Leaderboard

Popular Content

Showing content with the highest reputation on 01/13/23 in all areas

-

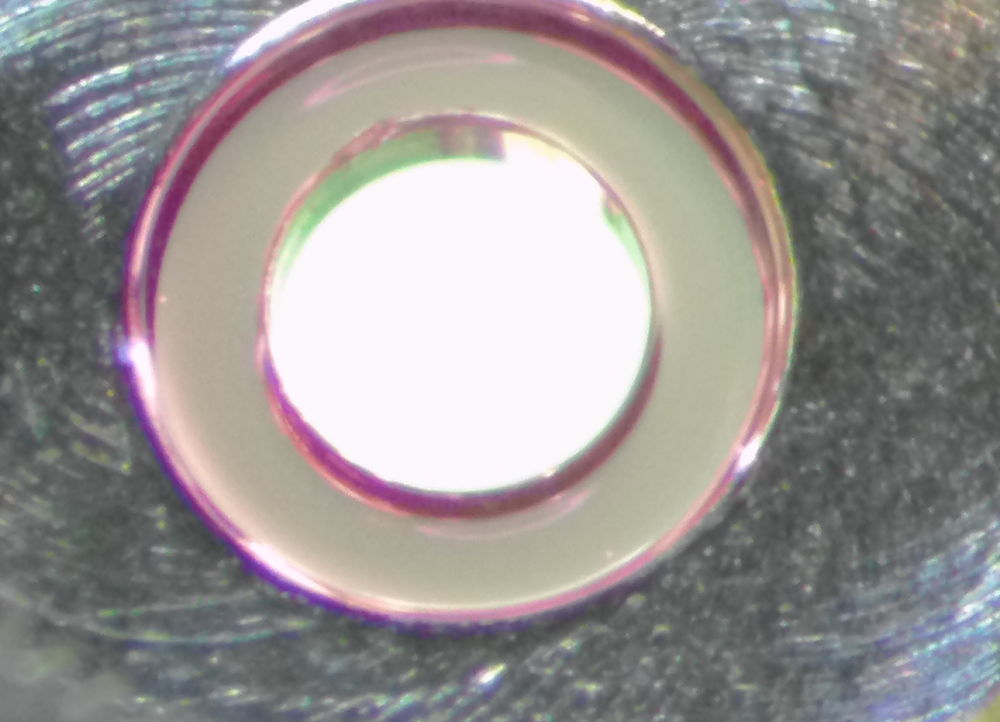

I've been working on a Seiko 6138-0040 Bullhead that belongs to an acquaintance of mine. He bought it new in the 70's, wore it until 1985 when it quit working, and it has sat in a drawer since that time. The issue of the watch not working was simple enough to fix. The hour recording wheel would not reset, and I found that the hour fly-back lever had snapped. Once I got the replacement part in I serviced the movement. After the initial inspection everything appeared to be in good order aside from some play in the upper barrel arbor port. That steel bushing was replaced with a jewel from Vintage Time Australia. Everything went back together nicely, but I was getting amplitudes in the 180-195 range. The Seiko 6138 generally runs at a lower amplitude, but this was too low. I took the watch apart again, thoroughly cleaned everything (again), and set myself to the task of rechecking everything, include end shakes and side shakes. Although the original mainspring looked to be in really good shape, I sourced another. Even with the brand new mainspring, the amplitude still wouldn't get above 200 degrees. At my wits end I took the watch down for the thrid time. This time I removed the barlow lens from my microscope, lessening my available viewing area and work space, but allowing me to zoom in much closer. I finally found that the inside lip of the lower barrel arbor jewel (located in the calendar plate of the 6138 movement, not in the main plate) had a very small chip in it. It was very difficult to see due to the way the light was reflecting from the jewel, but I finally managed to get a picture of it. The chip is at the 11 o'clock position of the inside jewel rim. After finding this chipped jewel I doublechecked the barrel arbor and did not see any scratches or other evidence of damage. Unfortunately this jewel is not the same lower arbor jewel that comes in the standard jewel upgrade kits (for the 61 & 63 series movements) because on the 6138 dual register chronograph movement the barrel arbor goes through the main plate and sits in a jewel on the front calendar plate. I sourced a cheap 6138 calendar plate but the barrel arbor jewel was in good shape. After swapping the jewels out and adjusting end shake, everything got cleaned (one last time), reassembled, and I'm happy to report that the amplitude issue has been solved. This one tested my ability, and most of all my patience. I wish I had a deerstalker hat so I could have called upon my inner Sherlock Holmes and figured this out sooner, but at the end of the day(s) a successful repair has been completed.4 points

