch on the timing machine? often times on watches like this the factory service bulletin will specify how to time it on your timing machine. For instance chronograph features should always be off as they generate extra noise which is not desirable. Then it looks like a relatively large heavy case that's going to be a problem. yes as you notice I don't always use the same secret identity other places on that message board everyone was using the real name so why not. So this means I'll just summarize what I've already posted in order for a timing machine the function it has to build a pickup a good clean signal. It doesn't matter which timing machine timing machine across couple hundred dollars or one that's approaching $10,000 like we haven't work. If you cannot get a good clean signal you will not get the results you desire. The unfortunate downfall of most of the Chinese 1000 machines are the lack of a volume/gain adjustments. This is found on the 1900 and some 1000 machines. Also found on most witschi machines. This is something is specified in technical sheets that say use a specific timing machine and this is how you adjust it. So 1000 is not have any such adjustment that will be a problem here. then I don't see the watch in the timing machine holder? In the case of a case stopwatch the recommendation is the crown should go out that's where the sensor is that's the best place to pick up a signal if you can pick it up at all. As I said large heavy cases are problematic or Seiko watches a lot of times are problematic as they my guess is the plastic movement ring interferes with the signal. We've had this at work the machine at work with the witschi with full automatic microphone approaching $10,000 sometimes with Seiko it will look like total crap. Remove the Seiko from the case put it back on the machine it's absolute perfect so it doesn't really matter whether it's a Chinese 1000 or very expensive witschi you need a good clean signal Oreo get unpredictable undesirable results you also need a timing procedure does the problem only occur in one position or does it occur other places? In other words you should time the watch dial down and then dial-up and one crown position like crown down and then we should build a look at all three NC if we see anything. When you're timing in the various positions you want to let it sit on the microphone at least 30 seconds before even reading it to allow the watch to stabilize. Depending upon the watch when you're moving the microphone around still be a time span words unstable when you get strange readings. Then you can set them on the 1000 and 1900 machines is usually a recommendation for an averaging time I think that 1000 starts at four seconds typically with witschi they recommend 20 seconds. Extending the average time helps to even things out then really helpful when you're having a issue like this especially because that's not a cheap watch a more expensive timing machine or timing machine software is required. This is where having our oscilloscope feature is nice. then often times with the oscilloscope the timing whatever will show you or tell you what it's trying to time from an based on that you can say out bad signal in other words you timing off the wrong part of the waveform. as you're not going to stop being obsessed I would purchase a better timing machine something with our oscilloscope would be nice. Then before sending it back to the factory get the factory to tell you what the timing specifications are in other words where should the setting for the gain be how long should you times ben averaging be you really need a timing specifications if you went meaningful results.1 point

-

Try this repairer. Used a couple of times and very helpful. Just ask if they can fit new dial feet to an existing dial and how they would do it Based in Leigh, Gtr Manchester. https://precisiontimeofleigh.com/1 point

-

1 point

-

First of all, just to close the loop, your similar post on the NAWCC message board has already been linked to and commented on here: https://www.watchrepairtalk.com/topic/25387-importance-of-amplitude/page/2/#elControls_220787_menu So the best answer you will get will probably be a duplicate of something JohnR has already posted. The most likely explanation for what you are seeing lies in the limitations of your timing machine wrt weak signals or background noise, or user error. If you can adjust the signal gain on your timing machine (less is sometimes more effective than more) try that. Make sure you are working in an environment with low backgroung noise. Try different orientations of the watch in the microphone clamp. Crown against the metal claw often gives the strongest signal. If none of that works, and you can't adjust the gain, get yourself a Weishi 1900 or even better, an all singing all dancing Witschi like the one Lange are using (and attend the training course if possible!). You obviously have the financial means! Whatever you do, rest assured that there is nothing wrong with your watch.1 point

-

1 point

-

I try to lift and hold the balance wheel in place and manipulate the movement around it- tilt, turn and rotate. It feels less fiddly than moving around with the dangling balance wheel…1 point

-

what's interesting is if you look at a watch like the expensive witschi machine you look at the time plot. You see the amplitude going up and down because the wheels are meshing ride 82 or something is worn out or was never made right in the first place because he didn't have a timing machine to impress hundred years ago. Then every time you run a timing cycle the numbers are a little different because of those problems. What becomes amusing is usually the problems on average out usually the watch would keep time if it's just running at the end of 24 hours another is the balance wheels has a decent oscillation whatever that is it can still keep decent time may not please the timing machine but they can still keep time.1 point

-

Thanks @VWatchie Great pics! There are many ways to skin a cat. As long as the way one uses works, that's what counts! BTW, Absolutely great walkthrough you presented there! Very precise and succinct and easy to follow. It will be a massive help for those wanting to service this movement.1 point

