Leaderboard

Popular Content

Showing content with the highest reputation on 09/11/17 in all areas

-

Well, the day is finally about to arrive (September 16)! After two years of living a split existence between my home on weekends in Berkeley Springs and weekdays in York, Pennsylvania, I'm finally done. I lived in an old rooming house in downtown York (see picture below) and my small school was a few blocks away. Two years is enough time to develop a habit of living and, waking this morning, I still felt like I had to make the 100+ mile drive to York this morning. But I didn't and that's a good and a bad thing. Good because I can now call my home my home again. Bad because a phase of my life has ended, probably for good. I'm sentimental about such things and this latest venture has often brought me nostalgic feelings about starting graduate school at New York University in 1980. That period ended in 1985 when I packed up and went to a post-doctoral fellowship at Northwestern University, both now over 30 years ago. So what can I say about watchmaking school? When I first started I wrote down on this website some of my initial impressions and followed it with an occasional update. For those who have the time and the resources I would say, go for it! It accelerates one's progress because you don't have to re-invent the wheel--something to be avoided unless you have a real affinity for wheels! I don't. For those who, like me were complete newbees, knowing nothing about the watch and clockmaking communities, it will allow you to quickly set up a network of fellow craftsmen. In my case going to York was very much like going to the historical heart of American watchmaking. Relatively speaking, there are a lot of watchmakers in central Pennsylvania; probably because nearby Lancaster was the home of the Hamilton Watch Company. It still is the location of the RGM Watch Company whose watches I greatly admire. Because of school I am now a member of the NAWCC, the Central Pennsylvania Watchmakers & Clockmakers Guild and the Horological Society of New York. Also it provided me with a steep ramp-up on acquiring tools--which our craft employs a greater complement than almost any other. I probably would never have seriously considered obtaining a watchmaker's lather or, if I had, not known how to get one that was both useful and reasonably priced. Sure you can get modern one's but they're pretty expensive and, frankly, appear to lack to quality of the older "vintage" lathes. But you have to be careful as there's a lot of old stuff that's been sorely abused and, unless you have a machinist background and recondition them yourself, not worth purchasing. Also what do you get: 6mm, 8mm, 10mm, or does it matter? (Actually, in America 8mm was the most popular and has the most available accessories.) Another advantage to me was that I was forced to work on pieces. Alone, my lack of self-discipline and my harsh internal critic, operant while working alone, pre-school, made it difficult to accept new challenges and complete work. I won't say I have this completely under wraps but I have now worked on a fairly broad range of pieces and have more confidence now. And it has cured me of one disease that I've heard some watchmakers say they had to be cured of: the feeling that you have to save every watch! Many I let go but am careful to inventory as parts watches. Also my fear of breakage is diminished; partly because I feel more confident that I can recover from a blunder and partly because I see my fellow students blunder and realize screwing up is part of the learn process and continues into common experience even for the experienced. (Which is not to say that I don't continue to work towards lowering my blunder rate!) Many will want to know whether or not I am a real, "stand-up", watchmaker like some members of this website? Probably not, though I can see real progress. It's a cliché that schooling, in any discipline, only takes you so far. The rest depends on time served and degree of dedication. As a former teacher, let us not get too hung up on a word I deliberately omitted, talent! Sure there are individuals who have it but my experience is that the bulk of progress is made by people of ordinary ability applying themselves conscientiously. Getting in there with our screwdrivers and tweezers is where, for the individual, our craft starts to take form. My only regret is that, at 66 years old, I won't have enough time to dedicate, say, 40 years to strive for a truly high level of achievement. This is where youth beats old age. Nothing can be done about it, though, except to provide a cautionary tale to those who are still young. Like most youth's I figured real self-examination, as to who I really was and what I would really like to do, fostered upon me by old dotards who weren't as smart as I was. Youth thinks the world is its oyster. Would that they could know otherwise. Sometimes, infrequently, individual youths do "get it" and listen to their elders. So be it but, whether they heed or not, at least those reading this can't say they never heard it from me. The attached pictures are two view of where I lived in York. The house is a nice example of antebellum architecture and is on the local historical registry. The very top floor was the servant's (some would say slave's) quarters. I had a very nice room with a beautiful black marble fireplace which I show decorated with some silly gewgaws I obtained from a local second-hand store. It's all been packed up and taken home, never to be so arranged again (some might say, amen to that!). I'll miss it and my housemates whom I hope to see from time to time. Finally I have a job interview in Philadelphia's diamond district later this month. In America there are jobs for watchmakers going unfilled. If they make the right offer then maybe my wife and I will, once again, pull up stakes and start a new chapter in our lives, in a totally unforeseen area to live. Who would have guessed Philly after living in NYC, Los Angeles, Chicago, Washington D.C. Life is full so unlikely tributaries. But we'll see.2 points