-

3 points

-

Do you have a multimeter and a watch pulse tester? The coil can be tested with a multimeter set to resistence measuring mode. A good coil should be in the range of 1K to 3K. If the coil tests ok, then a pulse tester should be able to determine if the electronics are ok.3 points

-

Another find at a local flea market: a 1918 Elgin trench watch. It was in sad shape when I found it. Needed a thorough cleaning, might have had dirt from a bloody ditch in France clogging some of the nooks and corners, the hands were bent. But outside of all that, hardly any scuffs and no dents or dings. I did the usual COA, straightened the hands as best I could, did a bit of light cleaning on the dial, and got the old thing going pretty well again. I'm glad I didn't need to swap out any parts because I'm understanding that, particularly with antiques that also count as war memorabilia, it is important for the piece to be as original as possible. That said, it had no strap when I found it so I had to replicate a strap (could not afford a genuine vintage strap). I'm enjoying wearing it, but this one is listed on Ebay because I need the money. Rough patch right now and I am switching to a different day job, which is horrible timing but I can't go along with certain matters of ethics where I am now. But I may wear it now and then until it sells. It's not really my style, but it's an endearing old thing.2 points

-

Have you tried replacing the battery? Then if this was your normal quartz watch damaging the coil would definitely be an issue but there is several coils in this watch so damaging one the rest should still function so something should be a working. Usually totally dead would be the battery or the circuit. But you really can't look at a quartz watch without proper test equipment or some test equipment. Just in case you don't have the tech sheet I'm attaching that 372235670_289_ETA251.252251.262251.272.pdf2 points

-

1 point

-

Hi there, I am rebuilding a Seiko 6309A movement and have it all cleaned and mostly back together, however after installing the pallet fork I noticed that when I add a bit of power to the gear train the pallet fork oscillates back and forth without stopping/ locking. I installed the balance anyway and tried to get to run, but of course it will not run correctly. Any ideas about what might be the issue here and how to fix it? I'm new and have not come across this before, so any help would be greatly appreciated. Thank you, Bill OK, well I figured it out, one pallet stone was slightly out of place. Not sure how it got moved, clearly I did it somehow. I was able to move it back into place and it works fine now. It felt like the stone was still held tightly, so I don't think I'll need to redo the shellac.1 point