-

Very good question and it will be a bone of contention, as it is regarding lubrication. Personally, I don't lubricate the hole. If you were it would be just on the inside of the pipe. The reason I lubricate the fourth wheel rather than the hole is because, if the hole if lubricated with 9010, then most of the fourth wheel arbor will be coated with 9010 as it is pushed into position through the pipe. If the fourth wheel arbor is lubricated with 9010 like I've shown in the pic, then it won't do that. When fitting the wheel only the 9010 will reach the pipe when the correct part of the arbor does. Job done. You have to give the ETA schematic service manuals a big pinch of salt in my opinion. just look at how they get you to oil the cap jewels by putting 9010 on the chaton! Enough said... I'd be interested how that goes? I tend to use Moebius 8217, as I've had good results with brass, ali and steel barrels. Also what type of barrel are you using it with? Always good to learn a new way. Do you add the disulphide to the grease? If so, where do you get it from? I've heard it has really good properties needed in the barrel.1 point

-

1 point

-

Well, "Speak of the Devil and he shall appear". As I mentioned (somewhere) I've been on the lookout for a Steiner Jacot tool in good condition having a runner for centre wheels. Well, the wait is over. This "Zapfenrollierstuhl STEINER hochglanz vernickelt Bestzustand" (Jacot Tool STEINER high-gloss nickel-plated excellent condition) popped up on German eBay (not found if you just search for "Jacot tool"), and I was, to my great surprise, the only bidder and got it for £165/€190/$204 Usually, in this condition, they go for around $500, and there are "buy now listings" for $600-$700 and sometimes more.1 point

-

1 point

-

It looks like the movement may have been left in a cleaner for too long in its life. Either that, or perhaps a cleaner that was too caustic? However, if it is tarnish rather than loss of plating, you might try rubbing the dark areas with Rodico. I had black discoloration on a Swiss pocket watch movement with a gilt finish, and the Rodico removed it with a bit of elbow grease. Good luck.1 point

