Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/16 in all areas

-

Couldn't help myself, always fancied a gold 7750. Gold 7750 Inbound by Micky Aldridge, on Flickr I'm still yet to disassemble that ETA with several complications, but having done some more research, it turns out the ETA 2836-2 movement has a module on the dial side, this add on part houses many gears allowing the ETA movement to have manually adjustable complications, what I haven't figured out is, how do those complications register automatically each day at midnight.2 points

-

Update on seized staking set. Took out the locking screw and loosened the cam shaft and then knocked out the shaft with a small hammer (scratched the nickel plating on the side a bit, but it needed convincing). Then I removed the table by knocking it with a punch from the bottom. The complete lot fell out. Then I took 1200 grit sandpaper and sanded the hole where the locking cam fits . Did a bit of this as there always some corrosion. Lastly I cleaned the table in lighter fluid and then alcohol and then I re-oiled once dry. Reassembled it and it works like a charm. Loose until I turn the back dial and then tight. Then turn the dial again and the table is once again loose. Thanks guys for the help and suggestions. I am operational and will be knocking on the balance and roller table once I get the right jewel for a 21 J Illinois PW I have been working on. I am in deep now and have a jeweling set coming in the mail next week. Seitz full set.https://vimeo.com/183234528 Sent from my iPhone using Tapatalk2 points

-

I'd bleed a very small amount of hp 1300 in there, metal on metal is never good left dry.2 points

-

Yeah I can totally agree with this now. Before I started buying tools I kept on reading 'don't buy cheap stuff, you'll end up buying twice replacing will quality' etc etc I bought a basic set of tools and all the Chinese stuff was terrible so I was so annoyed I'd not just bought decent stuff in the first place as advised. Now I think I've gone too far the other way. Hopefully I'll find a happy middle ground. I guess if I look after them they'll last forever or there's always eBay for the ones I don't need.2 points