-

How do you do. I'm Frank from Aberdeen, up in the north east of Great Britain. I'm an engineer by profession mostly telecommunications in the space and telco industries with some work in European technical civil service. I don't do any hands on work at work but I keep my hand in during my spare time with electronics repairs, including surface mount technologies. I've also an interest in botany. I'm struggling a bit without a stereomicroscope. I've some old watches to repair including a Tag Heuer SEL quartz (955.112) whose bracelet broke. I then put it aside forgetting to take the battery out, it leaked, the watch is now dead on the movement holder with the date ring turned to hard melted plastic. I'll be looking for guidance on cleaning it up and replacing, perhaps repairing the movement. My ex-neighbour is a watchmaker but I haven't seen him around his shop of late. I'll also be posting a bit about tools and equipment. I don't have that many watches to justify massively kitting up but many tools will come in handy for electronics, hacking etc.2 points

-

1 point

-

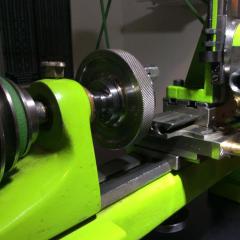

JD, I hope this provides some insight toward your lathe purchase. The best type of machine I have found to make tiny watch staffs and pinions is a watch lathe. The major issue I ran into was having the pinions break off after being turned down past .012 inches or less. A mini lathe has more mass and power with a trade off of less "feel". It was designed for larger size parts, such as clock parts, and can remove metal faster by taking larger cuts. Also, due to more size strength and power, a larger lathe will have less deflection from the cutter pressure thus providing more repeatable accuracy on each cut. That said, no matter how accurate the larger machine is, trying to turn a part down to .004 inches (.1mm) can be difficult or next to impossible due to overpowering the part. Larger parts can, in theory, be made on a watch lathe but a larger more stable lathe would be the better way to go for larger work. If you are going to use the machine to make watch parts (particularly staffs, pinions, stems, tiny screws etc.) I think you will find the watch lathe a better way to go. As I mentioned in previous posts, the Sincere Lathe is the going to be the best and most affordable option for this type of machine. You can always, at a later date, purchase a larger lathe in addition to this to make larger parts. I would also like to mention that some watchmakers will turn the pinion down as far as they can with the turning process and then grind or file it the rest of the way on a Jacot Lathe. This is generally not recommended as it can affect the concentricity and cylindrical properties of the pinion. The final burnishing on the Jacot Lathe should only be used only for the final .01mm -.02mm. This is the difference between making a pivot and making something that looks like a pivot to the naked eye. david1 point

-

Wow.. fantastic! Can you post a 'full frontal' shot? Thanks! Anilv1 point

-

That's the bit that makes me most nervous, more so than screws or springs popping. I don't want to be breaking that coil. That's my first watch disassembled, small parts cleaned and partitioned into milk bottle lids. I'll clean the molten date ring/battery electrolyte off the back of the dial and the chassis tomorrow. I'll need to get some grease and oil. I might just save myself the price of a new movement.1 point

-

I don't think it's assembled at all, the bits are just sitting there for the photo.1 point

-

Well, managed to obtain a NOS crystal on Yahoo auctions thanks to a member on another forum. Now to experiment in the old one [emoji6]1 point

-

1 point

-

Hi Jerry and welcome. You have followed the path just about how I would have suggested it. Starting on more forgiving pocket watches is ideal. You have made an investment in yourself as well....confidence means a lot. I guess now after servicing the watch you need to consider what's next. If you decide to continue I recommend the following. 1. Buy some books on watch repair. Amazon is cheap enough and has a good supply and keep finding videos 2. Be prepared to be bitten by the bug...advanced tools can be a bit expensive, but starting out ones are freely available at low cost. 3. You will break more things and lose many parts. I think it took me a couple of years to get reasonably competent with tweezers, how tight is too tight etc. 4. Get a good workspace free from distractions....you can really zone out! 5. Tell your friends, this is the way I got started. Most of my workmates have given me watches for repair/overhaul they get a service for free or parts cost and you get the experience. 6. Your friends will tell their friends and pretty soon you will have s steady stream of watches coming in that would otherwise sit in drawers due to normal retail repair costs. 7. About 7 years ago when I started the dollar was better from here and I used to buy all the older US watches (Elgin, Hamilton, Bulova etc) and practice on these often simple movements. 8. Seikos are usually pretty cheap as well...I used to go for the workhorses and also the high-beats... 9. Always strive to be the best you can be. If something's not right, then its not right. Keep going even if you have to take everything apart and start again (I had to do this many times). Anyway, that's just my thoughts, apart from this you will certainly impress people who would never be so brave and ultimately have the greatest pleasure in restoring something that had great sentimentality for someone who could not afford it to be done elsewhere... Go well. Hamish1 point

-

Welcome to the forum Jerry. Congratulations on your successes, for your first three forays into this enterprise to have been so positive is impressive; I don't think I'm alone in confessing to the destruction of at least half a dozen victims before I managed to get one running. Don't forget on your cost breakdown that although you spent $375 you still have almost $230 worth of tools and oils to lavish on future endeavours, which makes the cost of servicing your Omega even less. Nice watch by the way.1 point