-

1 point

-

1 point

-

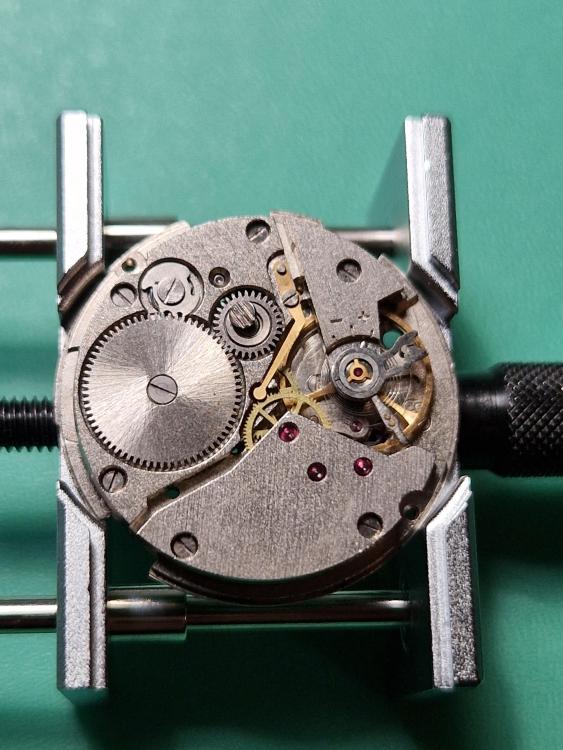

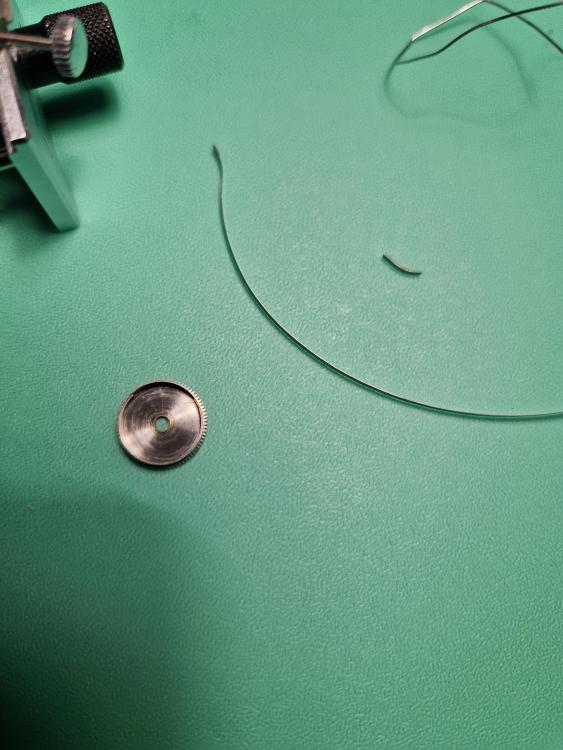

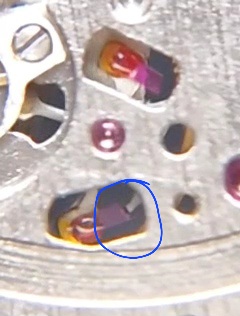

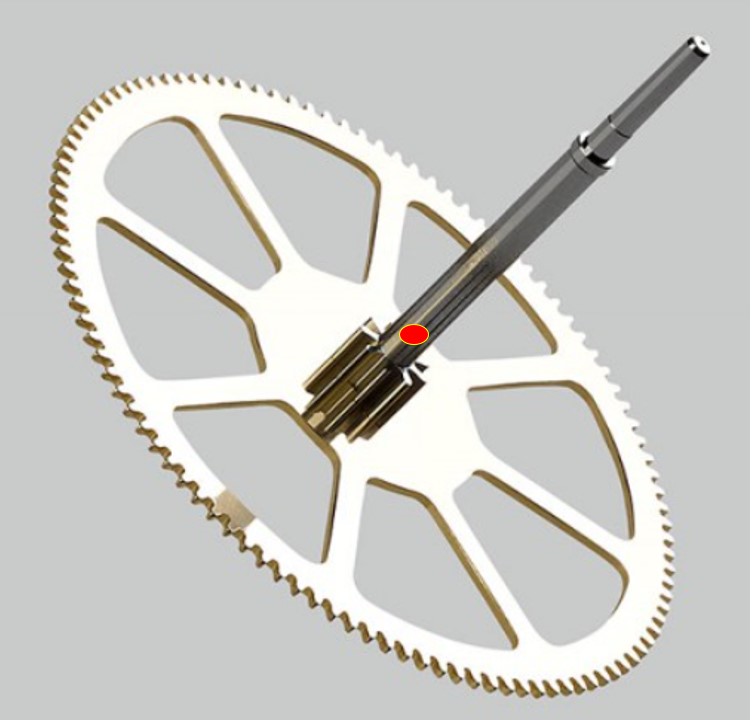

This is my Vostok 2414 from the late 1980s. It was my first ever full (and successful) service. Photos in reverse chronological order. The final product. I like how the dial colour has cracked in different levels of intensity as the shade of the paint changes. Full wind. Couldn't be happier. I'm a bit of an OCD person... note: lift angle is correctly set to 42°. Not sure if this is visible at all . But maybe you can see the small black area between the pallet (exit) stone and escape wheel tooth. That's lubricant (9415). Took me a while to get close to the recommended 60-70% of contact area (maybe I went slightly above..). And it took me the same amount of time to film it with my basic phone+loupe+slowmo technique. Oh boy, it took quite a number of attempts to get that drop of oil done well (being a first-timer). But I probably spent even more time with that bloody shock spring!!! Including 2-3 hours of searching on the floor... When I received it, the watch wouldn't wind. Upon opening the barrel and removing the mainspring, I found that the bridle had broken off... I followed a cool trick I saw somewhere (can't find the source anymore) and used a lighter to heat the spring and then bend it backwards to create a bridle. To my astonishment, it works perfectly and I get the full power reserve. Just some pics of the movement.1 point

-

1 point

-

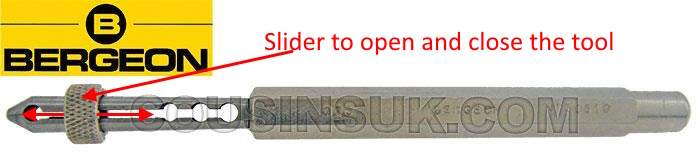

I have a Ø1.50mm Bergeon arbor holder and I absolutely love it. The 1.5mm size seems to be a decent fit for most normally-sized movements, but would probably be too large for a lady's movement and too small for a large pocket watch. I asked Alex at the Watch Repair Tutorials YT channel what size he would recommend and he replied: "The size I use almost at the time is the 150.", so that's why I decided to get the same size. Here's the video where he's using it and you'll find Alexs' reply if you look for it in the comments section. The arbor holder is much easier to clamp onto and release from the arbor (look at the picture). Also, it dramatically improves seeing what you're actually doing while removing and fitting the arbor from and into the inner coil of the mainspring. The head of the pin vice is most of the time so large it covers the entire arbor - and more - making it quite difficult to see what's going on. Absolutely not! It's just a whole lot less convenient in my opinion. None that I'm aware of I'm afraid, but we have some experts on Chinese watch tools on the forum so hopefully they can shim in!?1 point

-

It doesn't need much friction to run the hands, but if it's really loose it should be made tighter. For that you really need a staking set.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)