-

By the way didn't bring up the square versus round jars? Yes and watchmakers aren't bickering over lubrication they might bicker over having a square jar causes some sort of flow a difference versus around jar. Then yes there is a mental thing that goes in the bottom of the jars and as quoted below there is also must remember how one of the machines did it I think it was in the way it held the baskets it has a propeller like effects what causes the fluid to not just spin but also pushes it down her upper something so there's more movement of the fluid because yes if you're spinning it at some point time conceivably the fluid will synchronize with speed of your spinning and not getting enough motion Oh and if you really want to do some cleaning what about this. This is a machine we use at work it comes at a bargain price of around $16,000 will let Sewall price and it's gone up a little. Everything is programmable were at least as a lot of programming is a rather sizable book that comes with it and I'm currently waiting for its 50,000 mile checkup what has to go back to do some place to have a whole bunch the valves and other stuff replaced. We've already done the 10,000 mile and no it's not based on mileage there's calendars in their. Like when you change the fluid and reset the counters ill keep track of the cleaning cycles and remind you that you should change the fluid and then I push the button I'm going to ignore you and that will remind me later in a push the button again and only when it starts looking like maybe it's not cleaning which is a very long time for us do we change the fluids. But think the 10,000 mile checkup was we had the change the carbon filters change the internal filters that filters the fluids and something else we changed but we already have all of those. So you want the ultimate of cleaning this is it because of you could add in the vacuum feature with ultrasonic the vacuum sucks out all the little bubbles and stuff and against the fluid in the places they normally wouldn't get so in the case of American pocket watches you do not have to take the jewels apart and typically they do clean perfectly https://youtu.be/SCbFHf1BCdg Here's the problem with technical literature and why you've never seen this before it will never see the entire document. The watch companies have had supplemental information for a very long time for instance eta has technical communications that you can download off their website and sometimes they have the manufacturing information? Manufacturing information sheets I love those all the technical specs like the timing specs and other miscellaneous bits of interesting information but most people are unaware because they're seeking the service guide Omega for instance the delay bought out a watchmaker so I ended up with physical documentation from the 50s early 60s they had a cleaning guide back then it also talked about epilam and lubrication. But if you look at their service guides they don't mention that up until modern times were they were refer you to working instruction number 40. So they still won't even talk about things because you need the supplemental information so for instance where those images come from one of the Omega working instructions 27 I believe. Now what's the problem today with the technical literature for instance you go to the link below you use to build a search for the word working that now you have to specify much more the title you can even search for lubrication to find the link below which is really weird in case you look at the link there is working instruction number 40 hopefully on lubrication. Look at the corner of every single page notice it tells you exactly who download that's why you're not going to find in a modern literature on the web because somebody risks losing their parts a And nobody's going to risk that for discussion group. If you're lucky somebody might snip out something for you and airbrush out any corner marks that may be seen that's the best year ever going to get. https://www.cousinsuk.com/document/search?SearchString=Rules+for+lubrication1 point

-

Those are easy - if you can find replacements ! Undo the screws and the jewel with brass surround push out. Those train ones shouldn't be difficult. I bought some scrap Waltham movements and use those for parts. There were I couple of guys in the US I used to buy jewels for pocket watches from - they had a good stock of old jewels. I've lost contact details, so let me know if you find them !1 point

-

1 point

-

Hi from your pictures it gives the impression that the bezel comes off. Probably best to remove the movement before attempting any removal . Have a close inspection around the periphery of the crystal for signs of a gasket, it may just push out.1 point

-

Just FWIW, 200rpm is fine for spinning the basket in the liquid for washing. You want as much potential for liquid to flow over the parts as you can and spinning too fast sends liquid to the outer extremities of your jar where it doesn’t do much, apart from making foam. I’ve added expanded metal mesh placed inside jar outer circumference to break this up and “force” fluid back into the basket. In fact, just spinning the basket one way is pointless unless you have an impeller at the top of the basket forcing fluid through the inside of the basket. It’s for this reason many modern designs rapidly alternate the spin direction to create as much fluid “friction” over the parts (not sure if I’m making sense). Have a looking at how your typical clothes washing machine works for inspiration and note how it frequently alternates wash direction. ‘Where the high speed becomes important is when you lift the basket out of the fluid and need to spin off the excess as a spin cycle. I’m running around 800 rpm here. I also alternate the direction but the intervals are longer.1 point

-

Fifty. Five. Millimeters. That alone is insane but that watch is straight awful. It's like an all you can eat buffet, if all you can eat is vomit. 12 out of 10. Hahaha amazing! It's like an old diving helmet except way less cool! The best thing about this watch is you can seal it closed, and then put it in a box and seal that closed, and then throw the box in a volcano and then seal the volcano closed. Remember the nineties when all the watches had to look metal and edgy and like something a WWE wrestler would wear? It's like that now, but with clowns.1 point

-

ive had one like this, you need to use a drift to tap the drum out, some are so tight its a joke, the 3 screws you have i believe are there to hold the movement onto the drum, you will be able to access them once the drum is removed. My advise would be to mark the drum and the case so you put it back in the same orientation as it cam out due to the tightness of removal1 point

-

Try pulling out the crown to the hand setting position. A little tab will emerge near where the little arrow is pointing in your last photo. Depress the lever gently and withdraw the winding stem.1 point