-

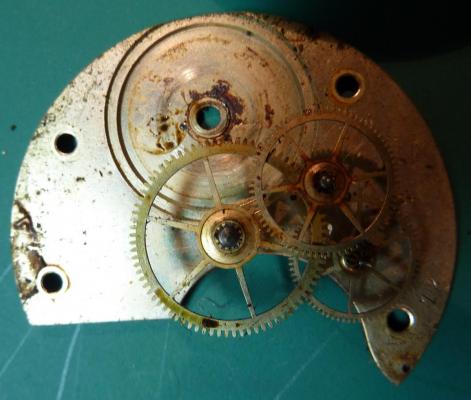

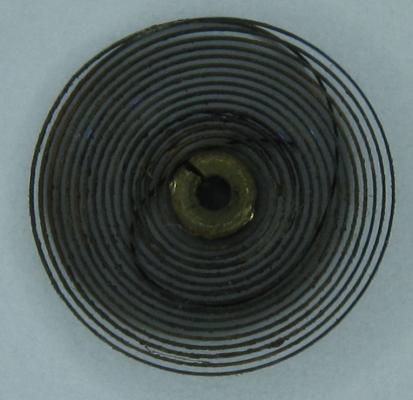

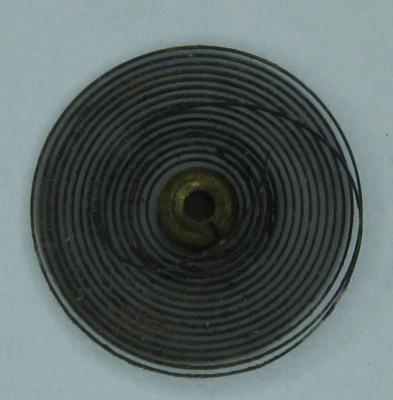

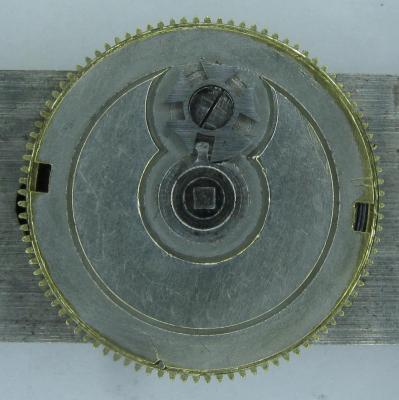

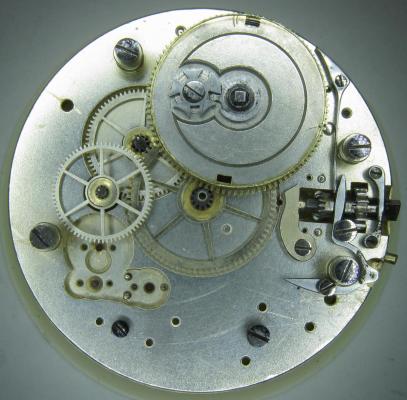

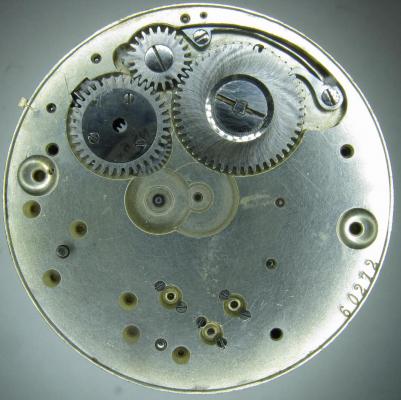

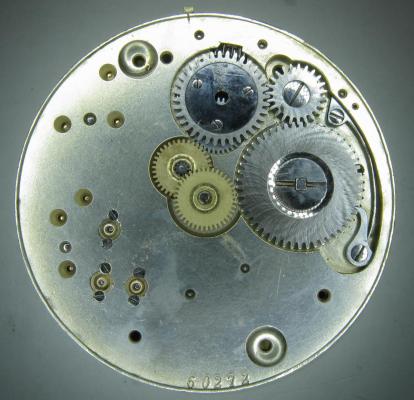

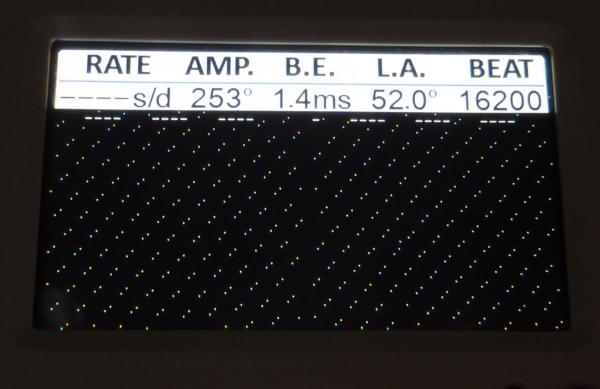

OK, so me and Mrs H did Christmas day with the family, and then we did Boxing day with the family, and then we were granted a day off so got to relax, and for me that meant I had the chance to tackle a little project that I had acquired as part of a job lot from a long retired watchmaker that had been sitting around in a shed for about 35 years (the job lot, not the watchmaker). Pocket watches are not usually my thing although I do own and use a couple. Orphaned pocket watch movements are even less my thing; but this little baby was in such a state that I couldn't resist the challenge. I don't think I have ever attempted to resurrect anything in quite such a sorry state as this before but it wasn't all bad. The balance was free and with sufficiently little end shake to hint that the pivots were not broken. However, the accumulation of dirt and dried grease obscured just about everything else. The inner coils of the hair spring also looked to be completely filled in with rust/gunk. With the balance cock and balance removed things got a little more interesting. Underneath the grime is a rather nice English Lever escapement with cap jewels on both the pallet and escape wheel pivots. A good sign, but I need to let down any power in the mainspring before I go any further, which means flipping it over and removing the dial as the keyless works are dial side. Not quite so bad under here as the dial has kept the worst of the dirt away. You can see too that both ends of the pallet and escape wheel pivots are capped, and the click spring is a proper cut steel affair, not wire. There is worrying evidence of rust on the steel work though. With the power let down the pallet and escape wheel cock is removed and you can now see the English Lever escapement in all its (rather grubby) glory. What a mess, but through the gunge there are just little hints of quality watchmaking peeping through; the thickness of the 3/4 top plate, and the cut and form of the teeth on the wheels. The top plate comes off taking the entire train and barrel with it as the pivots are seized in their bearings. The main plate is a mess. The under side of the top plate with the train still in place. The barrel has vacated its bearing revealing rust. Not a good sign but it could be worse. The train now removed from the top plate and dropped back into the main plate for a reference shot. The set lever and stem retaining bridge do not look healthy. Again though the set lever spring is cut steel, not wire. Oh yuk!!! The main plate now stripped. The barrel lid, with another nice touch; Geneva stop work, designed to only allow the central portion of the springs torque curve to be utilised thus reducing isochronism. Main plate, top plate, and escapement cock ready for cleaning. Ok, so whilst I was stripping all of this down, the hair spring, removed from the balance has been sitting in some Cola. The result is that the rust has softened and with a little careful tweezer work with a pair of Dumont #5's, most of it has been dislodged. The terminal curve of the Breguet over coil is badly out of shape due to a mishap when trying to unpin it from the rusted steel stud. I'll sort that out later. For now it's back into the pop to see if I can get those coils a little cleaner. Everything cleaned and ready for reassembly. I have a couple of spare jars for my cleaning machine and when I renew the cleaning solutions, the old stuff is kept in the spare jars. Any really heavily soiled movements get a "pre-wash" in the old chemistry so as to prolong the life of the new. With this watch everything was washed in the old gear and then very carefully gone over with peg wood, a G/F scratch brush, and tooth paste on a cotton bud in order to remove all of the staining that the bath didn't touch. All the jewels, bearings, and pinion leaves were also pegged out. Then it all went for another cycle through the old stuff before going through a normal cycle through the fresh chemistry. Main plate dial side prior to reassembly. And train side. Scrubbed up quite well I think. Stem, winding pinion, clutch, and stem retaining bridge reinstalled. Set lever and spring back in place. I haven't removed all of the rust pitting from the stem bridge and the set lever as it was too deep and to take it out would alter the shape too much, but it has been stabilised. The reassembled barrel and Geneva Stop work. I have reused the old main spring for now but made a note of its dimensions in case I choose to replace it. Another (gratuitous) shot of the Stop work as I just love it :-) Barrel and train back in place and things are starting to look fairly healthy. The top plate goes on. Quite a difference compared to the strip down shot from the same angle. The keyless works back in place dial side. And the balance, with reshaped and re-pinned hair spring goes back into place. After about half a dozen attempts to adjust the beat, removing the balance from the cock and turning the hair spring collet each time, and she comes to life!! Everything back in place dial side. And the cleaned up dial goes back on, complete with (broken) hands. And if you ignore the rate error for now (I need to re-pin the hair spring a little shorter), it's actually not a bad performance. As I said at the outset this was a challenge for challenge sake. I really enjoyed doing it and have learned a little bit about quality English watchmaking from the days when we were really rather good at it. I have absolutely no idea what to do with it now though although I want to try and find a bit more about it. Here is what I know; The name on the dial is T Donkin. There was a T Donkin watchmaker in Scarborough but I have no dates (yet) I'm guessing somewhere between about 1890 and 1910. It is a 19 ligne, 19 jewel English Lever escapement movement with capped balance, pallet, and escape wheel pivots (diamond on at least the balance top pivot). It has a screwed, split bi-metalic compensating balance, Breguet over coil hair spring, and Geneva Stop work on the barrel, and a 16200 train. A technical spec that suggests that it was of a reasonably high grade for its day. I still have a couple of issues to address though, the most problematic of which is that it has a slightly bent balance staff pivot. I decided not to tackle this on this occasion as the risk of breaking it whilst trying to straighten it was too great and I desperately wanted to see it running, but I may have a go in the future. I will re-pin the hair spring at the same time to get the rate up to where I can regulate it properly; it is currently about 25 minutes a day slow which is way beyond the range of the regulator. I also need to re-attach one of the dial feet and source some new hands. Then of course there is the question of recasing it. If you have made it this far then thank you for indulging me :-) I hope you have enjoyed it. If anyone can shed any more light on this little old lady I would be very grateful.1 point

-

1 point

-

1 point

-

Yes, Moebius A is 9010. As I've mentioned above, it's a better choice than HP1300 for this particular application (reaching to arbors of permanently attached wheels), because being a fluid rather than an oil/grease, it will alcually reach to the part to be lubricated. Seiko still recommends the same for the current movements, and to ease access, the wheels are manufactured with recognizable cuts. Check illustration *2 on page 3 of the attached. NE15-TG.pdf1 point

-

It indicates "Normal Quantity of Moebius A" which I believe translates to Moebius9010 although I would love to hear confirmation of that as this whole oil business is new territory to me. I was lucky enough to find the colour version in my hunting for info which I have hopefully attached to this post. Note: I can't remember where from so I can't be sure who to credit with the original upload, so apologies to the OP. 24._6309A.pdf1 point

-

You have probably heard me mention about bodge ups when it come to clocks. Here is one I found surprise yes folks it's on ebay. We have a Longcase clock with a 30 hour movement but the dial is from an 8 Day movement. As you can see two key holes but 30hour movements have a pull wind you pull the chain while taking the actual weight by your other hand this is to ease wear and tear. Also on the dial above the 6 is the markings for a calendar, there is no calendar workings. The dial is very late because it is fully painted and poor detail. £375 for something that http://www.ebay.co.uk/itm/ANTIQUE-HALIFAX-MAHOGANY-30-HOUR-GRANDFATHER-LONGCASE-CLOCK-/122140743212?hash=item1c7027d62c:g:bVQAAOSwnDZT-Q5k is worthless.1 point

-

1 point

-

welcome Dave. i wish i had saved those failed repairs. some with had only a lost screw. but, sometimes the yen to put them on the anvil and apply the hammer. vinn1 point